What can make noise?

Finding the optimal solution is not difficult, but first you need to understand why problems arise. We need to answer the question - what conducts sound in a plasterboard partition.

Drywall walls often require sound insulation

- GKL sheathing on the frame is a kind of resonator. There are cavities between the two skins; they constantly reflect acoustic waves. At certain frequencies, the sound is amplified and enters adjacent rooms (any sound equipment works on this principle).

An interesting point - if you simply increase the thickness, the sound insulation of plasterboard walls will not increase. If you look from an acoustics point of view, only the size of the resonator will change. Consequently, when it is increased, the acoustic resonance frequency will shift - towards lower frequencies.

- A certain percentage of vibrations are absorbed by the partition frame, because it is rigidly attached to the main adjacent walls (they are also often attached to ceilings). The solid wall of a building conducts sound perfectly (especially low-frequency) - this happens due to the high density;

- The entire partition at a certain frequency of sound performs the function of a membrane that vibrates in unison with the sound. The frame will transmit acoustic vibrations to capital structures and not only - it also additionally contributes to the propagation of vibrations between the sides of the plasterboard sheathing. All these nuances must be taken into account.

Covering the sheathing with acoustic plasterboard

To soundproof a partition, it is sufficient to use two materials: thermal insulation and acoustic plasterboard. However, if these are not enough, there is another additional option. It consists of installing a special sound-absorbing film, which is fixed on both sides of the frame. Sheathing with plasterboard is the final stage of the construction of the partition.

Acoustic sheets are distinguished not only by perforation on their surface, but also by a special edge shape. When installed correctly, the joints become as tight as possible and practically do not allow sound waves to pass through.

The sheets themselves are screwed to the profiles with self-tapping screws, the heads of which are slightly recessed. To achieve greater density and uniformity of the coating, the joints can be lightly puttied.

An example of finishing a ceiling with acoustic plasterboard

The result of the installation work will be an excellent plasterboard wall, which will differ not only in its aesthetic appearance, but also in its excellent soundproofing characteristics.

How to achieve silence

So, everything is clear about the reasons for the phenomenon. Now the problem needs to be solved - you need to figure out what and how to soundproof a plasterboard wall. By the way, plasterboard is also used for cladding ceilings - in this case, sound insulation may also be required. There are a number of effective options here, which will be discussed below.

Achieving silence is quite possible - there are different ways to do this

Damper tape

This is what a damper tape looks like - an invariable assistant in providing sound insulation

Where does soundproofing of plasterboard walls begin? First of all, it is necessary to perform their acoustic decoupling from the main adjacent walls and ceilings. To do this, it is enough to perform one simple action - between the guides (which are attached to these structures), as well as between the structures themselves, lay something, some kind of material that will take on the shock loads.

Foamed polyethylene is perfect for solving the problem - it is usually used. Polyethylene foam tape with an adhesive layer on one side is a product called damper tape. You can buy it at almost any hardware store.

Installation of tape - instructions:

Everything is simple here: the product is glued to the guide profile before its installation. After this, the profiles are secured with dowel screws - it is enough to maintain a step of 50 cm.

What if there is no damper tape in the nearest stores? It's okay - you can always cut it yourself. Foam insulation 4 mm thick is perfect for this (this can be energyflex, penofol, thermofol and more). A polyethylene foam backing under the laminate will also work.

We need to fill out the frame

Is it possible to remove acoustic resonance in wall cavities? Of course, there is nothing complicated here - you just need to add sound-absorbing material to the resonator.

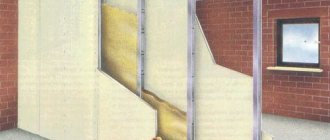

The space between the frame and the wall sheathing must be filled with insulation

Which sound insulator can be installed in a plasterboard wall at the installation stage?

- Simple mineral wool will do. Many insulation manufacturers offer customers special acoustic boards that feature improved sound absorption;

- Mineral wool absorbs noise remarkably well, it’s all about the structure of this material - there are many closed cavities in it, each of which serves as an excellent sound trap.

Useful tips on how and how to soundproof a plasterboard wall with your own hands:

- It is important that the mineral wool fills all the cavities between both sides of the wall sheathing and the frame studs. The slightest gap in the filling forms an acoustic resonator (and that’s exactly what we need to get rid of);

- We should not crush mineral wool when laying it in the frame. The higher the density of the material, the worse the sound-absorbing properties - the sound insulation of plasterboard walls will deteriorate;

- Glued mats are more preferable than rolled insulation. With a size of 1 by 0.6 m, they fit perfectly between the frame posts; no additional fastening is required.

In addition, glued down mats do not slide or cake due to their own gravity. This is good, because if the filler slides, the top of the wall will remain without filling, which will negatively affect sound insulation.

The frame is ready - all that remains is to do the rest, including sound insulation

Materials used to fill partitions

Effective sound protection for a plasterboard partition can be made using various options, which will vary according to the materials used. The following can be used as soundproofing materials:

- acoustic or soundproofing plasterboard;

- cotton filler;

- sound-absorbing membrane;

- soundproofing foam.

Sound insulation using acoustic plasterboard is distinguished by its simplicity. Acoustic sheets are installed on the manufactured frame, and the finishing layer is made using conventional gypsum fiber board.

An equally popular method is the soundproofing of plasterboard partitions using cotton fillers. Thanks to the soft and porous structure of the material, good results and effective protection can be achieved. To use such a material, it is necessary to make a profile structure that will hold the material and create the desired effect. There are a lot of varieties of cotton wool, so it is possible to choose the most suitable option in terms of cost and characteristics.

Photo: The process of creating a partition. Author: Konstantin Kostolomov

If it is necessary to create silence, and the thickness of the partition is quite thin, then noise-absorbing membranes can be used as an insulating material. Such a filler will be able to retain sounds, and due to its thinness, it can be installed in very thin interior partitions.

Some craftsmen use special foam as insulation, which, thanks to its porous base, absorbs sounds well. Foam is applied using appropriate equipment. In this option, it is important to adhere to technology and safety conditions. Foam sound insulation must be carried out by specialists.

Important! To achieve maximum sound insulation efficiency, you need to use high-quality materials that meet the requirements and characteristics of the intended product.

Results

This is approximately how you can get rid of noise when using plasterboard walls. Any owner can organize sound insulation with his own hands if desired - there is nothing complicated about it.

A video on the topic will help you with your work:

Installing plasterboard on walls with sound insulation is a great way to improve the room, while silence will reign in the neighboring rooms. This is very important, because nowadays peace in the room is priceless, especially during rest.

Rating: 4.4 / 5, total ratings: 7

Due to poor sound insulation, people in apartments have to listen to extraneous sounds from the street and neighbors. This is annoying, especially when you want to be in silence after a working day. Soundproofing plasterboard walls is not that difficult, but many extraneous irritants will disappear.

What are the advantages of the material and are there any disadvantages?

Gypsum fiber sheets, like other materials, have their advantages and disadvantages. The main disadvantage of GVL slabs is its cost. This material is currently somewhat more expensive than materials such as plasterboard, plywood, chipboard and MDF boards. Also among the disadvantages of the canvas is its significant weight

When making a frame, it is important to correctly calculate the strength indicator, since the mass of the slabs is considerable. As for the minuses, that’s probably all

Gypsum fiber has many advantages, which is why this material is often used in modern construction. Thanks to the hypoallergenic qualities of the finish, it can be used for residential premises and in particular children's rooms. The microporous structure of gypsum fiber sheets allows the walls to breathe, which helps protect the surface from fungal growth and mold.

Due to the hygroscopicity of the composition, the canvas can independently regulate the humidity of the apartment. If the apartment has high humidity, then the surface of the gypsum fiber board absorbs it. In case of increased levels of dryness, gypsum fiber releases moisture to create optimal climatic conditions. It is also worth mentioning the possibility of using GVL panels in rooms with temperature changes. Gypsum fiber sheet is an ideal material for finishing rooms without heating.

Is additional sound insulation needed for a plasterboard wall?

Drywall is a partial sound absorber. If there are strong sounds outside the apartment:

- roadway – busy traffic;

- landing;

- lift shaft;

- rowdy neighbors;

- entertainment centers or other clubs.

Then sheets alone will not be enough. Before installing the gypsum board into the frame, it is necessary to lay soundproofing material and also apply tape. This will enhance sound absorption.

In some cases, vibration suspensions are used to reduce vibration, which also leads to noise.

Features of working with Knauf Acoustics panels

When working with acoustic gypsum boards, you need to remember some important points:

The joints of 4PK panels are puttied without the use of reinforcing tape. The edges are pre-cut with a slight bevel, the panels are mounted with a gap of 3–4 mm. The seams will be filled with Uniflot putty, and the recesses from the screws will be filled with putty. After drying, the seams are puttied with finishing putty and sanded.

- The connection of 4FK panels does not require additional processing, since the joining is carried out using folds.

- Arched structures are made using dry and wet bending methods using plywood templates.

How to make sound insulation with your own hands

In order to soundproof a wall, it is necessary to allocate 10-12 cm of space around the perimeter of the room. They will go towards erecting a metal frame and laying the material.

To achieve maximum results, in addition to sealing material, acoustic plasterboard sheets are used. They are the best sound absorbers and help achieve silence in the room.

Choosing material for an apartment

For sound insulation, you can use ordinary materials. However, the installation technique should not be violated. If you do not use a damper tape during the construction of the frame, all the work will be in vain.

There is also KNAUF acoustic plasterboard to absorb sounds. If not, use regular plasterboard, sometimes in 2 layers. Materials such as polystyrene foam, penoplex, polyurethane foam reduce noise penetration by only a few percent. They are designed for insulation.

Glass wool has good performance. It can make a room quieter. However, if you do not use a damper tape, the performance will be reduced.

Under the double layer of plasterboard, three layers of sound insulation material “Soundline-DB” and a sound-absorbing board “Shumanet - ECO” are used.

If the drywall is already installed and there is finishing, then a wall membrane is used on top.

Choosing a soundproofing method

There are several methods for soundproofing a room.

- Laying insulating material into a metal frame for drywall. For this purpose, mineral wool is used.

- Application of acoustic plasterboard. Sometimes this is done in 2 layers.

- Application of soundproofing membrane.

Soundproofing under plasterboard walls in your home

For work you will need soundproofing material. If you choose mineral wool, you need to work with it with extreme care: only wearing gloves, protective clothing and goggles, due to the fact that small particles of the material spread and fly in the air.

First you need to install a metal frame on which the first layer of drywall will be attached. All electrical wires must be removed. We fill the metal frame 100 mm wide with dense sound-absorbing material. Once the entire interior space is filled, we quickly cover the walls with the next layer of drywall.

After completion of work, it is necessary to collect all construction waste, including mineral wool, gloves and, if possible, protective clothing, and pack them in a tight bag. The work area should be thoroughly washed to prevent the presence of sound-absorbing material, such as mineral wool, on the surface of the room.

Do-it-yourself noise insulation

In order to make soundproofing, you need to prepare. Initially, you need to determine what type of material to use for sound insulation. It depends on the room - temperature changes, humidity.

After this, prepare the surface. All cracks and crevices must initially be widened and then plastered using reinforcing tape. After this, the surface is cleaned of dust and primed.

The next step is marking the surface. This is done using plumb lines and levels. Upholstery cord is also used.

Materials

To carry out soundproofing under plasterboard on the walls, you will need the following materials:

- damper tape - it is glued to guide profiles, fixed with self-tapping screws to the wall, floor, ceiling;

- vibration suspensions for rack profiles - dampen vibration and sounds coming from outside;

- for sound insulation, you can choose mineral wool - the best option;

- You also need to use a membrane film.

Tools

To install a plasterboard surface on a frame base with sound insulation, you will need the following tools:

- construction knife with a set of blades;

- ruler, pencil, level, meter;

- plane;

- spatulas with different blade sizes;

- screwdriver, drill;

- metal scissors;

- hammer.

Progress

The damper tape must be glued to the guide profiles and hangers. After using dowels and nails, fix the metal strips along the marks. At a distance of 40 cm from each other, hangers are attached along the notched lines for the rack profile. Rack profiles are fixed onto them by inserting them into the guides. To create a rigid structure, metal strips cut from the racks are horizontally attached between the racks. Crabs are used to connect the planks.

Next, after creating the metal structure, mineral wool must be laid. To ensure dryness and greater sound insulation, a film is fixed under the cotton wool.

After laying the soundproofing material, you need to run the cables and make the electrical wiring. All electrical wires are hidden in corrugation.

After the work is done, plasterboard sheets are installed.

Decorative finishing

An important condition for the long service life of a plasterboard structure is sealing the joints. For this, putty and KNAUF tape are used.

After the putty has dried, the surface is primed, puttyed with a finishing solution, rubbed and covered with putty again. All subsequent finishing is decorative:

- Painting with water-based paint, water-resistant.

- Finishing the painted surface with molding.

- Wallpapering, liquid wallpaper.

- Decorative plaster.

- Finishing with slabs and ceramic tiles.

Each type of work has certain conditions and its own technology.

Features of a frame for plasterboard on a multilayer partition with a sound-absorbing layer

The situation described above speaks to the importance of proper frame assembly. Otherwise, sound energy will bypass the sound-absorbing layers through the hard components. As a result, the actual efficiency of the multilayer system will be much lower than the calculated values.

A wooden frame for plasterboard on a partition with a single-layer sheathing is least likely to contribute to acoustic comfort. If you replace the wooden sheathing with a metal base, the sound insulation index will improve by 4-5 dB.

Double cladding made of gypsum plasterboard will not only increase the strength of the structure, but will also increase the level of sound absorption by 9-10 dB. And if you approach the matter thoroughly and install a two-layer sheathing on the metal frame, then the sound insulation will improve by another 5-6 dB. As a result, practice has shown that the most effective option is a frame structure made of a metal profile filled with two layers of sound-absorbing material and covered with two-layer plasterboard sheets.

Important! All kinds of holes and cracks in bulkheads reduce their sound insulation parameters. For example, a door gap of up to 1.5 cm can reduce the Rw index by 7-9 dB.

How to zone the kitchen and living room with a multilayer partition made of plasterboard and mineral wool

The process of constructing a bulkhead from gypsum plasterboard is quite labor-intensive, but if you follow the technology, it can be done on your own. And if you already have experience in installing and puttying gypsum slabs, then you have the opportunity to save a large amount.

Frame

As already mentioned, a metal profile is the best choice for assembling a base. You don’t need to be particularly versed in construction to understand that sounds are transmitted through the load-bearing elements of a building. Vibrations are transmitted through the profile to an interior multi-layer plasterboard partition with sound insulation, so special gaskets are indispensable here.

A damper tape is used as a lining, which is placed under the profile. You can purchase two types of soundproofing strips in construction stores:

- Sealing tape made of foamed polyethylene. A prominent representative is the self-adhesive strip Dichtungsband from Isolon.

- Soundproofing gasket based on glass fiber material. Vibrostek-M100 rolls from Shumanet demonstrated good results.

For the construction of bulkheads, wall metal profiles with a thickness of at least 0.55 mm are used. This requirement is due to the quality and strength of this profile. The designs use CD60 and UD28 elements. To fully ensure acoustic comfort in the room, a system of high-quality profiles has been developed. Their surface is covered with a thin layer of vibration-damping mastic.

For assembling the frame, profile components have proven themselves well:

- Vibrofix Liner.

- Vibronet profile.

- Vibroflex-Wave.

You cannot ignore the fasteners, they are the first receivers of vibrations and transmit them from the load-bearing plane to the bulkhead. Plastic dowels will help solve the problem.

Soundproofing material

Many people mistakenly believe that dense material better prevents the penetration of sound waves. It has already been mentioned here that things like foam or cork are not suitable. The best results are shown by fiberglass, mineral and stone wool:

- AcousticKNAUF (KNAUF Insulation).

- Acoustic Butts from Rockwool.

- Schumanet-BM.

- Schumanet-SK Neo.

- AKULite Neo.

- TERRA 34 PN Noise protection (URSA).

- Schumanet-ECO.

- Knauf Insulation.

Bulkhead installation technology

The process of installing a plasterboard partition to organize the zoning of the kitchen and living room involves, first of all, fixing the guide profiles on the floor and ceiling. A sealant must be placed under them. The standard list of technological transitions includes the following items:

- Using a plumb line, make parallel marks on the floor and ceiling, then connect them using a marking cord.

- Fix the guide profiles using a hammer drill and dowels in increments of 900-1000 mm. First stick soundproofing tape onto the metal profile.

- Insert the rack profiles into the guides in increments of 600 mm and secure them with 3.5x9.5 mm screws using a screwdriver.

- Attach vertically oriented gypsum board sheets to one side and secure them with 3.5x25 mm self-tapping screws with a pitch of 60-70 mm and a distance from the edge of 15 mm. If you don’t need a whole sheet, then you need to cut the cardboard layer down to plaster to size using a construction knife. Then the sheet is broken along the line, after which the cardboard is cut on the other side.

- Insert sound-absorbing material into the spacer between the profiles. Usually the width of the cotton wool is already cut according to the standard, all that remains is to cut it in height.

- Screw the gypsum board sheets onto the other side. Apply sickle reinforcement tape to the corners and joints between the slabs. Putty the tape and the recesses from the screw heads.

All that remains is finishing work. When doors are inserted into the bulkhead, special attention is paid to the soundproofing of the opening. Complete tightness of the entire structure is important; any holes or cracks are unacceptable. Silicone sealant is used where electrical lines or other communication channels pass. It is not recommended to use polyurethane foam - it does not have adequate fire resistance.

Life time

A plasterboard structure, created according to all the rules, taking into account external factors - humidity, temperature, lasts 50 years. Mineral wool, unfortunately, has a service life of 10 years. But, to replace the soundproofing material, the gypsum board can be carefully dismantled.

When choosing a soundproofing material, you need to pay attention not only to decibel damping, but also to environmental friendliness, moisture resistance, and shelf life. In addition to sound insulation, furniture installed near a plasterboard wall serves as an addition. Wardrobes, dressing table, installed decorative fireplace. Created niche for TV.

Main characteristics

Using plasterboard, you can make effective sound insulation of walls, as well as interior partitions. Installation is carried out using frame and frameless methods, so you can choose the most suitable solution. It is worth noting that acoustic drywall is not soundproofing, but rather a sound insulator, and it cannot be compared to mineral or basalt wool.

Photo: Main characteristics of drywall. Author: Timur Bazorkin

Acoustic plasterboard boards are made with various perforations, which allows you to select the material not only in the form of sound insulation, but also as additions to decorative elements. The diameter of the perforation holes affects not only the external parameters, but also its ability to absorb sound waves. The location and diameter of the holes is selected individually for various purposes.

What can make noise?

During construction, sound insulation is not always created for plasterboard walls. Some masters are confident that if the partitions are of high thickness, then no additional procedures are required. There are always cavities in the wall that reflect sounds; they fall into adjacent rooms. Even if the wall thickness is increased without additional sealing, there will be no soundproofing protection. Noise appears due to vibrations of internal floors and vibrations of partitions.

Load-bearing structures in the room conduct sound well due to rigid fastenings, especially if this sound is low-frequency. The partition acts as a membrane, transmits sound vibrations, and promotes their propagation. GCR is able to block these vibrations. They will remain inside the ceilings and subside.

Which soundproofing material to choose

A plasterboard partition with high-quality sound insulation is a complex complex structure in which one or two insulating layers cannot be used.

You will need the correct choice of the drywall sheets themselves, the filling of the partition, frame materials and even fasteners.

So, the minimum set that will dampen up to 30% of noise includes:

- GKL (GKLV) PC plasterboard with a thickness of 9.5 or 12.5 mm - is arranged in two or three layers with gaps filled with sound-proofing material, with or without an air gap.

- The main soundproofing layer is sheet or roll material located in the spaces of the “pie”. The most widespread are: ecowool, basalt and mineral wool, felt or other substances.

- An additional soundproofing layer is used less frequently and involves gluing the internal supporting surfaces with cork, rubber-cork or foil backing. The backing is not very effective for plasterboard partitions.

- Frame – is a supporting structure, usually made of aluminum profile. Serves for fixing drywall.

Such an approach to soundproofing a partition will not bring the desired effect, even if the structure is made multilayer.

This is explained by the vibrational nature of sound waves, which propagate perfectly over communicating surfaces of high hardness. In this case, their role is played by the sheets themselves, the frame, and frame fastenings. The following measures will help reduce the impact of this chain:

- the use of OSB boards rather than plasterboard as an internal support sheet;

- the use of microporous rubber gaskets between sheet materials and the floor, ceiling, walls;

- gluing frame profiles with soundproofing tape materials;

- replacing the aluminum profile with timber made from durable types of wood, such as beech;

- installation of special soundproof dowels in the walls.

A correctly performed set of these actions will ensure at least 80% noise suppression, which means that voices, music at medium volume and the sound of moving furniture behind the partition will be almost inaudible.

How to achieve silence

A soundproof wall will provide peace and quiet. If it is made of plasterboard, then the level of protection can be increased using damper or polyethylene foam tape, as well as filler. The combination of two elements at once will create an acoustic decoupling from the capital adjacent walls and ceilings.

The tape is placed between the guides and takes on the shock loads.

What is required for sound insulation

To choose a filler, it is worth considering all the options that the construction market can offer:

Assembling the supporting frame

The installation of the frame for plasterboard cladding is carried out according to an identical scheme, regardless of the design features of the partition. The sequence of steps to install it is as follows:

- Using a level and plumb line, the initial profile is set. All subsequent racks will be guided by it. Therefore, it should be installed as evenly as possible in relation to all planes.

- A UW profile is attached to the floor and ceiling, which is necessary to ensure structural rigidity. It is fixed using drywall screws, which are screwed in every 40-50 cm.

- The guide profile is filled with vertical posts, which are installed every 30 cm or 60 cm. They are fixed using metal screws or a special cutter.

- To increase the load-bearing capacity, vertical rack-mount CD profiles are fastened with horizontal guides. They provide the frame with greater rigidity and immobility.

The process of installing a sheathing frame under plasterboard does not contain secrets and is carried out with your own hands in the shortest possible time. At the same time, the strength and appearance of the future partition will largely depend on the quality of installation work.

Strengthening sound insulation on a finished wall

If a wall made of plasterboard with sound insulation still allows extraneous sounds to pass through, then you can enhance the protection with the help of finishing materials. For this purpose, there are special wallpapers with a cork seal on the inside. This layer will enhance the sound insulation of the walls. The option is considered optimal, because other procedures will have to be carried out on top of the existing surface. Additional sound insulation is also created by special thin slabs made of cork or membrane. To fix them to the wall, special glue is used.

Some manufacturers provide an adhesive complete with the slabs.

Drywall and isolon

This combination is often used for insulation and soundproofing of balconies and loggias, and external cold walls of an apartment. Using this material, a whole range of effects is achieved:

- Vapor barrier.

- Waterproofing.

- Thermal insulation.

- Soundproofing.

- Windproofing.

Another undoubted advantage is the thinness of the material, which allows you not to steal too much space from the area of the room, which, you see, is very important for modern, small apartment premises.

Isolon is strong and durable - the material has a 90-year guarantee, almost a century!

The isolon is attached directly to the wall using glue or a small lathing (which is more appropriate in the case of subsequent finishing with plasterboard).

The material should only be fastened with the reflective side facing the inside of the room, and the joints should be sealed hermetically with special tape. That's all the nuances - cheap and simple!

How to calculate the thickness of a partition for walls

To calculate the size and thickness of the partition, use the formula. It is important to consider the size of the sheets, frame and filler. Standard indicators:

- partition width – 10 cm;

- plasterboard – 12.5 mm;

- metal profile profile – 9.5 mm;

- steel – size 50.

These parameters can withstand a load of 50 kg. If the insulation/filler is heavier, the performance increases. For weights from 70 kg, the size of drywall is from 18 mm, and metal slats are from 12.5 mm.

Formula for calculating thickness: metal lath size (9.5) * plasterboard sheet size (12.5): 2 = 59.4 cm.

Permissible loads on the partition

Noise insulation of a plasterboard partition should be carried out taking into account the permissible loads on the structure. The table shows the standards.

| Thickness of plasterboard sheet/mm | Permissible load if plastic dowels are used/kg | Permissible load if metal dowels are used/kg |

| 10 | 20 | 40 |

| 12,5 | 25 | 50 |

| 2x10 | 35 | 60 |

| 2x12.5 | 40 | 70 |

The load is calculated before installation work begins.

Permissible loads on the partition

Photo: Permissible loads.

Author: Konstantin Kostolomov When making an interior partition, it is important to correctly calculate the thickness and load that will be on the frame. Everyone wants to make a partition in such a way that it does not take up much space. When forming a structure, everything is selected depending on the profile parameters.

Photo: Permissible loads. Author: Konstantin Kostolomov

The most suitable size is considered to be a partition thickness of at least 12.5 centimeters. During installation of the partition, the load to which the structure is subjected must also be taken into account. With a load of 40-50 kilograms per square meter, the sheet thickness should be no more than 16 mm. If the weight per square meter is 70 kilograms or more, then it is recommended to use additional frame posts. The thickness of the structure will be greater, but it will remain reliable and durable.

Important Features

Sheathing increases sound insulation, but this figure can be increased if you add mortgages to the partition, use plywood instead of gypsum fiber board, or build a structure from double profiles. Some craftsmen suggest laying double sheets of drywall, but if you consider it from the point of view of financial benefits, it is better to immediately purchase a sheet of the required thickness.

Use of wooden mortgages

A plaster construction will be much stronger if you use wood embedded parts inside the structure. They are added to the profile and ensure the stability of the partition. With the help of mortgages, you can double the strength of the load-bearing elements of the product.

Using dual profiles

This method is called "overlap". Plaster construction is sometimes reinforced with a double profile. It is installed next to each other and secured with self-tapping screws. Thanks to this connection technology, the strength of the partition is doubled.

Drywall and wool

All the abundance of different variants of wat has the following characteristics:

- Doesn't light up.

- Does not deform when exposed to temperatures or compression.

- Does not come into contact with various environments.

- Easy to install.

Instructions for making sound insulation using these materials are as follows:

- Attach a water barrier to the walls and insulate the joints.

- Assemble the frame from wood or metal profiles according to the installation technology.

- Distribute the cotton wool evenly behind the frame, secure it, try to avoid uncovered areas.

- Attach sheets of drywall, putty the joints, and plaster the surface.

- Complete the repair work with any type of finishing (painting, wallpapering).

Soundproofing wall cladding

Let us remind you that for the strength of the structure, the fastening step of the profiles should not be less than 50 centimeters, the sheets are attached both in the middle and along the edges, adjacent sheets are attached to the same guide. The tools that you will need for such work can be found in every home: a screwdriver, a level, a plumb line, a ruler, a pencil, a stationery knife - this is the minimum set with which you can easily carry out your plans.

Preparing tools and collecting materials

The preliminary stage of work is drawing up a basic plan for the future wall. You can model it on a computer or simply draw it with a pencil on a piece of paper. Its creation makes it possible to get a complete picture of the scope of future work and visualize the object.

Installation of a plasterboard structure with soundproofing material on a brick wall

The finished plan must contain the aspect ratios, their geometric dimensions and angles. The only condition that is put forward for the project is maximum detail. It is this that is the key to success and allows you to significantly simplify the process of installing the partition.

A suitable plan for partitions and walls made of plasterboard, showing the location of profiles for installing a gypsum plasterboard structure

Obtaining a visual representation of the structure marks the beginning of construction work. However, their implementation will be impossible without preparing a tool for working with plasterboard, the list of which is as follows:

- pencil;

- level;

- plumb line;

- knife;

- spatulas of different sizes (narrow and wide);

- screwdriver;

- solution container;

- grout mesh.

Each of these tools must be prepared for work and stored in a specific place. At the same time, in order to understand the full structure of the process and assess the scale of construction, it is necessary to purchase a whole set of components for drywall, the list of which is as follows:

- rack profile-CD and guide-UD;

- three types of screws for the profile (25 mm, flea and 45 mm) and screws for fastening drywall;

- mineral wool;

- perforated plasterboard (acoustic);

- soundproofing membrane;

- reinforcing tape;

- gypsum putty.

As you can see, the list of necessary materials is quite extensive. However, each component in it is necessary and performs its specific function.

Watch the video: installation of a partition with sound insulation.