There are several factors that determine how long it takes for bathroom tile grout to dry. This is the amount of work, application technology, type of material, quality of composition, humidity and room temperature.

There are several types of grout mixtures that are most often used - epoxy and cement grout. They are different, each of them has its own characteristics, application methods and drying time.

It is worth taking a closer look at how long it takes for tile grout to dry in order to prevent mistakes and defects in the work.

How long does it take for grout to dry?

It takes about a week for the grout to dry completely. But you can start cleaning the room within a few days.

Sometimes it seems that the mixture dries out instantly, but this is only superficial. You can wet the surface with water in a day. The grout finally dries on the third day, but it is possible to fully use the room, continue repairs, install and do good wet cleaning only after 6-7 days.

After this time, when the mixture has completely dried, it is simply necessary to do a thorough cleaning. Clean the surface from excess grout.

Features of different types of grout

Main options:

- cement-sand – contains Portland cement and fine-grained sand, has moderate strength, the disadvantage is weak hygroscopicity;

- polymer mixtures (polyurethane, silicone) - characterized by increased elasticity, sufficient strength, do not absorb water and are often used in rooms with high humidity levels;

- epoxy grout - characterized by high strength, moisture resistance, contains resin and hardener, and is second only to the furan mixture in terms of reliability.

When can you start cleaning?

In order to complete the work, it is necessary to clean the surface of the tiles from excess material. This can only be done after the solution has completely dried.

Wet cleaning is carried out after 2 days, full cleaning - after 7 days. You can understand when joints can be wetted and a detergent can be used visually. It is necessary to see how much lighter the mass has become, but not in the area of the seams, but the one that remains after grouting. When the color has already begun to change and harden, you can start cleaning.

Scope of application of the composition

Epoxy grout is successfully used for both interior decoration and exterior work. It is indeed used for any cladding elements, not excluding even products with a glossy finish.

Grout based on epoxy resin can be used in the following cases:

- when you need to seal tile joints in the dining room, kitchen, hallway, bathroom or shower room;

- as a mixture for sealing the joints of tiles in a bathhouse, sauna or pool bowl;

- for reliable strengthening of tile joints on a terrace or open area;

- with joint widths ranging from 1 to 15 mm;

- technology allows you to apply this mixture even on a base equipped with a “warm floor” design.

Advice! If we take it more broadly, there are practically no restrictions in application. It is only necessary to make a small reservation that this grout paste is not entirely appropriate for lining stoves and fireplaces.

What affects the drying time of joints

To know how long it takes for tile grout to dry, you need to understand what affects it. To prevent various types of damage to finished seams, it is important to follow some recommendations for surface preparation, application of the composition and final processing.

Before you start using grout, you should check the seams. They must be clean and dry. Otherwise, the mixture will lose its properties, and accordingly the quality will be different.

Pros and cons of using epoxy grout

Speaking about the wide scope of application of this composition, we can come to the conclusion that it has only advantages. Undoubtedly, there are many positive aspects associated with the use of epoxy grout:

- Durability. The duration of the operational period is measured in tens of years. Some manufacturers express confidence that their products will last more than 50 years.

- Increased strength. For simplicity, we briefly note that such a composition, when hardened, forms a very strong layer that is difficult to dismantle.

- Practically does not fade. The shades of the grout are able to maintain their brightness and saturation, even when exposed to direct sunlight for a long time.

- Not susceptible to deformation due to sudden temperature changes.

- Dries without shrinkage or cracking.

- Does not interact with aggressive chemicals. Of course, if etching is carried out intentionally, the material will gradually deteriorate.

- Does not contain elements harmful to human health. As a result, the solution can be used in any home.

However, one cannot fail to take into account the fact that in addition to the positive qualities of the composition, there are some disadvantages in its use:

- The resin hardens quite quickly, which limits the time of work and correction. Therefore, all actions must be performed clearly and correctly. Setting time is about 40 minutes.

- Only a special tool is suitable for the work, which you need to learn how to use.

- The price of epoxy mixture is higher than other types of material. Because of this, finishing large areas can have a significant impact on the overall cost of the renovation.

- If it is necessary to replace the grout, you will have to dismantle it along with the tiles. Naturally, there is a special chemical method, but it is very harmful and labor-intensive.

It follows from this that before choosing this composition, you need to weigh all its positive and negative sides.

Specifics of grout application and drying time

Let's look at how to apply and how long it takes to dry tile grout. It is important to never deviate from the rules given by the instructions for mixing components.

- Prepare the mixture. Too much water or poor mixing can affect how long your tile grout takes to dry.

- Soaking. After the mixture is prepared, before starting the work process, you need to soak it. It is very important.

- Applying grout. Before applying, double check the seams to make sure they are dry and clean. And only after this can the grouting process itself begin.

- Cleaning from excess mixture. The very first cleaning should be carried out immediately after application using the dry method, using a silicone product for 10 minutes, since after drying it will be difficult to remove. If the grout is cement, then the excess is removed within 30 minutes. You can use a damp dish sponge for cleaning.

- Final processing. Final drying occurs after a week. If the grout is latex or acrylic, then after 10 days, and silicone grout requires drying within 20 days.

After drying, you can treat new seams with a compound to improve performance. After this, you can use detergents for 3 days.

Is it possible to do without grout?

If the tiles will be laid, for example, on a wall, the likelihood of contact with water and moisture is small, and the coating is not planned to be used for a long period, then in such conditions it is permissible to refuse to grout joints.

When the cladding is not affected by negative external factors (temperature limits, hot steam, water), then the process of destruction of the seams and the rough base will develop much more slowly.

In rooms where there is a significant level of humidity or the surface is subject to intense load (for example, in high-traffic areas), the coating cannot be used without additional protection. If you plan to lay the cladding for a long period, you should close the seam.

If you plan to lay the cladding for a long period, you should close the seam, and grouting the seams in this case is a mandatory step when performing the work.

Dry cement mixture

The most suitable and excellent option for construction work in your houses and apartments is to use a dry cement mixture. It is easy to use and excellent quality. Mix with water, mix well with a special tool or a simple spatula, and everything is ready to go.

The application time and the formation of a correct and beautiful seam will depend on how long it takes for the tile grout to dry on the floor or wall. It should be neat and not extend onto the tile from the edges. If the type of tile cut allows it, then it is better to make the seam completely filled so that the surface is smooth.

How to choose the right color scheme for Ceresit fugue

The color of the grout can vary significantly and depend on many factors. There are all sorts of types for grouting, ranging from light to dark tones. Everyone can choose the one that best suits their taste and colors.

All types of Ceresit grout are waterproof and resistant to weather conditions, including solar radiation.

Ready-made colors include the following colors and are numbered as follows:

- 04 Silver grey;

- 07 Grey;

- 10 Manhattan;

- 13 Anthracite;

- 16 Graphite;

- 22 Melba;

- 25 Sugar;

- 28 Peach;

- 31 Dew;

- 40 Jasmine;

- 43 Bahamas (beige), etc.

The colors refer to CE 33, CE 40 aquastatic, CS 25.

It is convenient to choose the color that most closely matches the interior of the apartment. Using a special number, the buyer can quickly find the shade he needs. The Henkel company produces high-quality products that are universally recognized. Over the years, the popularity of grouting mixtures has been gaining momentum. Such mixtures are widely used during repair work.

If the color of the grout is extremely important to you, then consider the color range of products CE 33 and Ceresit CE 40.

Methods and tools for applying grout

- Grater. This application is perfect if the amount of work is large. The finished mixture is applied diagonally to the seam and distributed over the entire surface with a grater. The mass will evenly come out over the tiles, and the seams will be filled with grout. You don't need to process very large areas. To accommodate during drying and initial processing.

- Putty knife. The grout mixture is taken onto a spatula and pressed into the tile seam. It is necessary to apply force, otherwise the mixture may spread unevenly. This option is suitable for epoxy and cement grouts.

- Cone - filled with grout in the required amount, preferably a little more than is required for grouting the seam, since the excess can then be removed. The cone application option is suitable for surfaces that are difficult to clean after grouting.

- Syringe gun. This gun is more often used when working with grout in outdoor conditions. Great for large and porous surfaces. The syringe perfectly fills all the voids, and the seam is very neat and quite attractive.

30 minutes after the grout application has finished, you can wet-treat the tile or tile joints. Since everything inside is still viscous, you need to carefully remove the unnecessary mixture without unnecessary effort. After stripping, it is necessary to rub and smooth the seams with a damp sponge.

How to avoid mistakes and not affect the drying time?

To avoid thickening of the layer of material in the space between the tiles, you should use special tools for applying grout:

- Rubber spatula - used in most cases, but due to its small width it is not recommended to use it if you plan to perform a large amount of work. A spatula with these characteristics is suitable for applying different materials.

- Grater - used when finishing mosaics, since in this case the use of a spatula increases the installation time. A construction float is also suitable for filling joints in large areas, which allows you to speed up work.

- Syringe gun - designed for filling deep seams. This tool is often used for applying polyurethane and silicone mixtures; thanks to it, neat seam joints are obtained.

- A cone is an alternative to a pistol. This option is suitable for cases where it is necessary to protect porous base material.

How to choose grout color

Without exaggeration, epoxy grout can be called reliable protection. A very important issue remains the choice of its color. The content of pigment additives in the grout allows you to enjoy a rich color palette. Of course, from a wide variety you can choose the most suitable shade, but often this is not so easy.

Thanks to modern technologies, it has become possible to create almost completely transparent materials. If you want to add sophistication to the surface, there are special components that, with their shine, create the illusion of tiny stars.

To obtain a high-quality harmonious coating, basic recommendations were developed. Compliance with them will help to veil some of the imperfections of the room and draw attention to its advantages.

- Light-colored tiles are combined with pastel-colored grout to ensure surface unity and compositional integrity.

- To obtain the opposite effect, use dark tones. In this way, it will be possible to highlight individual details of the composition by dividing the surface into parts.

- When using plain tiles, the grout paste should be selected based on the main color scheme of the interior.

- The versatility of white is undeniable. It is appropriate to turn to it for sealing seams in any type of interior. It is not recommended to use it in corridors and hallways where traffic is high.

Of course, everyone can be guided by their imagination. In any case, the main goal is to get a room that brings joy to its owner.

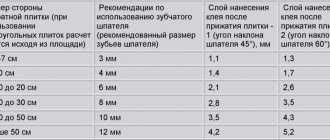

Grout consumption per tile joint

Approximate consumption figures can be found below:

| Seam width, mm | Tile size, cm | Consumption, kg/m2 |

| 3 | 5×5 | 0,7 |

| 2 | 5×5 | 0,5 |

| 5 | 20×20 | 0,5 |

| 3 | 15×15 | 0,4 |

| 3 | 10×20 | 0,4 |

| 2 | 10×10 | 0,4 |

Fact: material consumption is influenced by the quality of preparation of the base before application and the qualifications of the performers. Therefore, it is best to trust the grouting of joints to professionals in order to avoid overuse of the mixture and overpayment.

Technical characteristics, color palette

CE 33 consists of cement, mineral fillers, color pigments and polymer modifiers that add certain properties to the mixture.

All this provides the following technical characteristics:

- the amount of water for hardening is 0.32-0.33 l per 1 kg of dry solution;

- temperature of use – from 5 to 300C;

- density of the finished mixture – 1.75 kg/dm3;

- consumption time – from 60 minutes;

- frost resistance - from 100 cycles;

- flammability class - NG.

In the video, the grout is Ceresit Se 33:

In terms of performance properties, the solution is plastic, resistant to temperature changes, and easy to apply. At the same time, the mixture is completely environmentally friendly: after drying, it does not emit fumes harmful to health. A diverse palette will allow you to choose the tone for any tile. It comes in 26 colors including white, silver grey, grey, graphite, pink, brick, green, olive and blue.

This information will help you understand which moisture-resistant grout for the bathroom is the best.

How to use grout for floor tiles in the bathroom can be found in this article.

But what is the price of grout for tiles in the bathroom and what is the price category and what it depends on, is described in this article: https://resforbuild.ru/sypuchie-materialy/zatirka/kakaya-zatirka-dlya-plitki-v-vannoj- luchshe.html

What the instructions for epoxy grout for litokol tiles are and where you can use it are described in great detail in this article.

How long does it take for seams to wear out?

Before proceeding with the next procedure, you must wait until the composition used in the previous stage has completely dried. In particular, an approximate estimate of the drying time of the adhesive composition can be found in the instructions included with the material. As a rule, the time for complete drying of the adhesive composition is 24 hours.

Thus, according to the instructions, after a day you can start grouting the joints. However, the purpose of grouting, in addition to giving a beautiful appearance to the floor covering, is to prevent moisture and air from penetrating under the tiles. This in turn will prevent the formation of cracks in it and the development of mold. Good waterproofing of a ceramic coating after installation is achieved by preparing the seams for grouting by clearing them of any adhesive residue. Naturally, after it has completely dried (after 24 hours), this procedure becomes difficult to do.

Important! We clean the joints between the tiles from the mortar 6-8 hours after installation.

The traditional option for the width of the distance between the tiles is 3 mm. In rare cases, space between tiles of up to 12 mm is used. The specific distance depends on the size of the tiles, design, and installation method. It is not recommended to make seams less than 3 mm, since great difficulties will arise when grouting them and it will not always be possible to completely seal them. A large width leads to deformation of the floor covering and the appearance of edge defects on the tiles.

Choosing a mixture for grouting joints

Properly selected components for making the mixture allow for better grouting when laying tiles.

Materials should be purchased taking into account several criteria:

- Colors. The appearance of the tile covering largely depends on this. The most commonly used color is white, as in the photo. To ensure that the surface looks like a single monolith, before grouting the tiles on the floor, you should choose a shade for the mixture that is ideal for the tile. This is not difficult to do - you need to add color to the white mixture. Much less often, grout is chosen in a contrasting shade.

- Composition. When making a grout mixture, you can use Portland cement, alabaster, gypsum, epoxy resin and other materials.

- Properties Depending on the components included in the composition, the properties of the solution change. There are differences in what is used to grout the seams between the tiles on the floor in places where there is high humidity, or where there is an increased load on the floor surface. In the first case, it is necessary to use components with water-repellent properties, and in the second, it is best to prepare a more durable and coarse composition, for example, an epoxy mixture.

- Appointments. The standard type of grout is used to process the seams on the walls between the fragments. But its disadvantage is that over time it begins to wear out, which means it needs updating. For flooring, it is advisable to use more tenacious compounds, since the tiles are constantly under load from various objects and are walked on in shoes.

Tools for work

To properly grout the joints between tiles, you may need the following tools:

- Grout cone

- Grout float

- Rubber spatula

- A piece of cable for jointing

- Special device for jointing

- Drill or hammer drill

- Special attachment – mixer

- Mixture container

From the first three points, you will need to choose only one, and not buy everything, in order to grout the tile joints with your own hands.

Preparing the base

Filling the joints of the tile cladding should only be done after the period specified in the instructions for the adhesive used has expired. If a traditional cement-sand mixture was used to attach the tiles, filling the joints can be done no earlier than 7 days after laying the tiles.

The base and tile adhesive must be dry. The edges of the seams must be cleaned of tile adhesive, as well as dust, grease and other contaminants that interfere with the adhesion of the grout. It is recommended to moisten the edges of the tiles with a damp sponge. When grouting existing tiles, the old grout should be completely removed.

In the case of matte, unglazed or stone tiles, it is necessary to test the coloring of the tiles with pigments contained in the grout.

Main types of mixtures

Modern manufacturers annually fill the market with new, more advanced products. Today we can distinguish the following types of tile grout:

- Cement fugue - based on fine sand and Portland cement with the addition of modifying components.

- Latex is a more advanced version of cement grout; it has water-repellent properties, making it ideal for the bathroom.

- Furan is a chemically stable, ultra-dense mixture of black color.

- Epoxy is a viscous putty containing epoxy resins, which make it more durable and water-resistant.

Furan mixtures are not used at home; latex and cement mixtures are mainly in demand.

All of them dry quite quickly, and therefore it is necessary to work with mastic quickly.