| Place | Name | Characteristics in the rating |

| TOP 10 best facade paints |

| Plyolite paint Akterm Facade Pliolite | The best all-season paint, suitable for application in summer and winter | |

| 1 | Acrylic paint | The most popular facade paint |

| 2 | Silicone paint | Stain resistance |

| 3 | Rubber paint | High elasticity, reliable waterproofing |

| 4 | Facade paint for wood | Reliable protection against biological damage |

| 5 | Silicate paint | The most durable coating |

| 6 | Lime paint | Increased UV resistance |

| 7 | Textured paint | The best decorative facade paint |

| 8 | Siloxane paint | The best paint for mineral surfaces and use in difficult natural conditions |

| 9 | Alkyd paint | Better protection for wooden surfaces |

| 10 | Latex paint | The safest and most versatile |

Choosing paint for exterior work depending on the type of walls

In order for the decorative layer to serve as long as possible without the need for restoration, when choosing a paint composition, it is important to take into account the specifics of the base. Wood, foam blocks, brick and concrete have different requirements for the finishing coating.

For wood

It is quite difficult to find good facade paint for wood, since plank walls are capable of rapid fire, quickly absorb liquids and are susceptible to rotting. In such conditions, the optimal solution will be substances that are not afraid of constant exposure to moisture, exhibit high-quality adhesion and excellent ductility.

When choosing paint for a wooden facade, first of all, they turn to acrylic products, since they are characterized by full adhesion to wood, help maintain natural air exchange, are quickly applied and have an impressive service life.

For a wooden house, transparent and tinted compounds are used; in the first case, the beautiful structure of the natural material is emphasized; such products have greater vapor permeability.

For foam block

Foam block surfaces are characterized by high porosity; they require full protection from moisture and contamination. The paint must exhibit serious water-repellent and vapor-permeable properties, so experts here recommend rubber and silicone compounds. When painting, special attention must be paid to the integrity of the seams so as not to form cold bridges and not cause rapid destruction or peeling of the finish.

For brick

Brick, accumulating salts, periodically releases them in the form of stains; this effect is especially noticeable after the rainy season. On such a surface, peeling and mossy areas quickly form. Therefore, builders prefer to paint brick walls only after several years of operation of the building.

The following requirements apply to coloring compositions:

- neutrality in contact with chemicals;

- mechanical strength;

- ability to release steam;

- resistance to atmospheric agents.

To decorate brick facades, substances that exhibit excellent elasticity are used: temperature fluctuations can cause expansion or contraction of the base, under such conditions the finishing is at risk of deformation and cracking.

An example of applying façade paint for brick

For ordinary solid bricks, acrylic paints can be an excellent compromise - they do not interfere with air exchange, eliminate the formation of efflorescence, and are not afraid of moisture. Walls made of silicate material need to be finished only with cement or silicate products. Ceramic brick is not demanding; it can be combined with any type of coating.

Water-based rulers can also be used for finishing bricks, but they are not appropriate in all cases, since high susceptibility to moisture is a disadvantage in conditions of frequent precipitation.

For concrete

Concrete is painted not only to improve its decorative properties, it is important to strengthen its operational capabilities and protect it from climatic conditions. Despite its initial strength, concrete quickly deteriorates in conditions of high humidity. Concrete compositions must meet the following requirements:

- moisture repellency;

- long color retention;

- frost resistance;

- environmental friendliness;

- ease of application.

This base is compatible with almost any composition, but it should be borne in mind that each type of paint and varnish material has disadvantages when used in this way. For example:

- oil paints do not exhibit sufficient vapor permeability; they require preliminary preparation of the walls;

- water-based solutions do a poor job of preventing moisture absorption.

Silicone, acrylic, and rubber series are more appropriate here.

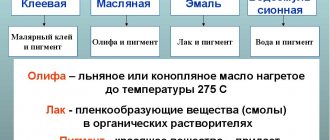

Composition and its impact on quality

The performance properties of paints directly depend on the amount of binders in them. The binder can be made from synthetic resins (for acrylic, silicate and vinyl grades) and mineral substances (for cement, liquid glass, lime). Cheap brands contain little binder, which reduces their performance by an order of magnitude.

The safety and environmental friendliness of a paint and varnish material is influenced by the type of solvent. Thus, the organic type (for example, white spirit) forms a dense protective film, but suffers from increased fire hazard and toxicity. Water-soluble compounds are more environmentally friendly and less flammable, and their reliability has been confirmed by decades of use.

No. 3. Mineral paints for facades

Mineral paints include lime, cement and silicate paints.

Lime paint

Lime paints are made from slaked lime. These can be ready-to-apply coatings or pastes that are diluted with water and pigment directly at the construction site. The pigment must be resistant to alkaline conditions, which significantly limits the possible color palette, but this is not the only drawback of lime paint for facades. It has low resistance to moisture, low durability, gets dirty relatively quickly and can be washed off by heavy rain.

The advantages of the material include low cost, high vapor permeability and excellent antiseptic properties . Today, coating is used less and less, but in some cases it is irreplaceable. Lime paint is still used for the restoration of architectural monuments.

Cement paint

Cement paints are produced in the form of powders, which are diluted on site with water or special preparations. The paint base is white or colored Portland cement, to which slaked lime (about 15%) is added to improve water-holding capacity and water-repellent agents (about 1%) to increase resistance to weathering. Such coatings have high vapor permeability, are inexpensive , and can withstand exposure to sunlight, but are not very resistant to moisture and tend to peel off.

Silicate paint

Silicate paints are produced on the basis of potassium liquid glass with the addition of ethyl silicate. The composition is resistant to sunlight, temperature changes, aggressive atmospheric influences (acid rain), has biological resistance , and due to the presence of water repellents in the composition, resistance to moisture is added to the advantages. The color palette of silicate paints is limited; they cannot be used over acrylic and silicone paints, and work must be performed in personal protective equipment.

Polysilicon paints

Polysilicon paints are also called silicate-ash paints . In fact, this is a more advanced analogue of silicate paint. The coating is resistant to moisture, vapor permeable, suitable for painting facades plastered with cement and cement-lime compositions.

Peculiarities

Facade paint for exterior use must have protective qualities in order to protect the walls of the building from negative influences. The main advantage of such paints is the ability to give both an attractive appearance and reliable protection for a building for a long time.

Modern facade coatings are distinguished by high strength characteristics, elasticity, resistance to moisture, and vapor permeability. The coating is smooth. There is a wide range of colors and interesting textures.

On video: interesting ways of applying façade paint.

Specifications

There are a number of characteristics that are important for external work. They may differ from one manufacturer to another, so you should check all the parameters using the accompanying documentation.

These characteristics include:

- Vapor permeability, that is, the ability to pass steam, preventing the formation of condensation and improving the operating conditions of wall and thermal insulation materials. Some manufacturers indicate the amount of water that penetrates a painted surface of 1 square meter. In this case, the indicator should be no lower than 120 g/sq.m per day. If the coefficient of diffuse properties is specified, it is designated as Sd. Normal vapor permeability in this case is 0.05-0.11 m.

- Water permeability is also considered an important parameter. For facade paint, it is important that the indicator is at a minimum level, otherwise the walls will be damp, fungi and mold may appear on them, and the layer will collapse before plaster. In technical documentation, the indicator is called the water absorption coefficient and is denoted as w. It should be no more than 0.03-0.05 kg/sq.m*h, but the lower the better.

- Resistance to ultraviolet radiation. Sunlight is useful because it prevents the appearance of mildew and mold, but it can destroy even high-quality paint pigments, and sometimes the rays cause the layer to swell or crack. Acrylic compounds have high UV resistance.

- Abrasion resistance. From the outside, the walls of the house become dirty even during normal use; they need to be cleaned periodically, otherwise the paint and plaster layers will be destroyed. This is why abrasion resistance is so important. Manufacturers determine it in laboratory conditions. It reflects the number of cleaning cycles that the coating can withstand. A good indicator is at least 5000 cycles.

- Drying time. Typically, acrylic paint dries within 24 hours, but under favorable conditions this happens even faster, which is important for façade mixtures.

Paint consumption plays an important role. The financial costs of finishing work also depend on it. Acrylic mixture is more expensive than other facade compositions.

24 hours is the time required for most types of façade paints to dry completely.

No. 6. Textured paint for facade

Textured facade paints differ from ordinary ones in their granular consistency , thanks to which it is possible to form a relief surface. Such compositions are also called structural and texture paints, but they always mean the same thing - acrylic paint, which includes granular granules. Less often, another base can be used instead of acrylic.

Textured paint is applied to the facade in a fairly thick layer, about 10 mm, so its consumption is higher than compositions that form a smooth surface. This is more than compensated for by the composition’s ability to hide cracks and chips on the wall surface, so there is no need for preliminary preparation and careful leveling. The resulting texture resembles decorative plaster, but the pattern largely depends not on the composition of the paint, but on the method of its application and the tools used.

Major paint manufacturers

A legal manufacturer is always available in retail chains. From the diversity, 3 companies can be distinguished:

- Dulux is the largest company with factories in 26 countries. All exterior paints have antiseptic properties.

- Tikkurila is a Finnish corporation that produces silicone, silicate, and acrylic paints. Tikkurila facade paint is a global standard.

- Marshall - a company from Turkey. Of the façade paints, only acrylic is supplied. The manufacturer is well known in the CIS.

Distribute spray paint cans to neighborhood children, your facade will become original

Advantages of acrylic paints

Upon completion of painting, a special film with good adhesive properties is formed on the surface. Adhesion characterizes the level of adhesion between dissimilar materials. The plastic film formed during painting serves as a barrier between the base (for example, metal) and the external environment (humidity, precipitation, etc.).

The main advantages of acrylic compositions are listed below:

- Increased heat and moisture resistance means that the material will not crack during temperature changes, and will also withstand very dry or humid weather.

- The service life of acrylic coatings reaches 15-20 years.

- Acrylic exterior paints are easy to apply and dry quickly.

- Acrylic compositions do not produce elements harmful to humans and are free of pungent odors.

- There is a wide variety of colors, as well as the possibility of tinting. The latter means that even if the desired color is not available, you can always apply white paint to the surface and then tint it.

Acrylic compositions are made on one of two bases: solvents or water. Solvent-based paints are more adapted to extreme climatic conditions, especially low temperatures.

Composition of acrylic paints

Acrylic coating is a thin plastic layer. The characteristics of plastic may vary depending on the scope of application of the composition, but essentially the structure of this material remains the same.

Main characteristics of acrylic compositions:

- The binding part is based on polymers that can be soluble in water or an organic solvent. Polymers are responsible for film formation as well as retention of color pigments and additives.

- Another important component of paints are color pigments. These substances are made from acrylic resins. Polymers and pigments combined into one structure form a durable surface that can withstand stress and environmental influences.

- Additives and fillers. These elements are added to the composition to give it certain performance qualities. For example, using fillers you can achieve a glossy or matte surface tone. Additives also make it possible to achieve water-repellent qualities, antiseptic, fire-fighting and other necessary properties.

Polyacrylic paints are produced on the basis of polymers and copolymers of alkyl acrylates. To obtain the desired glass transition temperature, acrylates and methacrylates, as well as styrene, are added to the copolymers. If necessary, special fillers can be added, for example, marble chips.

The resins that make up acrylic paints include special groups of elements that make coatings stronger. Powder paint and varnish compositions are made using epoxy, hydroxyl, and carboxyl groups.