15761 0 2

Icer June 8, 2017Specialization: master in the construction of plasterboard structures, finishing work and laying floor coverings. Installation of door and window units, finishing of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

The reliability of plasterboard walls and ceilings directly depends on the quality of fasteners.

Don’t know how to choose high-quality and reliable fasteners for plasterboard construction? I worked in a hardware store for several years and today I will share my experience, which you can use to choose the best screws.

Self-tapping screws are used both for fastening drywall and for assembling a frame from a profile

For fastening the profile to the wall, floor, ceiling

To secure the guide profiles - the basis of the frame for drywall - you can use:

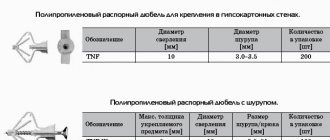

- Dowel-nails. Typically, fasteners with a diameter of 6 mm and a length of 40 mm are used.

- Self-tapping screws with a press washer (MCP) with dowels matched to them. The length of the screw for a brick wall is 41 mm (for concrete you can take it a little shorter), the dowel is 6 × 40 or 6 × 37 mm. It is with such a dowel that the self-tapping screw with a diameter of 4.2 mm will be screwed tightly and held tightly.

- Anchor bolts. They are used in special cases: when attaching a reinforced profile and under increased loads.

- Self-tapping screws for wood. Used for mounting guides on a wooden wall.

Mr. Build recommends: when choosing between dowel-nails and self-tapping screws with a press washer, it is better to choose the latter. In the first type of fastener, the screw is driven into the dowel, while the self-tapping screws are screwed in and provide a more reliable, “eternal” fastening.

There is another option for fixing the profile on the walls and ceiling - using a gas mounting gun. It is used for driving dowels into the base and allows you to get the job done quickly and easily. However, both the tool itself and the components are expensive, so only professionals working with large volumes can afford it.

The right choice when purchasing

Self-tapping screw coating. In addition to the main material from which the screw is made, it is covered with a shell.

- Phosphated coating – black in color. Fasteners are used in rooms with high humidity.

- Oxidized coating – black color. A protective film is applied and used in a room with normal humidity levels.

- Galvanized coating – for indoor and outdoor use.

Self-tapping screws also differ in the shape of the head, thread, and tip.

Tip difference

It is correct to choose a regular cross-shaped PH spitz for the bat.

Bit PH2 cross-shaped

When choosing self-tapping screws for gypsum boards, you should pay attention to size and weight. All elements must have straight heads and cross-shaped recesses must have clear edges.

To connect frame parts

Screws of this category are used to connect together elements of a metal frame - racks and guides. There are 2 types of such fasteners:

- With cylindrical head. Among craftsmen they are often called bedbugs, fleas or sunflower seeds. Such names are primarily due to the size of the hardware.

- With a press washer. These self-tapping screws have a thin but wide head, similar to a washer.

Self-tapping bug

For a profile with a press washer USEFUL INFORMATION: Profile for fastening plasterboard: ceiling, wall, load-bearing and guide

For screwing gypsum boards to the frame

To fasten sheets of drywall to the frame, self-tapping screws with a conical head are used: during installation, they are completely recessed into the depth of the material. This ensures that the fastening points are invisible after the holes are finished, meaning there are no problems during finishing.

Depending on the frame material, self-tapping screws are used:

- For metal with fine threads to attach gypsum boards to the profile.

- On wood, if the sheathing is made of timber.

To choose the right screws, let’s look at their types in more detail.

Self-tapping screws for metal and wood

Depending on how the plasterboard sheet is attached to the wall, the required type of screws is selected. If it is intended to use metal profiles, then use gypsum plasterboard for metal, and for attaching drywall to a wooden wall sheathing - gypsum plasterboard for wood. You can easily understand the purpose of a particular self-tapping screw by its appearance, or more precisely, by the differences between them in the form of threads. For wood, the thread pitch is rare, but for metal it is frequent. To attach drywall to a reinforced profile up to 2 mm thick, you should use self-tapping screws with a drill, which will eliminate the need to pre-drill the sheet and significantly reduce the time for attaching drywall to the wall, even despite the small distance between the screws. All types of drywall screws, regardless of their specifics (when choosing between wood and metal), have a number of similar characteristics:

- black color. This is an indicator that the screws have received an oxidized or phosphated coating, which serves as a reliable barrier against corrosion;

- thread in the form of a pointed spiral, which greatly facilitates screwing the self-tapping screw into almost any surface;

- the presence of a horn-type head, which, when screwed in, is completely recessed into the sheet of drywall and does not interfere with its further finishing (plastering, painting the wall, gluing wallpaper);

- cross-head slot PH-2 (Phillips), which makes it equally easy to screw self-tapping screws into a sheet either manually using a screwdriver or using screwdrivers. And the cross-shaped bits for this slot can be selected between options from the price category, or load resistance.

Fasteners for frames with a cylindrical head (“bugs”)

The stores offer a wide selection of such products with different characteristics:

- Length from 9 to 11 mm. Professionals recommend using shorter ones: there are practically no differences in the quality of fastening, and the savings are quite good.

- Black oxidized and bright galvanized. Beginners believe that the latter are more durable. In fact, the characteristics of both types are the same, so take those that are available.

- Sharp or with a drill at the end. Craftsmen recommend using sharp ones: they stay in the profile better due to the small, neat hole. In addition, their price is lower. The advantages of using self-tapping screws with sharp ends are visible in the photo.

- With and without serifs on the back of the cap. If possible, it is better to take serrated screws: they prevent the connection from unwinding during vibrations.

Signs of a quality self-tapping screw

Experienced workers know that the consumption of self-tapping screws on a plasterboard sheet can increase many times if a defective batch is received. Sometimes this happens due to a simple oversight, which can be completely avoided if you know what you need to pay attention to when buying self-tapping screws:

- appearance of self-tapping screws. All screws must be the same size. Thickening or thinning, various bends are not allowed; (Conclusion - the self-tapping screw was manufactured in violation of the technology; a significant reduction in its strength characteristics is possible);

- The hole for the slot on the screws should be clearly visible and located in the very center of the screw head. No sagging, distortion or protrusion of fasteners is allowed. (Each case of a poor-quality slot will, at a minimum, prevent you from tightening the self-tapping screw, and at maximum, it will ruin the bit attachment for the screwdriver);

- self-tapping screws must have an even black or gray-black color, the same for the entire batch, which confirms that the manufacturer has carried out high-quality phosphating or oxidation of the product, and, therefore, they are not afraid of corrosion; (conclusion - any increase in humidity will lead to the appearance of rust stains, including under the wallpaper, which are then extremely difficult to remove).

Important: a reputable manufacturer whose product quality is stable and always at a high level labels its self-tapping screws.

Even without having the manufacturer’s packaging in hand, they can be easily identified by the letter on the head of the screw. This is, for example, X, T, W, G, Z or any other. In this case, it doesn’t matter what letter is on the screw, it is important that the manufacturer does not hide, openly identifies himself, and is ready to be responsible for the quality of the product. Although the letter X is preferable, it is a sign of OMAX, one of the best manufacturers of fastening products.

Self-tapping screws with press washer (for frame)

These elements are also used to fasten metal profiles. They have several significant advantages over the type with a cylindrical head:

- The wide cap provides stronger adhesion of the frame elements to each other.

- They protrude less above the plane of the profile, which facilitates the subsequent installation of drywall sheets on it.

The main disadvantage is the cost: such hardware will cost more than “bugs”.

On sale there are self-tapping screws with a press washer up to 80 mm long, but for assembling a frame for drywall, 13–15 mm is enough.

They have a zinc coating and are available with a drill at the end (MCSP) or sharp (MCP). Professionals recommend MCP for a regular profile and MCSP for a thick one.

USEFUL INFORMATION: Drywall belt screwdriver

How many self-tapping screws are needed to mount the structure?

Fasteners are often used when assembling a metal frame under sheets of drywall. Their number depends on the design features. In the standard version, the step between the metal profiles is 60 cm, in the reinforced version - 40 cm. The number of jumpers must also be taken into account.

Let's carry out the calculation using the example of a wall measuring 3*4 meters. To increase rigidity, jumpers are used, installed at a distance of 50 cm from each other.

The distance between the profile elements is 40 cm. To install one sheet, you will need 4 elements and 6 jumpers of 40 cm each. The distance between the fasteners is 25 cm. For 1 profile you will need: 300/25+1=13 pieces. For the frame you will need 13*4=52 pieces. Per sheet of drywall: 52+6=58 pieces.

This is an approximate amount.

More accurate calculations are made per 1 square meter. The quantity must be divided by the sheet area: 52/3 = 18 pieces. For the entire wall area you will need 12 square meters. meters*18=216 pieces. Consumables must be taken in reserve, so the estimated need is 250 pieces. < Previous Next >

Self-tapping screws for attaching drywall to a metal profile

It’s easy to find out and select such hardware:

- A fine thread pitch will ensure a reliable connection to the metal frame.

- Length varies from 16 to 152 mm. For high-quality fastening, the length of the self-tapping screw must exceed the thickness of the material being screwed twice. Therefore, when installing drywall in one layer, 3.5 × 25 mm screws are used, in two layers - 3.5 × 35 mm.

- The cone head is recessed into the drywall. It is most convenient to use a screwdriver with a special limiter attachment during installation: it will not allow you to drive the screw too deeply and damage the material.

Craftsmen who professionally work with drywall use a tool with automatic feeding of screws. It costs a lot, so there is no point in purchasing it to renovate one apartment.

Fasteners for fixing gypsum boards on a wooden frame

When using sheathing from beams, use wood screws that have a wider thread. This is the cheapest type of hardware of all listed. The following screws are used to attach drywall to the bars:

- 3.5 × 32 – when covering walls;

- 3.5 × 25 – for ceiling work.

The length of the screw also depends on the parameters of the wood: for loose wood, longer screws are used.

Important! Wood screws are not suitable for fastening to a metal profile. When installing a metal frame, they are used to attach drywall to wooden blocks, reinforcing areas near a doorway or a place for hanging a TV or other equipment.

What fasteners are used in plasterboard structures?

Plasterboard structures include several materials - gypsum plasterboard (plasterboard sheet), metal profile, wooden spacers (if necessary, reinforcement). In addition, the structure itself must be attached to the load-bearing wall. It can be wooden or concrete (brick). The variety of materials used entails the need to use various hardware.

Fasteners for gypsum boards

Before installation, it is necessary to determine which screws to attach the drywall to the profile. This depends on the frame material to which the sheets will be attached.

Self-tapping drywall screws for metal are a screw with a cone-shaped shaft that is pointed at the end. They are used for attaching gypsum boards to a metal profile. If the metal thickness exceeds 0.7 mm, then profile screws with a drill at the end are suitable, instead of the usual point. They are used for profiles with a wall thickness of 07-2.2 mm.

1 - for metal; 2 - on wood

Self-tapping wood screws are an analogue of metal screws. Their difference is the thread pitch. Wood self-tapping screws have a larger thread pitch compared to metal screws and are used for fastening gypsum boards to a wooden structure.

Tips from the pros

We found out that different types of screws will be needed for different stages of work. A standard budget fastener kit for installing a plasterboard structure will include:

- dowel-nails 6 × 40 mm for fastening the guides;

- self-tapping screws with a sharp end without a drill for the profile;

- self-tapping screws for gypsum boards for metal.

Mr. Build recommends another set that experienced DIYers use. It will cost a little more, but it will make the structure more reliable and make it easier to attach the gypsum board.

- Self-tapping screws with a press washer (MCP) 41 mm long + dowels 6 × 40 or 6 × 37 mm for guides.

- MCP screws 13–15 mm long for fastening profiles together.

- Self-tapping screws for mounting plasterboard 25 or 35 mm.

Advice: wherever possible, it is better to use a cutter to fasten profiles. Screw in self-tapping screws only in hard-to-reach places. This connection method will ensure a tight fit of the drywall to the frame (there will be no bulges from the screw heads) and will help save on fasteners for large volumes of work.

Counting the required number of hardware

There are several ways to calculate the required number of hardware:

- Draw a detailed diagram of the frame, and then count the number of screws for its assembly and for fastening the gypsum board.

- Use the tables according to the Knauf method: they give the consumption of all components per 1 m2 of plasterboard covering.

- Use an online calculator.

USEFUL INFORMATION: How to prepare drywall for wallpapering: what should you use before gluing?

Table of approximate consumption of hardware for wall cladding in one layer:

| Name | Quantity per 1 sq. m |

| Dowel-nails | 1,6 |

| Self-tapping screws for connecting profiles | 2,7 |

| Self-tapping screws for fastening gypsum boards | 17 |

For a partition with plasterboard fastening in 1 layer:

| Name | Quantity per 1 sq. m |

| Self-tapping screws for gypsum boards | 34 |

| Dowel-nails | 1,6 |

For suspended ceiling:

| Name | Quantity per 1 sq. m |

| Screw LN 3.5 x 9 mm | 1,4 |

| Self-tapping screws for gypsum boards | 23 |

| Dowel for fastening profiles PN 28/27 | 0,7 |

| Anchor dowel | 0,7 |

Self-tapping screw calculator for drywall profiles

Advice from Mr. Build: purchase hardware with a reserve of at least 10%. During the installation process, screws can (and will) break and get lost.

When purchasing, even if the screws are sold in sealed boxes, it would be a good idea to open one of them and check the quality. The thread must be smooth and the hardware coating must be solid. It is not uncommon to encounter overheated self-tapping screws: when tightened with a screwdriver, their caps simply fly off. As a result, the body of the hardware has to be pulled out of the profile or timber using pliers. This is time-consuming, inconvenient, and not always possible. Therefore, it is recommended to purchase self-tapping screws from reliable and trusted stores. This will save time, money, and nerve cells.