Qualitative characteristics of fiberglass wallpaper

Let's consider the most significant characteristics of fiberglass wallpaper:

- Strength. The original production technology allows us to create exceptionally durable material. Threads are drawn from molten glass, which can have different thicknesses and densities. Then, from the resulting fiberglass yarn, panels are created on special weaving machines, which are impregnated with a special chemical composition based on starch.

Thus, the best properties of fabric and glass are combined, giving birth to a unique, surprisingly durable material. The reinforcing properties of fiberglass are actively used by professionals in the interior decoration of premises for various purposes. For example, where it is necessary to hide small cracks, glass wallpaper is irreplaceable. They are also used for ceiling insulation.

- Wear resistance. Fiberglass wallpaper has a large operational reserve - up to 30 years of service. This quality is determined by the special structure of the canvas and the specifics of applying glue and paint to it. The quality of the material is practically not affected by chemicals and water.

- Fiberglass fabric does not burn, does not smoke, and in case of fire does not emit volatile substances harmful to people.

- Environmental friendliness and safety of use. All components of glass wallpaper are of natural origin: lime, soda, quartz, dolomite. These natural materials are non-toxic, breathable and harmless to humans and animals. Accordingly, the likelihood of allergic reactions when covering a room with this type of wallpaper is very low. Indoor dust does not actually linger on walls and ceilings covered with glass wallpaper, since the antistatic properties of fiberglass are very high. Mold spores are also not able to exist on glass wallpaper for painting.

- Aesthetics. Manufacturers of glass wallpaper claim that properly pasted wallpaper can withstand about 10 paintings without losing its structure and properties. So, you can change the appearance of the interior without undertaking a major renovation, but only by repainting the walls and ceiling to your taste and mood.

Watch a video on how to glue glass wallpaper to the ceiling.

How to choose glass wallpaper?

When choosing glass wallpaper, you should be guided by the following 3 rules:

- amount of fiberglass. The combination of 70% fiber and 30% impregnation is considered the most advantageous;

- deep relief. The more pronounced the relief of the wallpaper, the less likely it is to smooth out after several paintings; moreover, such wallpaper requires more glue and paint;

- quality of weaving. If you look closely at the surface of the wallpaper, you will notice its fibers, which should be dense, even and smooth; otherwise, you should not take the product, since the first time you paint it, the entire pattern will disappear.

In addition, pay special attention to the edges of the wallpaper in the package. They should be even and smooth, and not shaggy, since the wallpaper itself is woven from fibers

On the back side of the panel there must be a stripe, thanks to which you can distinguish the front side from the back side, and not confuse the wallpaper pattern. There are also defects on the surface of the wallpaper - this is a technical error, which is compensated by increasing the area of the canvas.

Recommendations

In order for the work to be done efficiently, and the result to be pleasing to the eye for a long time, you must follow the recommendations:

- The maximum length of the canvas should not exceed two meters, otherwise problems with gluing may arise.

- Before gluing, you need to determine the front part of the material.

- During work, you need to use rubber gloves, a respirator and goggles to avoid the ingress of small particles.

- Fiberglass should be glued at a room temperature of 18 to 25 degrees above zero.

- It is better to start work on the opposite side of the door.

Fiberglass is an excellent material that will help quickly and efficiently remove any unevenness from the surface. By following all the rules and technology of use, you will be able to create a unique and neat room design.

Features of gluing

The technology of gluing walls or ceilings with glass wallpaper largely coincides with gluing conventional wallpaper.

But it’s worth paying attention to some features:

- glue should be applied only to the surface of the walls; applying glue to canvases is strictly prohibited;

- glass wallpaper should only be glued end-to-end;

- It is necessary to leave allowances of 10 centimeters in order to be able to join the pattern on the canvases. After this, all excess is cut off;

- the joint between the glass wallpaper can be horizontal or vertical;

- The wallpaper must be painted twice, the time interval should be 12 hours;

- It is imperative to monitor the amount of glue or paint, because a thick layer will negatively affect the performance of the wallpaper;

- the temperature in the bathroom should be from 18 to 25 degrees, and air humidity should not exceed 70 percent;

- It is necessary to beware of drafts after wallpapering.

It is not recommended to glue fiberglass wallpaper to all bathroom walls. It is not recommended to paste over areas of the wall where the bathtub and washbasin are located. Although this material is resistant to moisture, if it is in constant contact with water, glass wallpaper can change its appearance and peel off.

All other walls of the bathroom can be decorated with glass wallpaper, which can be painted in any color. To update the interior, you can repaint them in a different color or paint them in stripes, combining several colors.

Fiberglass wallpaper can be used for walls that are already painted with oil paint. But first you need to prepare the surface. It is necessary to purchase a special composition that acts as a primer. The wall needs to be treated with the solution several times, with time intervals for each layer to dry well. Most bathrooms are often already painted with oil paint, so there is no need to remove it, just be responsible in preparing the surface and the glass wallpaper will decorate the bathroom for many years.

Features of application

Fiberglass is used to secure finishing putty or other finishes. This thin and lightweight material can be used at any angle and on any surface. In addition, it improves the surface structure and ensures its wear resistance.

How and why to glue under putty

The fiberglass must be glued under the putty, otherwise after removing the finishing material the cobwebs will follow it.

If the walls were painted using fiberglass, the seams, joints and texture of this material will be noticeable.

Fiberglass is glued as follows:

Preparatory work. Before gluing the web, you need to prepare the wall. To do this, putty is applied to the drywall, which hides irregularities, joints, etc.

It is important to consider the following rules:

- Before filling, the walls should be cleaned of dirt;

- the places where irregularities were sealed should not be convex. To do this, you can use surface grinding;

- if there are still bulges, you can apply the putty again;

- Before applying fiberglass, the wall should be cleaned of dirt and sanded.

- Gluing fiberglass:

- the first layer should be glued from the corner;

- The glue itself must be applied to the wall, and only then the cobweb should be glued;

- It is better to cut the required number of sheets in advance, since gluing must be done continuously to avoid visible joints;

- then the excess glue and air are smoothed out with a spatula;

- use a knife to remove excess material;

There should be no joints between drywall and fiberglass in the same place, as the seam may crack.

Is it possible to glue fiberglass under wallpaper?

Fiberglass is a reinforcing material that is used for painting surfaces. It can also be used under wallpaper, but before doing this, be sure to treat the surface.

What density of the material should be

Painting fiberglass is made from quartz sand. It is sold in rolls of 50 meters and a width of 1 meter. For wall finishing, the density of the material should be 25-50 g/m2.

When choosing fiberglass for walls, it is better to give preference to a denser texture.

Where else is it used?

Fiberglass has a wide range of uses. It is used to make:

- Plumbing parts: dry closet, shower stalls.

- Sports goods - oars, ski poles.

- Creation of boxes and containers for household purposes.

- Medical products – fillings, prostheses.

- Tubes for household use - antennas, various holders, etc.

- Electrical products - indicators, fuses.

Fiberglass wallpaper per roll: price, density, texture, color

Fiberglass wallpaper is no longer a novelty and is sold in most specialty stores and large construction supermarkets. If they are still not available in your city, then contact online stores.

When turning to online stores, it’s a good idea to ask consultants to select all the add-ons: glue and adapters.

On average, one roll covers an area of 25 square meters if you use standard glass wallpaper. The price per roll in this case ranges from 1-2 thousand rubles, depending on the characteristics of the material. Considering the durability of the coating, such investments are fully justified. We invite you to familiarize yourself with the table of the most popular products:

| Name | Manufacturer | Density | Texture | Color | Roll dimensions (m) | Price per roll |

| Medium Christmas tree “Oscar” | China | 110 g/m2 | Herringbone | White | 25x1 | RUB 2019 |

| Polka dots “Wellton Optima” | China | 110 g/m2 | Herringbone | White | 25x1 | 3230 rub. |

| Wave “Wellton Optima” | China | 110 g/m2 | 3D, Wave, Relief / structural / textured | White | 25x1 | 2318 RUR |

| Vitrulan Phantasy plus | China | 210 g/m2 | Embossed / structural / textured | White | 25x1 | 10305 RUR |

| Vitrulan Phantasy plus | China | 210 g/m2 | 3D, Circles, Relief / structural / textured | White | 25x1 | 10305 RUR |

Glass wallpaper in the interior

Glass fiber in the interior of an apartment The best wallpaper for painting in a room with high traffic is glass wallpaper. In terms of its structure, it is a unique material made from woven fabric using fiberglass. Due to its physical properties, this type of wallpaper is an ideal solution for use in rooms where the factor of physical impact on them is very high. Fiberglass is very resistant to any mechanical stress and does not tear easily. In addition, their woven structure promotes stronger adhesion to the wall, which then becomes a significant problem when removing them from the surface. High resistance to mechanical stress and poor ability to absorb moisture increase the number of paint layers, which are limited only by damage to the structural pattern due to the increasing thickness of the paintwork material.

Fiberglass wallpaper for painting also has disadvantages associated with its poor air permeability. But this is rather their advantage, because only this type of roll covering can be used in rooms with high humidity. It will provide an additional waterproofing layer that will prevent moisture from entering and soaking into the wall.

Also sometimes, but to a lesser extent, they use paper wallpaper for painting as wall decoration, whatever paint is then needed so that they do not immediately peel off. In principle, this can be done with ordinary acrylic or latex paint, but it is best that it be thick. The less the paper gets wet, the lower the likelihood of it peeling off the surface.

Paint for glass wallpaper: 3 popular options

Paintable wall canvas can be painted with both alkyd and acrylic enamels and water-based paints.

Gloss paint WHITEenamel

Alkyd paint Enamel

Acrylic paint Enamel

It should be borne in mind that the tone of the future color depends on the main color of the glass wallpaper, so do not choose too light colors for application on dark canvases.

When painting, keep in mind that for successful work, the glass wallpaper must first stick to the glue, otherwise you risk displacement and damage to the appearance.

Application and putty of fiberglass

As noted above, gluing a cobweb is quite simple and you do not need to have any special skills to carry out this stage of work. However, before gluing fiberglass, you need to clearly understand the basic rules of gluing. So, the first thing you need to do is apply glue to the surface of the wall. However, it is necessary to prepare it in advance. After applying the adhesive solution, lay out the first strip of material and carefully fix it by lightly pressing along the edges. Then, apply glue to the rest of the work surface and attach the rest of the canvas.

Then it needs to be further processed using putty. This is how the surface is prepared for painting. It is applied after the installation of the Gossamer fiberglass itself has been carried out. Doing this is quite simple, and there is no need to have any special skills. All this can be done with your own hands.

By the way, we strongly recommend watching a useful video instruction on how to properly glue fiberglass web:

https://youtube.com/watch?v=tafb6MYDHHM

As for the actual laying of individual sheets, they should not be joined end-to-end, but overlapped, overlapping by a few centimeters. After this, it is necessary to cut both canvases along the connection line at the place where one of the canvases overlaps the other. You can cut them using a sharp construction knife. The remaining scraps can be thrown out, and then the sheets can be finally secured end-to-end along the new joining line.

In any case, before starting work, it is better to carefully study the installation issues, as well as everything related to the characteristics of the material:

- Its pros and cons.

- Correct painting and gluing technique.

- How to glue and with what glue.

- Installation of painting fiberglass on walls and ceilings.

We hope that after reading our information material you have a better idea of how to carry out all such work. We wish you a successful renovation!

How to stick glass wallpaper in corners

Gluing glass wallpaper in the corners is slightly different from the same procedure on the walls. First of all, you need to find out which corners in your room are straight or curved. As a rule, most of our houses have crooked corners. Still, let's consider both cases.

So, if the angle is straight

, the task becomes somewhat easier. First, we will describe the principle of working with an internal angle. As usual, you need to apply the glue to the work surface using an angled brush or an angled roller. After this, the canvas is applied to the wall and slightly moistened with a sponge in the corner. This is necessary so that the wallpaper straightens out a little and sticks better. After gluing, it is necessary to smooth both working surfaces well with a soft spatula. The operating principle is the same with the outer corner.

What to do if the corner is uneven

? Some difficulties await us here. In the inner corner, you first need to coat the walls well with glue and stick the wallpaper in the corner. As in the first case, you need to slightly moisten the wallpaper with a sponge. Next, you need to apply a ruler to the corner and carefully trim the protruding edge of the wallpaper. After this, glue is applied to the wall again. The next canvas needs to be glued with a small overlap. It will not be visible when painting.

If the outer corner has a curvature, then the glued fabric must be cut at the corner. The next strip will be glued to a wall pre-greased with glue with a small allowance at the corner. After this, use a sharp painting knife to cut off the protruding part at the corner.

Advantages, disadvantages

Pros:

- The material is environmentally friendly. Does not emit any harmful substances into the surrounding air.

- Due to the fiber structure, it is vapor permeable. Does not allow moisture to accumulate and prevents the formation of fungus.

- Fiberglass wallpaper is abrasion resistant.

- Subject to production technology, they can withstand repainting up to 20 times. The service life reaches 30 years.

- Fire resistant. In case of fire, they will not burn or release toxic substances.

- Moisture resistant. Resistant to direct water ingress.

- Immune to ultraviolet rays.

- Antistatic, repels dust from the surface.

- Not demanding in care. For preventative cleaning, it is enough to carry out wet cleaning.

Minuses:

Compared to paper counterparts, they are much more expensive. Gluing requires expensive adhesives. Dismantling can take a long time, but the high-quality glued canvas holds up very well. When working with fiberglass, precautions must be taken. Wear protective equipment: gloves, respirator, goggles, protective suit.

Look at the technical specifications

The density of the material must be taken into account. It is necessary to proceed from where the glass wallpaper will be glued. If the canvas is for the ceiling, the density is 25-30 g/m2, for wall decoration – at least 150 g/m2.

When producing fiberglass wallpaper, the manufacturer indicates the type of material on the packaging. The first grade canvas has high quality, the second grade can go on sale with minor defects. Sometimes defects are reflected not in the visible part of the product, but, for example, in the quality of the fiber. The product will cost slightly less, but will most likely last less time.

Fiberglass: questions and answers.

What is glass wallpaper? Fiberglass wallpaper (or glass wallpaper) is a decorative wall covering with a structure similar to fiberglass fabric. The starting material is special glass, from which fibers are drawn at a temperature of 1200°C, yarn of various types and thicknesses is formed from them, and then the material is woven. For glass wallpaper, textured patterns are woven - in several variants of applying decor in plain and wicker weaving, and for painting fiberglass (cobwebs) - just canvas. What is this special glass made of?

It is based on quartz sand, soda, lime and dolomite, which distinguishes fiberglass from other materials, since these are natural materials that guarantee the absence of harmful chemical elements and high wear resistance.

What is the difference between glass wallpaper and other wall covering materials?

Natural minerals used to produce fiberglass ensure that wall coverings are environmentally friendly and do not provide a breeding ground for microorganisms or parasites. Glass wallpaper and canvas are the same environmentally friendly materials as the glass in your windows, and fungus or mold will never appear under these wallpapers.

The use of natural minerals leads to increased strength - glass wallpaper does not tear, does not scratch, and is not afraid of chemical influences from concentrated disinfectants. Therefore, they can be washed, they also do not accumulate static electricity and do not attract dust.

Fiberglass wallpaper is a knitted material, like a wool sweater. And its open loop structure promotes the movement of water vapor, which improves indoor climate conditions.

And finally, they don’t even burn, which is an important requirement for fire safety of premises.

Are they really not burning?

Please! The non-combustibility of glass wallpaper is guaranteed according to Swedish standards CSN 73 0823, class B, C1 (corresponds to German DIN 4102/A2, B1), they are also certified in Russia.

How can you wash such wallpaper?

Fiberglass wallpaper can withstand almost all existing cleaning agents. The only thing you need to pay attention to is the properties of the paint with which you cover the glass wallpaper - not all paints can withstand even plain water.

What is a cobweb?

Painting fiberglass, which is also called gossamer because of its external similarity, is a decorative and at the same time reinforcing material for finishing surfaces in dry construction. Glass painting canvas is an ideal covering for premises where a combination of aesthetic and reinforcing effects, durability and ease of maintenance, and compliance with fire safety requirements are required.

What are the reinforcing properties?

Due to heating and shrinkage of building walls, thin and network-like cracks may appear in the plaster, invisible when the wall surfaces are dry. Fiberglass reinforcement eliminates this manifestation of cracks and creates a clean, smooth surface. The fiberglass reinforcement gives strength to the coating paint, closes cracks for a long time, is flame retardant, has high stability, and is very easy to use.

Where are glass wallpaper and painting fiberglass usually used?

In a variety of places: in homes, offices, restaurants, supermarkets, hospitals - wherever beautiful, durable surfaces that do not require complex maintenance are needed, and there are also fire safety requirements. For example, in the McDonalds chain and in the Intourist and Hilton hotels, in clinics, banks, car dealerships. Right down to the apartments.

How long does glass wallpaper last, for example, in offices with high traffic?

The average service life of glass wallpaper is 30 years, depending on the quality of the glue and paint and the frequency of washing. At the same time, the paint coating can be renewed up to 20 times, which solves the issue of changing the design and saves money.

What is the best way to glue and paint glass wallpaper and cobwebs? And How?

The glue is applied to the wall, not to the wallpaper; You need to use special glue. Fiberglass wallpaper is glued end-to-end - when cutting, you need to make an allowance of 5 cm in advance to fit the pattern; then the excess is cut off; but if you are gluing cobwebs or matting, then there is no need for large allowances.

If you use the second grade for finishing, you can make a horizontal joint, you can also glue any glass wallpaper if you still have a cut from the previous roll, or you cut the material incorrectly.

It is necessary to paint twice with an interval of at least 12 hours; in this case, an excessive amount of glue and paint can lead to the fact that the glass wallpaper begins to separate from the wall under the weight of the coating. If you need to cover a surface in a high-traffic area, choose your paint carefully - in this case, you need waterproof paint that is abrasion-resistant.

When choosing glass wallpaper, keep in mind that the faint texture is lost after several layers of paint.

On what surface can glass wallpaper be glued? And how to prepare surfaces?

It makes no difference whether the surface is made of wood, metal or plastic. You can cover concrete, cleared masonry, drywall and chipboard. During preparation, it is necessary to fill large cracks with putty and prime porous surfaces (with a weak glue solution). Small cracks will be reinforced with fiberglass, taking into account the inherent effect of glass wallpaper. For reinforcing surfaces and smoothing, we also recommend using painting fiberglass (spider web).

What is recommended to paint with?

When painting, it is important to know what result you want to achieve - and choose paint with this in mind. It is also necessary to consider what impacts the surface will be exposed to, how often it will be touched, how strong the touch can be, whether it will be washed; It is better to paint with latex gloss or semi-gloss paints.

What is the difference between cobwebs and glass wallpaper?

Gossamer, or painting fiberglass, has a lower density (35-50 g/m2, and glass wallpaper - from 100 g/m2) and structure. The purpose of the web is to cover a wall or ceiling to smooth the surface, apply finishing, reinforce small cracks, and glass wallpaper is a material for final finishing. The cobweb is used to achieve a “marble” effect - a perfectly smooth wall.

Wallpaper of the second grade, what is the difference between it and the first?

Among the series of glass wallpapers, economy-class glass wallpapers and second-class glass wallpapers are usually offered for economical buyers. Second grade rolls have a non-standard web length. When spinning glass fibers, problems sometimes occur - just like with conventional spinning. And manufacturers, when removing a defective piece, receive rolls not 50 m long, but 15 m and longer. When using the second grade, you can make a horizontal joint. The same technique can be used with the first grade, and if you carelessly cut a piece of the wrong length, or damaged the coating already on the wall, you can cut out this piece and glue a new one.

Are glass fiber wallpapers susceptible to mechanical damage?

Well, of course, if you try very hard - for example, by touching a heavy object with a sharp corner or rubbing it very long and hard - you can damage it. Fiberglass is not a concrete wall, but it can be broken through if desired. The main thing is that, unlike other materials, they are resistant to daily touches by hands, feet, and the back of a chair, and it is possible to replace a piece of glass wallpaper.

www.alaxar.ru

Preparing the surface

Regardless of the surface on which the glass wallpaper will be glued, it needs to be prepared. Thanks to this, you can achieve maximum quality of pasting. The service life also increases.

The preparation of walls includes the following steps:

Removing old finishing materials - wallpaper, putty, paint. Wallpaper made of paper can be moistened with water and easily removed with a spatula. The same goes for plaster. And the paint is treated with a construction hairdryer, followed by removing the residue from the wall. Next you need to evaluate the walls for damage, cracks and unevenness. They are sealed with putty. If the differences are more than 5 mm, then repeated puttying is carried out. After puttying, the layer is rubbed down with fine-grained sandpaper. Dirt, grease stains and other inclusions on the surface are removed. It is cleaned of dust and dirt. The final stage is priming. The substance will reduce glue consumption, improve adhesion and protect the wall

It is important to process all areas without gaps. It is best to use a roller and lubricate hard-to-reach areas with a brush. When the first layer is dry, you can apply the second

Drying time is indicated on the packaging. Subsequent work can be performed after the second layer of primer has dried.

When working with drywall, you need to use putty to treat the joints and hide the caps from the screws. The joints are glued with sickle mesh.

Surface preparation

Concrete, drywall, wood and any other surface need preparation before applying fiberglass. If you skip this point, the service life of the glass wallpaper will be significantly reduced.

What you will need to prepare the walls:

- metal spatula,

- plaster,

- roller,

- primer,

- putty.

Stages of surface treatment for gluing glass wallpaper:

- First, old finishing materials are removed. Paper wallpaper is moistened with plenty of water and removed with a metal spatula. If the wallpaper is vinyl, then first the vinyl layer is removed, and then the walls are wetted and the remaining base is removed (vinyl repels moisture).

- The cleaned walls are carefully inspected for significant cracks, chips and other defects. If they are present, the surface must be plastered.

- A layer of primer is spread onto the plaster using a roller. It will strengthen the adhesion of the putty to the wall.

- Next, the walls are puttied in one or two layers and left to dry for 12 hours. A layer of putty is necessary for good fastening of the glass wallpaper. It gives the walls a grainy look.

- After drying, the excess putty is cleaned off.

- Primer is applied again. After it has dried, you can start gluing the wallpaper.

If drywall is being prepared, then only the joints are puttied. They are filled with a special compound and glued on top with reinforcing tape, which is pressed in with a spatula. After drying, the surface is leveled with sandpaper and primed, now completely. Gluing begins after the primer has dried.

Wallpapering the wall

It is worth noting that when working with glass wallpaper, it is important to be properly equipped, wear gloves, long sleeves, and possibly glasses. The fact is that some types of glass wallpaper crumble, and the crumbs can cause unpleasant itching

When cutting glass wallpaper into pieces, please note that the front side of the canvas is usually located inside the roll, and is embossed and has a certain pattern. The wrong side is usually marked with a special blue or gray line; it is usually even. When cutting the roll into pieces, do not forget to leave a small allowance, around 10 centimeters

This will allow you to correctly align the pattern of the wallpaper, clearly align it, and prevent large gaps at the top and bottom.

When cutting the roll into pieces, do not forget to leave a small allowance, around 10 centimeters. This will allow you to correctly align the pattern of the wallpaper, clearly align it, and prevent large gaps at the top and bottom.

Fiberglass wallpaper comes in different qualities, these are not the bestWhen examining the topic of how to glue glass wallpaper for painting, it is worth noting that work with this finishing material is carried out according to a standard plan:

- Apply glue to the walls near the door or near the window, depending on where you plan to start gluing.

- Starting from the top, apply the wallpaper to the wall, making sure that the piece is evenly positioned relative to the drawn vertical stripes.

- Having carefully smoothed the wallpaper using a special plastic spatula and making sure that it is securely fastened, you should use a metal spatula and a sharp utility knife to cut off the excess part of the wallpaper.

- The next piece is glued in a similar way, only in this case you should carefully connect the pattern at the junction of the canvases. Is it possible not to connect the joints according to the pattern? In some cases, yes, when the ornament is a very small cell.

- Try to bring together pieces of glass wallpaper as efficiently as possible, making a beautiful joint without overlap or gap. Pasting walls with glass wallpaper is generally easier than working with conventional wallpaper, but high demands should be placed on the joints.

The drying time for glass wallpaper on the wall varies from one to two days, in rare cases it may take longer. After the canvas has dried, you can begin painting it. Paint for glass wallpaper should be selected taking into account the characteristics of the room, however, regardless of its type, painting is done in two layers. In this case, the second layer is applied to the glass wallpaper after the first has completely dried, which is approximately 15-20 hours.

The final result after painting

Many people are interested in how to glue glass wallpaper to the ceiling. In principle, the technique for working with the ceiling is similar, only in this case it is more convenient to work together. Working with a partner will allow for better gluing.

Considering the question of how to glue glass wallpaper, we gradually came to the conclusion that it is better to work with both the walls and the ceiling in pairs. Of course, a professional master can easily stick the wallpaper alone, but this will undoubtedly increase the work time, and the quality may suffer. Is it possible to paste such wallpaper yourself, of course, like any other, because, as can be seen from the article, there are no particular difficulties.

Now you know how to properly glue glass wallpaper, and therefore you can create a unique, exclusive and very durable interior in your apartment. Using glass wallpaper will help you transform any room, from the living room to the kitchen. Pasted on the walls, this finishing material will withstand repeated repainting, and therefore you will not get tired of it for a long time.

Pasting wallpaper on brick and concrete walls

How and with what to apply primer to walls before puttying or painting

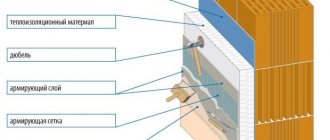

Typically, brick and concrete walls do not require any specific treatment before wallpapering. A layer of leveling plaster and finishing putty is sufficient. But, in some cases, a reinforcing material is used - fiberglass.

It is advisable to use fiberglass for putty in new, recently commissioned houses, in which the shrinkage process has not yet completed and there is a high probability of cracks appearing on the walls.

Thanks to its high strength characteristics, fiberglass glued to the wall will prevent the formation of cracks in the plaster and the tearing of the wallpaper above the crack. The second option for using high-profile fiberglass is gluing brick (concrete) walls painted with oil paint.

Not all wallpaper adhesives are capable of holding wallpaper on oil-based paints. Therefore, a painted wall needs preliminary putty. But putty, in turn, can also peel off from oil paint. To do this, reinforcing fiberglass should be glued to a painted surface using the same adhesives as when gluing to plastic panels. Before gluing the fiberglass, the painted surface should be treated with coarse sandpaper.

Glass wallpaper

This is a fiberglass material, made on machines, intended for wall decoration. Often used for painting.

Woven building material, during weaving of which designs are realized. There are fewer forms than paper counterparts, the pattern is poorly defined, but due to practicality and the possibility of re-dyeing, the shortcomings are almost invisible.

Drawings are divided according to roughness into fine, medium, and coarse texture. The “matting” design is considered common. The name was given from a woven material with a similar name.

Walls with glass wallpaper

Among the designs you can find Christmas trees, diamonds, and a checkerboard pattern.

Choosing glue for glass wallpaper

Standard adhesives intended for ordinary wallpaper are not suitable for decorating surfaces with glass cullets. Such compositions are not able to withstand the heavy weight of glass materials and will not be able to hold them on the wall or ceiling for any long time. If the fiberglass manufacturer has not given recommendations on the choice of specialized wallpaper adhesive, the choice of a suitable composition falls entirely on the shoulders of the home owner.

Glue for glass wallpaper can be powder or liquid. Liquid compositions are ready for use, while powder compositions must be diluted with water before installing the cladding. Some wallpapers already have an adhesive layer applied to them; such materials are very easy to install; just moisten the inside of the canvas with water and stick it to the surface.

Glass wallpaper requires special glue

There is a wide range of adhesive compositions on the market; professionals recommend choosing only adhesive brands from well-known, trusted manufacturers for work. One of these brands is Oscar - a PVA-based adhesive composition. It is hypoallergenic and completely safe for humans, contains special antifungal components, and can withstand several cycles of freezing and thawing without losing technical characteristics. Due to its resistance to moisture, it can be used to decorate any room, does not leave stains after use and does not turn yellow over time.

KleoUltra glue is another frost-resistant market representative based on starch, containing additives that prevent the appearance and spread of fungus. It is a dry solution that must be diluted with cold water before use. After dilution, the glue retains its properties for 10 days. Sold in high-quality packaging that protects the contents from any external negative influences.

Metylan Fiberglass Premium is an adhesive designed for working with glass wallpaper, it is easy to use, resistant to moisture, and does not leave stains or streaks on the walls. Quelyd Glass Wallpaper adhesive is easily and evenly applied, has protection against fungus and mold, can be used for manual and machine application to wallpaper, remains colorless and dries completely in 2 days.

Of course, you can glue glass wallpaper to the ceiling and walls using other compounds, but using glue from an unknown manufacturer, you risk not only performing poor-quality installation, but also simply ruining the purchased facing materials, and wallpaper made from fiberglass is quite expensive.

What is glass wallpaper

Fiberglass wallpaper is a finishing material for walls and ceilings. Most often used for painting. Fabrics, which are called “glass wallpaper,” are woven from fiberglass on special machines. By using fibers of different thicknesses and their different weaves, different patterns are obtained. There are not as many of them as on regular wallpaper, they are not too pronounced. And this is considered one of the disadvantages of this finishing material. But practicality, durability and the ability to repaint them up to 20 times outweigh this drawback.

Types of glass fiber matting type

There are drawings that are almost invisible, which after painting just give a slightly rough surface. The most common type is matting. It is called so because the weave is made in the same way as coarse cloth was previously woven - matting. There are small, medium, large. The difference is visible in the photo.

Herringbone, checkerboard and diamond patterns are also widespread. They also come in small, medium and large. They differ in the “scope” of the pattern. In addition to these types, there are other weaves, but they already belong to the category of designer or collectible and cost more.

This material is sold in rolls, usually 1 meter wide. Roll length - from 12.5 m (50 are also available). Price per roll - from $20 to $50. The cost depends on the length of the material in the roll, the complexity of the design, and the manufacturer.

The production process and what glass wallpaper is made of

Fiberglass wallpaper is made from a special type of glass with high softness. They are created using various methods, but the most popular is the classic method, which allows you to create canvases of any thickness and size.

The glass mass is heated and stretched until fibers of the required length and thickness are obtained, and then intertwined. The entire process is carried out using automated technology, which allows this stage to be completed as quickly and efficiently as possible.

There are glass wallpapers made of pressed glass with the addition of polymer components to increase flexibility. This finish does not have spaces between the fibers, but is more fragile and less durable.

Most wall coverings are additionally coated with various materials for smoothness.

Fiberglass wallpaper for painting

If you have chosen glass wallpaper designed for further painting, they are glued in a simple and familiar way, just like regular wallpaper.

Here it is important to achieve good quality of joining of the edges of the strips. Otherwise, after painting the joints will be even more visible.

The paint is applied only to dried wallpaper (the drying period of the ceiling surface covered with glass wallpaper is 2-3 days).

In this case, water-based paint, acrylic-based paints, or butadiene and styrene paints are suitable for painting. The listed materials are easy to work with, are durable and have good color saturation.

In all cases, it is important to use paint that does not emit a strong synthetic odor

For reference: the finished surface is painted in two layers. The drying time for each layer is 10-12 hours. The optimal paint consumption for these purposes is 0.5-0.6 g/m2.

Preparing for painting

For further coloring, wallpaper without color is selected - otherwise it may show through a thin layer of paint, and if you apply color in a thick layer, the relief will be hidden under it. For painting, water-based and water-dispersion paints are mainly used. There are also special paints designed for glass wallpaper. This should be indicated on the packaging.

How to paint fiberglass correctly:

- After drying, the wallpaper is covered with a thin layer of glue using a roller. The powder is diluted with double the amount of water.

- The first layer must dry before the second is applied, otherwise the fiber will begin to pill.

- The second coat of primer is applied in the same way as the first.

- After the primer has dried, you can change the color.

- Painting is done in two layers. The second layer is applied after the first has completely dried, after about 20 hours.

Don't neglect the primer. Fiberglass wallpaper absorbs paint well, so you will have to apply it in large quantities, which will affect the final result. By the way, instead of liquid glue, you can purchase a special primer for painting glass wallpaper.

How to make the right choice

- There is an opinion that the thicker and denser this type of wallpaper, the better it is. This is wrong. Manufacturers often use a large amount of impregnation, which makes the wallpaper dense. But in this case, when sticking, the pattern on the wallpaper becomes inexpressive, because impregnation, as practice shows, does not give any texture.

- Another misconception: the texture on the wall looks exactly the same as on a roll. However, some manufacturers use so-called fluff threads in the manufacture of glass wallpaper; they are slightly wider than usual. When the air is squeezed out with a spatula, such threads become flat, so that there is no trace of “looseness” left.

The question arises - how to choose fiberglass wallpaper? There are several options.

- Take a small piece of wallpaper and paste it on the wall. They paint and go over it with a spatula. In this way, a full test can be carried out. If the material is not flattened, this is a sign of quality. But it is not always possible to carry out such tests, so we propose a second method.

- You will have to trust the quality mark itself, or, as they say today, the brand. We recommend purchasing products from world-famous manufacturers. We remind you of the Swedes from: glass wallpaper Oscar, Tassoglas and Wellton. We also advise you to take a closer look at the German concern Vitrulan Textilglas GmbH, which produces Vitrulan glass wallpaper.

How to choose

Typically, glass wallpaper is selected according to the pattern, and the quality is determined by the density of the material in the roll. But it’s worth saying that not everything on the wall looks as voluminous as it does on a roll. To make the pattern look clearer, some manufacturers use fluffed threads. When sticking to the wall, all the fibers are pressed, the volume goes away. So the volume of the roll is not a guarantee that the design will be clearly visible on the wall. The solution is to purchase proven brands that guarantee a certain quality.

You need to choose not only by appearance

The situation is practically the same with the density of glass wallpaper “to the touch”. To give them additional strength, some manufacturers impregnate the canvas with starch. When applied with glue, this impregnation gets wet, the surface becomes loose, which is why it absorbs a large amount of paint.

Look at the technical specifications

How to determine good glass wallpaper in this case? View technical specifications. There is a line there - density. The higher the number, the denser the wallpaper (normal density is about 145 g/m2). If this indicator is not present, there is a roll weight. In this case, too, the heavier the roll, the greater the density of the material. But in the case of weight, you also need to look at the length of the canvas in the roll - it can be very different - from 12.5 meters to 50. There is another way out - trust trusted manufacturers or try it on a small piece - glue it, then paint it. Only the question of where to get this piece remains open...

What else is worth knowing about glass wallpaper...that they come in two grades - first and second. The first grade is of good quality and usually comes with a warranty. The second type is something like a lottery. They may be wow, they may not stick well, have a large number of defects, etc.

Glass wallpaper in the interior

A few words about marriage. It occurs even with good manufacturers - the threads are broken, they lie wrong, etc. This place is marked on one of the edges of the roll with a glued black stripe, and 50 cm (penalty) is added to the length of the roll. When purchasing a roll in transparent packaging, inspect the ends. The fewer black “markers”, the easier it will be when cutting.

Types of glass wallpaper

Rolls are produced 1 m wide and 25–50 m long. However, the sizes may be different, especially if the coating is produced to order - some companies provide this service.

The material is selected according to several criteria:

- Texture: smooth, embossed. The former are also known as glass interlining, and are more often used as a reinforcing coating. The latter have a clearly defined texture; a convex ornament or pattern can be seen on them, which depends on the loom - rhombus, herringbone, bamboo, matting, jacquard and others. This material is thicker and heavier than textureless material. The relief can be very deep and on the ceiling imitates decorative plaster with stucco elements.

- Class - 1, 2, economy. The most durable wallpaper of class 1, with a density of 100 g/m2 and higher. Such coatings last 30 years or more. Class 2 material is less durable, and the pattern and texture on it lose their expression when repainted. Economy category canvases are the thinnest and often defective.

- Compound. The coating consists of fiberglass and impregnation; the optimal ratio is 70%/30%, respectively.

- Density. The thinner the wallpaper, the lighter, cheaper and easier it is to glue. But thick material lasts longer and can be repainted more times.

- Color. There are two types of glass fiber - colored and paintable. In the first case, a topcoat is not required since the pigment is added to the fibers. But if desired, it can also be painted. Coatings for painting are usually white or milky in color.

- Special properties: anti-vandal, anti-claw. Such materials are resistant to mechanical stress and scratches.

When choosing wallpaper, it is important to pay attention to the quality of the canvas. The weaving should be neat and the edges should be even. Another critical parameter is water resistance.

Manufacturers provide this information on the label with wave-shaped icons:

Another critical parameter is water resistance. Manufacturers provide this information on the label with wave-shaped icons:

- one - withstands only a damp cloth and suede;

- two - medium level, soap may be used;

- three - the use of non-abrasive cleaning products is allowed.

Fiberglass may have other properties. Thus, you can purchase products coated on the back with glue, which is activated by water. When using them, the work is significantly reduced, and bubbles occur less frequently. Some factories, in order to reduce repair time, produce materials with a primer layer.

To get a high-quality coating, you should buy wallpaper from well-known and trusted manufacturers. A lot of low-quality products are produced, which often lack the advantages that high-quality fiberglass fabrics have. The following brands are considered the best on the Russian market:

- Practical;

- Pufas;

- Wellton;

- X-Glass;

- Colors;

- Kleo.

Criteria for choosing glass wallpaper for painting

The peculiarities of glass wallpaper production sometimes make it difficult to choose. It may be impossible to visually distinguish high-quality products from defective ones. Knowledge of selection methods does not help either. For example, the density and thickness of the material can be increased by impregnation. But this will definitely have an effect during the pasting process - the canvas tears, deforms, loses elasticity, and sometimes decreases in size. As a result, the clarity of the drawing is disrupted.

The ideal solution to the problem is to cut a piece from the roll, stick it on a solid base (not advisable on the wall, because if the quality is good, it will take a long time to peel it off), let it dry, and paint it. The test is completed by pressing the spatula onto the trellises. If they are not deformed or change their appearance, the quality is high.

If this is not possible, the choice should be made according to the following parameters:

- density;

- composition;

- class;

- pattern.

Density. The density criterion determines the durability of the trellis. There is a direct relationship here: the denser, the longer the service life.

Wallpaper with a density of over 100 g/cm2 is considered high quality. But this is the lower limit of the indicator. You need to focus on the figure of 150 g/m2 (European manufacturers have a standard value of 145 g/m2). Deeply patterned fiberglass fabric (jacquard) can be even heavier, up to 220 g/m2.

But here, as with any rule, there are exceptions. For the ceiling, 25 g/m2 is enough - that’s how much smooth cobwebs weigh. But for walls, the web canvas should have an indicator of 45-50 g/m2.

Compound. Many buyers underestimate such a selection criterion as composition. But in vain. The strength and durability of the finish depend on the indicator. At the same time, deviation of the ratio of 70% fiberglass to 30% impregnation in any direction worsens the consumer characteristics of the finishing material.

Information about the composition should be on the insert. Its absence should alert the buyer.

Class. On the insert you can also find the class of wallpaper (Russian manufacturers indicate the grade, which is the same thing). You need to buy first class fiberglass trellises. When purchasing second-rate decor, the density must be at least 100 g/m2.

Pattern. For the ceiling you need smooth wallpaper - cobweb. For the walls, the pattern is chosen depending on the taste of the owners (“matting”, “herringbone”, “drops”). At the same time, a pattern with greater depth can be repainted more times - the pattern will be preserved.

Gluing technology

Like any construction and repair process, gluing glass wallpaper is carried out in several stages

Here it is important to approach each stage with full responsibility and be extremely careful when carrying out all repair operations

Stage one - preparation

As always, it all starts with dismantling the old finish. Let's look at several types. For example, the most effective way to remove paper wallpaper from walls is to wet it with a sponge. To do this, use a roller or brush. The wallpaper is given a little time to get wet, after which they begin to peel it off (here you can use a regular metal spatula).

Walls painted with water-based paint are simply washed with a rag or sponge. But oil paint cannot be removed this way. It is often removed with sandpaper, but this is time-consuming and difficult, so there is a mechanical method. To do this, a special metal brush is inserted into the drill; with its help, the paint can be removed in a day. It is better to buy a special remover for oil paints. After its application, the paint softens and is removed with a spatula. In the worst case, you will have to put notches on the walls and putty them before gluing.

So, the wall decoration has been eliminated. Now, for better adhesion between the materials, it is primed. After drying, the wall surface is leveled and small defects are repaired at the same time. Fiberglass wallpaper itself, with its dense structure, can cover both small differences in plane and minor defects.

We offer articles on leveling walls: leveling with plasterboard, plastering on beacons. The last operation in the preparatory stage is priming the prepared wall.

Stage two - prepare the glue

We have already said that every operation in this difficult matter is very important. This also applies to the preparation of the adhesive composition, because the long-term operation of the wallpaper glued to the walls depends on its proper preparation. For glass wallpaper, for example, you cannot use glue for paper analogues. This is the biggest mistake that beginners sometimes make in this business.

The textured surface, which is also very dense, weighs much more than an ordinary sheet of paper. But glue for paper wallpaper is not designed for such weight, it simply will not hold the material on the wall, there will not be enough adhesion force.

Typically, manufacturing companies offer their own adhesive suitable for their material. Most often, Oscar glue is used for glass wallpaper with a colored pigment, which shows uniform application. There is also a universal frost-resistant adhesive for glass wallpaper: Pufas, Security GK 10, Kleo Ultra and others.

This composition is stirred with ordinary water to a certain consistency. But we won’t delve into all the details of preparing the glue; instructions are on the package.

Stage three - glue wallpaper on the wall

Let us note only a few nuances.

- An important point is equipment. Glass fibers will crumble and particles may cause skin irritation. To avoid this, we glue the glass wallpaper while wearing long sleeves and putting gloves on our hands.

- Glass wallpaper has two sides: the back and the front. In a roll, the front side is on the inside, the back side is always marked with a blue or gray stripe.

Now we glue the wallpaper. First, strips of material are cut with a small allowance, which compensates for the alignment of the pattern. Lay strips end to end

It is important here to connect them accurately without cracks or gaps. By the way, the glue must be applied to the surface of the wall, and not to the material itself. A roller is usually used for this

A roller is usually used for this.

Each strip is rolled with a clean roller or a special spatula to remove remaining air and glue from under the material. The joints must be cleaned of glue with a clean cloth or sponge. Using the same technology, you can glue glass wallpaper to the ceiling. The stage of pasting the walls is shown in the video:

Stage four - painting

You can paint fiberglass wallpaper only after it has dried thoroughly. Therefore, you will have to wait two days. Due to the porous structure of the material, the paint is quickly absorbed. To reduce its consumption, the finishing surface must be treated with a primer (it can be made from wallpaper glue). This is a thick aqueous solution.

Until recently, this finishing material was used only in public and office spaces. But with an increase in quality characteristics (let's give credit to the manufacturers!), fiberglass wallpaper can now be used to decorate walls in living rooms.

Video “How to glue glass wallpaper”

Before starting repair work, carefully look at this practical guide to gluing glass wallpaper. This will help you do everything according to technology and avoid typical beginner mistakes.

We recommend that you read

How to paint wallpaper for painting yourself

DIY wallpapering technology

Paintable wallpaper: pros and cons

Advantages and disadvantages

Like any other finishing material, fiberglass wallpaper is not without advantages and disadvantages, and since they appeared recently, few people are aware of them. However, having some idea about the pros and cons of glass wallpaper, you can already draw some conclusions.

What good can this finishing material offer us:

- Environmentally friendly - all modern wallpaper is made from substances that are harmless to humans. Fiberglass wallpaper is made from glass, which in turn is created from natural materials. Wallpaper made from artificially created material prevents the growth of mold and mildew.

- Non-flammability - glass wallpaper does not burn, it slowly smolders under the influence of high temperatures and does not emit harmful substances.

- Strength and strength - fiberglass wallpaper is one of the strongest, it is very difficult to tear or scratch. In terms of strength characteristics, these wallpapers are 2 times stronger than their vinyl counterparts.

- Durability - the service life of glass wallpaper from different manufacturers can vary from 20 to 30 years. At the same time, it is quite acceptable to regularly paint the walls throughout their service life.

- Moisture resistance - the wallpaper is made of artificial materials that are not at all afraid of water. In addition, the structure of the wallpaper allows steam to circulate easily, which benefits the overall microclimate of the room.

Fiberglass is a fairly popular finishing material, which is used not only for renovations in public institutions and offices, but also in residential apartments. In terms of its technical and practical characteristics, this finishing material can easily compete with paper, vinyl, and non-woven counterparts. In addition, you can use glass wallpaper for the ceiling, and not just for the walls, which is very convenient.

Popular manufacturers and prices

A well-known brand can guarantee quality. Among them are many world-famous companies producing fiberglass wallpaper:

- "Vitrulan";

- "Tassoglas";

- "Nortex";

- "Welton"

- "Oscar"

- "Bau Master";

- "X - Glass";

- "Saint-Gobain Novelio";

- "Waltex"

- "Veterman"

- "Mermet" etc.

"Vitrulan". Fiberglass wallpaper under the Vitrulan trademark is produced by the German concern Vitrulan Textile GMbH, the largest manufacturer in Europe. The company's technologists are constantly working to create a variety of lines of trellises, as a result of which they are distinguished by their smoothness, types of patterns, softness and color. And all this with quality that is commonly called German. The base price per 1 m2 ranges from 170-468 rubles.

"Tassoglas". The product of an American company with its factories in the USA, Europe and China. It achieved fame thanks to the widest range of surface textures among similar productions. Practical and high-quality fiberglass is used not only for finishing offices and organizations, but also for covering walls and ceilings in living rooms. Rarely found on sale. Costs from 82 to 450 rubles/m2, depending on density.

"Nortex". "Nortex" is a trademark of a Russian company. Production is located in China. Takes into account the requests of all buyer groups. Therefore, on the market you can find both premium-class wallpaper with a high density of 200 g/m2, and economy-class wallpaper with a density of up to 100 g/m2. They are distinguished by durability, a guarantee of over 30 years and a variety of patterns. The price range is significant. You can buy it for 66 rubles/m2 (“Medium matting”), and for 168 rubles/m2 (“Rain”).

Welton. A Swedish brand with established production in many countries of the world: Germany, Russia, Czech Republic, Finland and China. All production facilities produce high quality products with stylish design. The cost of 1 m2 is about 208 rubles.

"Oscar". Subsidiary, but with more affordable prices and good quality - 69-107 rubles/m2.

"Bau Master" China. They are distinguished by affordable prices and good quality. The cheapest wallpaper can be bought for around 33 rubles/m2, the most expensive - 130 rubles/m2.

"X - Glass." Russian manufacturer with a wide range of glass fiber and canvas in the middle price range. For example, fiberglass fabric can be found on sale for 47-80 rubles/m2.

If we consider specific wallpaper models, their rating for mid-2021 is as follows:

1. "Vitrulan Acoustic 904 Labyrinth". The wallpaper is unique in that a layer of heat and sound insulation is applied to the reverse side (reduces noise by about 2 times). Their density is 610 g/cm2, dimensions are 10.4 x 0.96 m, price is 20,866 rubles. per roll.

2. “Vitrulan Aqua Plus 604 phantasy microcrepe.” The highlight is that there is no need to select a design or buy glue - it is already applied to the back side. Density - 200 g/m2, dimensions - 1 x 25 m, price - 9400 rubles. per roll.

3. “Brattendorf B021 Rain.” German quality products costing about 9,360 rubles.

4. "Novelio Checkers 1023". Czech glass wallpaper 25 m long, density 195 g/m2, priced at 4,078 rubles per roll.

5. "X - Glass Gold." Finishing finishing material with a price of 3200 rubles. per roll.

Pros and cons of glass wallpaper for ceiling finishing

This type of coating has gained popularity due to its advantages:

- fire safety class KM1 - they do not support combustion, do not spread fire and smoke, and do not emit toxic substances;

- environmentally friendly;

- durable, have reinforcing properties, tighten cracks;

- serve for at least 30 years;

- protect the room from external noise;

- are breathable;

- easy to clean;

- the textured surface hides some rough finishing errors;

- dielectric, so dust does not collect on the ceiling;

- hypoallergenic and suitable even for a children's room;

- do not cause the formation of fungus or mold;

- resistant to moisture, temperature changes, and do not fade when exposed to sunlight.

Glass wallpaper for the ceiling will decorate the interior of any room. They are even suitable for the bathroom, kitchen and glazed balcony, if you properly prepare the surface and use waterproof paints.

However, the coating is not without its drawbacks. Of the minuses, the masters note:

- high price of both the wallpaper itself and related materials;

- peeling from the surface due to non-compliance with gluing technology;

- difficult dismantling, since glue and impregnations provide strong adhesion;

- irritation of the skin and mucous membranes - when working with the material, you must use personal protective equipment.

Preparing walls and ceilings

How to glue glass wallpaper, to do this you should thoroughly clean the surface of the walls or ceiling from old wallpaper or plaster and eliminate all irregularities. Cracks, holes and potholes can be filled with plaster, minor defects and roughness can be eliminated with putty.

After this, you need to perform final sanding using sandpaper or a scraper. It is advisable to treat the walls and ceiling with a fungicidal compound to prevent the appearance of mold.

The next stage of surface preparation is priming. This operation will increase the adhesion of the surface and completely remove dust from it. As a result, the adhesion rate of wallpaper glue to walls or ceilings will increase significantly.

For these purposes, both a deep penetration primer and highly diluted wallpaper glue (at a concentration of 50 grams of dry mixture per five liters of water) are suitable. Priming is done with a paint roller; the applied layer should be thin. Each wall or ceiling should be rolled over two or three times, after which the layers of primer should be absorbed and dry.

There is no need to worry if small unevenness or scratches remain on the wall after all these operations - the texture of the wallpaper will help hide these defects. On the other hand, wallpaper will not cope with sagging, so the walls must be checked especially carefully for the presence of such irregularities.

Advantages of the material

In addition to the fact that fiberglass coatings can be repainted up to thirty times without losing their beautiful appearance, this design option has other serious advantages over covering the ceiling with traditional wallpaper or conventional painting of the surface.

- The coating is very strong and durable.

- The width and length of a roll of such wallpaper is twice as large as that of standard options - this will allow for faster finishing.

- The fiberglass from which the coating is made does not support combustion.

- Fiberglass does not cause allergies, as it is made from non-toxic natural materials.

- Working with fiberglass is easy and even someone who has no experience in such matters can figure out how to glue such wallpaper on the ceiling.

- The cost of finishing will be low.

- The color of the coating is determined at will and can be absolutely anything.

With so many positive qualities, this type of design has no significant disadvantages. There is only one insignificant drawback - the not very large range of textures offered. However, for each room you can find a suitable option even using a limited number of textures.

Features and characteristics of glass wallpaper

Fiberglass wallpaper is very different from ordinary paper facing materials. They are made from special glass, which is melted at high temperatures and created from it into a canvas by joining glass threads. This production technology provides the canvas with high strength and allows you to create not only smooth, but also textured wallpaper and wallpaper with ornaments. Owners decide to glue glass wallpaper for painting, since this material allows you to hide small surface defects and makes the walls or ceiling smooth and attractive.

Embossed glass wallpaper is used for finishing

Fiberglass cladding consists of sand, clay, limestone and other environmentally friendly and completely safe natural materials for humans. Smooth wallpaper is usually used for:

- sealing surfaces to be coated;

- hiding minor surface defects;

- leveling the walls before finishing cladding.

Embossed glass wallpaper is used for finishing surfaces. Their density is significantly higher than that of standard fiberglass, which is why they are much more difficult to tear or stretch during use. The texture of such materials depends on the technology of their production. Conventional machines allow you to create only simple geometric shapes on the surface of fiberglass - rhombuses, triangles, rectangles and others. Specialized jacquard machines make it possible to create much more complex, sophisticated textured images on wallpaper.

Fiberglass wallpaper is sold in rolls 1 m wide. If used correctly, one roll of such cladding will be enough to cover more than 50 m2 of surface.

Glass wallpaper has become widespread today due to its positive qualities, which usually include:

- Possibility of coloring. Glass wallpapers are smooth and textured and are intended for further painting. Painting makes it possible to make the interior of decorated rooms brighter, more attractive and individual, and increases the durability of the cladding. High-quality glass wallpaper can be repainted up to 20 times, and it will retain all its technical and visual characteristics.

- Fire safety. When making glass wallpaper, glass threads are coated with special fire-fighting solutions, thanks to which the finished material can withstand even the strongest temperature influences. Thanks to this, they can be used in hot regions and in rooms characterized by sudden temperature changes.

- Resistance to humidity. Glass wallpaper does not interfere with air circulation and does not deform when in an environment with high humidity, so they can be used to decorate “wet” areas in the house.

- Ecological cleanliness. To produce such wallpaper, only natural, hypoallergenic components are used that are not capable of harming human health.

- Durability. The service life of glass wallpaper is more than 25 years.

- Resistant to electricity. Fiberglass does not accumulate an electrical charge and dust does not accumulate on it.

A big plus of fiberglass wallpaper is the ability to paint it in any color.

The disadvantages of fiberglass wallpaper include the following features:

- Fragility. If installed incorrectly, the canvas may break in your hands.

- A complex procedure for removing old wallpaper from surfaces.

- Low elasticity, so they can only be glued to flat surfaces.

- Large paint consumption when painting manually.

Among other things, glass wallpaper is much more expensive than other, more traditional means of covering horizontal and vertical surfaces.