Welcome to the kuzov.info blog!

In this article we will look at how a pneumatic spray gun works.

The basic function of a paint gun is to split the paint into thousands of miniature droplets and impart a directed speed to them. For this to be possible, the mechanisms and components that make up the spray gun must work smoothly and in unison.

Understanding how your spray gun works will help you recognize and troubleshoot spray problems, as well as better understand its adjustments and set up your gun expertly.

How does a pneumatic spray gun work?

The spray gun has two separate channels: one for air, the other for paint. When you pull the trigger, the air is first activated, and then the needle moves back and the paint begins to come out. Thus, the paint passes through the nozzle and immediately interacts with the air. In most modern spray guns that are used in body repair, mixing of paint with air occurs outside the paint gun, between the two protruding parts of the air cap (external mixing spray guns).

What happens when the spray gun trigger is pulled? The trigger operates in two stages. When you initially pull the trigger, the air valve opens, through which compressed air flows. If you continue to pull the trigger, the needle will begin to move back, allowing paint material to flow through the nozzle.

If you start to release the trigger, first the flow of paint stops, and then the air stops flowing. Thus, the delay in spraying the paint, when the trigger is initially pressed, ensures that the paint is sprayed with a formed torch. Also, when the trigger is released, the paint stops spraying, leaving a trace of a fully formed torch.

What are external mixing spray guns?

In these paint guns, air and paint are mixed from outside the air cap. They are used for spraying all types of paints and varnishes. A - Air cap, B - Paint head with nozzle, C - Needle, D - Spring that returns the needle after the trigger is released, E - Paint supply regulator, which limits the retraction of the needle when the spray gun trigger is pressed.

Principle of operation

An electric spray gun functions by converting electricity into pneumatic energy. The paint, under the influence of increased pressure, is directed from the tank to the sprayer, which distributes it over the surface.

Design of the operation of an electric spray gun

The container for the paint and varnish composition is located either above the device (drain) or below it (suction). As a result of pressing the lever, the airbrush passes compressed air through itself. If you press harder, the needle will shift and the flow of paint will decrease. In other words, the higher the air pressure, the less intensely the paint material leaves the spray gun.

There are separate types of paint sprayers for different paint consistencies. For example, for thick paints, devices with a larger outlet are used than for liquid ones. The volume of paint supplied is controlled using the so-called spray torch. The operating pressure also depends on the type of paint and varnish material. The air supply is regulated thanks to a special screw.

Any spray gun is equipped with a so-called pistol. This device, using a nozzle, forms a torch as a result of mixing the following components:

- High pressure air supplied from a compressor.

- A working composition (varnish, primer or paint) that meets the permissible viscosity parameters.

In the inside of the gun, the air is divided into two streams, one of which is directed centrally, and the second along the periphery. All electric spray guns are equipped with three controllers that allow you to set the required operating mode:

Structural elements of an electric spray gun with a hose

- Adjusting the total air supply makes it possible to maintain a balance between the volume of paint supplied and its application form at a certain speed. If the expected paint consumption is small, the tap is closed. After this, the flow rate will decrease and the paint will be sprayed more accurately.

- The pressure on the side jets on the periphery is controlled by a separate screw. The air flow determines the shape of the spray of paint and varnish: the stronger the air supply, the wider the perimeter. If you stop pressing the side jets, the feed shape will become round. However, this is an extreme option, since in this case the coverage of the paint will greatly increase, which will lead to drips.

- The consumption of paint and varnish material is determined by the volume of air supplied through the center of the electric spray gun. To make the flow less abundant, you should slightly close the tap.

Taps can be located in different places, depending on the modification of the device, but the most common are two schemes:

- The paint supply adjustment valve is located on the side of the gun. Somewhat lower is the general air supply valve.

- The general air supply tap is located at the end of the handle, near the inlet pipe. The tap that regulates the width of the jet is located in the same place as in the first case - on the side of the gun.

Paint containers can not only be of different sizes, but are often installed in different places. They usually take their place in the area of the front of the barrel, which improves the suction parameter. There are two methods of supplying paint and varnish material:

- By gravity. In this case, the composition rushes down under the pressure of its mass. It is difficult to control the flow rate in this case, since it entirely depends on the diameter of the outlet from the container.

- The use of the vacuum effect is more common. With this effect, a rapidly moving air stream creates negative pressure under the paint tank, as a result of which the composition is sucked in.

Note! The main difference between an electric spray gun and a pneumatic one is the presence of a built-in compressor. The advantage of such a device is that it is impossible to overload the compressor

Electrostatic painting

Separately, it is worth mentioning the electrostatic method of surface painting. During operation, the paint and varnish composition, upon contact with the electrode installed in the spray gun, receives a negative discharge (up to 100 kW). After spraying the paint, its particles flow along the force field exclusively towards the structure being painted. The advantages of the technology are obvious: reduced paint consumption and more accurate spraying.

What is the function of the air cap?

The air cap directs compressed air to the flow of paint coming out of the nozzle, splits it and forms a torch.

The entire process of mixing paint with air, forming a torch and spraying occurs thanks to the air cap of the spray gun. It contains holes of a certain size through which air passes and breaks down the paint coming out of the nozzle. The holes located on the protrusions of the air cap are designed for air, which forms a torch of sprayed paint.

What is the function of the spray gun nozzle and needle?

They restrict and direct the paint material coming from the gun into the air stream.

The nozzle is located on the painting head and is structurally combined with the air cap.

The tip of the spray gun needle is placed inside the nozzle. The size of the nozzle that the spray gun should have depends on the viscosity of the material being sprayed.

The spray gun needle has a wedge-shaped tip that fits into a nozzle of the same shape and closes the paint supply. The needle is connected to the trigger of the paint gun. When the trigger is pulled to a certain position, the needle moves back and paint begins to flow through the nozzle.

The spray gun nozzle has a cavity shaped like the tip of the spray gun needle. When the trigger is released, the needle is pushed by a spring located behind the needle and the tip of the needle enters the nozzle cavity, closing the flow of paint. At a certain stage of pressing the trigger, the needle moves back, opening a channel for the flow of paint.

The amount of paint material that comes out of the spray gun depends on the viscosity of the material, air pressure and nozzle size. To ensure proper application of different spray materials (with different viscosities and particle sizes), it is recommended to use nozzles of different sizes.

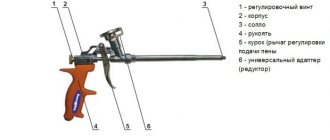

Main components of the mechanism

The design of a pneumatic spray gun is quite simple to understand, as it consists of a small number of components. A brief description of each detail will help to form the clearest possible understanding of the operating principle of this tool. The following list of elements is organized according to the order of air movement in the device: starting from entering the body and ending with departure from the nozzle.

Gun

The body of the pneumatic spray gun is an integral basis that combines all the details of the device. The handle of the gun has a special fitting where a hose for the spray gun is installed, providing the tool with air pressure. Above there is a shut-off valve connected to the trigger. The barrel contains a sealed air channel and several grooves with elements for adjusting the supply of material, the size of the torch and the air pressure. The last regulator can be located in the handle. In addition to the air channel, the spray gun has a compartment for material, the exit from which is tightly blocked by a thick needle with a cone-shaped tip.

The design of the trigger implies alternate opening of the valves. When pressed, the flap in the handle first moves back, clearing the way for air, after which the needle moves back, opening the supply of material. The final and most important element of the gun is the nozzle, where the air interacts with the liquid, breaking it into small particles.

Needle

A long metal rod with a cone-shaped tip, called a needle, is necessary to control the flow of paint material into the nozzle. Equipped with a stop for reliable fixation in the tool trigger. At the end opposite to the cone, it has a perpendicular groove designed for connection with the material feed adjustment screw.

The diameter of the needle for a spray gun largely depends on the size of the nozzle (nozzle), which can be located in the range of 0.5 - 1.8 mm (for standard type models). To effectively feed the material, these elements require great accuracy of fit, so they are often sold as a set (nozzle, needle and air cap).

Tank

The container for filling the material with further supply to the device can have several versions and locations. The most common 2 positions of the tank: upper and lower. On more compact models of pneumatic spray guns, the container can be installed on the side, which allows you to use the tool in any position, pointing it upward.

The lower location of the tank is most suitable for processing vertical surfaces when the gun is in a straight position. Such containers often have a larger volume (on average 1 liter) and are made of metal. The supply of paint and varnish material occurs according to the principle of rarefaction, which occurs due to the flow of compressed air passing over the outlet tube of the container.

A spray gun with an upper tank has a wider range of applications. When working with such a tool, you can hold it up, down, or in front of you (tilting within reasonable limits). In most cases, the containers are made of plastic and are located at an angle relative to the gun barrel. The material is fed into the nozzle under the influence of conventional gravity, causing the liquid to flow down.

Maximum convenience of working with a spray gun is provided by special vacuum tanks, which can be installed both above and below the gun. These devices consist of several elements: an outer plastic frame, an internal soft cup, an adapter and a lid with a mesh, which is a filter for the spray gun. During spraying, the internal, soft container contracts, allowing the tool to be used in any position. According to official data, tanks of this type are considered disposable, but according to user reviews, they are quite suitable for reuse after washing.

Nozzle (nozzle)

Intermediate element between the needle and the air cap. In simple terms, a spray gun nozzle is a monolithic metal part, with a hole for material in the center, and several air holes located along the radius. Serves to supply paint to the surface of the air cap, where it is sprayed using compressed air. The diameter of the spray gun nozzle affects the size of the droplets of the spray torch formed. This parameter should be taken into account based on the material with which you will be working. For water-based paints and varnishes with low viscosity, a diameter of 1.4 mm is suitable, and thicker enamels, primers and others will require 1.6 mm.

Due to frequent clogging or ineffectiveness of working with a particular material, the spray gun nozzle is one of the most popular replacement parts. In most cases, this element is sold complete with an air cap and a needle, since these parts require high dimensional accuracy from each other.

Paint supply regulator

This regulator controls the position of the needle. It limits the maximum possible flow of paint when the spray gun trigger is fully pressed.

After releasing the trigger, the spring returns the needle to its original state and the flow of paint stops.

The higher the paint flow is set, the more air is required to atomize the paint.

Gravity paint spray guns have a tank located on top. The paint flows into the gun naturally, thanks to gravity.

Spray gun or roller?

Many craftsmen who do their own renovations in their apartments use ordinary rollers. But hand painting has several disadvantages when compared to using a spray gun. For example, the smoothness and thinness of the coating that a special sprayer gives cannot be achieved using a roller.

But this is far from the only positive side of using a spray gun. When used correctly, the surface will be neat and smooth. This effect cannot be achieved when using a roller, which often leaves lint and other imperfections. This debris deposit, which is very difficult to get rid of, is often very noticeable and spoils the overall impression of the renovation.

In addition, do not forget that the spray gun makes it possible to apply paint not only thinly, evenly and accurately, but also as quickly as possible. For people who value their time, this is an important plus. You can also forget about the need to thoroughly clean the space around the surface being treated. When using a roller, situations often occur when paint drips onto the floor, remains on furniture, etc. The spray gun makes it possible to carry out the surface painting procedure much more accurately. However, especially valuable things and items that cannot be washed afterwards should be put away. During the use of the device, a cloud of paint particles often forms, which can settle not only on the surface being painted, but also beyond it. However, when using spray gun attachments, you can achieve excellent results, and the cleanup after painting work will be minimal.

Spray guns with a lower tank location

Paint guns with a bottom tank use a siphon paint supply. In siphon feed guns, when the trigger is pulled, the flow of compressed air increases, which creates a siphon effect (Venturi effect) in front of the nozzle, as a result of which the paint is drawn out of the tank.

The Venturi effect is a reduction in fluid pressure that occurs as a result of fluid flowing through a narrowed area of a pipe. (named after the Italian physicist)

In siphon-feed spray guns, the paint flows through a tube in the tank.

Compressed air provides energy and speed for the paint to be applied to the surface.

Additional elements for the spray gun to improve the quality of painting

When performing painting work, you will need to use auxiliary elements. Their use is not necessary, but if they are present, it is possible to ensure the most effective application of paint and varnish material to the surface. These auxiliary elements include:

- Gearbox for spray gun

is a device that consists of a pressure gauge and a pressure regulator. Installed between the spray gun and the connecting hose. Using this device, the operator can adjust the required air pressure. Moreover, the pressure gauge indication is not only mechanical, but also digital. It should also be noted that some manufacturers produce spray guns with built-in gearboxes and a digital pressure gauge. Using a pressure gauge, the operator determines the air pressure at the inlet to the spray gun. This is necessary in order to determine the exact amount of pressure, since when transmitted from the compressor to the gun through the hose, the pressure drops to 2 atmospheres, which negatively affects the painting process - The dehumidifier

is another important element that ensures air dehumidification. It is rational to use such a device when the operator is faced with the task of opening the surface with a high-quality paint layer. A dehumidifier is a filter through which air passes and is dried. In addition to the moisture remover, there are also filters that prevent the ingress of dust, dirt and oils. The issue of using such devices is especially relevant when the paint layer of a car body is being opened.

It is not at all necessary to use the devices described above, especially if a fence or gate needs painting. However, it is worth noting that their presence directly affects the quality of the paint layer applied, as well as the duration of its operation.