Leveling and covering walls with plasterboard is very often carried out during renovation work in an apartment. As a rule, this operation involves attaching gypsum boards to a metal or wooden frame. But there are cases when it is easier and more profitable to attach drywall to the wall without a metal profile and wooden sheathing.

When can you do without building a frame?

It is recommended to attach sheets of drywall directly to the wall if it is relatively flat and the differences in the plane are no more than 5 centimeters. This surface can be leveled using an adhesive. Installing drywall without sheathing has many advantages:

- GKL easily attaches to walls and partitions made of any material. It is only necessary to carry out appropriate surface preparation. Meanwhile, screwing the profile to a wall made of foam block or aerated concrete is quite problematic.

- This cladding method significantly saves free space in the room: a frame made of metal profiles or wooden beams “eats” at least 5 cm when finishing each wall. If you attach drywall to all 4 walls, then a small room will noticeably decrease in size.

- Savings: no need to buy profiles, as well as various connecting elements. Adhesives will be much cheaper.

- Installation of drywall without constructing a frame is done quickly and does not require special professional skills.

Note! If the wall is very crooked, you cannot do without a frame. This will be feasible both from a technical and economic point of view. Sheathing is also needed if you plan to insulate or soundproof a room, hide communications, or place lighting elements under sheets of drywall.

If lathing is still required, but for some reason it is not possible to use a profile, in some cases it can be made from wooden beams. All the pros and cons of a wooden frame, as well as the procedure for its installation, are described in this article.

What brand of drywall do you use?

USEFUL INFORMATION: DIY plasterboard niche

The easiest way: supports and temporary clamps

You will need aluminum profiles for drywall or wooden slats. For support, measure the distance to the ceiling, subtract 1-1.5 cm to fit the plasterboard sheet. Cut the stand to this length.

Clamps are made from small pieces of profile or bar. They need to be screwed to the ceiling frame at the place where the plasterboard is attached, but not tightly, but so that there is room for free movement. The clamps are placed parallel to the frame.

A sheet of plasterboard is applied to the ceiling in the right place. Then a support is placed below, placing it closer to the edge near which there are no clamps. It's okay if the profile is slightly angled. The main thing is that the gypsum board stays tightly.

Then turn the clamps perpendicular to the frame so that the part protrudes under the sheet. A couple of pieces on different sides are enough. For reliability, you can put another support.

If necessary, the position of the sheet is slightly adjusted so that the edges adhere to the adjacent ones. After this, you can screw in the screws.

Preparing the base

In order for the plasterboard coating to last a long time, it is necessary to treat the surface of the walls. It will prevent not only peeling of the plasterboard, but also the appearance of fungus or mold underneath it.

- If there is a significant layer of plaster on the walls, then it is better to remove it. You can leave a thin and firmly adhering layer. Any fragments whose reliability is in doubt must be shot down. Here's how to do it in detail.

- Deep cracks must be widened using a chisel, cleaned of dust, primed and covered with a cement-based repair compound.

Advice. It is convenient to use a sealant to treat small cracks.

- Protruding areas are knocked down.

- The leveled surface is covered with a primer in two layers. Be sure to let each of them dry.

Having prepared the wall, you can proceed to marking its surface.

Ready-made devices from hardware stores

If a do-it-yourself drywall lift is not suitable for some reason, you can buy a factory one. They are divided into two main types: supports and machines. The differences are in operating principles and cost.

Lift-strut

The device is a telescopic tube, at both ends of which there are small areas for emphasis. The spacer extends to a length of 150 to 290 cm. Such devices are inexpensive, on average 1500-2500 rubles.

Lifting machines

This is a more complex device, which consists of a frame holding the sheet, a telescopic support with a winch and a base on wheels.

The sheet is laid edgewise on the top, and then turned horizontally and raised to the ceiling. Drywall can be positioned not only evenly, but also at an angle. This will be useful if you are sheathing an attic ceiling or erecting a structure with complex shapes.

Devices vary in maximum lifting height and weight limit. Depending on how the gypsum board is lifted, the machines are divided into three types:

- Mechanical.

- Hydraulic.

- Electric.

Such machines are much more expensive. The approximate price is about 15-20 thousand. It is not advisable to purchase such a device for home repairs.

A gypsum board lift is a device that facilitates repairs. It makes it easy for a person to attach drywall to the ceiling alone.

Marking, important points

This operation is carried out with a standard set of tools. You will need a level, plumb line, tape measure, rule and square. A laser level is very convenient, but it is not always possible to borrow it from acquaintances or friends, and buying it for one-time work is too expensive.

The following points must be taken into account:

- Gaps remain between the ceiling, floor and sheets of drywall. They are made in case of shrinkage of the house and prevent warping of the plasterboard. The gap between the sheet and the ceiling is 3–5 mm, the distance to the floor is 8–10. At the top it is enough to draw a line marking the boundary of the drywall, and at the bottom it is more convenient to use spacers of the required thickness made of chipboard or plywood. After attaching the drywall, they are removed and the gaps are filled with foam.

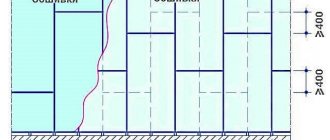

- One sheet may not be enough vertically to cover the wall. In this case, an additional line is drawn indicating the boundary of the entire gypsum board. As a rule, cut pieces are placed on top, although craftsmen advise fastening whole sheets and halves in a checkerboard pattern.

- To correctly install the first slab, use a plumb line to draw a vertical line in the corner of the room. All other fragments of drywall will appear in a single plane with the first sheet, which is why its correct installation is so important.

USEFUL INFORMATION: Installation of sockets in plasterboard: how to install a socket box and socket in plasterboard

Using a metal frame

Most modern craftsmen answer the question “how to fix drywall to the wall?” will give you the following answer: using a metal frame. Most often, this mounting option is currently the most common.

There are several reasons for this: the possibility of laying insulation, masking communications, installing built-in lighting and leveling walls

.

How to strengthen a plasterboard wall on a metal frame? Everything is simpler than it seems. To do this, use guides and rack profiles for drywall.

Guide profile.

The guide profile is the basis of the structure and is mounted to the floor and ceiling. In addition, such profiles are often used as jumpers between racks. Such partitions are necessary when installing door frames in partitions.

Rack profiles are vertical posts in a frame. It is on them that the plasterboard sheets are attached. They are attached to the guide profile using dowels.

Rack profile.

Installing a metal frame under a plasterboard wall is generally no different from installing wooden sheathing.

How to attach drywall to the wall?

There are several methods for fixing gypsum boards. The choice of a specific one depends on the condition and nature of the base surface.

- For a flat and smooth wall, you can choose any adhesive composition: a mixture based on gypsum or cement, foam or polymer mastic.

- For unplastered brick walls, too much foam or mastic will be required, and they may not provide reliable fastening. It is better to choose a composition based on gypsum or cement, which will fill all the depressions in the masonry.

- GKL is mounted on wooden walls using wood screws. It's as simple as hanging a shelf or a picture.

- The situation is more complicated if the wall surface needs adjustment in some plane. Here you will need beacons that set the correct position for the sheet of drywall. They can be made from gypsum board scraps or other available materials. The plate is fixed to the wall with screws, and with their help the necessary position adjustment is carried out. Subsequently, the cavity between the wall and the drywall is filled with polyurethane foam.

Fastening gypsum boards with glue

After completing all the preparatory work, marking and laying the necessary communications, the adhesive composition is diluted according to the instructions. This is the case if you do not use ready-made glue, usually supplied in tubes for a glue gun.

For reliable fixation, it is not at all necessary to cover the entire back surface of the drywall with the composition: this will only lead to unnecessary costs. The glue is applied in separate cakes, placing them in a checkerboard pattern, and always in a strip along the entire perimeter of the sheet. The second option is a grid of strips placed at a distance of 10–15 cm from each other.

The gypsum board is pressed tightly against the wall surface. To distribute the glue evenly, you can use a wide rule or a board: carefully move it over the area to be glued several times.

The setting time of the solution is about 30 minutes. During this period, you need to check the position of the fixed fragment and make the necessary adjustments. In the future, this will no longer be possible.

The adhesive composition can be applied directly to the wall surface. Some masters claim that this is much more convenient.

The adhesive installation method is described in more detail here.

Foam mounting

It is carried out in exactly the same way as with the adhesive composition.

An important point: the foam expands when hardening, so the sheet is fixed in the desired position for at least an hour. This can be done in two ways:

- using various supports;

- securing the gypsum board with dowel nails and placing strips of foam foam under its surface as shock absorbers.

USEFUL INFORMATION: Sealing tape for drywall profile

Mounting on polyurethane foam with void filling

Drywall can be attached to a curved wall using corrective underlays. But the presence of a void between it and the base surface is undesirable. To ensure secure fastening, it is better to fill this cavity with polyurethane foam. The algorithm of actions in this case will be as follows:

- Using markings, we position the sheet of drywall in the desired position.

- We make 10–12 holes in it, spaced evenly over the entire area. In this case, the drill marks the recesses for the dowels in the wall.

- We remove the gypsum boards, expand and deepen the holes in the ceiling to the required size, and then hammer in plastic dowels.

- On the back side of the sheet we glue strips of foam rubber or penofol of the required thickness as shock absorbers.

- We carefully attach the gypsum board to the wall with screws with a wide head. Another option is to use washers with regular screws. By releasing or twisting them, we align the fragment in the required plane, controlling its position using a level and using the created markings.

- We make the required number of holes in the drywall intended for injection of foam. We place them between the screws, the diameter of the holes is 7–8 mm.

- In order not to overdo it with foam, it is better to pump it using a special gun, adjusting it so that when pressed, an amount is squeezed out that is enough for a circle with a diameter of 120–150 mm.

After the foam has dried, you can unscrew the screws securing the gypsum board. But professionals advise simply recessing them into its surface by 1–2 mm.

Homemade mops

With this method, improved supports are used. A beam or piece of profile is attached perpendicularly to the end of the rack. The result is a structure in the shape of the letter “T”. Additionally, it is reinforced with slopes.

You will need two such mops; for small pieces of gypsum plasterboard, one support is enough. Slats about 40 cm long are screwed to the short crossbar of one of them, and the long part is taken with a reserve. Then the support can be placed at a distance from the wall.

The first mop is placed against the wall. The plasterboard sheet is lifted and placed behind the support. The second one is placed on the other side. Mops securely hold gypsum boards without damaging surfaces. If necessary, the drywall can be moved, aligning the position with respect to adjacent sheets or the wall.

Wooden wall mounting

The easiest possible option. The gypsum board is secured with wood screws. To screw them in, it is recommended to use a screwdriver: this way the drywall crumbles less, and there is less chance of pushing it through if you correctly set the required force on the tool.

The position of the fixed sheet is corrected by loosening or tightening the screws. If there are no chamfers on the plasterboard, they are made using a painting knife or an edge plane.

After covering the wall, the standard treatment of the plasterboard surface is carried out: reinforcing the seams, sealing them and the holes for the screw heads with putty, grouting and priming the entire area of the new wall. After the coating has dried, the base is ready for further finishing.

Ask all questions about the installation process in the comments - a finishing expert will answer them.