Metal is widely present in our premises, and is used where its unique physical properties compared to other materials are needed. However, metal often also decorates the living area with its presence. And in order to make its visual characteristics even more interesting, the metal surface can be given a particular color or texture. Metal painting itself is most often done for protective purposes, but the decorative painting technique has many differences.

Advice for those who are planning to paint a metal surface at sub-zero temperatures

Although this advice may apply more to ordinary painting than decorative painting, situations are different. For example, you need to immediately paint a part that has just been brought in from the cold. Therefore, we will give some tips:

- The best way to paint in cold weather is to use alkyd enamels with a jelly-like consistency that have high adhesion (the ability to penetrate the surface structure);

- Painting a surface cooled to temperatures below +5 degrees Celsius should be done exclusively with preliminary treatment of this very surface with a torch or heat gun. Otherwise, condensation will form on the surface on which the paint simply will not adhere;

- If the room itself is cold when painting, the drying time of the layer can increase several times, which is especially unpleasant for decorative painting. Therefore, it is recommended to install a heat gun and cover the surface with film.

What are blacksmith paints

Recently, forging paints, specially optimized for working with forged materials, have become very popular. Such paints are applied to forging for decorative purposes, which makes it possible to imitate a wide variety of surfaces, from gold to cast iron.

The cost of such paints is higher than that of ordinary ones. However, this is due to their increased shelf life, which reaches 5 years or more. At the same time, such paints also look really impressive, allowing you to give the required visual effect by the very fact of their presence. Without the need for different painting methods.

Today there are many types of such coating, but the most popular is the German WS-Plast paint, produced by Weigel & Schmidt GmbH. These paints allow you to give metal surfaces a variety of different colors and textures. Here you will find emerald color, graphite with red tones, and various types of antique painting. Moreover, such a coating not only decorates, but also protects the metal surface from corrosion and other troubles caused by the influence of nature.

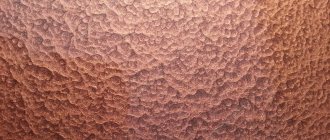

Also popular is hammer paint (Hammerite), which is currently becoming more and more in demand. The reason is that such paint does not require the application of a primer, and can even be used directly on surfaces damaged by corrosive processes. However, if the rust is loose, it will still have to be removed. The surface treated with this coating becomes monochromatic with the effect of unevenly shaped patterns and aluminum flakes.

The application of this paint is mainly practiced on ferrous metals such as steel and cast iron. However, it can also process some non-ferrous metals.

Aging materials

Metallic-effect paints are most often used to paint forged metal. These are compositions in which the transparent varnish (binder) contains a large amount of non-ferrous metal powder (copper, bronze, aluminum, etc.).

As a result, a decorative coating is formed on the structures, reminiscent of the surfaces of silver, bronze or brass products. Decorating allows you to get the effects of gilding, and with aging techniques, make it slightly worn.

Decorative paint WS-patina is an acrylic composition for artistic finishing of forged products.

Among modern materials:

- acrylic-based paints and varnishes, with gloss;

- polyurethane paint and varnish coatings (glossy and matte);

- nitro enamels;

- alkyd;

- three-component forging compounds with a rust transformer and primer (Zinga brands, etc.).

The main requirements for a dye when choosing are its purpose for working on metal, resistance to weather conditions and the content of anti-corrosion components. You can use both brush and spray formulations.

When purchasing patinas and paints for interior decoration, you must choose brands intended for interior use. A special mark or information on the packaging will help determine this. When finishing street structures, materials for external work are purchased. Three-component compositions are used without preliminary cleaning of the metal, removing only a loose layer of rust.

Pay attention to: Features of metal painting

Antique painting

One of the most popular ways to paint black metal is the antique effect. In this case, several coating options are applied to the metal surface in a certain order. But first, the metal itself must be properly prepared. It must be cleaned of corrosion, sanded, and dirt and grease are removed. Only when you are confident that the surface is clean can you begin the process, which is divided into several stages:

- Using a brush, apply metallic paint to the surface. Don't be afraid to do it casually, as this will only help with the effect we are creating;

- Once the first layer has completely dried, it is necessary to apply a craquelure primer. The latter allows you to obtain a layer of transparent film created from polymers;

- The craquelure coating is applied after the primer layer has dried, which allows you to get characteristic cracks, similar to those that appear on things that have been used for decades and even centuries.

Important! Instead of a craquelure composition, the effect of antiquity can be achieved by applying burnt umber to the paint. In this case, it is best to work with a dry cloth, and remove the residue after the paint layer has dried.

Creating the effect of dilapidation and wear

Artificially giving wood a shabby and dilapidated look is called brushing. The production uses sandblasting, during which soft fibers are removed from the top layer, causing the structure of the wood to become more pronounced.

When processing antique wood in a similar way with your own hands, the surface is first covered with matte acrylic paint. After it dries, abrasions are formed using a metal sponge or sandpaper, while individual areas can be affected more intensely to obtain a more natural look. The product is cleaned and a second coat of paint is applied.

At the end of the processing, it makes sense to go over the wood with a fine-grained abrasive tool.

Without using paint, you can achieve the effect of antiquity by painting wood with stain. This special material stains the wood by penetrating into its outer layer.

During absorption, the stain colors the wood in its natural color, while emphasizing the texture. There are also colorless compositions that perform exclusively protective functions.

The stain is applied with a cotton-gauze swab - a piece of cotton wool is wrapped in folded gauze. The composition is poured into the cotton wool so that it saturates it, but does not leak out when you press the tampon. Then the stain is rubbed over the entire surface. The process is repeated several times.

Sandpaper creates abrasions on the treated surface. The result is a natural wooden plane with pronounced texture and wear, characteristic of antique interior items.

Bronze metal painting

Bronze coating is one of the most visually impressive. Therefore, people often strive to recreate it. And there are several ways to do this, and they all involve the use of bronze paint.

First of all, the surface is prepared. Dirt, grease and rust are removed. After this, a layer of metal primer is applied to it, which will increase the adhesion of the layers applied above. At the third stage, bronze metallized paint is applied in 2-3 layers.

If you want to give this bronze layer the effect of antiquity, then the recesses must be treated with patina, which allows you to get the effect of darkening over time. After this, glazing is carried out, during which we go over the protruding elements and those places that are characterized by abrasions with white paint. After the latter has dried, a transparent varnish is applied to seal the effect.

Bronze painting

Antique cast bronze is an expensive way to decorate the interior, so most often they use imitations of cheap metals (forged steel, aluminum) or even non-metallic objects. Do-it-yourself painting with a golden-colored alloy and patination (old bronze darkens when exposed to air) helps give them an antique look.

Giving a monochromatic effect

Decorating as antique bronze begins with painting and giving the black metal an external resemblance to a casting from a non-ferrous alloy. If the product is made using hot forging technology, it must be sanded to a clean and shiny steel surface. A dark deposit of scale, which forms due to heating, can interfere with the even application of the dye or fall off during use, destroying its layer.

Pay attention to: How to paint metal products with spray paint in cans

Cold forged and bent products are cleaned of dirt and rust. When using acrylic or polyurethane paints without solvent additives, it is advisable to clean them in the same way as for hot-forged products.

When using a three-component forge mixture, you can only remove what weakly adheres to the metal: a thick layer of rust, peeling old coating or dirt.

After removing deposits with sandpaper, coat the product with a metal primer. When using three-component color mixtures, this step is also optional.

After drying the primer layer according to the manufacturer’s instructions, proceed to painting:

- apply a layer of bronze paint of the desired shade to the product (dark or light, old bronze, etc.);

- dry the product until the coating is completely cured (the minimum period is specified by the manufacturer and is about 24 hours);

- paint again, dry and apply 1 more layer;

- The product, ready for aging, will acquire a uniformly golden surface with a shine characteristic of polished bronze.

To achieve antique bronze, special paint and varnish coatings are used, which are applied using the contour method to the product.

Achieving the effect of antique bronze

Patination helps to achieve the effect of bronze darkened over time - painting the surface with special compounds (for example, WS-Patina or others). Translucent dark varnish can also be used as a patina. It is more convenient to apply patina with a brush; this will fill the recesses with a thicker layer, creating dark areas there. The bumps will be lighter.

The final stage is the application of light bronze paint to the highest points of the relief. When using bronze products, these protruding points are polished upon contact with hands (for example, railings, handles, etc.), they look lighter and shine.

This effect can be artificially created with a semi-dry brush or foam sponge with a minimal content of coloring composition. Using a tool, blot all protruding parts of the pattern.

Pay attention to: How to degrease metal before painting: main selection criteria

After glazing, the product is allowed to dry again and coated with varnish. It will protect the results of the work done from rapid abrasion during operation and accidental mechanical damage.