- Decorative plaster

- Venetian plaster

- Textured plaster

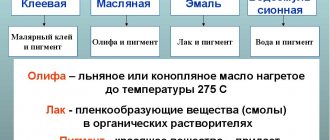

- Decorative paint

Repair or decoration in the modern world is rarely complete without decorative plaster. In an effort to improve his home, a person calculates every finishing material as much as possible. The vast majority of people choose ease of installation, forgetting about performance characteristics and service life. In addition, the choice is limited to several types of wallpaper, which do not always harmonize with the interior decor. This article contains details about decorative, structural and Venetian plasters, how to properly finish with decorative plaster, as well as where and how to buy high-quality decorative coatings at affordable prices.

What is decorative plaster?

Decorative plaster is a ready-to-use composition intended for finishing walls and ceilings, as well as decorative and architectural interior elements. After application to the walls, this liquid composition hardens and over time turns into a durable monolith. In other words, decorative plaster is an alternative to wallpaper, liquid wallpaper, and painting. Decorative coatings differ in composition and purpose. Let's tell you a little more.

Let's find the difference between liquid wallpaper and decorative plaster

With the advent of liquid wallpaper on the market of construction and finishing materials, they have become a huge competitor to finishing with decorative plaster. Owners of houses and apartments have a question: what to choose? Let us describe a brief comparative description.

Characteristics Decorative plaster

- Suitable for all interior styles ★

- Environmental friendliness, safety ★

- Vapor permeability ★

- Protection against mold, mildew ★

- Advance preparation required ★

- Easy to apply/install ★

- Possibility of applying it yourself ★

- Presence of seams, joints ✘

- Resistant to shocks and scratches ★

- UV resistance (fading) ★

- Number of wet abrasion cycles from 10000

- Non-flammability ★

- Maintainability ★

- Lifespan 15-20 years

- Cost of finishing material for 1 sq.m. from 200 to 1500 r/m2

- Variety of colors and textures More than 90 colors and different effects depending on the application method

Characteristics Liquid wallpaper

- Suitable for all interior styles ✘

- Environmental friendliness, safety ★

- Vapor permeability ✘

- Protection against mold, mildew ✘

- Advance preparation required ★

- Easy to apply/install ★

- Possibility of applying it yourself ★

- Presence of seams, joints ★

- Resistant to shocks and scratches ✘

- UV resistance (fading) ✘

- Number of wet abrasion cycles 5-100

- Non-flammability ✘

- Maintainability ✘

- Lifetime 3-10 years

- Cost of finishing material for 1 sq.m. from 50 to 2500 RUR/m2

- Variety of colors and textures On average 20 shades in the collection, few solid colors

Many construction portals describe the “mythical advantages” of liquid wallpaper, such as resistance to shrinkage of the house. The fact is that the house cannot shrink; in principle, it does not dry out. And if precipitation does occur, it will tear any material (except for wallpaper, which will simply peel off a little at the tear site). In addition, another dubious plus is that liquid wallpaper can be easily removed from the wall. The logical question is - why? There is no need to remove decorative plaster, because its beauty and aesthetics never get boring. If this does happen, you can initiate a small cosmetic repair and simply change the color of your coating directly on the wall.

The main difference between finishing with decorative plaster and liquid wallpaper is environmental friendliness. Liquid wallpaper is paper, thread and a binder, and decorative plaster is water and natural marble components.

Whatever material you use to create your interior, it will always have strengths and weaknesses. The strengths of decorative plaster include:

- Versatility

- applied to any substrate: aerated concrete, brick, plasterboard, concrete, wood, etc. - Plasticity

- some decorative putties can hide even significant defects. - Impact resistance

– coatings are not afraid of mechanical stress. - Durability

– service life exceeds all finishing analogues. - UV resistance

- the color does not fade or fade during the entire service life, thanks to imported high-quality colorants. - Integrity

- due to the absence of joints and seams, a beautiful, aesthetic and modern interior is obtained.

Additional advantages of decorative plaster

- The environmental friendliness of decorative plasters allows them to be used in bedrooms and children's rooms.

- Moisture-resistant properties prevent destruction when exposed to high levels of humidity, which allows the decor to be used in bathrooms and pools.

- Vapor permeability creates protection against the emergence of microorganisms.

- Easy to clean - no chemicals required, decorative coatings do not attract dust and dirt.

- Facade plasters can withstand temperature changes and aggressive weather conditions. Operating temperature -40 - +60°C.

- Variability in the implementation of design ideas and elements.

Additional disadvantages of decorative plaster

- High cost of decorative materials, as well as finishing work.

- The technology for applying certain types of decorative plasters is impossible without the involvement of specialists.

- Thin-layer mixtures require ideal surface preparation (as for painting)

- The completion of all dust-generating work is required, as well as compliance with a number of rules when decorating.

- It is not recommended for use in new buildings that have not completed the settling process, there is a high probability of material ruptures after drying

Types and types of decorative materials

Decorative plaster is divided into smooth (Venetian) and textured.

Textured plaster. Includes several materials with different, but clearly defined textures (relief, structure). It is used indoors and outdoors, and some are used on facades and can withstand harsh operating conditions. A facade made of decorative plaster is a reliable, high-quality and cost-effective alternative to tiles and stone. Textured plaster is popular not only because of its unusual appearance, but also because of a number of properties:

- Used for interior and exterior decoration

- Huge selection of colors, their combinations, various structures and reliefs

- Most of the existing coatings can be applied with your own hands, thanks to simple technology

- Suitable for walls, ceilings and various design elements

Smooth (Venetian) plaster. This type includes almost all thin-layer putties, paints, Moroccan plaster, and Venetian coatings. There are many more varieties of them than textured ones, but they are inferior in number and options for decorated effects. Main characteristics:

- Used only for interior work

- Can be used in rooms with high humidity only when treated with protective varnish or wax

- Resistant to cleaning, including detergents

- They are combined not only in colors, but also in effects

Types of polymer plaster

Each synthetic plaster contains polymer components at its base, which determine its properties. According to the classification by composition, there are acrylic, silicone, silicate, siloxane and some other types of plasters.

Acrylic plaster

This material is the most popular among polymer plasters. Acrylic building mixture consists of polyacrylic resins with the addition of fillers, dyes, and modifying components. After application, the water evaporates, polymerization of the resins occurs, forming a durable, moisture-resistant, but vapor-permeable structure. Simply put, the hardened layer of acrylic plaster is not afraid of water, but partially allows gases to pass through, so it does not disturb the microclimate in the room and does not cause dampness on the walls.

Acrylic plaster has other advantages:

- easily connects to concrete and other mineral substrates;

- suitable for interior and exterior decoration, most often contains frost-resistant additives;

- does not deteriorate from exposure to ultraviolet radiation, almost does not fade in the sun;

- includes substances that increase fire resistance;

- makes it possible to wash off the unsuccessfully applied area with water and apply a new layer;

- has sufficient elasticity, so it does not crack from vibration or base displacement.

Facade plaster LITOTHERM FACTURA ACRYL

Acrylic plasters also have a number of negative properties. So, if you do not prime the porous base, moisture will be drawn out of the plaster even before the resin polymerizes, which will disrupt the natural drying process. It is advisable to use deep penetration primers, and apply at least 2 layers (we are talking about concrete and brick surfaces).

Acrylic resins themselves are flammable, so manufacturers add special additives to plasters that reduce the risk of fire. However, it is not recommended to apply mixtures to surfaces located near open fire. A dried layer of acrylic plaster attracts a lot of dust due to its tendency towards strong static, and surfaces will have to be cleaned more often. Another negative quality is associated with the need to apply the material without long breaks in work. Otherwise, ugly boundaries will appear between individual areas.

Silicone plaster

The composition of this material includes silicone resins, modifiers, emulsifiers, as well as structural fillers - stone chips, mineral flour, quartz sand and others. The cost of silicone mixtures is an order of magnitude higher than the price of acrylic ones, but the quality is also at the highest level.

Plasters with silicone are highly elastic. The coating formed by them is capable of serious stretching, so it will not crack even with significant shrinkage of structures or shifts, which are typical for seismic zones. Silicone mixtures have a lot of other positive qualities:

- universal in use - suitable for outdoor and indoor work;

- frost-resistant, weather-resistant, withstand regular exposure to precipitation and wind;

- serve for decades without loss of aesthetic properties;

- have high vapor permeability, while literally repelling water and creating a waterproofing coating on the surface;

- boast excellent adhesion to a wide variety of building materials;

- resistant to ultraviolet radiation, do not fade, their color does not fade;

- they have no restrictions on the thickness of the finishing layer (after all, they often act as a thin-layer coating due to the high cost);

- withstands heat and temperature changes, does not soften after complete polymerization;

- durable, do not respond to moderate mechanical loads;

- strengthen weak foundations and extend their repair-free service life.

Decorative coating based on silicone Baumit

Silicate plaster

This plaster is based on molten (liquid) glass. May include mineral fillers, coloring additives, plasticizers, modifiers. Typically, silicate plasters are used for exterior work because they have increased resistance to damage, abrasion, and wear. They are incredibly resistant to temperature changes, any precipitation and wind, and aggressive operating conditions.

Silicate mixtures are often used to insulate rooms, because they have excellent thermal insulation abilities and also enhance sound insulation. The plasters are waterproof, but allow air and moisture vapor to pass through, so they are suitable for all rooms without restrictions. The minimum service life of the finished layer is 20 years. The adhesion of silicate mixtures to concrete, brick, and any insulation materials is considered maximum. They are not subject to dust and contamination, do not support combustion, are fireproof, and dirt can be easily washed off from them.

Among the disadvantages of such funds it is worth noting:

- short pot life of the finished mixture, difficult to apply for beginners;

- medium elasticity;

- poor color range;

- high price;

- tendency to color fading.

Silicate plasters are produced not only in finished form, but also in the form of a dry construction mixture, so you can choose a convenient option in terms of volume and cost.

Siloxane plaster

Siloxane's chemical structure is similar to silicone, representing its “immature” version. It is the siloxane molecules that become silicone after combining. Most silicone plasters additionally contain acrylic, and in larger quantities. In fact, acrylic plays a dominant role in such building mixtures, and siloxane is intended to form a thin waterproof film on the surface of the plaster layer.

Silicone plasters are cheaper than silicone plasters, but do not provide protection from moisture throughout their entire thickness. When used outdoors, surface waterproofing is gradually destroyed under the influence of ultraviolet radiation, and the moisture resistance of the coating drops sharply. Due to their short service life, siloxane-based materials should be used only indoors, or the finish should be regularly updated.

Facade siloxane mixture Dufa Premium

Polymer cement plaster

As is known, strong and reliable cement plasters have a number of significant disadvantages. The disadvantages of such building mixtures are poor elongation, susceptibility to cracking from shrinkage and vibration of buildings. To level them out, polymer-cement plaster was developed, which is a mixture based on cement and at least 30% polymer fibers. In such material, the following indicators seriously increase:

- tensile strength, bending strength;

- resistance to abrasion, cracking;

- adhesion to building materials;

- plasticity and elasticity;

- workability;

- heat resistance.

Leveling polymer-cement composition Effect Euro-L

Polymer-cement plasters can be applied in a fairly thin layer while maintaining the performance and protective properties of the coating. They cover cracks, joints, holes and seams and are used for restoration work. Mixtures are produced only in dry form, because cement hardens quite quickly after contact with water. The price of the compositions is lower than that of other polymer plasters, so this finishing option is considered economical.

Polymer decorative plaster

Various polymer building mixtures are considered decorative, which, in addition to the base, contain a structural filler or are pigmented. The following additives can act as fillers:

- pebbles, ground stone or stone flour;

- different types of sand;

- expanded clay and vermiculite;

- artificial fibers;

- shells or their fragments;

- mica;

- metal dust;

- flocks.

Decorative polymer plaster can be finely dispersed or contain inclusions of a larger fraction. The aesthetic effect is created thanks to the color of the plaster, the interesting shape of the filler, and special techniques for finishing the layer. The material may be uniform in texture or contain inclusions of different sizes (small and some larger ones). Examples of possible polymer plaster textures are:

- roughness, or “goose bumps” effect (obtained from fine-grained plaster);

- relief (created with a roller, brush, notched trowel);

- “bark beetle” (formed by grinding a mixture with large granules).

Application of decorative plaster

According to this characteristic, decorative plasters are used for interior and exterior work.

In turn, decorative plaster is divided into types: External plaster. One of the simplest ways to create a beautiful and attractive facade of a house is to cover it with decorative plaster. Unlike simple painting, a decorative layer will eliminate minor surface defects, improve the heat and sound insulation parameters of the walls, and also protect your home from adverse weather influences.

External decorative plaster

One of the simplest ways to create a beautiful and attractive facade of a house is to cover it with decorative plaster. Unlike simple painting, a decorative layer will eliminate minor surface defects, improve the heat and sound insulation parameters of the walls, and also protect your home from adverse weather influences.

Interior decorative plaster

In order for your interior to become truly unique, luxurious, and at the same time have high performance characteristics, decorative plaster is used. Creating unusual effects such as polished marble, crocodile skin, tree bark, wet silk, craquelure, frosty frost and others depends on the material you choose. Such coatings will not be able to hide defects, so high-quality preparation is required.

Acrylic decorative plaster

Acrylic plaster is made from an aqueous dispersion of acrylic polymers. The fillers are crumbs and granules of natural stones - marble, granite, slate, pebbles, etc. The resulting surface can be smooth, rough, or voluminous.

Supplied in buckets from 9 to 45 kg. The most popular container is 25 kg, since with it you can easily climb scaffolding. Its price depends on the chosen material, the amount of work and tinting, ranging from 1600 to 6500 rubles per bucket. Supplied in white, tinted according to international tinting catalogs (NCS, Ral, Nova, etc.) or painted after drying.

The excellent mobility of the solution, ease of application and versatility of acrylic compositions have made them the most popular among decorative materials.

Also, acrylic decorative plasters combine the following qualities:

- Resistant to climatic fluctuations and factors (sultry summer, severe winter, rainy autumn, etc.). These criteria allow it to be used both inside buildings and on facades

- Excellent thermal insulation properties

- The plasticity of the material will hide minor defects and cracks, and the elasticity will prevent the appearance of minor cracks at the slightest settlement of the building

- The service life of coatings is more than 15 years

- Environmentally friendly. The base contains no phenols, resins, or volatile alcohol compounds

- Vapor permeability will allow the facade to “breathe”, preventing the “greenhouse effect” and the appearance of microorganisms

- Easy to care for – easy to clean, including with a stream of water under pressure. In addition, the façade is self-cleaning in rainy weather.

Among the disadvantages:

- Higher price compared to mineral base

- When working with some plasters, an experienced craftsman is required

- High electrostatic ability, attracts dust to the surface

When buying acrylic decorative plaster for finishing, be sure to check its expiration date!

Silicate plaster

This plaster contains liquid glass silicates of potassium and sodium. Manufacturers also add mineral additives and color pigments. The chemical composition is alkaline and requires compliance with safety precautions. Work should be carried out wearing gloves, protective clothing and goggles.

This type of plaster is applied to aerated concrete, mineral bases made of plaster or putty. It is used mainly on the facade, and in the interior the use is limited due to the presence of dangerous additives in the composition.

The main advantages can be considered:

- Vapor permeability. That is why the use of this composition on aerated concrete is justified.

- Moisture resistance and frost resistance make the coating most suitable for loose and porous substrates, including insulation.

- Elasticity. When applying the solution, no cracks or sagging are formed.

- High hardening speed. The advantage is relative, because rapid setting of the solution requires the involvement of specialists who work quickly and efficiently.

- Long service life (from 30 years)

- UV resistance.

- The antiseptic effect is convenient because mold will not appear on the surface.

The disadvantage of silicate plaster is the need to use a silicate primer before applying the finishing composition, because good adhesion occurs only on mineral or silicate bases. And this is an additional cash expense.

Also, with relatively good resistance to UV radiation, dark colors of plaster will still fade.

In addition, the cost of silicate plaster is quite high compared to acrylic, for example.

One of the features of silicate plaster is its ability to harden quickly. We have already mentioned this. Just 2-3 hours of unused mixture and it becomes unusable for application. Therefore, this stage must be entrusted to professionals.

In stores you can find one of the varieties of silicate plaster - silicate-silicone, which got its name due to the addition of silicone resin to the emulsion base.

In addition to liquid silicone, the mixture includes an aqueous solution of acrylic resin, a water-repellent additive, mineral filler, modifiers and coloring pigments.

This solution is perfect for bathrooms or kitchens, because it has increased moisture resistance, antiseptic effect and durability.

Silicone decorative plaster

Silicone decorative plaster was developed specifically for facades. It has increased vapor permeability. It is the silicone base that is recommended for the “wet facade” system. In addition, its properties do not exclude indoor use.

It is produced, like acrylic, in a ready-to-use form, packaged from 15 to 45 kilograms. The high cost is due to the supply of silicone resins from European countries. A 25kg bucket costs from 3,000 to 9,000 rubles, also depending on the coloring and the amount of work. Decorated effects – bark beetle, fur coat, lamb.

The price of silicone decorative plaster is its only drawback. But among the advantages we highlight the following: Self-cleaning due to weather precipitation.

- High resistance to ultraviolet radiation

- Frost resistance. Not afraid of sudden temperature changes

- Does not collapse when saturated with water

- Vapor permeability eliminates the occurrence of microorganisms such as fungi and mold

- Extended service life - manufacturers claim at least 25 years

- No perfect surface preparation is required - the plaster covers minor defects and cracks

It should be remembered that silicone plaster is applied to the reinforced layer after installation of insulation - high-density mineral wool slabs.

Before you buy silicone plaster, make sure that your facade requires its use. If your house is built from vapor-permeable materials and insulated with mineral slabs, this is necessary. In other cases, you should not overpay, an acrylic composition is enough.

Preparing walls before plastering

It is important to remember that the building must be completely settled and other types of work completed before applying mineral plaster. Failure to comply with this requirement may result in cracking of the finished façade.

To prepare the walls, you need to clean them from dust and dirt with a wire brush. If soot is present, it must be removed with a 3% solution of hydrochloric acid, and then rinsed with water. Oil stains should be covered with greasy clay. After complete drying, the clay must be cleaned off and the wall washed with water. Cracks and irregularities must be covered with cement mortar. Notches are applied to the prepared wall for better adhesion of the plaster to the base. After this, a primer is applied, and it is worth choosing a primer composition with an antiseptic effect to better resist fungi and mold.

If plastering will be carried out over insulation, it is necessary to install a plaster mesh. Having diluted the composition according to the instructions and wetted the tools, you can begin to work. It must be remembered that the plaster mixture must be prepared immediately before application. The finished plaster should sit for 10 minutes, after which the thickness should be of a creamy consistency.

Mineral decorative plaster

Mineral plaster is a dry mixture, for use you only need to add water. Its composition is cement, sand, fillers made from natural stones similar to other bases, and various plasticizers and additives.

It is also sold dry, in 25 kg bags, prices vary from 450 to 2700 rubles, depending on the brand and its quality.

According to the type of pattern, mineral plaster is divided into:

Pebble "Lamb"

Plaster "Bark beetle"

Plaster Odyssey “Fur coat”

Advantages of mineral plaster

- Price. Finishing with mineral plaster is the most economical and budget-friendly

- The strength characteristics of mineral plaster are the highest, since the binder is cement

- Impact resistant

- Resistance to negative weather factors, moisture, water and frost

- Environmentally friendly - contains only natural ingredients

Disadvantages of mineral plaster

- Not tinted. Subject to subsequent painting

- Any deviation from the instructions will render the material unusable for use.

- A skilled craftsman is required, as mineral plaster sets very quickly

If you decide to save money on the facade, hire a professional to finish it, as there is a risk of ruining the work and paying for the material twice. In addition, mineral plaster is very limited in choice.

Silicate decorative plaster

Thanks to the use of sodium and potassium silicates, this type of plaster received the name “silicate”. The properties of these binders are close to sodium formate (liquid glass). As with similar compositions, it includes marble, quartz, granite and slate fillers.

Produced and supplied in standard containers from 15 to 40 kg, the cost of 25 kg is from 2200 rubles. up to 7,000 rubles, depends on the manufacturer’s product brand.

Advantages of silicate plaster

- High strength

- Resistance to changeable and harsh weather conditions

- Durability over 15 years

- Easy to maintain, can be cleaned with non-abrasive detergents

- More favorable cost compared to acrylic analogue

Disadvantages of silicate plaster

- Higher work speed is required, since silicate plaster dries extremely quickly

- It does not tint well, so it is most often applied in white and then painted

- Does not have vapor permeability

Some manufacturers combine silicate and silicone bases in order to confuse the buyer, who unknowingly believes that such a combination is vapor permeable, but even the brands themselves position them as not having vapor permeability.

Technique for applying mineral plaster

1. Interior decoration of the room.

For interior work, it is necessary to spread the plaster in a thin layer not exceeding the size of the fraction. It can be applied from top to bottom or vice versa. It is not recommended to apply the mixture over the entire wall area at once if you want to create a texture. The rough layer is leveled with a spatula, and the angle between the tool and the wall should be approximately 15 degrees. The texture is applied over a fresh layer. The corner is formed using a perforated corner. It needs to be pressed to the corner, plaster applied on top, and then leveled. It is possible to apply the composition by machine, but leveling must be done only by hand. If the finished finish needs to be painted, this should only be done after the plaster has completely dried.

2. Facade finishing.

Plastering a facade differs in the technique of applying the mixture. After the preparatory work, the first layer of plaster is applied. This layer is applied by spraying, no more than 5 millimeters thick, after which it is rubbed over. A day later, the main primer layer is applied. Its thickness should not exceed 8 millimeters. The layer is also leveled and left for a day. The covering - the finishing layer of plaster - depends on the fraction of mineral additives and varies from 2 to 5 millimeters in thickness. As in the case of interior work, the texture is applied over a fresh final layer. After complete drying, painting can be done if necessary.

Classes of decorative plasters

Based on the type of pattern, decorative plasters are divided into several classes - structural, relief and Venetian. There is still no consensus among decorators regarding such coatings as “bark beetle”, “lamb”, “fur coat” - some classify them as structural, others as relief.

Textured plaster

Differs in surface roughness. It is applied in one layer, then processed with tools until the required texture is obtained.

Relief plaster

Forms a surface that is smoother to the touch, but has a relief. These can be skillfully created panels, niches, bas-reliefs. It also includes plasters that require 2 or more layers when applied.

Venetian plaster

Custom material. Apply from 3 to 10 layers, each thickness no more than 1 mm. After all the work of grinding, processing and ironing, it forms an imitation of expensive types of marble. Also, thin-layer putties and paints are mistakenly referred to as Venetian, which, however, are not inferior to it in elegance and aesthetics.

Effects of textured plaster

With the help of textured plaster, the well-known “bark beetle”, “lamb” and “fur coat” effects are achieved. They are obtained with the help of simple manipulations using different tools. Apply in 1 layer, evenly, using a trowel. The bark beetle effect is achieved by rubbing the unhardened material with a plastic trowel. The fur coat is rolled out with a special structural roller. The lamb is obtained by smoothing the plaster with a metal trowel, setting one direction.

The predominant use of textured plasters on building facades. These materials are not afraid of cold, rain, or mechanical damage. They can be tinted initially, and also painted later.

Relief plaster mixtures

Relief plasters include plastic decorative mixtures that easily take on a given shape. The creation of various architectural elements is only possible with such compositions. However, such work can only be done by professional plastering artists, which is why it is extremely difficult to master application technologies. Before decorating, perfect surface preparation is not required, since relief plasters hide small cracks, irregularities, potholes and defects.

Creating a facade from such materials is a labor-intensive process and requires a certain skill from the master. They are tinted in desaturated (pastel) colors. After complete drying, they are tinted with paints or varnishes.

A special type of Venetian plaster finish

A special type of decorative plaster finishing that requires a certain skill and knowledge is Venetian plaster. When choosing this decor, ideal preparation of the base is required (as for painting). With the help of Venetian plasters, a surface is created that imitates natural marble, precious stones, etc. This is achieved by applying many thin layers. When light hits, the layers begin to show through, making a heterogeneous structure visible, like that of natural marble.

Currently, there are many decorative coatings on the market that are classified as subtypes of Venetian plaster. In fact, these are separate types of decorative plasters that are not Venetian.

Owner reviews

- Review #1. My husband and I bought decorative “sand” plaster on purpose. We were missing some unusual effect in the living room. Our furniture is far from new, we wanted to add some touch of freshness. We did pretty well. The walls look very unusual and fresh. The shade range was created by specially hired craftsmen. For two years now, this style has prevailed in our living room, which we are still happy about.

- Review #2. I applied the silk plaster myself in the bedroom. This style seemed to me the most successful and calm. The pretentious hues and design ideas were not to my liking. I wanted something calm, dim. The “sandy wind” style was ideal, adding a touch of a light breeze on the seashore to the space. The interior has been transformed: unobtrusive decoration immerses you in an atmosphere of calm and sound sleep.

Decorative mixture with sand is a common type of finishing. Mastering the technique of applying it is easy even for a beginner. Go ahead, practice: the decoration of the walls in your home will delight you with a beautiful and original coating for years.

How and what kind to choose decorative plaster

The following criteria will help you in choosing decorative plaster, which also need to be given due attention:

- Environmental friendliness

- Desired appearance of the final drawing

- Strength characteristics of products

- Layer thickness, relief

- Vapor permeability properties

- Difficulties of decorating

- Operational properties and purpose

In addition to these criteria, it is also necessary to take into account the purpose of the decorated premises. When used in bathrooms, swimming pools, and basements, decorative plaster must have moisture- and water-resistant properties. If, contrary to the instructions, you still decide to decorate your bathroom with decorative plaster, be sure to use a protective varnish. It will give the coating waterproof properties without spoiling the appearance.

Traditional design recommendations

- In the corridor and hallway, use high-strength decorative plaster with marble filler

- Use waterproof compounds in the bathroom and kitchen, as well as Venetian plaster treated with wax

- In living rooms, thin-layer coatings imitating silk, velvet, sandy wind or frosty frost, treated with varnish to make them resistant to wet cleaning, would be an excellent option.

- It is recommended to decorate children's rooms and bedrooms with Venetian plasters and relief coatings in pastel colors

- It is also recommended to cover ceilings with thin-layer putty-paints or Venetian coatings

- Architectural elements are created from relief putties and Venetian plaster

Necessary materials for wall preparation and tools

Long before finishing with decorative plaster, you should take care of the preparation, buy all the necessary rough building materials, suitable tools, and correctly calculate the need. If this is done by a construction team, you just need to monitor each stage in a timely manner. However, regardless of whether the repair is done by a company or you decide to do the finishing yourself, knowing all the stages will not hurt.

To properly prepare the foundation, you need to consider the following nuances:

- Correctly calculate decorative materials

- Purchase finishing building materials

- Stock up on tools, consumables and provide convenient access to the base

Calculation of decorative plaster consumption

Decorative plaster is purchased based on the consumption indicated on the packaging, and it is individual for each type. Knowing the square footage of the area to be decorated, you can easily calculate the required amount of mixture, but you should take into account a number of “practical” factors:

- Some decorative materials are applied in at least two layers, which must be taken into account when calculating and purchasing

- The larger the fraction (grain size of components and fillers), the higher the consumption. Also keep in mind that to achieve an ideal pattern, the plaster is applied in a thickness equal to 1.5 grain thickness

- Try to calculate thin-layer putty-paints according to the maximum consumption, since when saving there is a high risk of bald spots and, as a result, lack of aesthetic appearance

- To avoid surface gaps and bald spots, you should also use primer and quartz primer tinted to match the coating. They improve adhesion to the base and normalize decor consumption

- Due attention should be paid to leveling the walls, as unevenness and flaws will increase the consumption of finishing material

Required materials for surface preparation

To obtain the proper decoration result, the walls should be prepared properly. To do this, you should assess the degree of unevenness and purchase building materials for the appropriate purpose.

- Primer to strengthen the surface and improve adhesion (cohesive properties to the surface)

- Gypsum or cement plaster mixture for leveling rough defects and unevenness

- Polymer or cement putty mixture for ideal preparation for subsequent decoration

- Fiberglass mesh or fiberglass to create a durable, reinforced base

However, these materials alone will not level the wall, so it’s worth taking care of tools and consumables.

Consumables tools for preparation and decoration

For each mixture, be it decorative or leveling plaster, there is a specific tool

- Brushes, rollers, ditch for priming before each finishing stage

- Spatulas, rules, trowels should be used when leveling walls before decorating

- Polyurethane floats, sanding blocks, sandpaper, etc. for sanding dried layers of putty or leveler

- Mixer for mixtures, bucket or basin for solutions

- Covering film and masking tape to protect surfaces from contamination

The tools that you will need for decoration differ greatly in price and quality from ordinary general construction tools.

- The trowel, used for almost all decorations, has a trapezoidal shape, as well as rounded corners and edges. It is used to apply Venetian plasters, thin-layer paint putties and relief mixtures.

- Brushes, smoothers, rollers and various sets of textures will be needed, depending on the material purchased

- A plastic trowel directly for the bark beetle, a structural roller for the fur coat and a metal smoother for the lamb

- Regular masking tape can damage the finished coating, because... particles of decorative material accidentally left during finishing of corners fall on top of it, so we additionally recommend using Tesa masking tape, which will protect the surface from damage during removal

- Make sure you have access to heights - you will need scaffolding; in extreme cases, a stepladder will do

Facade repair

For restoration work, it is necessary to take plaster that matches the strength and characteristics of the old mixture. The use of more durable types is not acceptable. With a high degree of probability, in this case, the fresh plaster will peel off from the old layer. In this case, to repair cracks and cracks, it is necessary to use a cement type of plaster. If it is necessary to refresh the appearance of the building, use a terrazite mixture. The plaster is applied in a thin layer depending on the filler fraction, leveled and, if necessary, a texture is applied.

Preparing the base for applying decorative plaster

Finishing with decorative plaster is not carried out on an unprepared base, therefore preparatory procedures are initially carried out:

- The surface to be leveled is first primed with the necessary composition: a highly absorbent base (plastered with gypsum or cement mixture, foam concrete, aerated concrete, etc.) is treated with deep-penetrating primer, a weakly absorbent base (PGP, putty, gypsum plasterboard, gypsum plasterboard) is treated with a universal or strengthening primer, and a smooth concrete surface subject to concrete contact treatment. Produced with a roller or brush.

- The surface that requires strong leveling, has rough irregularities, chips, protrusions, cracks must be plastered with gypsum or cement mixtures (depending on the purpose of the room, interior or exterior work). To do this, the mixture is dissolved with water in the ratio specified in the instructions on the bag, using a mixer or drill with an attachment for sand and gravel mixtures. The resulting solution is applied to the walls using a trowel, ladle or trowel, and then leveled with a spatula or rule. The completely dry surface is sanded with sandpaper, polystyrene foam or other grinding materials.

- Minor irregularities or defects are eliminated with polymer, cement or organic putty. Dry putty, like plaster, is dissolved in water according to the instructions, but most often a ready-made putty composition is used. Apply a thin, even layer, almost to scratch, using spatulas and/or a trowel. The dried putty is sanded manually with sandpaper or a sander until smooth. Don't forget about dust removal and priming before decorating.

- When using fiberglass or fiberglass, a thicker layer of putty is required. It is important that the mesh structure does not appear on the surface, because this will refer to surface defects.

Applying the “Bark Beetle” texture

“Bark beetle” is currently one of the most popular types of texture. The appearance of the finished wall looks like wood worn away by a bark beetle. Applying such a texture is not difficult; it is easy to do even for the least experienced craftsman.

After the initial preparation and plastering of the walls, you need to take a construction trowel and rub the wall. The granules, clinging to the tool, will make the necessary grooves. You can move the grater depending on the desired result - vertically, horizontally, in a circular motion. The resulting grooves will be located in the appropriate direction.

Application of decorative plaster

Due to the huge number of varieties, the application of decorative plasters cannot be considered in a general topic, since each has its own nuances, application methods and decorated effects. Therefore, we will consider the most popular material - Venetian plaster.

Application of Venetian plaster

Venetian is the most difficult of all existing decorative plasters to apply, so it is not recommended to take on it without knowing the nuances. Masters with extensive experience are ready to take on your every whim, but if you need to apply a single-color Venetian, you are quite capable of mastering this technique. We conduct a master class especially for our clients, the training is absolutely free!

To apply Venetian plaster you will need:

Venetian plaster of the selected color. We do not recommend tinting it yourself, especially with liquid colorants, which are sold in all construction stores. The consistency of the mixture itself is very thick. By adding liquid color, you simply turn the Venetian into paint, thereby depriving it of its properties and characteristics. To avoid this, you should order the Venetian in advance in the desired color, with factory powder tinting. It's better to waste a few days ordering than to redo all the walls.

- Trowel for Venetian plaster with rounded corners and edges, made of surgical stainless steel. It is possible to take and cut an ordinary trowel, but with light tones of the material it will leave black marks when ironed

- Japanese spatula for working in hard-to-reach places

- A rag or waffle towel for regularly cleaning the trowel from dirt

- Sandpaper of at least P2000 grit for sanding

- Wax to create a protective waterproof layer and a mirror-glossy effect. Although Venetian plaster is ironed to a gloss, additional protective properties will not harm it

- Fur mitten or angle grinder with a sheepskin attachment

- Masking tape Tesa

The first layer of Venetian is applied to the previously primed surface in an even, thin layer. There is no point in sticking to any specific pattern; the first layer serves as a substrate. Let the Venetian dry for at least 12 hours. Sand the entire area with sandpaper, removing all ridges and overlaps, and then wipe with a damp cloth to remove dust. The second layer is applied with chaotic strokes so that the base is visible through them. Each subsequent stroke should overlap the previous one by several millimeters. Each layer is ironed (glazed) with a Venetian trowel, and it must be held almost parallel to the surface. The pressure force is minimal at the beginning and maximum at the end. The more layers of Venetian you apply, the deeper and more effective the design will be. The last layer is also sanded and then treated with an even layer of wax. After 24-48 hours, the wax is polished with a fur mitten or angle grinder.

The result of applying Venetian is an effective and enchanting marble effect, with its centuries-old pattern and veining.

Conclusion

By purchasing decorative plaster for your home, you become the owner of a rich and aesthetic interior, protected from the influence of everyday factors. Decorative plaster will last you much longer than any analogue, and your friends will admire the wealth and luxury of your home!

You can find out more about all decorative plasters from our specialists by calling the number provided. You can submit a request for material or work using the feedback form. We also invite you to our salon, where you can come into contact with the works of our craftsmen, purchase any plaster and tools, and also undergo training.

The "Plaster" store is your reliable, durable and modern interior and facade!

Application technology

Working with polymer compounds is more reminiscent of puttying, because the layer being performed will be only a few millimeters. On the base, minor defects are allowed, which are no more than 3 times the diameter of the filler grains. If you apply the polymer material in a layer that is too thick, the unevenness will be very noticeable, as will the uneven color of the coating. The plastering process is carried out at air temperatures within +5...+30 degrees, humidity - less than 80%.

Surface preparation

First, remove the old coating, clean the base from dirt, and wipe off greasy stains with a solvent. The cracks are opened, sealed with cement mixture, and allowed to dry. The surface is primed to bind dust, strengthen the base, equalize absorption and enhance adhesion.

Preparation of the solution

Mix the prepared mixtures well before application directly in the original container. If acrylic or silicate plasters become too thick, dilute them with water, but not more than 10%. Dry mixtures are diluted with liquid according to the instructions, accurately measuring the proportions and introducing the dry ingredients into the water, and not vice versa. After the first kneading using a construction mixer, the solution is left for 10 minutes to “mature”, then mixed again and put to work. It is important that the mass has optimal thickness, otherwise it will slide off the wall or be difficult to rub on the wall.

Tools

Typically, a trowel or spatula is used to apply the material, and a grater (polyurethane or metal) is used for leveling. You also need to prepare in advance a plumb line, masking tape for covering window and door openings, and rags. If you plan to apply drawings, you need to have rollers, stamps or stencils on hand.

Tool for plastering walls

Plastering

The material is picked up with a spatula and applied to the wall surface. When leveling, hold the tool at an angle of 40-50 degrees, making a thin layer. In addition to a spatula, it is convenient to apply the polymer mixture with a trowel, pulling it out in an even layer. You can make strokes from bottom to top or, conversely, from top to bottom. Work from corner to corner is done in one approach. If you have to take a break, stick masking tape along the line of the last application of the solution, and remove it after resuming plastering.

Within 15 minutes after applying the solution, take a grater and begin rubbing or adding a decorative texture. The plaster does not stick to the tool, but is not yet hard. It is impossible to delay the rubbing process, as a strong film is formed on the surface, which can be damaged. The polymer mixture must dry within 24-48 hours, and during this time it must be protected from direct rays of the sun, drafts, and temperature changes.

Rubbing the polymer coating