Types of glue for polyurethane

Adhesive compositions designed specifically for polyurethane are practical, lay on the surface in a thin layer and fill all voids. Most of them dry quickly on the surface and firmly attach sheets of elastomers to each other. They are resistant to moisture and do not crack due to temperature changes.

The glue sets quickly and allows you to paint the surface in any shade after drying.

Manufacturers

On store shelves you can find an abundance of polyurethane adhesives from various manufacturers, including domestic and foreign, including countries such as Turkey, America, Italy. In the vastness of Russia there are also many companies that produce polymer glue, oriented for use on a production scale, and also suitable for household use.

The following manufacturers deserve attention:

1. Adesiv is an Italian brand that produces two-component Pelpren PL6 adhesives. The composition is suitable for professionals, as it is produced on the basis of epoxy resin and polyurethane. Ideal for working with wood.

2. Bostik is an American manufacturer that produces one-component and two-component compositions for installing parquet.

3. Dow Chemical Company is an international brand that produces universal Insta-Stik formulations packaged in 750 ml, 10.4 liter volume containers. Ideal for working with insulating materials, ensuring their fastening to any horizontal and vertical bases.

4. Duayen is a Turkish company that has been supplying polyurethane glue to Russia since 2001. PU glue is used mainly in grades A-121 and A-338 for rubber bases, as well as bonding to rubber, metal, wood and concrete. Brand A-138 is suitable for creating rubber floor coverings for the street, A-118 provides reliable fastening of parquet flooring, A-128 is used in shipbuilding and furniture production.

5. Henkel from the German brand also sells polyurethane adhesive for various purposes in Russia for household use and industry.

Using polyurethane glue (2 videos)

Polyurethane glue (16 photos)

Polymer adhesives

The compositions are made on a polymer basis and harden in a few minutes. They securely fix the material on bases made of:

- concrete;

- wood;

- drywall;

- brickwork.

Important! They work quickly with polymer glue: due to the accelerated hardening process, it is impossible to level the surface. After application, immediately wipe off all smudges, since it will be difficult to work with them afterwards: you will have to use a solvent or sandpaper.

*

After drying, the seams remain intact and do not crack or expand with temperature changes.

Polymer formulations are produced in tubes with a convenient dispenser spout

They are inserted into a mounting gun and applied to the surface. After 40-60 seconds, the material has already set, so during this period it is necessary to press the two planes together. Polymer glue is white and transparent; it can be used to glue polyurethane skirting boards.

Adhesive putties

*

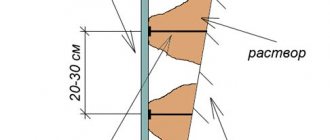

They are used for general construction work and interior finishing. The material makes it possible not to level the wall before gluing polyurethane products, since the consistency of the putty allows this to be done during the process. The adhesive mixture quickly hides surface unevenness, defects and potholes. After application, polyurethane does not need to be pressed against the plane for a long time. Work with the material is carried out indoors, as it does not emit harmful substances.

Advantages:

- reliability;

- strength;

- ease of use;

- availability;

- uniformity of application;

- making your own mixture.

The main component is PVA or acrylic

*

You can make this composition yourself: for this you need PVA glue, dry finishing putty, water and a container for preparation. Proportional calculation - 4 parts dry putty to 1 part PVA. All components are mixed in a bucket, water is added to form a thick suspension. The composition is left for 5 minutes, mixed, and used as directed. Ready-made putties are sold in buckets or tubes - inserted into a gun for installation.

Assembly adhesive

To fix light-weight polyurethane products, special mounting adhesives are used. More often they are used for fastening stucco moldings, ceiling plinths and cornices. They fix products on glass, tiles and other surfaces. The mounting compound is used for mounting on the wall - it is durable and elastic, but it is not recommended to use it for joints, as cracks will appear over time.

Available in 310 ml tubes

Despite this quantity, one tube is enough for 7-8 applications, since the consumption of mounting adhesive is uneconomical. Its thick consistency spreads evenly on the surface and fixes the product even on a wooden base.

Advantages:

- does not leave marks after drying;

- when it hardens, it looks like a light-colored primer.

In construction stores you can find construction adhesive in cans or buckets of 500, 1 and 5 kg. It is recommended to apply the composition with a spatula.

Important! Instead of assembly glue, liquid nails are also used. They are made on an acrylic base and are designed for fixing light-weight products.

*

Joint adhesive

It is better to glue polyurethane using mounting tubes, and joint adhesive is suitable for seams. To fasten moldings at joints - cornices or moldings, this composition is suitable. The joining mixture differs from the mounting mixture:

- Has high adhesive ability. Polyurethane products experience heavy loads at the seams; over time, cracks appear here and material comes off. Docking adhesive will securely fix the products in a certain position without changing the appearance.

- Used instead of putty. Available in white or transparent, it is suitable as putty in places where you need to level the surface or disguise a seam. The gaps between polyurethane skirting boards are perfectly covered with joint glue and hide unevenly cut edges.

- Sets quickly. Within a minute of pressing the material against the wall, the mass hardens. After a few minutes, it will be difficult to tear the product off the wall, and the adhesive mass will remain on one of the parts of the finish.

- Paintwork materials adhere well. Polyurethane skirting boards are painted before fixing, and the joints are tinted after finishing. The glue creates a light layer that can be painted in several steps.

The time allotted for correcting the layer is no more than 20 minutes.

After this, the composition can no longer be adjusted, so you must immediately fix the product evenly and correctly.

Flaws

Polyurethane adhesive is in demand due to the mass of advantages based on its properties. However, there are a number of points that are important to familiarize yourself with before using the composition. Thus, at low humidity, the film takes longer to form than at high humidity. Due to foaming, parts may shift and joint strength may be reduced. Moreover, the process is more active when there is a lot of water nearby.

The dry residue is inert to almost everything, but before its formation, toxins are released, and the skin and mucous membranes may react negatively to fumes or glue. It is difficult to wash the mass off your hands.

Popular glue brands

*

Depending on the properties of the adhesive composition, its adhesion changes, as well as the time for adjustment. Popular brands of adhesive mixtures for polyurethane:

- NMC Adefix P5 is a product from Belgium, designed for fixing polyurethane or polystyrene to a porous plane.

- Moment DecoStyle is universal – suitable for a wide range of applications, elastic and waterproof. Can be used in bathrooms.

- TITANIUM Wild – sets quickly, is resistant to moisture, and easily tolerates low temperatures. Used on concrete, wood, drywall.

- Europlast Mounting - has a paste-like consistency, fixes polyurethane well on a porous base.

- Docking Orac Decor - made on a polyurethane base, sets in 30 minutes.

- Joining DECOMASTER – forms a transparent seam, sets in half an hour.

It is better to choose compositions based on polyurethane - they fix joints well, or based on acrylic - they firmly attach products to the wall with any base.

How to dilute and wash

Sometimes polyurethane adhesive needs to be diluted slightly before use. To do this, special activators are used that can improve the heat resistance of the composition and increase its adhesive properties. However, activators are used only for diluting two-component liquids. If you need to dilute a one-component mixture, you will have to use ordinary water or alcohol. You can also use special thinners, which are sold in many hardware stores. These include methyl ethyl ketone, ethyl acetate and acetone.

To clean tools from adhesive residues, use acetone. If the mixture has not yet dried, it is rubbed off mechanically.

How to use

When you have chosen how to glue polyurethane products to the wall, begin to study the recommendations on the packaging of the composition. If it is a dry putty, it is diluted with water until the desired consistency is obtained. If a tube of compound is used, it is inserted into the mounting gun and the spout is unscrewed. Before use, the wall surface is cleaned of dust and dirt.

Glue is applied to the back of the polyurethane product and quickly pressed firmly against the wall.

Press down for 40 seconds and release. If a joining mixture is used, it is applied between the edges of the products and the evenness of the distribution and fixation of the material is corrected. After 30 minutes, the glued products will become completely motionless; the joint can be painted.

Storage

There are several features of storing polyurethane glue that you should familiarize yourself with:

- If the composition is in a closed container, the storage temperature should be 15-30 degrees above zero.

- The container with the composition should be placed away from light sources and heating devices.

- The glue should be stored in hard-to-reach places that are not accessible to children.

- When opened, the glue can be stored for 5-6 months.

Calculation of the amount of glue

Most often, polyurethane baseboards are fixed using adhesive mixtures. To calculate the amount of mass, calculate the perimeter of the room, and also add the length of all the protrusions where the baseboards will be installed. The calculation is simple: on each tube the number of linear meters is indicated for which this pack is enough.

When choosing which glue to fix polyurethane products, take into account their weight, as well as the presence of additives in the composition. For example, if the finish is not made from pure polymer, but with the addition of chemical plasticizers, then a certain type of glue may not be suitable. Before purchasing, it is better to immediately clarify all the characteristics of the composition.

How long does it take to dry?

The hardening time of polyurethane glue is determined by its composition, as well as the presence of additional ingredients in it. On average, this time ranges from 20 minutes to 1 hour. While the glue is in a liquid state, it is necessary to press the glued base very tightly to ensure fixation for a short period. It would be optimal to apply pressure to the surfaces for 1 hour to ensure uniform, tight and reliable fastening.

During work, some of the glue may appear on the surface of the materials after curing, so its excess is removed mechanically. Complete hardening of the adhesive composition occurs in 1-2 days. During this time, the adhesive seam becomes as strong as possible. During this period, it is necessary to ensure that the surfaces being bonded are static and at rest, and free them from mechanical influences. The curing time can also be influenced by the ambient air temperature. If a hot method was chosen for polymerization, then complete curing will be completed after 4 hours.