Fiberboard is a very interesting and non-standard option for wallpapering. The fact is that the components that are included in the composition cannot always correctly perceive adhesive solutions. Therefore, when directly gluing, pay attention to several features. Firstly, if you glue paper backings, they may be too thin. Because of this, joining seams can be visible through the fabric. It is also possible that the fasteners also oxidize and develop poor properties, which have a negative impact on the material and the coating.

Simple and complex methods for gluing wallpaper on fiberboard

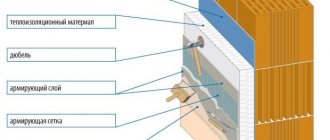

A more complex method includes thorough preparation of the surface using putty, mesh and a primer made of PVA glue. The fact is that fiberboard absorbs water. This prevents the use of adhesive materials and solutions that contain large amounts of water. Therefore, a complex method includes processing the slab with several preparatory layers in order to subsequently use a conventional adhesive solution.

That is, first the surface is covered with a primer solution, which must be prepared from PVA glue, because we carefully avoid getting moisture on the working surface. Next, the primed surface is covered with fiberglass mesh. Gypsum putty is applied to it in one or several layers (it all depends on your goals). After the gypsum putty has completely dried, flaws after direct putty are removed using sanding or sandpaper. After this, the putty surface can already be coated with a deep penetration primer, and the usual process of wallpapering can begin.

A simpler way is to treat the surface using concrete contact and special impregnation. In fact, preparation in both cases will take approximately the same time. The only difference is in the approaches, materials, as well as the accompanying nuances that will appear with the choice of a certain material.

Gluing technology

For better adhesion to PVC wallpaper, you can upholster it with fiberboard. Due to the above-mentioned features of both PVC wall panels and wallpaper adhesive compositions, it is not possible to obtain a sufficiently strong adhesion between them. Therefore, in order to, it will be necessary to increase their adhesion. You can do this in two ways:

- Covering PVC walls with another material, more suitable for working with wallpaper glue. It is best to use fiberboard sheets in this case - they are quite cheap, easy to cut and install, and are also perfect for gluing wallpaper on them.

- Increased adhesion of PVC panels themselves.

The first option is quite understandable - fiberboard sheets are simply attached on top of PVC panels using self-tapping screws. The second requires special consideration. Preparing old polyvinyl chloride surfaces for wallpapering includes several stages.

Processing with abrasive materials

Abrasive sponge Initially, the old plastic surface is thoroughly cleaned from dirt, dust, grease, etc. To do this, use a sponge soaked in soapy water or any household chemicals. After all dirt has been removed and the surface of the panels has been dried, the smooth plastic surface should be given a rougher texture.

To do this, you should use the so-called Scotch-Brite - an abrasive sponge. It needs to be properly processed over the entire plane of the panels. The movements should be intense, and sufficient pressure should be applied to the washcloth so that the glossy surface is covered with many small scratches.

After this treatment, the plastic panel becomes indistinguishable to the touch from a surface covered with putty or well-leveled plaster. That is, the adhesion of PVC panels using this operation was increased to quite acceptable levels.

Primer

Apply several layers of primer Before applying the primer composition, the surface should be cleaned of fine dust remaining after treatment with abrasive materials. The primer composition is applied to the surface of the panels using a paint brush or roller. To do this, you should use a special primer composition designed for treating glossy surfaces - tiles, glass, plastic.

Considering such a “complex” base as a plastic plane, it is advisable to apply it in two or three layers. In this case, each subsequent layer must be applied no earlier than the previous layer has dried. After the primer has completely dried, you can begin gluing the wallpaper.

Wallpaper glue

After preparation, almost any glue should form a good adhesion to the PVC panel.

However, experts still recommend playing it safe by using a special composition for pasting wallpaper, prepared with your own hands; for this, ordinary wallpaper glue is taken and diluted in accordance with the type of wallpaper used (vinyl, non-woven, etc.).

Then universal PVA glue is added to it in a proportion of ¼ of the total mass of glue. For more information on how to hang wallpaper, watch this video:

PVA can significantly improve the technical characteristics of any wallpaper adhesive, and this composition will provide much stronger adhesion between the PVC panel and the wallpaper.

Often, when decorating a room, we are forced to resort to using several types of finishing materials at once. In some cases, this can be explained by the design conditions and features that are inherent in a given room or apartment, and based on which we must make certain decisions on interior design. Very often, one of the optimal solutions is the use of combined types of finishing, when several decorative materials are used at once.

This approach makes it possible to focus on the obvious advantages, while hiding, at the same time, some of the disadvantages of both the room itself and each of the finishing materials. Today, one of the most popular solutions is a combination of wallpaper and panels: plastic, PVC, wood, MDF, SIP and others

By the way, this method has shown itself to be excellent when working in both residential and non-residential premises with high ceilings.

Features of wallpapering on fiberboard

- Before gluing wallpaper, it is necessary to spend time thoroughly preparing the working surface so that the wallpaper retains its operational capabilities;

- It’s even worth taking into account the fact that the joining seams between the slabs and various fasteners are visible - nails, dowels, paper clips from a construction stapler;

- In order for the result to please you, it is very important to follow the gluing technology and the stages of surface preparation.

- It is not enough to apply so-called barriers against moisture penetration. It is important at the intermediate stage to level the wall. And besides, there is a possibility that the fiberboards were already initially deviated from the vertical. If such a defect is present, even with the correct actions, the wallpaper will not last long;

Conclusion

As you can see, it is possible to glue wallpaper onto hardboard, but you must follow a certain technology. Additionally, watch the video in this article. And if you haven’t found answers to any of your questions on this topic, ask them in the comments, and I will definitely help you figure out the unclear points.

Is it possible to glue wallpaper on fiberboard? What problems may arise during the sticker process? How to avoid them? In this article we will look at several solutions of varying complexity that will help the reader with repairs.

Stacked particle board does not look like a reliable base for wallpaper.

How to glue wallpaper on fibreboard with your own hands: step-by-step instructions

First you need to prepare all the tools and materials for work.

- Wallpaper;

- Adhesive solution;

- Primer solution;

- Drying oil (solution for treatment as protection against moisture);

- Container for diluting glue;

- Roller with a long handle for applying primer;

- Wide paint brush for applying glue;

- Plumb line, construction ruler or level;

- Pencil;

- Putty;

- Fiberglass mesh;

Wood fiber board primer

The first step in surface preparation is to prime the wood fiber board. This stage is also called pre-priming. The primer is applied using a long-handled roller or brush. It is preferable to use drying oil (that is, the simple method that we mentioned above). So, drying oil is applied to the wall hot. If this does not happen, then it is heated with a hair dryer or other devices. But unfortunately, due to the fact that this special solution creates a film, its adhesion is minimal. Therefore, contact concrete is used. Adhesion is created due to the fact that the composition contains quartz sand. After this, you can successfully move on to the next stage.

Pasting wallpaper onto fibreboards

The surface is completely prepared and now you can proceed to the actual wallpapering. The technology remains the same:

- the adhesive solution is diluted;

- then the canvases are prepared, that is, the grip is sobered by a maximum of 5 centimeters;

- Future wallpaper is marked on the wall;

- Before gluing, the pattern is carefully checked;

- Before and during gluing, the vertical is checked using a level;

- Applying glue to the canvas or surface (it all depends on the type of wallpaper);

- Pasting the canvas and removing excess air.

But the most important question remains choosing the right adhesive solution. This is important not only for the wallpaper itself, but also for the work surface. After all, we must not forget that fiberboard is very finicky. We advise you to carefully look at the recommendations indicated on the packaging of the adhesive solution. It is recommended to purchase universal glue for all types of panels and types of surfaces.

Problems

As they say in Odessa, there are them.

- Fiberboard (aka hardboard) is extremely hygroscopic . It will safely absorb the glue applied to the wallpaper; If so, you can count on reliable adhesion using the traditional sticker method.

In addition: once saturated with water, hardboard is likely to warp. Uneven moisture will cause the walls and/or ceiling covered with it to become ripple.

- Seams between fiberboard sheets will be visible under thin wallpaper . The swollen ends of the sheets will be doubly noticeable: when moistened, the linear dimensions of the hygroscopic material change unevenly. Thick textured wallpaper, however, will partially hide the unevenness of the base.

- Finally, let's remember about the method of attaching hardboard . Nails or screws, right? And often non-galvanized. Each of them will, after a short time, become the center of an untidy rust stain.

The photo very clearly demonstrates all the problems described.