Recently, many private developers have given preference to natural building materials, such as wood. The use of wood in the construction of residential buildings has always been considered a sign of good taste, even if only the finishing is made from it. However, not all homeowners are ready for the fact that wood needs to be protected and the coating periodically renewed. How to treat a house block so that it is not damaged by fungus, mold, or insects, and to increase its service life?

What is a block house?

Block house (translated from English as “house element”) is a modern wood finishing material that resembles a log structure from the outside. In fact, it is a type of planed board or lining, that is, a panel that is a segment of a rounded log or profiled beam. Made from hardwood of the best quality (aspen, pine, larch, spruce, birch, linden). It is used with equal success both for exterior decoration of the facade of a house and for interior decoration.

You can cover a block with a house on surfaces made from almost any building material: brick, aerated concrete, foam blocks, wooden beams, etc. If necessary, a layer of sheet or roll insulation is placed under the sheathing. The panels are mounted on an additionally installed vertical sheathing, and the connection is made using grooves and tongues cut on a milling machine. Thus, the cladding is a monolithic layer that is not afraid of wind, snow, or rain.

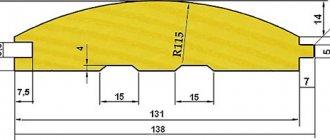

The house block is made from 2 to 6 meters in length, the width of the front decorative surface is from 90 to 190 mm. The thickness of the material is indicated at the most convex point from 20 to 40 mm. Interspersed knots, wormholes, resin pockets and microcracks (up to 1-2 mm) are allowed.

Types of paint - what is the best way to cover the surface?

To paint a block house, transparent and opaque coloring compounds are used.

Transparent paints contain pigment substances that enhance the effect of wood texture.

Transparent types of paint include:

- varnishes;

- impregnations (oil, acrylic, water-soluble, alkyd);

- glazing compounds.

It is not always advisable to use varnish for facade work, since, despite the good density of the coating and emphasizing the wood texture, not all varnishes are able to withstand aggressive environmental influences. In addition, varnishes are not able to maintain natural vapor exchange; they retain moisture, which can cause mold and rotting of the wooden surface.

Impregnations, unlike varnishes, are capable of providing vapor exchange and impart expressiveness and richness to the natural texture. The most popular are glazing agents that have the combined properties of varnishes and ordinary impregnations.

Glazing compounds reliably protect the coating from exposure to ultraviolet radiation and are also waterproof. For such colorless paints, you can use tinting of the composition by adding a small amount of dye to it.

This ensures the preservation of the wood texture and creates a decorative color design for the coating of a wooden block house.

Opaque paints include the following compositions:

- on organic solvents (oil, alkyd, acrylic, vinyl chloride, polyurethane);

- water based.

NOTE!

The most common are organic coloring compositions. The coating with such compositions is easy to apply and of high quality.

Alkyd compounds are especially widely used due to their low cost and ensuring the hydrophobicity of the coating. However, such coatings have their drawbacks: they are quite toxic and fire hazardous.

They protect well from external influences of acrylic-based paint.

Polyurethane compounds can create reliable protection for a wooden base and are the most effective in terms of wear resistance.

Features of the material

The service life of such material is approximately 12-15 years, and repair work consists of updating the decorative layer.

How to treat a block house if it was received raw?

There is simply no definitive advice for finishing exterior carpentry. This material is very specific, capricious, of biological origin (and different breeds have their own characteristics), which means it suffers differently from moisture or drying out, ultraviolet rays, mechanical stress, pests, drying conditions and speed, and other factors.

Initially, it is necessary to study the condition of the wood (since most buildings turn gray and are affected by pests even at the construction stage), then select the necessary paints and varnishes. Treat the planks, sheathing and base (if it is also wooden) before facing, let it soak well, attach and paint with a decorative layer. So it is quite possible to cover a block house with high quality with your own hands and it will last no less than one processed in a production environment.

Home cooking protection or savings for workaholics

Of all the wood coatings that can be made by hand, the most positive statistics are collected by the so-called Swedish paint, used in Scandinavia to protect wooden buildings since the 16th century. This composition can be considered a leader in economic efficiency, because purchasing the components for making 150 liters of Swedish paint yourself will cost the same amount as you can buy 10 liters of domestic enamel in a construction supermarket. It is applied in just one layer and does not lose its protective properties for up to 20 years, counteracting wood rot, mold and damage by insects. The surface of the block house must be new, without treatment. The composition has clear proportions, which are convenient to measure on a kitchen scale. For 2 liters of paint (7 sq. m. facade):

- water – 1500 ml;

- drying oil – 107 ml;

- rye flour – 193 g;

- table salt – 87 g;

- iron sulfate (broad-spectrum antiseptic) – 87 g;

- iron minium (colors the composition red-brown) – 87 g.

Flour is poured into a heat-resistant container, into which half the volume of water is poured in a thin stream while stirring, and cooked until it becomes a paste. Then salt and iron sulfate are added, and after they are dissolved, red lead is added. Drying oil and the remaining water are added last: the paint is ready.

It is important to know

Natural drying oils are flammable materials, while synthetic ones are fire and explosion hazards. When adding drying oil to paint, you must ensure that the flame is not too high, otherwise the composition may catch fire.

The paint should be applied to the house block while it is hot, as the mixture may thicken when it cools. For this reason, it is better to cook the paint in small portions.

Processing of block house at the installation stage

To protect the exterior of carpentry, preserve their external beauty and extend their service life, it is recommended to treat them with paints and varnishes before starting installation work. For these purposes, all kinds of stains, varnishes, paints, glazes, impregnations, drying oils, etc. are used.

How to cover a block house if preference is given to the natural structure of wood?

Transparent varnishes and glazes will help in this matter, while tinted opaque paints, on the contrary, will hide all the imperfections of the wood and fit into the style invented by the author.

Impregnations are used to protect wood from fire, bad weather and pests.

- Water-soluble acrylic impregnations

are intended for coating fresh wood, do not have a strong toxic odor and can be used for painting indoor surfaces, even while residents are living. - Alkyd impregnations based on resins

create a more resistant, durable and high-quality coating, but have a pungent odor and are intended for outdoor use. - Oil products

are made on the basis of flaxseed oil (or any other natural oils). A durable coating that has long been time-tested, but takes quite a long time to absorb and dry. After oil impregnation of the house block, decorative finishing with some paints will be impossible!

Stains leave the grain of the wood unchanged, but change its shade, usually to give the color of a different species. It is applied to the treated surface, penetrates inside, dries without forming a film or smooth layer on the outside of the surface.

Stains can be water-based, solvent-based (nitro stain), wax-based, or alcohol-based. The latter almost always have protective qualities. You can also paint the block house with a colorless stain, which is intended solely to protect the wood and the primer.

Procedure for painting external walls

Block house is a universal material. There are varieties that are only suitable for interior cladding, but for the most part, imitation wood cladding can be used both inside and outside buildings. But when choosing painting materials, you should thoroughly familiarize yourself with each of them in order to correctly decide how and with what is better to treat the block house outside or inside.

If there is a desire to preserve the natural beauty of wood, then oil-based glazing compounds will be the most suitable. Coating wood with decorative compounds will enhance its visual appeal and create a reliable protective layer.

Finishing work should be carried out in the warm season, in the absence of rain. Since the surface area to be finished outside the house is usually significant, weather conditions must be predicted for several days. You will need to not only have time to complete the work itself, but also have enough time for the paint to dry completely.

The coloring process is carried out in stages:

- Before painting the block house outside the house, you need to clean it of old paint (if any), dust, and dirt. To do this, use scrapers, rough brushes, and rags.

- Planks that have darkened over time must be lightened using solutions intended for this purpose.

- If damp or moldy areas are found, they must be immediately treated with an antiseptic.

- The preparatory work is completed by coating the surface with a primer. Practice shows that the primer should be purchased universally, or, better yet, from the brand from which you decide to use paint. The primer will help improve the adhesion of the paint composition to the wood, and will also reduce paint consumption.

- There is no point in using rollers to paint imitation logs, since the surface is somewhat wavy and working with this tool is problematic, although it is not prohibited. How to cover the block house outside the house? Typically, paint brushes or a spray gun are used. The choice of tool depends on the consistency of the dye. If the paint is liquid and can be sprayed, then it is convenient to use a spray bottle. It is easier to apply a thicker composition with a brush. The brush is also used for applying paint in hard-to-reach places and painting seams and joints.

- The painting process should be started from the top of the wall so that drops of paint do not spoil the already treated surface.

When choosing colored paints, varnishes and glazes, keep in mind that often the color indicated on the label differs from the contents of the can. And in order not to make a mistake with the amount of material purchased, you should make a calculation in advance.

According to standards, a two-layer coating requires 250-300 grams per square meter of painted area.

Decorative covering of block house

Varnish and paints.

They cover the wood with a dense layer that reliably protects them from bad weather and the influence of sunlight. Varnishes are usually colorless or can slightly change the shade of the material, while paint is designed to change color (can be matte, glossy or semi-matte). For better adhesion of facade paints to a wooden base, it is recommended to coat the working surface with a specialized primer, preferably from the same manufacturer as the paint.

During use, varnishes and paints may crack or begin to peel, then to restore the coating it will be necessary to remove (sand) the entire layer down to the base and only then paint again.

Azure.

Create a thin moisture-proof film on the coating. A significant difference between glaze and varnish is that they, like impregnation, penetrate deeply into the thickness of the wood.

Transparent azures are designed to highlight the noble texture of the material. Decorative, imitating shades of different types of wood or slightly tinted, allow you to process surfaces instead of the usual oil or acrylic paints. Water-repellent glazes (alkyd, alkyd-oil, acrylic-oil) protect the facade from weather conditions, ultraviolet rays, rotting, as well as mechanical damage (alkyd-urethane glazes).

Wax.

Traditional natural coating, light-repellent, waterproof, with a specific matte shine. To update the layer, it will be necessary to remove the coating to the base. It is recommended for interior work, but some brands are also intended for treating facade walls. It is not always possible to paint a wax coating with paints or enamels.

You can process and paint the house block with any roller or brush, the main thing is that the working surface is dry and free of dust, dirt, old paint or varnish. Coating options are selected based on personal preferences, wood condition, operating conditions and budget. It is recommended to cover areas of increased mechanical stress with an additional 1-2 layers of coating or varnish, but from the same manufacturer as the main paint and varnish.

If a wooden block house is used as decoration for the house, then the building looks very nice. Presentation is not the only advantage of the material, which is why consumers make a choice in its favor. But there is a second side to the coin: the tree needs to be protected. Finishes made from it can become a victim of house fungus or insects. Therefore, a logical question arises for those who decide to use the material: how to treat the outside of the block house so that it lasts as long as possible. A considerable amount of impregnation will help protect wooden panels, and therefore increase their service life. The question can also be posed this way: how to paint the outside of a block house, because this material can be coated with coloring compounds that change its natural color.

Deep impregnation

How to treat a block house?

Modern manufacturers, to increase the service life of a block house, often use all kinds of antiseptic impregnations that perfectly protect natural wood from rotting, fire and biological factors (wood-boring insects). Special chemical protection agents, called anti-frozen agents, can significantly increase the fire resistance of a blockhouse.

In order for block house processing to be most effective, special autoclaves are used in industrial production. Processing the material according to the “vacuum-pressure” scheme allows impregnating chemical compositions to penetrate most deeply into solid wood, with further distribution throughout the thickness. As a result, even inexpensive species (pine and spruce) acquire all the performance properties of hardwood.

Surfaces with any geometric cross-section can be impregnated (sawn timber, round logs, blockhouse). Some wood defects (tarting, browning, false heartwood) make processing difficult. The bark along with the bast must be removed from the logs.

An autoclave or pressure chamber is a sealed vessel. Processing of a block house occurs in several stages:

- before processing the blockhouse, residual moisture and air from the wood capillaries are additionally removed from it in a pressure chamber under an initial vacuum;

- after this, a reagent for processing is pumped into the pressure chamber;

- under the influence of hydraulic pressure, the wood is impregnated with a protective composition. Processing time and parameters depend on the type of wood. Aging of coniferous species (larch, spruce or fir) lasts 400 minutes, and for birch 195-200 minutes are enough. In addition, the part of the trunk from which the blockhouse is made is of considerable importance. The peripheral wood (sapwood) is easily permeable to the preservative, but the central part (core) is much more difficult to impregnate. The depth of impregnation is regulated by GOST 20022.0 -93 and is 5 mm for cedar, 2 mm for other conifers;

- after the end of exposure in the solution, excess chemical is pumped out and the wood is again subjected to vacuum to remove surface moisture;

- The final stage of processing is holding the material at atmospheric pressure to fix the preservative liquid.

Such deep treatment with fire retardants and biopyrenes will be much more effective than covering a blockhouse at home and allows not only to protect the wood as much as possible from rotting, but also to give it a certain fire resistance.

If you purchased a blockhouse without treatment, then you can improve its properties yourself.

Products with transparent texture

Thus, the answers to the question of how to paint a block house outside and for interior decoration can be very different. All products have their own advantages, all have nuances of application. And only after studying all the available options can you begin to change the “appearance” of the room.

Ekaterina Nevzorova, Minsk, 2014

- Should you choose wooden decorative panels? Or should you still choose a vinyl block house for a log? This question arises before everyone who decides to cover the facade with cladding...

- A metal block house under a log is made of galvanized metal. Using special technologies, it is coated with a special polymer...

- Insulation of the walls of a house from the outside is necessary, regardless of the material used (wood, foam block, brick, reinforced concrete, and so on). To complete this process, in any case, you must...

- Houses made of wood are buildings that are distinguished by their reliability, aesthetics and environmental friendliness. Despite the simplicity and naturalness of the material, structures made from it are quite expensive and affordable...

- Once upon a time, there was only one answer to the question of what kind of block house there is. At the dawn of their existence, the panels were exclusively made of wood, and only then they began to be made...

The smart ones came up with it, practice showed it, and a nice person posted it, I’m just quoting... and thanks to them all

Antisepticize unpainted wood On a similar forum, one guy said - such (From: St. Petersburg): “Under no circumstances paint fences and wooden houses!This is a waste of time and money. It’s better to follow the wise experience of the Finns and prepare a special composition for coating wood.

Take 720 g of rye flour, 1560 g of iron sulfate, 360 g of table salt, 1560 g of dry lime pigment, 9 liters of water.

And now - attention!

When preparing the solution, it is important to follow the technology. Add flour to 6 liters of cold water and stir until a homogeneous mass with the consistency of thick sour cream is obtained. The paste is filtered and put on fire. Stir constantly, add salt, then iron sulfate and dry lime pigment. The remaining 3 liters of water are boiled and added to the resulting composition.

The consumption of this “paint” is 300 g/sq. m. Apply to wood twice. If your building or fence was previously painted with oil paint, it will have to be completely cleaned off.

After this painting, your building will last for 20 years without external repairs! The Finnish wood coating composition, unlike oil paint, is more durable and breathable.

Swedish recipe

Painting a house, whether big or small, is not a very pleasant pleasure: it’s hard, dirty, tiring. I didn’t have time to paint it - everything was peeling off again, the paint was hanging in tatters... And again - material costs. We need to get back to work. But we can’t not paint, because we do it not only for beauty, but also to protect the wood so that it doesn’t start to rot.

So the house painter dreams, sadly waving his brush, that scientists will come up with such a composition that once he paints, he paints forever...

By the way, there is such a composition. And it was not invented by scientists, but by the homeowners themselves, those who live in Scandinavia - Swedes and Finns.

To protect the wood, it is enough to paint the house just once. The wood will be reliably protected, and scraps of paint will not irritate you. True, the “color” will fade over time, but that’s another conversation. Let’s make a reservation right away: you can only paint with this composition clean wood, that is, wood that has not been painted before, or plaster. No pre-treatment is necessary.

Here is the lineup from Sweden. Just please, don’t take any liberties with the numbers. Do it exactly as it is written.

So: rye flour - 580-600 g, table salt - 250-260 g, drying oil - 240-250 g, iron sulfate - 250-260 g, red lead - 250-260 g, water - 4.5 liters. Dry pigments can be used to create different shades. The natural color of the composition will be yellowish.

The cooking technology is simple and accessible to everyone.

Pour rye flour with 3 liters of water. Place on low heat. While stirring, prepare the paste, making sure there are no lumps. When the paste forms a homogeneous mass, without removing from the heat, add salt and vitriol and continue to boil until the crystals are completely dissolved. Then add the red lead and knead the mixture until completely smooth.

Finally, pour in the drying oil, stir again and bring to the working volume (i.e. add another 1.5 liters of water), again without removing from the heat. The prepared solution is used for coloring immediately, while warm. After some time, it will begin to thicken, then you will have to dilute it with warm water, which is generally undesirable, because when the solution is “thinned,” the paint layer will become less durable.

It is more convenient to cover wooden surfaces with this solution with a brush, and plaster with a roller. The consumption of “Swedish” paint is approximately 250 g per square meter. _________________ “...In order to increase the level of general education...”

Modern finishing material block house can be used both for exterior decoration of the house and for decorating the interior, creating the illusion of a log house. Typically, manufacturers coat the block house with various protective agents - it becomes resistant to adverse environmental influences and does not require treatment for decades. But sometimes on the construction market you can find material that has not been treated with protective compounds. If you are “lucky” to purchase just this one, then you need to select a high-quality impregnation for the block house.

Folk recipes

In addition to ready-made paints, wooden houses and houses finished with block houses are often coated with self-made compounds. For example, for finishing untreated wood, the following “Swedish” composition is recommended:

- 600 grams of rye flour;

- 250 grams each of table salt, drying oil, red lead and iron sulfate;

- 4500 grams of water.

To make it, rye flour is brewed with 3 liters of water into a paste, and without removing from the heat, salt and iron sulfate are added. The mixture is constantly stirred until individual crystals disappear. After this, red lead is added. After the last component is mixed into the mass, gradually pour in the drying oil and the remaining 1500 grams of water. The composition is applied to the wood while warm. Application work must be done at maximum speed, since over time the paint begins to thicken.

This composition will give the wood a warm yellow tint. However, if you wish, you can add dry pigments to the mixture. The consumption of such paint for a blockhouse is about 250-300 grams per square meter of surface. This composition will protect your home for many years without requiring renewal. Its only drawback is the color fades over time. But you will be spared from hard, routine work, and scraps of old paint will not depress your eyes.

Requirements for the impregnating composition

To protect the finishing material from darkening, drying out, fungus or mold and preserve the beautiful structure of the wood, it must be covered with a protective layer. Impregnating compositions are divided according to their properties:

- Fire retardant - reducing the likelihood of fire. These compounds, applied to wooden panels, with a significant increase in temperature form a film on the surface that prevents combustion.

- Antiseptic - preventing the occurrence of fungi, rot or mold on wood. Some also repel mice and rats.

- Waterproof - preventing moisture and dampness from penetrating into the wood structure of the block house.

- Combined - combining several protective qualities.

For a residential building, it is advisable to purchase combined mixtures that reliably protect finishing panels from fungus, rodents and fire.

To cover or not to cover?

The price of a blockhouse depends not only on the species and type of wood. By purchasing beautiful and inexpensive material at the nearest sawmill, a happy buyer will most likely pay extra for the savings a little later, choosing compounds to protect it. The more expensive, factory-made version of the house block is often sold with protective impregnation, which not only frees the owner from headaches in the first years, but also significantly improves the physical properties of the material.

Industrial impregnation of a house block is carried out using unusual brushes and spray guns. The material is placed in an autoclave, where first the residual moisture is extracted from the capillaries of the wood by vacuum, then an antiseptic composition is injected under pressure, impregnating the wood to a certain depth, after which the excess liquid is sucked out again and the wood is dried. This processing method allows the structure of the material to be etched almost entirely, which is why even the cheapest and softest types of wood acquire premium qualities. Factory treatment will provide the blockhouse façade with several years of protection without additional measures.

Types of impregnating compositions

When thinking about how to treat a block house outside or inside your home, you should keep in mind that the panels, thanks to their wood structure, are very beautiful. They do not need final painting (it is recommended to paint only an old block house that has lost its presentable appearance), so the impregnating compositions will also serve as a final protective coating. Depending on the purpose, the following protective and decorative impregnation solutions can be used:

- Alkyd ones provide complete protection from mechanical damage, repel mice and other rodents, but have a pungent odor. If treatment is carried out inside the house, care should be taken to ensure good ventilation of the room. They are very well suited for the facade of a house finished with a block house, providing it with long-term strength and reliable protection.

- Acrylic water-dispersion ones are environmentally friendly, but short-lived, suitable only for impregnating walls inside the house.

- Oil paints with or without tinting will help to significantly improve the decorative properties of wood, protecting it from destruction for a long time.

- Glazes are the most expensive, beautiful and durable processing option. Impregnation with glaze provides reliable protection from moisture, UV rays, rodents and insects, while maintaining breathability, providing the wooden surface with the necessary air exchange. Glaze compositions also highlight the unique wood structure, giving it a matte or glossy shine.

Coloring rules

Regardless of what composition is used for painting, the surfaces must be prepared, that is, cleaned of flaking parts, dust, and old paint (varnish). You can clean it with special brushes or grinding attachments. It is advisable to cover darkened areas with bleaching agents. For lightening, special stains are used.

If the choice is made and you know how to paint the outside of the block house, and how to update the internal coatings, pay attention to some nuances in the painting rules:

- external work in warm and not rainy weather . Study the forecast for the future. Since there is a lot of work to be done, take into account the painting and drying time. After thorough cleaning, the surfaces are primed. Thick paint is best applied with a regular brush. For liquid ones, you can use a spray gun. Coloring starts from the top. This is done so that the paint does not spoil the already treated surface.

- Interior painting of a house block requires caution when using paints and varnishes. Read the instructions, follow the proportions and safety rules, especially if you use varnishes and paints with a strong odor. The primer increases adhesion; it is advisable not to ignore this important stage and ensure reliable adhesion. When using protective impregnations, you can get by with surface application; in this case, deep processing is not required.