Cement particle board (cement particle board) is a well-proven material in the facing materials market. Cement particle boards (CSP) appeared in construction about 30 years ago; in recent years, due to the high pace of construction of low-rise buildings, they have become very popular in the design of facades. Thanks to the structural monolithic nature of the slabs, a facade made of fiberboard combines the best qualities of cement and wood - resistance to dampness and low temperatures. Thanks to the addition of chips of various types of stone (marble, granite and others) to the DSP, such a facade looks modern and attractive.

Advantages and disadvantages of DSP facades

DSP facades have characteristic features associated with the structure and manufacturing technology of DSP boards. The dimensions of the material (2,600 by 1,250 and 3,200 by 1,250) allow them to cover large areas, which distinguishes them favorably from the board coverings previously widely used in individual construction.

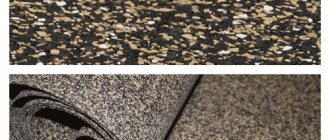

The structure of the slabs consists of wood chips bonded with cement mortar and a layer of stone chips

Thanks to these and many other advantages, cement particle board is one of the most common options in facade interiors.

The advantages of such facades include the following qualities:

- ease of installation, which allows almost every person to participate in it; the material is amenable to any mechanical processing;

- the surface does not require labor-intensive finishing; any paint used for exterior work with preparatory priming is suitable for this;

- materials are environmentally friendly, non-toxic, non-toxic;

- due to the high cement content they do not burn or smoke;

- are not susceptible to insects and putrefactive fungi, even with very high and prolonged atmospheric humidity;

- durable, does not chip, resistant to impacts;

- have good sound insulation;

- the possibility of applying natural stone chips to the top layer makes them very diverse, attractive, modern and cozy. Along with the undeniable advantages, this type of facade has some disadvantages arising from the technological features of the DSP. These disadvantages are much smaller than the advantages. They are as follows:

- the rather large dimensions and weight of the slabs require the involvement of assistants for their installation, and when lifting to the upper floors - special equipment;

- for external work, slabs with a thickness of at least 16 mm are suitable, since thinner material can be broken when installing the facade;

- mechanical processing of the material when installing the facade requires special tools for cutting stone or concrete (grinder);

- When cladding large areas of the facade, you always have to pay great attention to the quality of sealing the seams between the slabs in order to avoid their frequent cracking.

Domestic manufacturers use only environmentally friendly materials

Caring for cladding material for half-timbered design

Individual wooden elements are located one at a time along the entire facade of the house, but despite the fact that they are well ventilated and impregnated with special products, they periodically need care using high-quality chemical compounds.

German creators of reliable oils, impregnations, glazes and paints recommend using them depending on the season of the year. At one time, it is necessary to protect the planken from drying out and corresponding cracking; at another time, deformation may be associated with high humidity. For all problematic situations, manufacturers have provided high-quality formulations:

- creating an elastic surface and imparting a glossy shine;

- having a dirt-repellent effect;

- securing the indicator of resistance to scratches and other defects;

- oils that penetrate the structure of the wood and highlight the natural beauty of the wood;

- oils that preserve it, strengthen it, without clogging the pores and at the same time allowing it to “breathe”;

- wax enamels that protect wood from insects, are resistant to fading and make the surface perfectly smooth, protecting it from atmospheric influences.

Materials for facade installation

To assemble the facade, the following materials are required:

- DSP 16–20 mm thick. Due to their fragility, thinner slabs are used in small areas or for interior work. The need for material is determined based on the area of the facade with a margin of 15%.

- A block measuring 50 by 50 for sheathing. The required amount of material is calculated based on the fact that the bars are mounted horizontally or vertically at a distance of about half a meter from each other. For this purpose, you can also use a galvanized plasterboard profile with hangers.

- Basalt wool as insulation based on the surface that needs insulation.

- A wind barrier that protects the insulation.

- Special umbrella dowels that secure the insulation; 5 pieces of these plastic fungi are needed per square meter of area.

Thanks to the large area of the slabs, finishing the house occurs very quickly

Installation of planks on half-timbered houses

Installation of the plank is carried out in accordance with the selected drawings:

- the crossed beams are called "St. Andrew's Bridge";

- planks laid out in the shape of the letter “F” symbolize protection from fire;

- when the lateral lines are located, which do not intersect, but at the same time tend to each other, then this drawing is called “Swabian woman”;

- when the lateral lines intersect in the middle or at one third of each of them, then such a pattern is called “Wild Man”.

Note! If you use ready-made ornaments, you can make your house not only beautiful and interesting, but also stylize it with amulets that our ancestors used (curls, symbols of the sun or scary masks).

First you need to think over and select the drawings that will be present on the facade, calculate the required volume of required material, costs and begin installation:

- Preparation of necessary materials, fasteners, lathing. These can include TsSN slabs, planken, insulation, windproof film and bars.

- Preparation of tools: a hammer drill for attaching the frame using dowels, a screwdriver for tightening screws, a grinder for cutting slabs, a level, a square and a tape measure.

- Construction of a façade frame for half-timbering.

- The material for the metal sheathing is treated with an antiseptic.

- Next comes the laying of a layer of insulation, and on top of it a windproof film.

- DSP sheets are attached to the frame.

- Decorating using planken and painting DSP sheets.

The location of the wooden planks is preferable at the connecting seams, but if the design suggests otherwise, then it is not necessary to change it. The planken is attached using self-tapping screws along the marked lines. Installing a wooden decorative element on a house in a half-timbered style is a simple process, but, so to speak, a jewellery. This requires precision and attention, which can be provided by specialists.

Facade installation

If the walls of the house are not wooden, then the sequence of installing the DSP is as follows:

- at a distance of six tens of centimeters in the vertical or horizontal direction, brackets or bars are fixed to the wall;

- insulation is installed, which is reinforced with two mushroom dowels;

- a wind barrier is installed, it is secured by three more fungi;

- The sheathing is installed, and a thread is used to check the correctness of its installation. Moreover, a small gap of approximately 10 mm is maintained between the frame and the wind barrier;

- The last to be installed are the façade panels, which are secured with self-tapping screws; 3 fastenings are made for each slab. Before this, they are drilled under them with the plates in a horizontal position on the plane of the hole. A gap of several millimeters is maintained between the plates. If the façade is installed on a wooden base, it is first treated with a special impregnation. After this, the waterproofing is installed using thick paper - roofing glassine with bitumen impregnation, fastened with a construction stapler.

DSP facades are very popular and allow many design solutions to be implemented

Then the sequence of actions is as follows:

- A frame of painted boards measuring 30 by 90 mm is installed; it must be strictly in the same plane with a gap of four tens of centimeters between the planks.

- The next layer is foam, which retains moisture.

- On a wooden stand, a sheet of DSP, previously cut with a grinder, is primed on one side, placed on the stand to dry, then turned over and impregnated on the reverse side.

- After drying, all sheets are placed in a stack, covered with film in case of rain, and a press is placed on top to prevent them from warping. It is not allowed to keep the DSP sheets in the sun.

- The preparation of holes for self-tapping screws is carried out in the following order: using a screwdriver, retreating from the corner to 10 cm and from the edge to 2.5 cm, make holes at a distance of 25 cm from one another; Use a large drill to countersink holes for their heads, and place stops on the drill.

- Mark the centers of the frame strips at the top and bottom.

- Nails are driven into the outermost strip of the frame at the top and bottom. Pressing the edge of the sheet against them, firmly fasten it with self-tapping screws. The same procedure is done with all the other sheets, gradually moving the signal strip with nails. You need to drill holes in a staggered pattern.

- The sheets are installed from the edges of the window towards the edges of the wall. First, whole sheets are mounted, and then pieces are added.

- The heads of the screws are sealed with gypsum putty with water and PVA glue twice. Self-tapping screws must be galvanized so as not to rust.

Stone chip coating can be made from various rocks

Features and Issues

OSB boards are not initially a finishing material that can be used “as is”, without additional finishing. Therefore, many may have natural doubts about the resistance of such materials to the effects of various types of precipitation, temperature changes, and so on. In principle, if you choose moisture-resistant sheets, then nothing bad will happen to them. If the OSB is ordinary, without special impregnations, then minimal treatment with various antiseptics and subsequent painting with weather-resistant paint will also solve the problem.

Next, it should be taken into account that the surface of the sheets is not smooth. It is rough, will absorb moisture from the paint and the finishing will be difficult. However, by using a little more paint and varnish when finishing, you can solve this problem. There remains one more point that not everyone takes into account - excess moisture on the inner surface of the sheets themselves.

If you simply sheathe the building with OSB and make the internal insulation accordingly, then the problem is solved immediately. You just need to think about the ventilation system. However, many decorate already erected buildings, simply strengthening their walls with additional sheathing, and at the same time laying a couple of layers of insulation. In this situation, it is already necessary to leave a special gap between the sheathing sheets and the surface of the load-bearing wall. It will give moisture the opportunity to escape without remaining “sealed” inside the structure.

Seam processing

The final touch in installing a DSP facade is sealing the seams. There are two ways to do this work. One of them is the final finishing with cement sealant using a special gun. The sealant compares favorably with other similar materials due to its elasticity, which allows it not to crack during thermal expansion and contraction. Part of the packaging is placed in such a gun, then added as needed. After this, the instrument is cleaned. It is important to start processing the seams only three days after installing the slabs, since during this time they dry out by 1 mm. After the sealant has dried, cut off the excess with a knife, apply self-adhesive mounting tape and putty the seams twice. After the putty has dried, these places are sanded. The last stage of finishing work is priming and painting with exterior paint. For reliability, add 10% PVA glue to water-based paint. We recommend reading the article about installing façade panels.

Cement particle boards can be used to finish the base

In another case, metal or wooden planks are placed at the joints of the slabs. A tree of contrasting color looks very impressive on the façade.

DSP facades are widely used in frame construction of low-rise buildings and have their own advantages:

- it is non-toxic, non-flammable;

- due to the moisture and frost resistance of the material from which it is made, it can be installed at any time of the year;

- has good sound insulation;

- quite durable, shock-resistant;

- has many variations of stone chip coating that look advantageous.

Things to consider

A few tips from the practice of people who have used similar technologies will help you do everything faster and easier:

- It is better to paint OSB sheets before attaching them directly to the walls - this is much easier and the result will be better. Before painting, they must be impregnated on both sides with an antiseptic.

- The joints of the slabs are covered with a decorative board, which will become the main imitation of half-timbered wood. However, if the boards are brushed or aged with special paints beforehand, the effect will be more interesting.

- Be sure to paint the ends of the parts before installing them in place. This will save them from swelling and moisture penetration.

In general, there is nothing complicated or difficult in creating such imitations. If you have an assistant and for some reason you don’t like the appearance of OSB, you can use DSP boards. However, remember that they weigh a lot and you simply cannot cope with lifting the parts to the top of the facade alone.

Installation of planks on half-timbered houses

Installation of the plank is carried out in accordance with the selected drawings:

- the crossed beams are called "St. Andrew's Bridge";

- planks laid out in the shape of the letter “F” symbolize protection from fire;

- when the lateral lines are located, which do not intersect, but at the same time tend to each other, then this drawing is called “Swabian woman”;

- when the lateral lines intersect in the middle or at one third of each of them, then such a pattern is called “Wild Man”.

Note! If you use ready-made ornaments, you can make your house not only beautiful and interesting, but also stylize it with amulets that our ancestors used (curls, symbols of the sun or scary masks).

First you need to think over and select the drawings that will be present on the facade, calculate the required volume of required material, costs and begin installation:

- Preparation of necessary materials, fasteners, lathing. These can include TsSN slabs, planken, insulation, windproof film and bars.

- Preparation of tools: a hammer drill for attaching the frame using dowels, a screwdriver for tightening screws, a grinder for cutting slabs, a level, a square and a tape measure.

- Construction of a façade frame for half-timbering.

- The material for the metal sheathing is treated with an antiseptic.

- Next comes the laying of a layer of insulation, and on top of it a windproof film.

- DSP sheets are attached to the frame.

- Decorating using planken and painting DSP sheets.

The location of the wooden planks is preferable at the connecting seams, but if the design suggests otherwise, then it is not necessary to change it. The planken is attached using self-tapping screws along the marked lines. Installing a wooden decorative element on a house in a half-timbered style is a simple process, but, so to speak, a jewellery. This requires precision and attention, which can be provided by specialists.

How to decorate the frame façade?

We guarantee the confidentiality of the information received. The processing of personal data is carried out for the purpose of effective execution of orders, contracts and other obligations assumed by the company.

This consent applies to the following personal data: last name, first name and patronymic, email address, contact phone number, payment details. The validity period of the consent is unlimited. You may revoke this consent at any time by sending written notice to dom mechtaevo. The catalog is for informational purposes only and is not a public offer. Prices are for houses with basic configuration. Depending on the configuration chosen by the Customer, the price of the house may change.

Images do not reflect complete information about the finishing materials used and the construction of the house.

A Finnish house is a one-story frame residential building with a classic gable roof and walls made of timber or OSB slabs. Almost always it is supplemented with an attic floor and a spacious veranda terrace, sometimes with a glass facade and often a balcony is installed directly above it. When designing, it is possible to additionally plan a basement floor used for a garage or other needs.

What do we take as a basis? What does the market offer?

Caring for cladding material for half-timbered design

Individual wooden elements are located one at a time along the entire facade of the house, but despite the fact that they are well ventilated and impregnated with special products, they periodically need care using high-quality chemical compounds.

German creators of reliable oils, impregnations, glazes and paints recommend using them depending on the season of the year. At one time, it is necessary to protect the planken from drying out and corresponding cracking; at another time, deformation may be associated with high humidity. For all problematic situations, manufacturers have provided high-quality formulations:

- creating an elastic surface and imparting a glossy shine;

- having a dirt-repellent effect;

- securing the indicator of resistance to scratches and other defects;

- oils that penetrate the structure of the wood and highlight the natural beauty of the wood;

- oils that preserve it, strengthen it, without clogging the pores and at the same time allowing it to “breathe”;

- wax enamels that protect wood from insects, are resistant to fading and make the surface perfectly smooth, protecting it from atmospheric influences.

The original exterior decoration using wooden cladding fits perfectly into the overall design of the half-timbered style. The quality of planken, its durability and reliability have been tested by more than one generation of developers.

To create a unique design, wisely allocate your budget, and implement all your planned solutions, pay attention to this inexpensive material, the possibilities of its processing, simple installation and maintenance. Undoubtedly, this is the best finishing material of all that is offered on the construction market today.

Review of the best options for finishing a house in the half-timbered style

Table of contents:

The modern half-timbered construction style for private housing construction migrated from Europe to Russia. Today, many developers are intrigued by a new option for finishing facades using ancient traditions of the Middle Ages. This style does not involve the use of only wooden material in the cladding: lining, planken or imitation timber.

A block house and imitation timber, representing a round log or beam, respectively, are not at all suitable for cladding under half-timbering, and lining is mainly used for interior decoration. It is likely that the finishing of a house in the half-timbered style will be carried out using pine or larch planks.

finishing the facade for half-timbered dacha - DSP, SML, OSB?

IMHODom › Forums › free topic › finishing the facade for half-timbered dachas - DSP, SML, OSB?

This topic has 28 replies, 13 voices, and was last updated by elena 4 years ago.

I'm torn about choosing...

LSU - not praised, full of Chinese, with low quality.

DSP is heavy, they say it swells.

OSB - I like it all, but the surface is structural, there are doubts that it can be puttied.

After all, it is impregnated with wax and resin - I don’t think that adhesion will be good.

Which way to look?

- Spacious

OSB is perfectly plastered, I’ve personally seen it, albeit indoors. I don’t know how it will be on the street.

- Admin Pensioner

User Gusarova sent their photos for this topic:

This is our dacha. I did everything myself, in the sense of finishing.

- April

If you start putting putty on OSB, invite us to take a look.

I also thought about it for a long time, I’m planning LSU, for example, here they promise Uralchem, and in TechnoNIKOL (the joint venture of which did not happen), the invoice for payment for which they gave me also indicated the production of Uralchem.

Of course, 8mm is a little thin, but I checked in Chinese from Stroypark that two 450mm bars between them (based on 500mm insulation) can withstand my weight of 80kg, although if I jump, it breaks. One of the main advantages is its white color, I think it’s enough to paint it once and that’s it, no need for putty or primer. At work they made a ceiling out of it (Chinese from Stroypark), only the seams were puttied and sanded, and everything was repainted with white water-based emulsion once. I haven’t seen Uralkhimovsky and haven’t held it in my hands, but “...they don’t praise it, it’s full of Chinese, with low quality...” I don’t know, but how to tell the difference, which means bad quality. In Stroypark they immediately told me Chinese, but the certificates showed that when the ceiling was made with normal sheets, the front surface was smooth without defects, the geometry was really not very good, the sheets were not quite rectangular, and the chamfers along the edges were removed crookedly, but the seams still had to be sealed. There is one more minus, or maybe on the contrary a plus, the surface of the sheet is durable, you have to countersink under the head of the screw, otherwise the self-tapping screw itself will not be recessed, even for GVL with a small head and notches, we first marked it on the floor, drilled and countersunk it for all the screws at once, and then the sheet was twisted. The price is also low, compared to OSB, you can do it in two layers with an overlap and it will still work out cheaper.

What is UralChem? This is a plant producing chemical fertilizers in the Urals and a trading house with a similar name that has nothing to do with the production. The SML plant does not produce. the trading house also does not have such resources. All UralChem is imported from CHINA. Because LSU is NOT produced in Russia.

Everything is true, but this is for internal work...

And how will LSU behave on the facade - in the rain and snow?

Well, there’s no smell of fencing here...

or dark sticks nailed onto light white ones - is this fachwerk?

- April

I also think that LSU will not survive in the snow, rain and wind... it will crumble to pieces.

Half-timbering (German: Fachwerk - (frame structure, half-timbered structure) - a type of building structure in which the supporting base is a spatial section of inclined (at different angles) beams made of softwood. These beams are visible from the outside of the house and give the building a characteristic appearance ; the space between the beams is filled with adobe material, brick, sometimes also wood. Half-timbering appears in the 15th century in Germany and becomes very popular in Europe, especially in the northern part (from Britain to Poland). In the 20th century, this style experienced a new flourishing thanks to the medieval flavor and the effect of natural building materials. Taken from Wikipedia. And the fact that in the photographs is an imitation of half-timbered wood. But it looks great! Agree!)) I also plan to decorate the facade this way!

Trading House Uralchem LLC is part of the Sideco holding and is engaged in the production and sale of the latest building materials. The company's most famous product is glass-magnesite sheet (SML), which has superior characteristics to materials such as plasterboard and gypsum fiber.

I couldn’t find any information about Sideko, it looks like a Chinese company whose products are carried by Uralchem, it’s a pity...

- Tomsk

I installed LSU on the street. I sewed up the outside of the walls without plaster or paint. 2 winters and no LSU. It crumbled, although they said that it was standing under precipitation. My opinion: you can install it, but there must be something water-repellent on top. Seal the joints too.

By and large, both OSB and DSP are not suitable for this either, in general, if you need to do it and forget it, say for 50 years, that is, there are only two options: red or sand-lime brick, well, you can also try painted metal siding, but 50 years of experience in its use I think not with us, all other materials require constant maintenance and repair, some less often, others more often, but they still require it.

You can use flat slate, it stands on the balconies of Khrushchev-era buildings, nothing is done to it, the paint will not peel off.

Painting the facade of a Finnish house

To comply with all the nuances of the half-timbered style, it is not enough to cover the facade with boards. You also need to paint the OSB boards in a color that contrasts or harmonizes with the color of the facing boards.

The shades of OSB finishing and boards should be in harmony

The photo shows an example of contrasting home design

Transparent coatings can be used for painting. But rarely does anyone leave the slabs in their natural color. They look much better painted. Therefore, the optimal choice is covering enamels, stains and tinting impregnations. Any covering enamels can be used:

- oil

- silicone;

- alkyd;

- pentaphthalic;

- acrylic;

- latex.

You can learn about the features of each type of paint from the table.

| Type of paint composition | Characteristics |

| Silicone | The most high-strength, durable, crack-resistant and frost-resistant. They are suitable for surfaces with old paintwork. |

| Alkyd | After these compounds dry, an elastic film remains on the surface of the slabs, which successfully protects the wood from moisture. Do not fade, frost-resistant. |

| Pentaphthalic | They form a dense film that is resistant to mechanical damage. An excellent choice for houses whose facade is in one way or another in contact with tree branches and other plants. |

| Acrylic | The most popular choice. They dry quickly, do not fade, and are vapor permeable. It is recommended to apply at least two layers. |

| Latex | Popular in areas where air humidity levels are high. They are characterized by a high degree of moisture resistance and frost resistance. Wide color palette. |

| Oily | They have a high degree of viscosity. When applied in 2 layers, they can mask the unevenness of the slabs. Disadvantages: long drying time, high consumption. |