If you have a limited budget, you can use the simplest and most affordable materials to decorate your home. At the same time, you do not necessarily sacrifice the effectiveness of the setting. An inexpensive plywood interior is a stylish, fashionable space with an emphasis on environmental friendliness, simplicity and practicality.

The implementation of such an idea will cost a small amount, but it will look expensive and impressive. This is a simple and economical alternative to wood finishing.

Plywood: can inexpensive finishing be fashionable?

Not so long ago, plywood was not taken seriously as a finishing material; it was often neglected by architects and designers. It was unfairly considered unsightly and too cheap, not intended to create home comfort, a comfortable office or study. But today the use of this inexpensive and versatile finishing material has become a new trend in interior design, coming to us from America and Europe.

The increased demand, especially among supporters of eco-friendly housing, for furniture, decorative elements made of plywood, and interior decoration is explained by the following nuances :

- safety and naturalness;

- flexibility and strength, allowing you to create complex structures that “grow” out of the walls;

- thinness and lightness, making it possible to manufacture decorative elements of any configuration;

- excellent noise absorption and suppression of the reverberation effect, which is especially important in home theater areas.

But the main quality and advantage of interior plywood is its minimal cost.

Original kitchen design with plywood sheets Source saveig.com

Plywood in construction - decorativeness, low cost and wide possibilities

Set in the New Zealand countryside, the house's three frontal, peaked forms follow the contours of nearby buildings. The architects were given a task; build a convenient and comfortable home with minimal construction costs.

Construction materials have been selected to reduce operating costs. Metal profiles for the facade, wooden frames, metal structures and plywood interior decoration fully meet these requirements. This made it possible to build an affordable and comfortable cottage for a family of several people.

Lightweight and inexpensive structural elements give the building an effortless gracefulness and at the same time reduce the cost of building a foundation, since the requirements for its strength and volume are reduced.

How plywood can be used in the interior

When used correctly, ordinary plywood will bring any design of an apartment or house to perfection. For example, painted sheets have found application in decoration and wall decoration. With their help, you can also visually highlight the corner of the room and perform zoning of the room.

Small plywood details will ideally complement the interior in the Loft and Chalet styles, and painted sheets of lilac or blue will look great in the Provence style. Decorations in the form of gray, white or black elements are ideal for the Scandinavian style.

A plywood interior can be very stylish Source erbrus.ru

There are many options for using plywood, here are the most common ones:

- finishing of walls, ceiling, floor;

- production of furniture: durable beds, original chairs and tables in any style;

- production of lamps and table lamps of unique design;

- construction of durable and strong racks and shelves;

- production of children's toys - cubes, cars, construction sets;

- creation of various accessories and decorations;

- production of kitchen utensils - spatulas, boards, stands.

The right combination of material and available space will definitely lead to impressive results.

A cozy plywood lamp Source svet-x.by

Plywood finishing: preparation

To do the job efficiently, you need to know certain nuances regarding the proper use of this material. It must be properly prepared by the start of finishing activities.

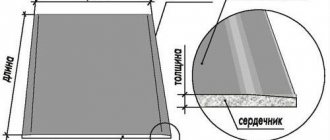

Let us dwell on the features of the production of the material. All plywood intended for upholstery of floors, walls and ceilings is made from coniferous or birch veneer.

An important factor is the grade of material.

There are several types of brands, the most popular of which are on the market:

- FB is plywood impregnated with a bakelite composition, which thanks to it has acquired high resistance to moisture, including sea water.

- FC - this brand is the most popular. It has average resistance to liquids; urea-formaldehyde resin is used as the adhesive component.

- FSF is a special plywood with increased water resistance, which is ensured by phenol-formaldehydes included in the composition.

- FOF - usually used in furniture production. It is a laminated sheet, one side of which is embedded with decorative plastic.

Walls: plywood paneling

Upholstery of walls with plywood is often carried out in dachas, attics, dressing rooms, etc. This process is not complicated, but the specifics of the technology must be observed.

In a wooden house, such upholstery can be done without first constructing a frame.

In that case, of course, if the surfaces of the walls are sufficiently smooth. If they cannot boast of this, then they should first build a frame from a wooden beam.

If it is necessary to sheathe a concrete base with plywood, then a frame must be made. The timber used must guarantee the required rigidity for the entire structure, and provide the ability to attach two sheets to it so that the joints fall on the sheathing. The distance between individual bars should be no more than half a meter. If plywood is intended for finishing, for example, a balcony, then you will have to choose a material option with increased moisture resistance.

After all, during the cold period it will be exposed to low temperatures and high humidity. In some cases, insulation is placed under sheets of plywood. Then the distance from the wall should be one centimeter greater than the thickness of the insulation used.

Mineral wool is well suited for this role. It is an excellent heat insulator, lightweight and resistant to rodents.

The layout of the sheets relative to their location on the wall is thought out in advance, so that later you do not have to redo the entire frame. Whole sheets should be located in the center of the wall, individual parts and pieces are arranged along the edges, below, where they are not very noticeable. When finishing a van, the material is fixed to its metal structures.

Use special self-tapping screws with a special drill tip, or high-strength polyurethane adhesive mixtures. It is advisable to cover the joints with connecting steel strips. How to cover plywood-covered walls as protection and for greater decorative effect? You can use any compositions intended for processing wood - varnishes, glazes, paints, impregnations, whatever you like.

Ceiling: plywood paneling

Upholstering the ceiling with this material is actually no different from finishing the walls with it. Sheets can be nailed directly onto a flat wooden ceiling; in other cases, a special frame made of wood (beams) is preferable. If you do all the manipulations yourself, do not forget that the electrical cables are laid before sewing the surface. It’s easy to cover the walls yourself, without an assistant. To finish the ceiling you cannot do without it: it is unrealistic to simultaneously hold a sheet of material and secure it in place.

Floor: plywood paneling

This procedure has some peculiarities. If it is intended to use plywood as the final covering of a wooden house, then it must certainly be the first grade.

The material should be at least 12 mm thick, or even 16 mm, since it will have to bear a considerable load.

To prevent the coating from sagging under heavy objects, the logs should be spaced at least 40 cm apart.

If plywood only plays the role of a substrate for another finishing coating, then low-grade materials can be used. Plywood is often used for stairs, attics, and for finishing the inside and sometimes outside of a wooden house.

Plywood as wall decor

The use of plywood is an original solution for finishing walls in a modern style on a limited budget. The sheets can be used in any room - bedroom, hallway, corridor, nursery. An exception is the use in the bathroom and kitchen: under the influence of steam and high humidity, the material is deformed.

For decoration, sheets with a thickness of more than 16 mm are used. The sheets are fastened to a pre-installed profile frame. To improve the aesthetic characteristics, the surface can be stained or varnished. To design a room in a non-standard way, you can burn an original design onto the surface of the sheets and paint it.

To further enhance the effect of plywood walls, the design can be complemented with lamps and other decorative elements made of plywood or natural wood.

Plywood is suitable for the original decoration of any room Source pinterest.ru

Finishing with plywood is an easy way to decorate a room

10 ways to make any room more comfortable

Plywood is a material well known to all developers. At one time, this was the best way to improve a room, but nowadays the choice of building materials is huge and, nevertheless, finishing using plywood has not lost its attractiveness.

The natural structure of wood will be relevant at all times.

In the photo: decorating a room with plywood at the dacha - everything is covered, from floor to ceiling

This material has a number of advantages:

Natural origin of the material - veneer sheets made from birch or coniferous trees are used for production. High surface strength after installation - plywood is much stronger than drywall. The low weight of the material makes it easier to transport, loading and unloading and installation. Wood has high sound-proofing properties, which is important when installing floors. After finishing the work, you get a flat surface that can be finished at your discretion. Low price of the material - there are several grades, and you can choose the best option in accordance with the specifics of use. For example, if plywood serves as a base for flooring of another material, then you can purchase products of a lower grade and cheaper.

The lower the grade, the lower the cost

Plywood ceilings

The ceiling covered with plywood sheets has an attractive appearance; with the help of this inexpensive material, an original stylization of a room or even an attic is carried out. The main advantage is its low weight and the ability to create different shades using stain.

Strict and at the same time cozy living room interior Source sdelaipotolok.com

See also: Catalog of companies that specialize in interior redevelopment.

For ceilings, sheets of grades I and II are used, which are distinguished by a neat, uniform pattern with a small content of defects (color differences, healthy knots). The fastening is carried out on a frame made of metal profile. Please note that when covering, the ceiling level will decrease by 5-10 cm. Therefore, interior design from plywood is not recommended for rooms with low ceilings.

Preparing and installing the frame for plywood

Even before assembling the frame, the surface must be cleaned of old materials and the cracks present in it must be covered with a solution. If you plan to use insulation, then it is necessary to knock down and level all the bumps and protrusions, and then prime them with an antifungal primer.

Then the strapping is assembled, which runs along the perimeter of the wall. To create it, a beam with a cross-section of 5–8 cm is used. Next, racks and horizontal jumpers between the racks are installed, located in increments of 50–70 cm and adjusted to the size of the sheets so that the joints of the sheets are in the middle of the beam. The timber is pre-treated.

If the owner wants to get higher insulation, he can lay mineral wool, polystyrene foam or extruded polystyrene foam inside such a frame.

After laying the mineral wool insulation, the entire structure is sheathed with a vapor barrier or foil foam. If the thickness of the mineral wool is equal to the thickness of the block, then 1.5-2.5 cm thick slats are placed on the frame and vapor barrier for air circulation and then plywood is attached. If the thickness of the insulation is less than the thickness of the frame, the vapor barrier should fit tightly to the mineral wool and bend around the relief of the sheathing.

You can learn more about how to install a wooden frame on a wall for cladding by reading the article Cladding walls and ceilings with clapboards with your own hands.

If you wish and have sufficient experience, by covering walls with plywood using a frame method, you can make various structural solutions, just like when using plasterboard. For example:

-various protrusions, protruding boxes for hiding pipes,

-nisshi in the wall – False window in the interior with your own hands,

- suspended, two-level or combined ceilings.

I think you understand my train of thought, and then everything depends on your imagination.

We fix the plywood to the wall frame

The surfaces of plywood sheets adjacent to the wall must first be sanded.

The plywood sheets are not fastened end to end; there should be a damper gap of a couple of mm between them, the joints of which are subsequently sanded and puttied.

Self-tapping screws are used to install plywood sheets. Each sheet is attached to all elements of the frame structure. The fastening elements must be positioned at a maximum interval of 30 cm. Otherwise, the sheathing will not be rigid. Plywood sheets cannot be fixed flush to the ceiling or walls. It is necessary to leave a small gap of 2–3 mm.

Plywood floor

Plywood is often used as a base for parquet, carpet, laminate and other floor coverings. It can also be installed as a finished floor - it has the required strength, and its appearance is quite suitable for these purposes.

There are several ways to use plywood sheets for flooring:

- For an interior in the “Loft” style with plastered or brick walls, the surface of the sheet may not be decorated. The sheet is simply attached to the subfloor, varnish is applied - durable, wear-resistant and a beautiful floor is ready. This solution is perfect for wooden houses - sheet material is several times cheaper than natural wood and its use allows you to save a lot.

The more interesting the texture of the sheets, the more expressive the floor Source presstile.ru

- An equally effective option is the use of impregnations that darken the floor and give the surface a luxurious look. Preferably polyurethane-based impregnations are used, which have high wear resistance.

The right shade will make the floor luxurious Source pilorama-chita.ru

- A good solution is to paint the sheets in different colors - this makes the floor unusual. For example, you can decorate a child’s room or any other room in which a plywood floor would be appropriate. The choice of colors is unlimited; they are selected depending on the interior.

Multi-colored floor - why not Source www.pinterest.ph

- Another option that requires patience and free time is to lay sheets cut into squares like tiles . This floor looks original and impressive. The disadvantage is the low moisture resistance of the coating, due to the large number of joints and seams.

Rules for installing plywood sheets

Installation is carried out on a frame, the elements of which are ordinary wooden slats. The dimensions are selected based on whether insulation will be placed under the sheets or not. If “YES”, then the height of the slats is selected taking into account the thickness of the heat-insulating material. They should be 1 cm larger. Although this parameter can be beat with direct hangers used for installing and fastening frame elements. If “NO”, it is better to choose slats that are not the largest in height, so as not to reduce the distance between the walls.

Frame assembly

Regarding the installation of slats, direct hangers used for installing drywall are used for this. The slats are set vertically, the distance between them is determined by the size of the plywood sheets. There are several positions here, common sizes: 1500x1500, 2500x1250, 3000x1500 mm.

Frame for plywood cladding

For example, if the first position is used, then the distance should be 750 mm - this is the maximum, because the sheet material must lie on at least three slats: one in the middle, two at the edges. Two more recommendations:

- Two adjacent sheets must be joined on one strip.

- A gap of 0.3-0.5 mm is left between the sheets of plywood in case of thermal expansion of the material.

First, vertical lines are drawn on the wall, defining the installation locations of the frame elements. Straight hangers are mounted along them every 40-60 cm, secured to the wall with self-tapping screws and dowels. You will have to turn on the hammer drill.

- The two outermost slats on the wall are installed.

- They are placed in the same plane using a thread and a level.

- Both elements are immediately attached to the hangers.

- 3-5 threads are stretched between them, defining the plane of the future plywood wall.

- Intermediate slats are installed along them.

The frame is ready, all that remains is to treat it with an antiseptic composition that prevents the formation of fungi and mold.

Insulation between frame elements, covered with a waterproofing membrane

A few words about the thermal insulation material and its installation. Most often, mineral wool in mats is laid under plywood. This is a hygroscopic material, so it must be covered on both sides with protective films: against the vapor barrier wall, against the waterproofing plywood.

If the wall is wooden, then the vapor barrier is applied to it in strips with an overlap of 10-15 cm. If the wall is brick or block, then the frame is first mounted, then the vapor barrier layer is laid so that the membrane forms cells between the slats. Next, thermal insulation material is laid, and a waterproofing film is placed on top of the slats.

The insulation is cut so that it fits tightly between the slats, pressing tightly against the frame elements. This solves the problem of the absence of cold bridges.

If the walls of the house are smooth, the sheathing can be installed without hangers. The slats are attached directly to the wall with self-tapping screws and dowels. In this case, you can use a vapor barrier laid directly along the wall, which will adhere to the surface with slats. Most often they use penofol (foamed polyethylene with a foil side), which is two in one: insulation, insulation.

Wall covered with foil insulation

Installation of plywood panels

We move on to the final stage of finishing the wall with plywood sheets - installing the sheet material itself. There are no strict requirements here. Simply, each sheet is laid on the sheathing and attached to it with self-tapping screws: along the edges every 15-20 cm, in the middle every 30-35 cm. A distance of 1.5-2 cm should be maintained from the edge of the sheet to the place where the screw is screwed in. In this case, all fasteners must be located on the same line, so these lines are first applied to the plywood. To increase the aesthetics of the cladding, it is recommended to widen the outer edges of the hole for fasteners with a drill with a diameter equal to the diameter of the screw head. Thus, the latter will not protrude beyond the finishing.

If the plywood is not finished with finishing materials, then you need to adjust their sizes and shapes strictly to the place where they are laid in even rows. Everything should turn out symmetrical. As for the seams between the sheets. They should not be filled with putty, which, under the influence of thermal expansion of the plywood, will begin to crack and peel. The best option: sealant, decorative strips (wooden, metal). The plywood joints near the floor are covered with skirting boards, and at the ceiling with cornices. The screw caps are covered with plastic decorative caps.

Installation of plywood sheets is a simple processPlywood Home Decor

Using plywood you can easily decorate any room. Lamps illuminated from different sides, stylish lampshades, and sconces are made from it. Other items created from plywood sheets are no less popular:

- three-dimensional silhouettes of people and animals;

- curly inscriptions;

- key holders and hangers for hallways;

Hangers of unusual shapes are a wonderful interior decoration Source www.thecollection.fr

- screens for heating radiators;

- lambrequins for curtains;

- stylized shelves for flowers and books;

- clocks and calendars;

- coffee and tea stands;

- figurines with movable parts, music boxes

Cute plywood trinkets Source pinterest.com

Installation of plywood panels

Rough wall cladding is not a complicated process: the work is not painstaking and does not require special precision.

- The sheets are sewn to the wall vertically. If the geometry of the room is incorrect, each plywood sheet on top will have to be adjusted individually, coordinating the dimensions each time.

- Covering the walls with plywood begins from the corner of the room.

- The first sheet is placed against the frame, and checking the vertical level, it is baited in 2-3 places.

- The sheet is fastened with self-tapping screws so that it fits into the wooden frame by at least 2-3 cm. The fastening step is about 15 cm - you should not split it.

In order not to miss and hit the frame, you need to make the appropriate marks at the top and bottom. Also, for convenience, you can pull the twine and navigate along it. If you are not sure where the frame lath is located under the plywood, you can lightly tap the plywood sheet at the expected location with a hammer and determine the location of the bar by the sound - the sound will be muffled.

- When installing the following sheets, you should not strive to reduce the joint gap: 2-5 mm. acceptable, since wood requires a thermal gap.

- All subsequent sheets are attached in the same way.

An interesting solution for a country house

Plywood in children's rooms

Plywood easily transforms a little tomboy's room. For example, you can purchase and install a compact rack for books, toys or souvenirs in a place convenient for the child. The following items will also fit into the overall appearance of the room:

- multifunctional cabinet furniture;

- sets for games (bedside table for toy instruments, store display);

- desks - play furniture with stands for markers, sorters, paper clips;

- furniture for dolls (tables, chairs, cradles);

- houses designed for storing and conveniently placing soft toys, cars, dolls.

Children's room made of plywood - what could be better Source csi-interior.ru

Materials used for painting and impregnation of children's sets must be absolutely safe and odorless.

Using plywood for interior work

Inside the house, laminated veneer sheets are widely used for covering the main surfaces - walls, floors, ceilings. The scheme of work is similar, but there are some differences.

Leveling concrete and wood floors

Properly laid plywood is a good base for a finished floor covering. The rough flooring made from this material is durable, wear-resistant and smooth.

There are several ways to level the floor with plywood:

- Secure it to the old wooden flooring using self-tapping screws.

- Glue the sheets onto the concrete base.

- Lay the sheet material on the anchor studs pre-installed in the concrete floor.

- Cover it with a wooden frame made of joists.

On the leveled floor you can lay linoleum, laminate, parquet or lay ceramic tiles.

Wall and ceiling cladding

The finishing of plywood walls and ceilings in a wooden house is carried out using the same technology. It consists of installing a frame, which is then sheathed with sheet material. The finished coating can be rough or fine. It all depends on what type of material was used.

Work on finishing walls with plywood is carried out as follows:

- Prepare the base - remove old material, level the surface.

- Mark the work area.

- Install a sheathing made of wooden beams or metal profiles. In the latter case, special hangers will be needed. The pitch between the sheathing elements should be equal to ½ the width of the sheet or the width of the insulating mat.

- Check the sheathing using a building level.

- Attach plywood sheets to the sheathing.

- Process the sheathing joints.

Note! If you want to use decorative plywood, then during installation you need to take into account the presence of special interlocking connections on the sheets

Making a door with your own hands

A neat interior door made of plywood, varnished or painted, is a good solution for both a country house and a city apartment.

You can do the work yourself as follows:

- Measure the doorway.

- Cut the door leaf according to the obtained dimensions.

- Along the perimeter of the future door, slats are glued or secured with self-tapping screws.

- The same slats are used to make lintels along the door leaf. They are needed to give the product rigidity.

- Using a chisel or machine, make a hole for the lock and handle.

- The door is sanded and varnished.

If you need a double door with insulation, then first a frame made of wooden blocks is assembled for it. Then, on one side, it is sheathed with sheets of laminated veneer, and insulation is placed in the resulting cells. They sheathe the second side of the door.

You can also make a shelf, rack, chest of drawers, or coffee table from plywood. This material gives many opportunities for creating beautiful things and interiors. The main thing is to choose it in accordance with the tasks.

Plywood furniture

The love for plywood design came to us from Scandinavia - in this region, almost all the furnishings of houses and apartments are made from sheet material.

For many, the combination “kitchen made of plywood” will seem somewhat strange, but, nevertheless, there is a huge selection of sets on sale that can last no less than traditional options. To create kitchen furniture, material is used that has been treated to increase moisture resistance with various impregnations. You can purchase a ready-made kit or order its production according to your own design.

Kitchen furniture made of plywood - inexpensive and stylish Source architizer.com

Chests of drawers and bedside tables made of plywood look no less impressive. The main thing is to choose the right size so that the items do not look too bulky. Objects are not painted, as paints and varnishes will hide the texture and deprive them of their natural appearance.

An elegant chest of drawers will decorate any room Source www.livemaster.ru

The choice of chairs and stools is huge - from portable folding ones to those that seem massive and heavy. It’s enough just to choose a configuration that fits organically into the interior.

Original plywood furniture will become a real interior decoration Source et.dikidaycare.com

An equally popular option are various plywood shelves. Their cost is minimal, wall mounting is standard, and their appearance is attractive.

You can create shelves of complex shapes from plywood Source stroitelcentr.ru

Lately, designer plywood furniture has enjoyed incredible success. The secret of its popularity lies in the implementation of original ideas and the production of a set in a single copy.

Plywood is the favorite material of designers Source ar.pinterest.com

Types of plywood - their properties and scope of application

Plywood is classified according to several criteria. These are the moisture resistance of the material, scope of application, grade, processing method.

Classification criterion - moisture resistance

The degree of moisture resistance depends on the adhesive composition used. The most moisture-unresistant varieties of plywood are those for the production of which albumin-casein adhesives are used. The finished FBA brand material is environmentally friendly, but impractical. Urea compounds provide a low level of moisture resistance of sheet plywood. It is safe, but is only suitable for the manufacture of certain pieces of furniture, packaging containers and interior decoration of “dry” rooms. The material is marked with the FC marking.

If the veneer layers are glued together with a melamine compound, then the FKM marking is made. The finished sheets are characterized by average moisture resistance and safety. When heated, formaldehydes are released from melamine resins, but they are not as dangerous to humans as phenols. The latter are not found in FCM plywood.

FSF brand material is highly moisture resistant, but is not recommended for use inside the home. Toxic phenol-formaldehyde adhesives are used as a binder. FS grade plywood is even more resistant to moisture. Its layers are connected with bakelite glue. The material can be used in aggressive conditions of the sea, tropics, and northern regions.

Types of plywood - what distinguishes them from each other

The grade of plywood determines the quality of its surface and the raw materials used for production. Grade is assessed by the outer layers of veneer.

- Grade E – material with a smooth surface, without deformations, cracks, or chips. It contains no harmful impurities or foreign inclusions. These are the highest quality sheets.

- Grade I (first) – assumes the presence of no more than three minor defects. These can be: edge defects up to 2 mm, pin knots, closed cracks up to 200 mm, falling knots.

- Grade II (second) is plywood with no more than six defects. In addition to the disadvantages of the first grade, these include: minor dents, scratches, glue seepage up to 2% of the sheet area, veneer overlap and discoloration of plywood.

- Grade III (third) assumes the presence of no more than nine material defects. These are widening cracks, even greater leakage of glue, torn fibers, and falling knots.

- Grade VI - these are the obvious above-mentioned defects, wavy and fleecy surface, wormholes on the outer layers of veneer.

A detailed description of each variety can be found in GOST 3916.1-96, however, their visual differences will not allow you to make a mistake in your choice.

Types of plywood depending on the scope of application

All plywood is divided into construction, decorative, and specialized. The scope of application of laminated veneer sheets is the construction of frame and prefabricated panel houses, carrying out interior finishing work. The thickness of such material can reach 19 mm. This is necessary so that the plywood walls can withstand heavy loads.

Unlike construction plywood, decorative plywood is intended for finishing interior surfaces of premises and making furniture. Its outer layer can be decorated with: tinting, carving, laminating layer, polymer film. Often the surface is artificially aged. One type of decorative material is bent plywood, which is made in a factory using molds. The bending value can reach 15 cm. This material is perfect for creating arched structures.

Note! You can bend plywood at home by cutting or steaming the bend. Engineered boards, boats and boxes for transporting large loads are made from specialized sheet material.

Engineered boards, boats and boxes for transporting large loads are made from specialized sheet material.

Plywood panel

Rooms decorated with plywood panels look unusual. These are made quite simply: paintings and scenes are printed on a sheet, burned or cut out.

You can purchase a multi-level or flat panel, color or monochrome. Interesting applications made of cardboard, fabric, or leather can additionally be glued to the sheets.

Plywood panels are an excellent option for wall decoration Source khaleejesque.com

What else is made from finishing plywood?

Plywood is such a versatile material that you can make anything out of it.

For example, original stands for bowls will make the life of pets even more comfortable. You can choose a folding or non-folding design, choose the color and size depending on the interior and the available free space.

Your pet's favorite piece of furniture Source www.kb-zigzag.ru

Plywood also makes original door handles. They can be either single-sided or double-sided, painted or simply impregnated with special compounds.

Door handles in a simple style Source sudokuweb.ru

Elegant wine stands will become a real decoration for the interior of your living room or kitchen, or an original gift for any occasion.

Original wine coasters are a great gift Source projbuild.ru

Bathroom mirrors look no less original and fit perfectly into any design.

Stylish mirror with plywood shelf for the bathroom Source stapico.ru

Garden furniture is also popular. For example, a light and airy plywood swing chair.

A chair-shaped swing will become a real decoration for your garden plot. Source instaphenomenons.me

Plywood doors, which are an excellent alternative to natural wood products, belong to the middle price segment. You can easily purchase both solid models and those with glass or inserts made from other materials.

Plywood doors - inexpensive and beautiful Source the-dots.com

The advantages of such doors include light weight, original appearance and low cost.

Advantages and disadvantages of the material

When answering the question about the advantages of wood sheets, one cannot help but note their cheapness. At the same time, the inexpensive building material is ideal for various jobs. You can use it to assemble reliable beds, cabinets, tables, or create stylish interior decoration. Other benefits of wood sheets include:

| A wide range of | The materials differ in composition (types of wood used), grade, size, surface (polished or unpolished). |

| Ease of preparation | You can cut and glue the material together without special skills. |

| Wear resistance | They are resistant to minor mechanical stress and do not require special care. |

The disadvantages of the material include the inability to use in rooms with high humidity. Even moisture-resistant types, when exposed to water, can emit harmful fumes due to the presence of glue.