How to attach plastic skirting boards to a concrete wall

Attaching the floor plinth is the final finishing operation of the room.

The phrase “Well, all that remains is to attach the baseboards and that’s it” is sacred for the builder-finisher. The more responsibility and professionalism is required when performing this type of work. Flaws in fastening profiles can no longer be hidden, so the correct choice of method and fastening materials is very important. When choosing fasteners and the method of fastening, the main factors are the wall material and the type of baseboard. It is also important to pay attention to the manufacturers' recommendations. As a rule, their instructions contain very valuable instructions, following which even a non-professional can properly attach the floor plinth.

A few decades ago, when the choice came down to one type - wooden, and the floors almost everywhere were also made of this material, fastening was carried out by simply driving a nail. Today, consumer choice is much wider. There are also plastic skirting boards with or without cable duct, classic wooden ones, made of MDF, expanded polystyrene. New metal and chemical fasteners have appeared. How to attach a plastic plinth to a concrete wall? Let's look at the most popular options.

Organizational matters

First of all, you need to plan your actions.

What is the best way to attach the plinth?

Clamp for fastening slats.

- If the floors are wooden - traditional planks, parquet, made of solid or parquet boards, and the walls are concrete, it is better to fix the baseboard to them. Driving screws or nails into concrete walls will be much more difficult.

- The opposite rule also applies: if the floors are concrete or screeded, and the walls are wooden, fixing the baseboards to the wood is much easier.

Note! Before attaching the plinth to a concrete wall, consider what it is lined with. If it is leveled with gypsum board, plaster, or soft stone, then the skirting boards can only be secured with special finishing nails (yellow) with miniature heads. Ordinary screws, dowels and nails will not hold securely in such a base.

- It is also possible to attach plastic skirting boards to a concrete wall by gluing them to “liquid nails”. However, here it is worth considering that it will not be possible to remove the strips later.

- Another modern method is to fix the slats with special clips (clasps). However, if you do not have experience working with such fasteners, it is better not to take on the job.

Types of skirting boards

Floor skirting boards can be:

- plastic;

- wooden;

- metal;

- polyethylene;

- ceramic;

- concrete;

- rubber;

- vinyl;

- from laminate;

- from MDF.

The type of plinth is selected based on the type of floor surface. Plastic models are suitable for carpeting, linoleum, and laminate. They are inexpensive, thanks to the wide color palette you can choose any color and shade. Plastic materials tolerate moisture well, they are aesthetically pleasing, and can be easily washed using detergents. The disadvantage of the building material is the unreliability of fastening and the need for additional fixation.

For bathrooms and rooms with tiled floors, concrete or ceramic baseboards are suitable. They have moisture-resistant properties, are durable, wear-resistant, and easy to maintain. They are attached using liquid nails or glue.

Wooden structures are suitable for parquet and plank flooring. They do not tolerate moisture well, but are environmentally friendly, reliable, durable, wear-resistant and durable. The price of wooden building materials is higher than plastic ones.

The materials for metal skirting boards are stainless steel, aluminum, and non-ferrous metals. Most often, such structures are installed in kitchens, hallways, bathrooms, and toilets. They are not cheap, but will last for several decades.

Polyurethane skirting boards are very flexible, resistant to mechanical stress, high moisture and sudden temperature changes. They are an ideal budget option for the bathroom, as they can be easily washed with powders and gels. Laminate products are suitable for laminate floors. MDF models are similar to laminate ones, but they are characterized by increased strength and wear resistance.

Mounting features

Depending on the material from which the plinth is made, one or more of the described methods for installing the specified elements is used.

Installation of plastic plinth

Such elements can be installed with glue, with special clips or with self-tapping screws. When installing with glue, there is no dust; before attaching the floor plastic plinth, you need to clearly measure them, keep in mind that they are glued once, and they cannot be dismantled.

It is necessary to dose the glue correctly and try not to smear the floor covering.

If you want to securely fasten, use self-tapping screws . Although this is a lengthy process, it is the most reliable.

First, holes are made in the plank at a distance of 50-60 cm, then it is placed against the wall and the places for the dowels are marked. In the marked places, holes are made into which dowels are inserted, after which a strip is applied and secured with self-tapping screws.

If the strips do not have a cable channel, then the caps of the screws are closed with special plugs, which the craftsmen recommend gluing, and if there is a cable channel, then they will be closed with a special strip.

Plastic plinth can be attached to the floor using special clips .

This installation method allows you to dismantle the baseboard, but when using it, the walls must be perfectly flat, and this is not always the case.

Do-it-yourself installation of plastic skirting boards, step-by-step instructions:

- Mounting points are marked on the wall;

- holes are made in the baseboard;

- insert dowels and, using self-tapping screws, attach special clips, the distance between which is 40-50 cm;

- Now all that remains is to apply the plinth and with the help of light blows with your fist, it is fixed.

Wooden

Installation of wooden plinths is more difficult than plastic ones, since there are no special corners. The corners are butted together and in order to cut the baseboard correctly, you will need a miter box. It's rare that a room has a 90-degree angle, so the adjustment of the planks is usually done locally, and done by hand.

Installation is carried out using self-tapping screws, with a distance between them of 70-100 mm. After marking, screw the screws into the plank so that they appear slightly on the other side, then place the plank against the wall and mark the holes for the dowels. Drill holes, insert dowels and fix the bar.

What should I attach the bar to?

First of all, you need to solve several organizational issues:

- If your floor is wooden, that is, traditionally plank or parquet, and the wall consists of concrete, then it is better to attach the baseboards to the horizontal plane.

- There is also the opposite rule: if the floor is concrete or screeded, and the walls are made of wood, it is better to attach the baseboards to the wall.

Important! Before attaching a plinth to a concrete wall, consider what the cladding is made of. If it was leveled with gypsum board, soft stone, or plaster, the baseboards will have to be secured using special yellow finishing nails (they have miniature heads). It is better not to use screws, dowels and nails, as they will not hold the plank securely.

- You can glue the plinth to a concrete wall using “liquid nails.” However, it is worth taking into account that it will be very difficult to remove the slats later.

- You can also secure the slats with special clips (or clamps). Please note that if you have not worked with such material before, then it is better not to take on the work.

Fastening process

Fastening with special elements is a mandatory procedure. Before attaching the floor plinth to a concrete wall, the optimal fastening option is selected. Docking can be done with screws, self-tapping screws, studs, nails, dowels.

Preparatory work

High-quality installation of panels is very important. A good result can be achieved only if there are no depressions, irregularities, or protruding bumps on the surface of the floor and walls. If this is not taken into account, then there will be empty gaps at the joining points, worsening the appearance of the finishing frame. Smooth walls and floor surfaces speed up and make it easier to attach the plinth to a concrete wall.

Material purchase

Not only do you need to know how to attach skirting boards to a concrete wall, it is important to correctly calculate the required quantity before purchasing decorative materials. You need to buy more material - 10-15 percent. This is necessary, since when cutting, mechanical damage, breakdowns, and incorrect measurements cannot be ruled out. You should also calculate how many additional elements are needed. There is no need to buy more, this will lead to unnecessary expenses. If any part is damaged during installation, you can always purchase an identical one. Replaceable without removing panels.

Processing the workspace

Before attaching the plastic plinth to the concrete wall, individual areas are prepared. The main zones consist of places where the panels are joined: floor, walls, corners. At this stage, the working surface is carefully inspected, leveling is carried out, and cracks are sealed.

Fastening with self-tapping screws

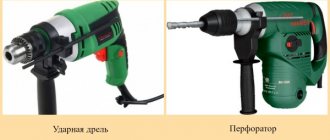

How to screw baseboards to a concrete wall using a self-tapping screw? Despite its simplicity, this method of fastening is reliable. The work is carried out using power tools - a screwdriver, a hammer drill, a drill with a screw attachment. In the concrete wall, holes are drilled with a hammer drill for plastic cases for self-tapping screws.

To carry out installation correctly, you need to know how and with what to screw the baseboard to the concrete wall. A step-by-step implementation is provided:

- Installation work begins from one of the corners of the room. To properly install and screw the plinth, it must be moved close to the work surface. The marker marks the points and locations of the fasteners.

- In the panel body, in the places where the points are marked, holes are drilled for screws, through which the marks are transferred to the wall. Using the marked points, you should also make holes for dowels, but only in the wall. The work is carried out using a hammer drill with a Pobedit drill. The pitch between fasteners should be up to 50 cm.

- When all the cases are installed in the holes, the stage of attaching the planks to the wall begins. The screws should screw in easily, without pressure. The screws are driven in with a hammer.

- At the end of the installation, additional elements are installed - connectors, plugs. The edges of decorative panels, cut at the desired angle, are covered with corner elements.

It is advisable to know not only how to screw baseboards to a concrete wall, but also other options. For example, how to secure skirting boards to a concrete wall using adhesives or clips.

Using glue

Before attaching plastic skirting boards to a concrete wall, you should choose the right adhesive. The decorative strip can be secured with glue or liquid nails. An important factor when carrying out such work is the complete absence of errors on the walls and floor. Points where the panels will be fixed are marked on the prepared surface. If the plinth is long, gluing becomes difficult, so it is advisable to cut it into pieces of equal length.

The inside of the panel is filled with an airtight mixture. A spatula is used to level the applied layer. The back side of a piece of panel is pressed firmly against the work surface. But problems may arise due to the lack of a tight fit. How to attach plastic skirting boards to a concrete wall to ensure reliable fixation. You can use self-tapping screws or press the panel with heavy objects and devices.

Installation of plastic skirting boards with cable duct

How to attach a plastic skirting board with a channel to a concrete wall? Laying should begin from the corner of the room. Decorative panels are placed along the wall. Correct cutting of the joining sections is important. Next, marks for screws are applied to the slats, and holes are drilled with a hammer drill. The pitch between the fastening points depends on the unevenness of the floor and wall, as well as on the thickness and width of the planks (but not more than 100 cm). The installation process is identical to fastening with self-tapping screws. The cables are laid in the technological recesses after the installation of the panels is completely completed, and are covered with a narrow strip.

Preparatory stage

How easy the process of attaching the plinth will be depends on the correct preparatory work. There should be no holes, protrusions or depressions on the surface between the floor and the wall. Ideal surface condition will significantly speed up the process.

It is important to prepare the work area before installation. Fragments of previous finishing, screws and nails should be removed , and all cracks should be carefully sealed so that after the repair is completed there will be no blowing from them.

It is necessary to hide obvious imperfections in the walls and floors, level out uneven areas and fill in recesses. After all, a plinth can hide only small flaws. If you tidy up only the area where the plinth will be located, you will notice that the overall surface differs from the leveled one. Therefore, you need to take into account the condition of the entire wall.

Purchasing material

You need to approach the choice of material with all responsibility. The plinth must meet the operating requirements. If there are protruding wires and cables, it is recommended to use products with special gutters. They can easily hide telephone or Internet wires.

Products created specifically for carpet allow you to lay the covering immediately after installing the baseboard. At the bottom of the panel there is a groove in which the edges of the carpet are hidden. This allows you to change the flooring material without dismantling the baseboard.

It is recommended to purchase 10-15% more material. This is done in case the product breaks down or the technician makes a mistake during installation. Purchasing skirting boards with a reserve will not greatly affect your wallet. Also in the store you need to carefully look at what elements are included in the kit: you will need plugs, corner connectors and several baseboards.

Installation with glue

You can attach the panel to the concrete surface using glue. Perhaps this is the easiest method among all. The method is considered easy and incredibly fast. The products are fixed with special glue or liquid nails. For installation on a flat surface, you will need a fixing compound, a ruler and a spatula. If the wall has unevenness, you must first remove all the errors.

Algorithm for performing the work:

- Mark the mounting location on the wall.

- The plinth is divided into equal parts, because it is not so easy to control the tightness of pressing the product to the surface.

- The adhesive composition is applied with a spatula to the plank and distributed evenly.

- The product is pressed firmly against the wall. To ensure a tight fit, the edges of the panel are fixed with self-tapping screws.

This installation method has some disadvantages: the inability to reuse the plinth, the need for a perfectly flat surface for maximum tight fit and a careful approach to applying the glue so as not to stain the front side of the plinth.

Fastening with self-tapping screws

This is a fairly simple and reliable method, which is most often chosen for attaching skirting boards. In order for a self-tapping screw to be screwed into concrete, you need to first drill holes in the wall and use a hammer to drive special spikes into them, which are firmly fixed in the wall. After this, you can screw self-tapping screws into these tenons, fixing the baseboard to them. To complete the work you will need:

- A simple pencil.

- Ruler.

- Hammer.

- Hammer.

- Self-tapping screws.

- Spikes.

- Skirting board.

It is recommended to attach the baseboard from the corner of the room. Connecting corners are attached to the extreme part of the plinth, pressed against the wall and installation begins. With this fastening method, accurate markings are extremely important - it will be difficult to re-drill holes in concrete walls.

Installation using self-tapping screws

People often ask the question: “How to attach a baseboard to a concrete wall?” There are many proven methods for installation. But before work, you should prepare the workplace; you need to remove excess plaster, pieces of wallpaper, and protruding elements from the wall surface. If there are small differences in the plane of the wall, then it is better to fill them with putty solution. Only after this work begins on installing the plinth.

To attach skirting boards to the wall, you will need the following tools: a hammer, a hammer drill, a hacksaw, self-tapping screws, dowels, a pencil, and a tape measure. This method of fastening is the simplest; the skirting boards are screwed to the wall using self-tapping screws into pre-prepared holes.

Installation of the baseboard to the wall should begin from the corner of the doorway along the entire perimeter of the room. At the junction of adjacent walls, it is necessary to install a connecting corner into which PVC slats are inserted on both sides. If the panels need to be cut to the required size, then a hacksaw is used for this. With it you can quickly and efficiently cut the product.

The finished structure of two slats and a corner is applied to the surface. If it lies across the entire plane without gaps, then it is attached to the wall with self-tapping screws. To do this, drill holes of the required diameter in the rail. Markings are recorded on the brick surface with a pencil.

Using a hammer drill, holes of the required depth are drilled in increments of no more than 50 cm. After this, you need to place dowels in all the holes, which should be driven in with a hammer.

After this, the structure is pressed against the wall so that the holes of the baseboards and the wall coincide, and the lower edge bends slightly outward. Only after this are the screws screwed into the dowel.

Fixing the screws along the edges of the plinth, insert the plug

Before fixing the screws along the edges of the fillets, it is important to insert a plug or connector onto the rail.

Place communications or wires only after securing the baseboard to the wall.

Then the masking strip must be snapped into the baseboard itself. They begin to secure it from the edges, gradually approaching the middle.

The plinth should not be tightly screwed to the wall, as the PVC material is fragile and can break. If the surface of the walls is uneven, then you need to screw in additional screws in the locations of the depressions. In this case, the plinth will be tightly pressed to the recess, and no gaps will appear.

A little about the material

The first step is to choose the material. Plastic skirting boards today come in different varieties. If just recently the choice was not great, today this choice is quite wide, which allows you to choose a plinth to suit your room’s characteristics. Plastic skirting boards come in different heights and shapes. There are simple plastic plinths and plinths with a cable channel, which also serves as a place for attaching the plinth to the concrete wall. If you have no need for a cable channel and all your wires are laid in the walls, then the baseboard will be fastened in a special plastic box, onto which the baseboard itself is then snapped. Everything is done in such a way that in the end the fastening points are not visually visible.

Plastic skirting boards have a number of big advantages compared to their wooden counterpart.

- Firstly , such a plinth better presses laminate or parquet, so if your flooring sticks out slightly at the edges of the room, then you can lightly press this covering to the floor with a plastic plinth.

- Secondly , plastic plinth can be installed in rooms with high humidity, because if it comes into contact with water, such a plinth will not deteriorate in any way, but in the case of a wooden plinth, the material would be susceptible to rotting.

- Thirdly, it is more convenient to work with a plastic skirting board, since it is easier to cut corners and so on than with a wooden counterpart. This allows you to install the plinth much faster than with wooden plinths.

Today there are many plastic skirting boards on the market in different colors, so you can always choose a skirting board to match your flooring.