Today it is difficult to imagine finishing work without the use of modern building materials and means. After all, they allow specialists to implement higher-quality, durable and long-lasting coatings. Such important means include primer. It increases adhesion (adhesion, adhesion) of materials and smoothes out surface roughness.

Many people consider using such a solution before painting or wallpapering walls useless. Basically, this opinion arises among novice craftsmen or people eager to decorate their home with their own hands. Accordingly, after a while they begin to realize how seriously they were mistaken. Since pre-treatment of walls with primer solutions helps to significantly save time and money, reducing the consumption of finishing materials.

Any specialist will confirm to you that all walls in a residential area must be coated with a special primer, regardless of what repair procedures will be carried out in the future: putty, plaster, coating the walls with special paint, and also before wallpapering, etc. .d.

What is a primer used for?

The presence of another layer between the decorative finish and the wall itself is necessary to ensure that the aesthetic appearance of your room remains at the proper level for a long time.

The main purpose of the product is to create good adhesion between the wall and the finishing layer. It is thanks to the primer coating that wallpaper or paint will last a significant period of time. It gets into even the smallest cracks, closing them completely, which makes the wall of the living space more even, and this is very important when carrying out repair work.

The main advantages of the primer coating:

- creating a solid foundation before carrying out repair work;

- providing better adhesion for slippery-smooth substrates;

- eliminating stains and other contaminants from the walls of the room;

- the product is endowed with excellent antibacterial and antifungal properties;

- protection of metal from rust;

- decorated coverings look brighter and more beautiful on the walls;

- after applying the solution, the base can be painted even in light shades of paint, despite the fact that it was previously a dark shade;

- the paint applied to the treated surface has a less pronounced odor. And this is a very important point when carrying out renovations in a residential area. We also recommend that you read the article - how to remove paint from clothes;

- manifestation of texture on wooden bases.

Of course, it is impossible to list all the capabilities of this product; there are many more of them, but the list described above may well impress with the scope of the capabilities of this emulsion.

In order for the repair to be at the proper level, it is advisable to purchase a primer separately for each material from which the surface is made. This will provide additional protection from the environment, insects in the case of a wooden base, as well as from corrosion or mold.

Despite the fact that traces of processing are practically invisible on the walls, there are still significant benefits from this procedure: the adhesion to the wall is better, consumables will be wasted in smaller quantities. It will also reduce the required amount of glue when it comes to wallpaper.

When should you prime?

The primer mixture can rightfully be called the most universal remedy for repairs. It helps to more firmly connect building materials together and prevents the formation of corrosion.

If the walls were plastered during the work, then they can be primed only after a month . Before painting the walls, you need to stir the mixture thoroughly. Usually it is applied in one layer, but in some cases it is necessary to apply several. The second layer is applied after the first has completely dried.

Primers are applied to plaster or paint. In such a situation, the primer acts as a link between particles of paint or plaster, this helps make the wall or ceiling smoother and allows you to save paint or glue by reducing the absorbent properties of the surface.

When working with putty, it is also necessary to prime the walls. If it is applied in several layers, then before each new layer it is necessary to cover the surface with a primer mixture.

Regardless of what the wall is made of, there will be cracks and various irregularities in it. The primer mixture helps smooth this out. Due to this, the next layer of finishing material lies more evenly.

We recommend: What is a water-dispersion primer and where is it used?

The primer improves the adhesion of paint to any surface . This protects the paint from cracking. The primer mixture helps save putty. When it dries, it forms a special film that prevents stains and fungus from appearing.

It is much easier and more even to apply a layer of putty onto the primer . The mixture contains various elements that prevent the formation of fungus and mold.

The primer is applied to dry surfaces, previously well degreased . If you do not follow these rules, you may end up with unevenly applied paint, cracks, or peeling of putty and wallpaper.

Before you start wallpapering, the walls need to be well prepared.

The primer mixture is diluted in a large container according to the attached instructions. If lumps appear, they need to be mixed thoroughly . A drill with a special attachment will help with this.

Then the resulting solution must be applied to the wall. Experienced craftsmen use a roller . This helps to minimize your time costs.

After the first layer is applied, you need to wait a certain time. The amount will depend on the type of primer. Then the second layer is applied, and after it has completely dried, you can begin finishing work. This will help reduce the amount of material absorbed into the drywall.

https://youtu.be/O6DQfS6uK0Q

&feature

Types of primer and its properties

Today there are different types of emulsions on sale, each of which is produced to perform specific tasks. They all differ in properties and included components, which determine how long the primer takes to dry on walls and other substrates.

Drying oil or alcohol mixture

Designed for work on wooden surfaces. To make it dry faster, you need to preheat the base that will be processed.

As you know, all trees secrete resin, especially when it comes to conifers. That is why the wood needs to be carefully processed; coating with this product is also simply necessary so that the paint or wallpaper adheres well to the base of the walls. There are types of mixtures on the market that will protect wood surfaces from rot and insect damage.

Acrylic primer

This tool is universal. It can be used on any type of surface: wood, metal, or concrete. This type of solution will fulfill the hopes placed on it well. Accordingly, this particular product is most often purchased by specialists and ordinary residents.

Do not forget that even if non-woven wallpaper is glued or painted, the base must be coated with such a composition. You can perform this procedure either independently or with the help of specialists. If you decide to carry out repairs yourself, you should carefully study the procedure for priming surfaces in order to avoid negative consequences.

Oil or alkyd

Used when working with metal surfaces. Can be used over corrosion, as this type has an anti-corrosion effect. But also suitable for wood.

Metal also needs a primer coat. This will ensure minimal impact of the corrosion process on the coating. But it is still impossible to completely avoid corrosion due to the nature of this process. Non-ferrous metals also need to be worked on so that the decorative coating adheres well to the surface.

In modern construction stores you can purchase various types of emulsions that have the property of converting rust. So the composition is applied directly to the place where corrosion appears, then the top is covered with paint.

Contact mixture

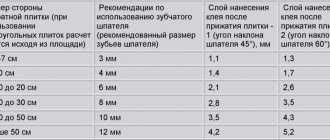

Used to increase adhesion. It contains quartz sand. This type perfectly fills even the smallest cracks, which makes the base perfectly smooth. Prepares the coating for tiling.

Varieties

How long the putty dries should be considered from the point of view of the basic composition of the mixture, since each has certain characteristics.

The type of putty is selected based on its method of use and application.

The qualitative characteristics of the dry mixture, in particular the base substance, determine the quality of the layer.

The overwhelming majority uses the following classification :

- starting putty - its grains are quite large, it is somewhat thicker than the finishing putty and is applied in a large layer;

- finishing putty is a mixture that is used to finalize the outline of the walls; it is fine-grained and applied in a small layer;

- a universal mixture is a prepared solution that combines both functions of the listed putties at once - leveling and finishing;

- Wood putty is a completely different type of mixture, as it is used to level wooden products. It is applied in a small layer of no more than 2-3 mm at a time;

- putty for metal - often used at service stations to form smooth coatings on cars.

Which one is better? Starting putty is used to bring the surface into one plane, that is, to eliminate large irregularities.

The peculiarity of the material is its very large layer, which can be applied at a time - up to 15 mm.

Starting

A second layer is also possible, but here the same question arises: how long does the putty take to dry, since a wet surface is not suitable for applying the mixture. Otherwise, all efforts may be in vain, as the wall will quickly crack.

Finishing putty is the final stage of forming the correct silhouette and contour of the walls. Thanks to it, smoothness and final polishing of the surface are achieved.

To avoid deformation, it is necessary to apply a layer of 5 mm or less, some can even be used only for a 2-3 mm layer of application.

This layer is quite sufficient, since serious unevenness has already been removed with the starting mixture. How long the finishing putty dries is of more interest from the point of view of completing the entire repair; usually paint, wallpaper are applied to it, structures are mounted, etc.

Finish

The universal mixture is much more expensive, because there is no need to purchase several putties. Most often it is used for small volumes of work with large irregularities.

It allows you to close deep surface defects and at the same time level it at the final stage, forming an even layer.

Universal

Wood putty is a mixture for forming the required shape, creating a plane, and sometimes creating a pattern on wooden products, mainly doors and windows. When applied in a large layer, it cracks, you need to limit it to 2-3 mm, after drying you need to repeat the procedure again.

Metal putty is very similar in consistency to the previous one.

It can be applied in a slightly thicker layer, but it has significantly greater strength and also adheres well to the metal.

Also, putty is divided according to material into:

- plaster;

- cement;

- polymer.

Plaster

First of all, let's look at how long it takes for gypsum putty to dry. It is used exclusively for indoor walls, and it is highly susceptible to moisture, since gypsum is a hygroscopic material that absorbs water.

It cannot be used not only outside, but also in wet areas. But the putty is easy to use, has excellent adhesion to a variety of materials, and prevents the formation of cracks and shrinkage. This variety is the fastest drying.

Plaster

Complete drying of the layer occurs within 3-6 hours.

It is impossible to determine more precisely, since it all depends on the layer. During a working day, you can apply at least 2 thin layers. Quick drying is certainly a useful feature of putty, but it should be taken into account that it also behaves during the application process.

It is not worth preparing large volumes of solution, otherwise it will lead to excess consumption of materials. The usable condition of gypsum putties in the form of a solution is extremely short-lived. Without using the mixture for 1 hour, it begins to coagulate into lumps.

Cement

This also includes cement-limestone putty. The drying time for this putty is 24 hours, provided that the environment has normal humidity. But this mixture is more durable and is perfect for forming a surface for heavy materials.

Cement

In this case, the solution does not dry out in the container for a long time and large portions can be prepared.

It is possible to use cement putty outdoors or in rooms with high humidity, and it is resistant to freezing. Also well suited for covering large gaps and cracks.

Given its advantages, most users have to turn a blind eye to the drying time. An additional advantage is the reasonable price.

Polymer

This variety, like cement, perfectly tolerates the influence of moisture, so it can be used in any room and outside. The cost is significantly higher than a regular mixture, so they are used for small areas of work or for leveling several but large uneven areas.

Sand is a granular material that is formed due to the destruction of various rocks under the influence of water. Here the volume of sand is in a ton.

Cement is a kind of binding substance, which is impossible to do without during construction and repairs. Here are its brands and applications.

Decorative plaster is a popular and progressive finishing material that hides defects and makes walls interesting. By following the link you will learn how to make it yourself.

The substance has a high level of plasticity , and it does not dry out or deform after drying. It spreads much more slowly, since due to its elasticity it can be applied in a layer of 1 mm.

Polymer

Considering how long it takes for finishing putty to dry on walls and ceilings, many craftsmen prefer to speed up the repair process using a universal substance.

When using polymer putty, after 3-4 hours the surface can be processed further.

The duration of preservation of useful properties before applying the putty to the wall is longer, so it can stand in an airtight container for up to 2 weeks.

On wood

Like most other varieties, wood putties come in a variety of varieties, but the hardening time is approximately the same. So you can begin further application of the layer or stripping after 2-4 hours, provided that a small amount of the mixture is applied.

On wood

The manufacturer, when asked how long it takes wood putty to dry, answers that complete hardening occurs after 24 hours, but it becomes hard much earlier.

For metal

The question of how long it takes for putty to dry on walls has a clear answer, but when considering the mixture for metal, the situation is different.

Drying time varies greatly depending on the amount of thickener.

For metal

For example, two-component polyester putty dries in 5-15 minutes.

Two-component polyester

White putty of the Kolomix brand dries in 1-2 hours.

Colomix

The process of complete hardening is much longer and can take up to a day, and sanding can be done after 1 hour.

For more information about the types and use of putties, watch the video:

What affects drying time?

The time it takes for the primer to dry completely varies and depends on certain conditions.

The main factors that influence the drying process:

- Moisture and temperature levels. Usually the product dries in 4 hours if the humidity is at 65% and the room temperature is more than 25 degrees. If the weather outside is good without precipitation, then in order for the composition to dry faster, you can open the doors and windows. The main thing to remember is that the solution should dry naturally.

- Thickness of the applied layer. The solution must be applied in a very thin layer. If the surface is very uneven, then it is permissible to use several layers. But, naturally, the composition will take much longer to dry.

- Type of mixture. So, acrylic dries within 4 hours, and contact dries in almost a day. There are also water-based formulations that dry in only about two hours. Oil-based ones take more than 24 hours to dry.

- The type of surface on which the mixture is applied.

- Porosity of the processed material.

- Alkyd polymer is used to fill small cracks. This primer forms a semi-matte film, on top of which paint is applied. It is used for wooden and metal surfaces. The disadvantage of this coating is poor absorption. This composition dries in about a day.

The drying temperature should be natural. Artificial drying can lead to undesirable consequences.

Primed walls, when should they dry?

The minimum time is 1-4 hours (for quick-drying compounds), the maximum is 48 hours.

Drying time for popular compositions:

- Kills primer is oil or latex based. The primer dries before applying putty for 1 hour (at optimal temperature and humidity). The mixture perfectly insulates the coating and prevents the growth of mold and mildew.

- The Rustoleum Primer mixture dries for 1 hour at temperatures of +21...+27°C and humidity 50%. After applying the primer, you can begin decorating the wall.

How long does it take for primer to dry?

In order for the repair to be carried out competently and efficiently, you need to choose the right product. It must be taken into account that not all soil solutions can be used for interior decoration.

Each type of solution is endowed with certain properties, on which the drying speed of the composition depends:

- The composition of the acrylic mixture is very wide: it includes dyes, resins, and antiseptics. The quantity of each element may vary. This leads to different densities of the solution. Acrylic impregnates well and penetrates even the smallest crevices, providing excellent adhesion for bases made of concrete, wood, brick, and plywood. Most often, such products are used in bath and kitchen renovations. The mixtures do not emit a strong odor and dry quickly - up to 4 hours. Knauf and Ceresit are the main manufacturing companies.

- The perforated composition is used only for external work, since the substances included in it are toxic. This type of mixture can be used on any type of surface. Good at preventing rust. Special additives protect against corrosion and protect the base from destruction. Among the additives of this type of emulsion there are a considerable number of additives that help speed up drying. The drying process at a temperature of 20 degrees is very fast - about 1 hour. Popular manufacturers are APP and Artelit.

- Phenolic solution is most often used on loggias, balconies and verandas, that is, in places that are located in the open air. It forms a thin film and is not susceptible to temperature changes and dampness. Drying times depend on the amount of special additives. If you work with it in the warm season, the drying process lasts approximately 8 hours. Recommended, "Pufas", "Ruslux" and "GLIMS®Prime"

- If you need to make the paint color brighter, then you need to purchase a polyvinyl acetate primer, which is based on a synthetic element. This solution is effective during repair work on drywall, as the product removes lint.

Types of primer compositions

The building materials market offers a solid selection of primers from different manufacturers. Primer mixtures differ in composition, purpose and drying time; they can be universal or special, for interior or exterior work.

Based on their properties and purpose, primers can be divided into the following types:

- Concrete contact - the mixture includes quartz sand, cement, and other fillers; an acrylic binder is the basis of the composition. Designed to increase the adhesion of smooth, weakly absorbent surfaces (concrete, tiles, old paint) with plasters, putties, and ceramic tile adhesives.

- Penetrating universal – prepares surfaces before tiling and painting. Strengthens loose, crumbling substrates and reduces their absorption capacity.

- Colorless - used for treating wooden surfaces in order to preserve the natural structure of the wood. Forms a waterproof film that protects the wood from rotting.

- Contact – enhances the ability of a hard surface to “adhere” to various solutions (paints, adhesives).

- Film-forming – used when working with problematic surfaces. Strengthens the base, creates a film that limits the flow of moisture. Can be applied to any surface, from cement floors to fiberboard. It dries quickly, which is convenient when deciding to put wallpaper on the walls.

Useful tips

Recommendations from experienced specialists who will ensure work at the proper level:

- Outdoors, as well as in rooms with high humidity levels, it is necessary to use certain types of primer. Surfaces that have been treated will not reduce vapor permeability.

- To ensure better adhesion between the base and the decorative layer, you need to rid the walls of stains and other contaminants. Recommended reading: How to remove primer from glass.

- To understand whether the surface is ready for work, you need to attach polyethylene with tape. If no condensation is detected on the film, then repair work can begin. Otherwise, you need to pause for 24 hours. And some types can be absorbed for 10-15 days.

- The manufacturer always indicates the drying speed on the container label. But this value is only approximate, so it is worth adding at least another hour to the specified time. If the surface is treated a second time and subsequent times, the drying speed will be even slower. Also, drying depends on the temperature in the room; if it is very warm, then the composition will dry in the shortest possible time.

What determines how quickly the mixture dries?

As mentioned earlier, the rate of curing and uniform drying is affected by the temperature level, air ventilation or the use of additional heating.

For example, if the room is +25°, the product will dry out very quickly. It is important not to forget about the humidity level, if it is more than 65%, then drying will take a very long time.

The drying time also varies depending on what further wall treatment will be done:

- Before gluing the canvases, you should wait until the primer dries well.

- Before applying putty or plaster, the surface must be thoroughly dried. Otherwise, the substance will not lay down in an even layer, and then it may fall off.

- But, according to previous materials, the time will vary from various external influences and from the composition of the base. For example, on plaster made of cement and sand, the substance dries in a couple of hours in a normal external environment, and there is no need to wait for complete drying. If the plaster is made of cement and lime, then the time will increase to 6 hours. The primer will lie perfectly on the putty and quickly saturate it. But professionals recommend not to rush too much with the next stage: it’s better to wait a day.

- If paint will be applied to the ground, then it is important to take into account some points. A fresh composition will not cause the old one to peel off if you apply soil to the base and allow it to dry. You can paint walls with plaster; here it is also important to apply the primer several times. A new layer can be applied when the previous one is completely dry. The paintwork is applied beautifully to a base with a primer, without smudges. This also reduces financial costs because the cleaning agent is used more slowly.

- In all cases, before using different finishing materials, it is important to carefully read all the technical parameters and indicators, as well as the conditions under which you can work with the selected composition. It is difficult to say specifically how long it will take to dry the product; this is influenced by many different conditions. And many of these factors have been described above.

Summarize

These products are used as auxiliary materials during construction and finishing. The quality and durability of the repairs performed and the duration of the repair interval depend on the implementation of all the rules and adherence to the technology for treating the base.

Since repairs require a relatively small amount of product, professionals strongly recommend applying the mixture to the base according to the technology, at least 2 layers.

Thus, the drying time of the primer depends on various parameters - humidity and temperature in the room, the nature of the base and other factors, but the main thing that you should definitely pay attention to is the composition of the product. Concrete contact does not dry for long - about 2-3 hours, contact emulsions dry the slowest - up to 24 hours. For proper drying, any temperature changes, drafts/open windows and excessive heating are not allowed.

Execution of work

The walls should be treated with a primer before and after puttying. You need to pay extra attention to the seam, joint, cracks and screw heads. If you prime the gypsum board correctly, the putty solution will last long enough and will not crack or fall off in entire layers. Applying the adhesive mixture is very simple - just use a brush or roller.

There are no rules in which direction to prime the surface - this is a rough coating that will not be visible under the finishing coating. The main rule for applying a primer is to treat the surface without skipping any areas and let the solution dry on its own. In some cases, the hydrophobic and waterproofing material is applied in two layers - this affects the drying time of the coating.

Important! There is an opinion that a primer can not be used for a gypsum fiber sheet, but in this case the untreated building material will have fewer advantages.

It is thanks to the primer, which has the ability to penetrate deeply into the surface, that the latter acquires moisture-resistant and moisture-proof properties. The waterproof layer protects the base from microbiological attack, which makes it possible to lay tiles in rooms with high humidity and in the bathroom much faster. The primer is performed as follows:

- The liquid solution is applied using a roller; the material consumption per 1 m2 is indicated by the manufacturer on the packaging. In some places it is better to roll over several times, so purchase a primer with a reserve. If a dry version is used, the instructions indicate how to dilute the material

- After this, you need to use reinforcing mesh and putty. First of all, joints and recesses from self-tapping screws are processed. Video and photo materials for beginners show how to putty drywall

- After the putties have dried, you need to cover the entire surface with a primer - you need to make an even layer, so monitor the quality of the work

- Different brands of applied mixture dry differently. There are quick-drying solutions, and there are deep-penetrating soils - having chosen the one you need, check the drying times and postpone all subsequent processes for this period

Important! Particularly popular is the Knauf primer, which is produced in a wide range of products and is used for preparing rooms and exterior surfaces for finishing, painting, and wallpapering. Knauf is used for GKL-1 for tile adhesive, non-woven trellises and photo wallpaper. Primer for drywall is affordable for literally everyone. Its low cost has made it an indispensable assistant in the rough preparation of foundations.