Installation of cardboard

Fundamentally, the installation technology does not differ from standard or moisture-resistant drywall, it is simply somewhat complicated by the high rigidity of the coating. For installation, a reinforced guide profile is used, which can withstand higher loads than the standard one.

Photo - editing

Step-by-step instructions on how to install fireproof drywall:

The first stage is preparing the walls. They are stripped of the old coating and treated with priming and, if necessary, leveling compounds.

Please note that many professional builders also recommend additionally covering the walls with fire-resistant substances, which will help increase the fire safety of the home; Next, mark the installation location of the cardboard. The profile is mounted at a distance of 10 cm from the ceiling, and up to 5 cm from the floor (depending on the type of frame)

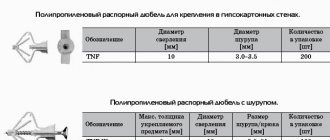

It is secured with elongated dowels; Direct installation of drywall is also carried out using special fasteners. They must be made of fire-resistant material (alloy steel) and have high torsional resistance. This will increase the rigidity of the support system.

The finishing process is carried out in the same way as for other sheets - the surface is primed with a special primer, after which the seams and slopes are rubbed down.

You can buy fire-resistant plasterboard in any city in Russia and the CIS countries; the price of the coating may vary depending on the brand and size of the sheets. Construction materials from Knauf, which are additionally processed with resistant compounds, are considered to be of the highest quality. Cost 12.5*1200*2500 Knauf:

What ensures fire-resistant qualities?

The gypsum core with glass fibers does not require special treatment. The inorganic base has natural fire-resistant properties, which are enhanced by special firing of the gypsum mass.

Cardboard cladding is impregnated with fire retardants to increase fire resistance. The entire plasterboard board is thoroughly pressed. The presence of air bubbles between layers is excluded. As a result, fire-resistant plasterboard has improved fire-resistant characteristics.

The absence of air layers prevents the product from being easily flammable. A standard fireproof sheet can withstand 20 minutes of exposure to an open flame.

Select manufacturers produce products with increased fire resistance. The fire resistance limit of plasterboard is increased by an additional inner layer of clay. Depending on the composition of the clay mass and the thickness of the layer, the fire-resistant properties may vary.

Manufacturer's choice

Types and characteristics of fire barriers

The plasterboard of the German brand Knauf is considered the most resistant to fire due to the surface impregnated with a special fire-resistant compound. The fire resistance limit of Knauf plasterboard is 60 minutes, after which destruction begins. Characteristics of Knauf heat-resistant plasterboard include the fact that it does not conduct electric current in the event of heavy water flooding from neighbors above or leaking water pipes.

Knauf fire-resistant plasterboard has the character of environmental safety, water resistance, and fire resistance properties. Fireproof plasterboard is used:

- for fireplace

- suspended ceilings

- partitions in private houses

- in high-traffic public places

- in schools, childcare centers

The product is the most in demand on the market, 2/3 of gypsum plasterboards are sold with the Knauf trademark.

in Volgograd produces fire-resistant plasterboard with a high degree of fire resistance - 45-50 minutes. The material costs a little less than imported analogues.

The beveled edge of heat-resistant boards with a line applied by the Rigips company (Rigips) facilitates the marking and installation of fire-resistant sheets.

from the city of Saransk supplies fire-resistant plasterboard with increased strength and flexibility. Heat-resistant plasterboard has high class A characteristics, environmental safety and high dimensional accuracy and a refined edge. The fire resistance limit of Magma plasterboard is 45 minutes after the start of ignition. Fire retardant blocks are available in pink and gray colors.

They cover schools, walls, ceilings of children's rooms, fire-hazardous fireplaces, and combustible bases with fireproof plasterboard.

Comparative table of prices for fire-resistant plasterboard brands on the Russian trade market.

Brand name | A country | Specifications | Dimensions (mm) | Price of 1 sheet in rubles. | Fire rating (minutes) |

| Knauf | Germany | GKLO | 2500x1200x12.5 | 380 — 470 | 60 |

| GYPROC | Scandinavian countries | GKLO | 2500x1200x12.5 | 365 — 403 | |

| NORGIPS | Poland | GKLO | 12.5x1200x2600 | 310 | |

| Belgyps. | Belarus | GKLVO | 12.5x1200x3000 | 304 | 45 |

| GIFAS (Gifas) | Russia, Sverdlovsk plant | GKLO | 12.5x2500x1200 | 346 | |

| Volma | Russia, Volgograd | GKLO | 2.5x1.2m x 12.5 | 306 | 45 |

| Rigips (Rigips) | France, Compagnie de Saint-Gobain SA | GKLO | 12.5x1.2x3.0m | 372 | |

| Giproc | GKLO | 12.5x1200x2500 | 337 | ||

| Magma | Russia, Saransk | GKLO | 2500x1200x12.5 | 311 | 45 |

As can be seen from the table, the difference in prices is insignificant. More expensive are the imported analogues Knauf, GYPROC, Rigips.

Characteristics and features of fireproof plasterboard

Finishing work involves the correct choice of material in terms of the safety and reliability of the resulting coating. Situations arise when, instead of conventional gypsum boards, it is necessary to use fire-resistant plasterboard. These products are ideal for areas subject to constant heat, as well as for areas that require special protection due to their susceptibility to fire.

Main characteristics of fire-resistant plasterboard

It is worth noting that standard plasterboard sheets and fire-resistant plasterboard sheets have slight differences in appearance. For a professional who understands building materials, what is important here is not what shape the cast sheet has, its edge, thickness and manufacturer, but also other characteristics:

- Flammability of materials;

- Tendency to ignite;

- Parameters of smoke formation, asphyxiating and toxic substances;

- The presence of toxic substances in the material and environmental safety.

In addition, the need to use plasterboard construction in the construction of individual building structures - partitions, cladding of wooden walls and partitions, their installation on the ceiling and attic floors and attic rooms - is taken into account.

Characteristics and properties of gypsum plasterboard

The fire-resistant type of gypsum plasterboard has the following technical parameters:

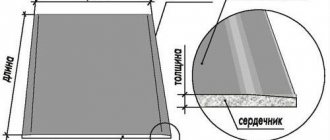

- Standard size is 2500 × 1200 × 12.5.

- Weight – 30 kg.

- Density – 850 kg/m3 (for comparison: regular Gyproc plasterboard – 800 kg/m3).

- Flammability class - G1 (low-flammable material).

- Flammability index – B1 (low flammability).

- Toxicity group – T1 (low-hazard).

- Thermal conductivity – 0.22 W/Mk.

- Thickness – 6.5, 9.5, 12.5, 14, 15, 16 mm.

- Width – from 0.5 to 1.3 m.

- Length – from 3 to 5 m.

In addition to high fire resistance, gypsum plasterboard has the following properties:

- Excellent sound and heat insulation.

- Durability - due to increased strength, it lasts longer than conventional gypsum boards.

- The ability to absorb excess moisture and release it into the environment when there is a deficiency.

GKLO has a pink or red color, less often – gray with red markings, so heat-resistant GKL is easy to recognize by its appearance.

Types and characteristics

There are 2 types of heat-resistant drywall on the modern Russian market: GKLVO and GKLO. GKLVO – plasterboard moisture- and fire-resistant sheets. This is a combined building material that combines the moisture-resistant properties of gypsum boards and heat-resistant gypsum boards.

It is used in industrial or domestic premises with high humidity levels. The color of the front side of the cardboard is green, marked strictly in red. GKLO – plasterboard fire-resistant sheets. This heat-resistant type of drywall has a high level of fire resistance.

It is advisable to use it for interior cladding of rooms with normal or low humidity.

Manufacturers of fire-resistant plasterboard

Construction projects: how to correctly determine their purpose and avoid mistakes

Fireproof plasterboard is produced by many factories, but one of the largest manufacturers on the market are Volma and Knauf. It is the products of these brands that we will consider in more detail.

Volma

A domestic manufacturer that has been producing plasterboard sheets for more than 10 years. It occupies a leading position in the building materials market due to strict adherence to production technology and the use of high-quality raw materials. The great demand for gypsum boards of this brand is due to high technical and operational characteristics. At the same time, it is practically not inferior in properties, with the exception of minor points.

Figure 11. GKLO manufacturer Volma

Advantages:

- stable characteristics;

- high strength for a material of this type;

- low price - about 30% lower compared to Knauf products.

The disadvantages include slight waviness of the sheets, but this does not in any way affect the speed and quality of installation.

Knauf

A company that includes more than 10 enterprises in the Russian Federation. The use of modern technologies and powerful advertising promotion ensures great demand for the products of this brand. The main quality of GKLO manufacturer Knauf is an increased fire resistance limit, which is within 50-60 minutes.

Photo 12. Fireproof gypsum board produced by Knauf

Competitive advantages:

- increased density and strength;

- ideal sheet geometry;

- long service life.

The disadvantages include the high cost of the material - even compared to plasterboard from other popular foreign brands, it is 20-30% higher.

Drywall Volma 2500*1200*12.5 Fire-Moisture-Resistant Sheet finishing material made from an environmentally friendly gypsum core…

From 434 RUR/pcsRead more

Drywall Volma 2500*1200*12.5 Fire-resistant Sheet finishing material made from an environmentally friendly gypsum core…

From 398 RUR/pcsRead more

Drywall MAGMA 2500*1200*12.5 Fire-Moisture ResistantUsed for interior wall decoration, installation of suspended ceilings and creation of interior spaces…

From 378 RUR/pcsRead more

Drywall MAGMA 2500*1200*12.5 Fire-resistantUsed for interior wall decoration, suspended ceilings and creating interior spaces…

From 345 RUR/pcsRead more

Drywall Volma 2500*1200*12.5 Fire-Moisture Resistant

Drywall Volma 2500*1200*12.5 Fire resistant

Drywall MAGMA 2500*1200*12.5 Fire-Moisture Resistant

Drywall MAGMA 2500*1200*12.5 Fire resistant

Fire resistance limit of non-combustible fire retardant plasterboard

In our case, the fire resistance limit means the duration of exposure to fire on the drywall itself until the latter begins to collapse. According to GOST, this limit varies from 20 to 25 minutes, which is quite enough to, for example, call the fire department before the fire spreads throughout the entire area. Some brands of fire-retardant drywall begin to deteriorate only after 45 minutes of open fire. They are naturally more expensive, but they enjoy the same success on the market since safety remains above all else. By the way, due to the fact that such drywall contains a certain percentage of moisture inside itself, it becomes a kind of “firefighter” for itself, since under the influence of fire the crystalline structure that contains water bursts.

In conclusion, I would like to say that heat-resistant plasterboard for a fireplace is a very useful material with various useful properties, which will prevent rapid fire in places working with open sources of fire or high temperatures. Regarding industrial scale - in the event of a fire, it will provide invaluable response time to eliminate it. On a domestic scale - using it for cladding elements such as fireplaces or baths - you will protect not only your property, but also your entire family. Follow safety precautions! Good luck!

If the article was useful to you, share it with your friends by clicking on the buttons: Below, leave your comments, suggestions, ask questions, express your opinion - this is very important to us!

Drywall flammability group

What non-combustible materials are used for wall decoration?

The flammability group is a conditional characteristic of a certain material, reflecting its ability to burn.

In relation to drywall, it is determined by conducting a special flammability test, the conditions of which are regulated by GOST 3024-94.

This test is also carried out in relation to other finishing materials, and based on the results of how the material behaves on the test bench, it is assigned one of three flammability groups: G1, G2, G3 or G4.

Is drywall flammable or non-flammable?

All building materials are divided into two main groups: non-combustible (NG) and combustible (G).

To qualify as non-combustible, the material must meet a number of requirements that are imposed on it during the testing process.

A sheet of drywall is placed in an oven heated to a temperature of about 750 ° C and kept there for 30 minutes. During this time, the sample is monitored and a number of parameters are recorded. Non-combustible material must:

- increase the oven temperature by no more than 50 °C

- give a steady flame for no more than 10 s

- decrease in weight by no more than 50%

Plasterboard sheets do not meet these requirements and are therefore classified in group G (flammable).

Combustible building materials also have their own classification and are divided into four flammability groups: G1, G2, G3 and G4. The table below illustrates the standards that a material must meet to receive one of the four groups.

The specified parameters refer to samples that have passed the test using Method II, according to GOST 3024-94. This method involves placing the sample in a combustion chamber, in which it is exposed to a flame on one side for 10 minutes so that the temperature in the furnace ranges from 100 to 350 ° C, depending on the distance from the bottom edge of the sample.

In this case, the following characteristics are measured:

- Flue gas temperature

- The time it takes for the flue gases to reach their highest temperature

- Weight of the test sample before and after the test

- Dimensions of damaged surface

- Does the flame spread to that part of the samples that is not heated?

- Duration of burning or smoldering both during heating and after completion of exposure

- Time it takes for the flame to spread to the entire surface

- Does the material burn through?

- Is the material melting?

- Visual change in the appearance of the sample

Having collected and analyzed all the above indicators obtained in laboratory conditions, the material is assigned to one or another flammability group. Based on the figures that were recorded when testing a gypsum board sheet with dimensions 1000x190x12.

5 mm according to Method ll described above, it was found that the flammability group of plasterboard is G1.

According to this group, the temperature of its flue gases does not exceed 135 °C, the degree of damage along the length of the sample is no more than 65%, damage by weight is no more than 20%, and the self-combustion time is zero.

Watch a visual process of testing drywall for flammability in the following video:

Fire hazard class

Standard partitions on a metal frame made of plasterboard sheets with an average density of 670 kg/m³ and a thickness of 12.5 mm according to GOST 30403-96 belong to fire hazard class K0 (45).

This means that when an unloaded material was exposed to fire for 45 minutes, no vertical or horizontal damage was recorded in it, and there was no combustion or smoke formation.

At the same time, in practice, the load-bearing capacity of a single-layer plasterboard partition is lost after just 20 minutes of fire exposure to the surface of the material.

In addition, it should be taken into account that the fire safety of a particular plasterboard partition will depend on its design.

Is it installed on a metal frame or on a wooden sheathing, is there a layer of insulation inside and is it flammable?

In addition to fire hazard and flammability, such characteristics as toxicity group of combustion products, smoke-generating ability group and flammability group are also applicable to plasterboard.

In terms of toxicity of combustion products, gypsum plasterboard sheets are classified as low-hazard (T1).

The smoke-forming ability of a material characterizes it as having a low smoke-forming ability (D1) with a smoke generation coefficient of no more than 50 m²/kg (smoke optical density).

For comparison, wood during smoldering has a value of this coefficient equal to 345 m²/kg. The flammability group for plasterboard is B2 - moderately flammable materials.

Installation nuances

Fireproof plasterboard is manufactured to resist fire , and there is virtually no risk of flammability, but experts recommend adhering to the following rules when covering floors with a wooden structure:

- before starting work, rack profiles are installed around wooden floors;

- profiles are sheathed with gypsum plasterboard sheets;

- a special tape is laid in the space between the walls;

- joints in the corners are covered with metal corners;

- When creating additional insulation of plasterboard sheets, it is carried out with mineral wool material.

- The installation process is allowed on metal products that make up the rack profiles.

- If there are vertical communication shafts in the room, they must be additionally insulated with special non-combustible materials. Craftsmen often use foil-coated mineral wool for such purposes.

When carrying out installation work, it is recommended to use self-tapping screws as a fixation for sheets. The distance between fastening elements should not be more than 0.2 meters.

Area of use

Fire-rated plasterboard is not usually used to line walls in ordinary rooms. It is not used for arranging the ceiling. However, there are situations where fire protection is very useful. This should include:

- fireplace lining;

- wall cladding in bathhouses and saunas;

- finishing of walls in the boiler room, industrial premises, boiler rooms;

- finishing of wooden houses;

- creation of household air ducts.

Fireproof plasterboard is also used for the construction of partitions, in the interior of which power cables are supposed to be laid.

Real fire in a plasterboard fireplace

It is certainly not possible to light a real fire with wood in a plasterboard fireplace. Firstly, this is non-compliance with fire safety requirements. Secondly, a false fireplace does not have a chimney to remove carbon monoxide and other combustion products. Modern technologies allow you not only to look at the artificial fire in the hearth, but also to bask in its warmth.

Biofireplaces are an excellent way out. They are fireproof. In addition, as a result of combustion, only carbon dioxide and water are released. To start a fire, a special fuel is used - bioethanol. You can buy it at any hardware store.

The cost of biofireplaces starts from 5-6 thousand rubles for the simplest models. More expensive specimens can be built into drywall, rather than installed as an independent structure.

Despite their fire safety, biofuel fireplaces are not recommended to be left unattended, since in any case it is a fire that can burn you.

Alternatively, you can make a simple burner yourself. To do this you will need:

- glass heat-resistant container;

- ethyl alcohol or lighter fluid;

- pebbles;

- sand;

- shells;

- aluminum can;

- basalt wool.

Take a can and cut it into 2 parts. The workpiece should not be higher than the glass container. Drill 3-4 large holes in the bottom of the jar. Place basalt wool inside the jar. Connect the top and bottom of the jar. Place the structure at the bottom of the glass container. Cover it with sand and small pebbles. Place large stones and shells on top. Pour ethyl alcohol or lighter fluid and light it. You will get a small and beautiful bio-fireplace.

To install such a burner in a plasterboard fireplace, the interior of the structure and, in particular, the place where the burner will stand, must be finished with fireclay stone or other heat-resistant material. A built-in metal structure using basalt wool or similar heat-resistant materials works well.

Of course, the appearance of such a burner can be anything. The main thing is that the design features are respected.

Structure and purpose of the material

GKLO are pink or gray sheets with a red stripe. Their dimensions are the same as regular material.

What is GKLO made from?

The base of the middle layer of sheets is gypsum.

Sheets composition:

- Double-sided kraft cardboard cover. To reduce the flammability of this cellulose material, it is impregnated 2-3 times with a fire retardant.

- Gypsum core. It consists of building plaster.

- The base material is reinforced with refractory clay. It contains 20 percent crystallized water. The formula of the material is CaS04-2H20.

- The gypsum layer can be reinforced with filament threads (fiberglass).

When exposed to high temperatures, crystallized water is released from the gypsum in the aggregate state of steam. Until all the liquid has evaporated from the material, the temperature of its reverse side will not be higher than the boiling point of water, namely +100 ºC.

The photo shows fiberglass reinforcing the sheets.

Fiberglass and clay added to plaster help the sheets shrink less when exposed to flame. Therefore, the structure of the structure is maintained for a longer period of time.

Area of use

Fire-resistant material has a wide range of uses.

The manufacturer's instructions note that GKLO sheets were specially designed for building structures to which increased fire safety requirements apply.

The thermal conductivity of drywall is 0.22 W/m∙ºС. This is significantly lower than that of conventional sheets.

Fire-resistant gypsum can be used:

- As a basis for fastening insulating types of materials. This can be done in both vertically and horizontally oriented building structures.

- To increase the degree of fire protection. Surfaces can be covered with two layers of sheets, this will increase the strength of the structure.

The scope of application of GKLO is very wide:

| Image | Application of GKLO |

| Surface cladding in industrial premises. In those that have special safety requirements. | |

| Finishing walls and ceilings in boiler rooms and boiler rooms. Premises can be private or communal. | |

| Construction of interior partitions. They may be filled with heat-resistant insulation. Or be hollow, if you lay utility lines in them yourself. | |

| Covering surfaces in children's rooms. This is done to increase their fire resistance. | |

| Surface finishing in public buildings and establishments. | |

| Surface cladding and construction of partitions in educational institutions. | |

| Fireproof internal cladding of wooden buildings. | |

| Arrangement of air ducts. |

Features of the material

There are several types of such products on the market today, which differ in their technical properties. Fireproof plasterboard differs from other analogues in a number of properties:

- Visually, it is covered in pink cardboard, which indicates its specific purpose.

- Drywall contains a special layer containing clay and reinforcing fiberglass. This allows you to significantly increase resistance to temperature and reduce the likelihood of destruction.

- The structure of the leaf core also includes crystallized water, which is an additional obstacle to the spread of fire. The amount of this component in some cases can reach 20% of the total mass.

When purchasing heat-resistant drywall, it is advisable to check all certificates for this product confirming that it belongs to this group of products. They already describe in detail all the specific characteristics of the material, which will make it possible to select only a high-quality and reliable substance.

Heat-resistant drywall consists of several main components:

- Gypsum dihydrate, filament threads and several types of organic substances. The percentage of these components in the structure reaches 93%.

- Cardboard covering (6%).

- Moisture. The amount of this product often does not exceed 1%.

7 photos

What it is

Fire-resistant or fire-resistant plasterboard is a material that consists of a cardboard and gypsum layer treated with special substances. Thanks to the properties of these materials, it can withstand up to 60 minutes of open fire, without spreading smoke or combustion. You can distinguish them from other options using color markings - moisture-resistant cardboard is green, regular cardboard is gray, and fire-resistant cardboard is red (pink).

Photo - fireproof cardboard

As well as moisture-resistant, this material consists of gypsum reinforced with fiberglass, which significantly improves its performance. Enhanced flammability properties are most often provided by clay, which perfectly withstands high temperatures. Advantages of using fire-resistant plasterboard:

- Can be used in all rooms. Due to the complete environmental friendliness of the material, it does not pose any danger. They can be used to cover children's rooms, kitchens, and bathrooms;

- In addition to high fire-fighting qualities, the material is also known for its excellent moisture resistance. Therefore, it is even used for finishing swimming pools;

- Cassette plasterboard with an increased flammability limit begins to collapse only after 45 minutes of open fire and spreads combustion after 60 minutes;

- Almost all well-known manufacturers of fire-resistant cardboard use crystallized water for the core, which can also act as protection during combustion. With high heat, cardboard can reduce its temperature for some time;

- Due to the fact that wall cardboard has an additional clay layer, it has high levels of sound and heat insulation;

- Excellent durability parameters. It will last 5 years longer than all other analogues.

Of course, fire-fighting plasterboard will not be able to suppress fire indefinitely, but for buildings made of wood or timber, even half an hour can make a big difference. This coating is used for hazardous production, decoration of false fireplaces, finishing of ceilings and walls of living rooms, window or door slopes.

Photo - fireplace decor with fireproof coating

But at the same time, the use of fire-resistant drywall is significantly complicated by its reinforced core. Due to the presence of an additional layer of clay inside the sheets, installation is somewhat complicated. You will need to use special screws and tools. You also need to take into account that this coating is somewhat heavier than other types of gypsum board.

What you need to know before finishing

precisely the design component

Materials and design should match the overall style of the room. Decorating with wooden half-bars in a strict hi-tech interior will look ridiculous, just like, in principle, “marble” cladding in a log house.

If you want to decorate the fireplace with tiles or some kind of pattern, you should do this only if there are no such elements in the surrounding interior. Otherwise it will look too intrusive. Examples of good design can be seen in videos on the Internet or on relevant forums. People often share their work there, so you can learn something for yourself.

Also, special attention should be paid to the form. It is necessary to maintain proportions so that the upper and lower parts are in perfect harmony

Often people make a small open furnace firebox from below, and the rest of the space, right up to the roof, is occupied by plasterboard finishing. It looks strange, to say the least.

Composition and technical characteristics

Heat-resistant drywall contains moisture. It is located next to special crystal lattices in a layer of gypsum and ensures the stability of the structure. At high humidity, the liquid is distributed along the grate and does not cause the sheets to swell. And when the level of moisture in the room is low, the liquid in the plasterboard sheets maintains the internal microclimate of the products.

A fire-resistant board consists of the following elements:

- Gypsum dihydrate.

- Filoment threads. They are responsible for the long-term resistance of gypsum to fire after charring of the cardboard covering.

- Chemical impregnation to increase the heat resistance of the material.

- Cardboard, about 6%.

- Water, 1%.

The distinctive characteristics of fire-resistant plasterboard include a sheet thickness of 12.5 mm and the presence of a reinforced core. Moreover, the markings on such plates are done exclusively in red.

Fire safety certificate

According to test results, in the fire safety certificate, GKLO has the following indicators:

- Smoke generating ability D1;

- Flammability G1;

- Flammability B3;

- T1 toxicity.

Despite the high level of flammability of the cardboard covering, fire-resistant plasterboard belongs to the KM1 fire safety class as a slightly flammable material.

Fire resistance limit

The fire resistance limit of any material is determined by the time during which it is not destroyed by fire. The countdown during the testing process ends at the moment when the first structural destruction of the heat-resistant element begins. For fire-resistant drywall, this is a layer of gypsum with a reinforced core.

According to the results of experiments, the minimum fire resistance limit of gypsum plasterboard is 25 minutes. The average value reaches 35 minutes. In this case, the duration of protection largely depends on the temperature and proximity of the fire.

Flammability group

According to GOST 30244 on the boundary values for determining the flammability class of materials, fire-resistant plasterboard belongs to group G1. In this case, the material has the following characteristics:

- The flue gas temperature does not exceed 135 degrees.

- There is no spontaneous combustion.

- The degree of damage along the length is no more than 65%.

- The total damage to the structure mass does not exceed 20%.

When fire-resistant drywall is exposed to flame, molten burning droplets do not form.

What temperature can drywall withstand?

Fire-resistant sheets are able to withstand any negative temperature when it naturally occurs. And also the structures are not afraid of standard increases in room temperature. Noticeable damage begins only when the slabs are directly exposed to open fire.

For interior decoration, fire-resistant plasterboard is used almost everywhere. But more often gypsum boards are installed in the following places:

- Home boiler rooms;

- Interior partitions containing electrical wiring;

- Decorating bedrooms and rooms where a large number of people are often present;

- Household ventilation systems;

- Interior space of residential wooden buildings.

The material is required for use in rooms with increased fire safety requirements. Heat-resistant plasterboard is installed in production workshops where small melting furnaces are located. The material is also suitable for interior decoration of baths and saunas. In cottages and private houses, heat-resistant plasterboard for the fireplace is useful. However, the material is placed only on the outside of the structure, as an element of decorative finishing.

Fire-resistant fireproof plasterboard: types, requirements, application

Following the beautiful, alluring concept of “European-quality renovation” and other miracle finishing materials, technologies supposedly unknown in the Soviet Union; The magic word “plasterboard” has entered the everyday life of people seeking to redesign or renovate their apartment or private residential building.

Architects and designers, sales consultants of trade organizations selling sheet building materials, foremen of enterprises, organizations involved in interior decoration of office and residential premises, foremen of self-employed workers unanimously with amazing confidence told the amazed owners of real estate that plasterboard is moisture-resistant, fire-resistant, and Moreover, it is a very light material compared to brick and reinforced concrete structures. Therefore, they can do anything up to the construction of fire partitions, the allocation of fire compartments and sections in buildings and structures using it.

Today, when the advertising frenzy has somewhat subsided, it is worth taking a closer look at all the advantages and disadvantages of this, without a doubt, good construction and finishing material in terms of ensuring fire safety measures and compliance with regulatory requirements when using it.

Species and types

Since there are not so many varieties of this material, and in order to know what they look like, it’s easier to talk about them all. This will be helped by the marking of plasterboard, uniform for all manufacturers, in accordance with GOST 6266-97, which establishes the technical conditions for the production of sheet plasterboard:

- GKL is ordinary drywall, often called dry plaster. The color of the sheet is grey, the marking applied to the back of each sheet with indelible paint, a stencil, a stamp or any other method is blue. Designed for installation and finishing work on walls, ceilings, and installation of internal partitions in rooms with normal conditions/microclimate.

- GKVL – moisture-resistant plasterboard. The color of the sheet material is green, the markings are blue. Used for work in rooms with damp conditions, which may occur during operation; mold and mildew on coated building structures.

- GKLO - with resistance to flame, most often called fire-resistant, as well as fire-resistant plasterboard. The color of the sheets is pink or gray, the markings are red. It is used for cladding the walls of rooms with an increased risk of fire, for finishing evacuation routes and exits, as elements of structural passive fire protection of building structures.

- GKLVO - plasterboard with increased fire resistance and moisture resistance. The color of this commercial sheet material is green, like moisture-resistant, but the marking is red, like fire-resistant. It is used for finishing, fire protection of individual building structures, installation of internal fire-resistant partitions in rooms with high air humidity under normal operating conditions.

That is, fire-resistant (fire-resistant) types of drywall, according to this GOST, include GKLO and GKLVO.

It would seem that we can put an end to this, but rule-making in Russia, incl. concerning PB issues, presents another surprise. It turns out that there is another GOST 32614-2012, which establishes technical requirements.

conditions for gypsum construction boards, put into effect on January 1, 2015, and the origins of both documents in force today are well-known in the production of all types of plasterboard in Europe and the CIS countries.

Actually, everything would be fine, but this document adopts a completely different labeling of types of sheet plasterboard, which is not surprising, because

The details section states that this document has been prepared on the basis of a translation of a European standard.

First of all, all types of these sheet products are now called not plasterboard - GKL, but gypsum building board - GSP with the letter designation of the type of material in “foreign” letters:

- A – normal type. According to GOST 32614-2012, GSP-A corresponds to plasterboard.

- D – with a given density.

- F - with increased resistance of the gypsum core to fire, due to the introduction of mineral fibers and/or other additives into it. GSP-DF corresponds to fire-resistant plasterboard GKLO.

- H – moisture resistant. GSP-N2 corresponds to GKLV.

- I – with increased surface hardness.

- P – with applied gypsum plaster or glued tile materials.

- R – increased strength.

Fire and moisture resistant plasterboard GKLVO corresponds to GSP-DFH2, i.e. There are still only two types and types of fire-resistant cardboard.

Characteristics and requirements for materials

The technological characteristics of gypsum plasterboard/GSP are the same - it is a base of sifted, finely ground gypsum raw materials, purified from impurities, formed into a single mass with the addition of water, various binding additives, including those special for certain types of commercial material, between two layers of dense, capable of resistance , paper cardboard:

- Reducing hygroscopicity - for moisture-resistant varieties.

- Solid mineral additives - for types with increased strength and surface hardness.

- Fireclay clay, non-combustible mineral fibers - in fire-resistant types of plasterboard/gypsum building board.

An important characteristic when ordering/delivering, for transportation, construction and installation work is the standard sizes of finished commercial products:

- For GKLO, GKLVO. Width – 0.6 and 1.2 m; length - from 2 to 4 m in increments of 50 mm, thickness - from 6.5 to 24 mm.

- For GSP-DF, width – from 0.6 to 1.25 m; length - from 1.2 to 2.5 m, thickness - from 9.5 to 15 mm.

Fire characteristics of fire-resistant cardboard, like all other types of gypsum boards, according to GOST:

- GSP/GKL belongs to the flammability group G1 - flammable, with zero ability of independent combustion: in terms of smoke generation ability - D1, in terms of flammability: GSP - B2, GKL - B3.

- Resistance of GKLO, GKLVO to fire should be at least 20 minutes.

- Classification of gypsum boards and GSP into a less fire-hazardous group is possible only on the basis of appropriate tests of samples of serial products of a specific manufacturer.

Conclusions: the name commonly used by designers, builders, and finishers in relation to this material is more of an advertising nature, because the fire resistance limits of fire-resistant cardboard based on test methods and the minimum requirements of GOST 6266-97 are 20 minutes, GOST 32614 is even less - 15 minutes ., so it is more of a fireproof drywall.

Fire retardant efficiency groups of plasterboard

But, in addition to the fact that it practically does not burn, this material has a lot of other advantages that make it, in terms of its combination of qualities, with proper design, structural fire protection of wood and metal structures, very attractive for use in both new construction and reconstructed facilities; when carrying out major repairs, redevelopment of premises in buildings for various purposes, but more on that a little later.

Test procedure

It is carried out when serial commercial products are put into production, and then periodically - at least once a quarter; and also when changes are made to the production process, new materials and additives are introduced into the recipes of raw materials. According to GOST, the test procedure for fire resistance is similar, but according to GOST 32614 it is carried out under more stringent conditions:

- Take three sheets of plasterboard or 6 sheets of GSP from a batch of commercial products.

- Two gas burners are directed onto the cut sample to achieve a value of 800±30℃ - for gypsum plasterboard until destruction, measuring resistance to open flame in minutes, normally not less than 20 minutes; 1000±50℃ – for GSP for 15 minutes (normal) or until destruction.

- All samples are subjected to tests, and if at least one of them does not pass them, losing its integrity, collapsing into two or more parts; then the tests are considered unsatisfactory, the batch of GKLO, GKLVO or GSP-DF cannot be accepted as a fireproof/fire-resistant material.

Application on objects

Fireproof cardboard is usually used as follows:

- In finishing, cladding walls, ceilings on evacuation routes in public, administrative, industrial and domestic buildings.

- In the finishing of walls, ceilings, installation, lining of internal partitions in private residential buildings, cottages built from wood materials, both to create smooth surfaces for plastering, painting, wallpapering, and in order to increase the fire resistance of buildings, safe installation of lighting wiring.

- When covering fireplaces and walls around solid fuel stoves.

- When installing air ducts for general exchange and exhaust ventilation, and installing suspended ceilings.

- When cladding wooden, metal beams, rafters of structures of attic floors of residential buildings, incl. in multi-storey construction.

- When installing internal partitions during the redevelopment of premises. Thus, a fire-resistant plasterboard partition is not a myth if a metal frame is used in its creation; all voids inside are filled with non-flammable mineral substances, such as fire-retardant basalt material; surfaces on both sides and areas adjacent to fire walls are treated with fire-retardant plaster.

Application of fire-resistant plasterboard

It is difficult to overestimate the importance of using fireproof cardboard when finishing wooden interior surfaces in the private residential sector, on escape routes, instead of combustible finishing in public buildings; after all, this significantly reduces the risk of fire from low-power ignition sources, from short circuits, overheating of electrical wiring at the junction of wires/cables, installation electrical products; ensures safe evacuation of people.

It is generally accepted that Knauf fire-resistant plasterboard, produced and widely distributed and in demand in Russia, has excellent fire-resistant characteristics and product quality. Thus, according to some estimates, more than 70% of fireproof sheet material marked GKLO, GKLVO, GSP-DF is sold under the Knauf trademark.

In addition, in the last few years, the company has launched the innovative sheet material “Knauf-Fireboard” with a thickness of 12.5–24 mm, which can rightfully be called truly fire-resistant plasterboard based on the results of fire tests confirmed by obtaining certificates of conformity:

- Because it belongs to the NG group - non-combustible materials.

- It consists of a gypsum core with the addition of fiberglass and vermiculite, and all surfaces, except the ends, are covered with fiberglass.

- The designs of fire-resistant partitions on a metal frame created on its basis by the Knauf company; single-layer and multi-layer cladding of internal load-bearing metal structures of building structures; even without filling with non-flammable mineral slabs and roll materials, they are certified by the laboratories of VNIIPO EMERCOM for 45, 60, 90 minutes of fire resistance.

This is an undoubted record for similar structures made of lightweight, quickly installed materials, without the use of additional expensive fire-retardant plasters, coatings, paints, mastics, varnishes, with a high degree of maintainability during the operation of buildings and structures.

According to the specialists of this company, this is far from the fire resistance limit for fire protection of metal building structures and building frames.

Thus, based on the calculations and full-scale fire tests, they obtained high results for multi-layer installation/cladding with Knauf-Fireboard panels: with a thickness of 60 mm, a fire resistance of 120 minutes is achieved, and with a thickness of 70 mm - 180 minutes; which is comparable to the creation of a brick wall/partition with a much higher consumption of materials, the total cost of performing the work, and a huge load on the floors of buildings and structures.

Who offers labor protection outsourcing services - review of the TOP 5 companies with favorable conditions

Both part of the functions and the entire labor protection service can be transferred to professionals. If in small companies it is not so difficult to monitor and implement security programs, then in large companies it is advisable to have a full-time specialist. It is more profitable for large organizations to delegate only part of the functions to outsourcers in order to improve the skills of their own specialists.

1) Harmony

The training certification center has been operating in Russia since 2007. It offers services in the field of education, training and professional retraining of specialists in labor protection, ecology, fire safety and other areas of activity.

Seminars and webinars are regularly held with the participation of representatives of the Labor Inspectorate, where you can share experiences, ask questions and discuss real cases. The company uses modern technological advances to improve the skills of its employees.

The company's advantages include:

- flexible payment terms and individual approach to the client;

- modular training system (shortened certification periods);

- consultation and support after fulfillment of the terms of the contract.

"Harmony" works efficiently and within the agreed time frame.

2) OkhraPro

It has been constantly working and developing in the Russian Federation since 2009. It provides a wide range of services, high-quality and profitable labor protection services.

The company strives to keep up with the times, using the most progressive achievements. Tries to guess time trends and further developments of events. Provides a 5-year guarantee on its activities! Legally accompanies the work done, using the most effective ways and advanced technologies. The main principle of the company is the best prices!

3) Unital-M

The training center was organized in 1995. Rich experience allows us to develop production control programs. Among the company's clients are enterprises of various sizes, which indicates a variety of activities.

Provides services in the areas of:

- Labor protection.

- Fire safety.

- Electrical safety.

- Environmental safety.

The specificity of the enterprise is assistance in the development of control and licensing of life safety in production.

The company develops and offers its clients the most up-to-date solutions, which helps to increase the level of safety in enterprises and creates a positive image among employees.

4) Intersectoral Center for Occupational Safety and Health

The company positions itself as a team of highly qualified, multidisciplinary specialists with many years of experience in the field of occupational health and safety. Introduces and provides services at enterprises, constantly expanding the range of services provided. Guarantees 3 months of information support after signing the work completion certificate.

Works with large organizations throughout Russia. It has a transparent pricing structure that allows you to instantly calculate the required package of services. Motto

Focuses its work on enterprises with a wide variety of activities.

5) Berkana

Since 1992, he has been providing consulting services on labor protection. Demonstrating excellent growth dynamics, the company covers the entire market for safe work services.

Develops its own unique services:

- personnel records, audit and verification of personnel documentation;

- resolving labor disputes;

- representing the interests of the customer in all state regulatory authorities;

- legal services.

The company’s specialists are ready to monitor compliance with established rules and ensure the safety of employees in the workplace. The company has its own testing laboratory.

Providing a full range of labor protection outsourcing services, the company’s specialists have a wealth of knowledge and skills. A team of professionals provides a reliable system of work and offers affordable prices.

Scope of use

The versatility of fire-resistant drywall makes it a highly sought-after product. This substance is used to solve several specific types of problems:

- Arrangement of ventilation ducts. It is not used to form chimneys, as it is not able to withstand long-term temperature loads.

- Covering almost all types of baths (Russian, Turkish and Finnish).

- Fireplace cladding. Often, drywall here acts as an intermediary between the hot surface of the frame and the main wall.

- Internal cladding of light industry workshops, etc.

As already mentioned, drywall can be used to form the frames of fireplaces, but several nuances should be taken into account:

- It is not advisable to cladding fireplaces with this material for structures made of stone, refractory brick, etc. These substances themselves are excellent insulators. Cladding with plasterboard is often only done on fireplaces made of steel or cast iron in order to further protect them and give them a certain decorative look.

- It is advisable to use this material in cases where the firebox is installed directly in a wall niche.

- When covering fireplaces, special heat insulators must be placed between plasterboard and its walls, which will reduce the effect of temperature on the structure of the product.

It should be understood that heat-resistant drywall is not brick and is not a reliable protector. With its help, only the possibility of a fire is prevented for some time, but does not exclude it during prolonged exposure to high temperatures.

Scope of fire-resistant gypsum plasterboard

The use of standard drywall in rooms with increased requirements for fire resistance and non-flammability is irrational, since the material quickly loses its properties when in contact with high temperatures. Therefore, in rooms with increased fire safety requirements, it is best to use fire-resistant plasterboard.

It is most often used for:

- finishing of industrial premises and home boiler rooms

- cladding for domestic fireplaces

- production of interior partitions, inside of which electrical cables are supposed to be laid

- design of children's rooms and public spaces

- decoration and finishing of educational institutions of various levels of accreditation

- manufacturing of household air ducts

- interior decoration of wooden houses, country houses and cottages.

Room decoration

Fireproof plasterboard: characteristics, fire resistance class

The use of drywall in repair and construction work has long become the norm. This material can be used in different situations, even when there is a need to provide walls with fire resistance quality. Regular drywall is not suitable for such purposes, but you can find a heat-resistant version of this material on sale.

It consists of a plasterboard layer, which is treated with special substances. Due to its properties, the sheet can withstand exposure to open fire. This prevents the spread of smoke and combustion. Fireproof plasterboard can be distinguished from other varieties of this material by markings and color. The canvases are painted pink.

Specifications

Fireproof plasterboard has a density of 850 kg/m3, this figure is higher than that of standard plasterboard. In the case of the latter, the density is 800 kg/m3. It is also important to pay attention to the thermal conductivity, it is equal to 0.22 W/Mk, which is 0.13 higher compared to a regular sheet.

The fire resistance class of a material is determined by the fire resistance limit. This parameter is equal to 45 minutes. If we look at the wall variety in more detail, then its fire resistance limit is 20 minutes. This time will be required for the complete destruction of the sheet when exposed to flame.

During the production process, cardboard is impregnated with special substances, gypsum contains reinforcing additives, and the core contains crystallized water, which occupies a fifth of the mass of the material.

When a fire occurs, water prevents the fire from spreading. If you decide to purchase fireproof plasterboard, you need to make sure that it is such.

To do this, you should request a fire safety certificate from the seller.

Flammability class

After reading the documentation, you can find out that fire-resistant plasterboard corresponds to flammability class G1. As for toxicity, this parameter is designated as T1. In terms of flammability, fire-resistant plasterboard corresponds to class B3. Smoke formation is also important; the material described in this regard corresponds to class D1.

Before purchasing fireproof plasterboard, you should pay attention to the fact that the sheet must meet the standard thickness, which is equal to the limit from 12.5 to 15 mm. As for other dimensions, for fire-resistant plasterboard they remain the same as for a regular sheet.

Reaction to fire

Fireproof drywall will behave normally when exposed to high temperatures; problems arise only when exposed to open fire.

The longer the material resists the flame, the better. But the cardboard shell will still burn, while the gypsum core will crack.

This happens much more slowly compared to plasterboard walls.

The fire resistance limit can be 50 minutes. This parameter varies among different manufacturers, which affects the price of the material. After this period, the leaf is destroyed, but everything will depend on the intensity of the fire.

Due to the fact that the material corresponds to the flammability class mentioned above, it can be classified as non-combustible materials that do not spread fire and do not support combustion. In 45 minutes, the material will retain its load-bearing capacity and integrity, eliminating the passage of fire in the opposite direction.

This is true when drywall was used to construct a partition.

Area of use

Fire-rated plasterboard is not usually used to line walls in ordinary rooms. It is not used for arranging the ceiling. However, there are situations where fire protection is very useful. This should include:

- fireplace lining;

- wall cladding in bathhouses and saunas;

- finishing of walls in the boiler room, industrial premises, boiler rooms;

- finishing of wooden houses;

- creation of household air ducts.

Fireproof plasterboard is also used for the construction of partitions, in the interior of which power cables are supposed to be laid.

Description of fire-resistant plasterboard from

Fireproof plasterboard "Knauf" is popular among modern consumers. It is used to decorate the external and internal walls of a building, which are subject to fire safety requirements. GKLO found its application in the construction of houses that were built from flammable materials.

The characteristics of fire-resistant drywall allow it to withstand high temperatures for a long time. The canvases can be exposed to flame for up to 60 minutes, while combustion and smoke will not spread.

If we compare it with moisture-resistant drywall, then the material described in the article also consists of reinforced fiberglass, as well as gypsum, which improves performance.

Fire resistance properties are provided by the clay, which can withstand high temperatures.

Fireproof plasterboard degree of fire resistance - Fire safety

The use of drywall in repair and construction work has long become the norm. This material can be used in different situations, even when there is a need to provide walls with fire resistance quality. Regular drywall is not suitable for such purposes, but you can find a heat-resistant version of this material on sale.

It consists of a plasterboard layer, which is treated with special substances. Due to its properties, the sheet can withstand exposure to open fire. This prevents the spread of smoke and combustion. Fireproof plasterboard can be distinguished from other varieties of this material by markings and color. The canvases are painted pink.

Installation of heat-resistant drywall

In general, the installation process does not differ from what happens in the case of conventional plasterboard. However, there are still a few nuances:

- To increase fire resistance, a double layer of this material is often used, which increases the load on the frame and places higher demands on it. The situation is similar with self-tapping screws, which must have the required length;

- If the edges of the sheet are rectangular, it is necessary to thin them by about a third of the original thickness. In this case, the corners are usually closed with perforated metal corners;

- Frame material. You should not make the frame wooden, as this neutralizes the fire-resistant properties of gypsum plasterboard. Aluminum profiles are ideal. The same goes for insulation if you plan to use it. In the case of installing fire-resistant drywall, it is best to select non-flammable insulation;

- Non-flammable plasterboard is often used for sheathing wooden buildings and beams. In this case, it is necessary to build a structure of rack profiles around it, and put a special tape in the gap between the tree and the sheet. As for self-tapping screws, in this case they are usually screwed at a distance of no more than 12 centimeters from each other;

- During the installation process, it is best to leave the sheets in the room where they will be used for about a day before starting work. This will give the material the opportunity to “get used” to the local climate. As for the climate itself, it is undesirable to carry out work in high humidity and temperatures less than 10 degrees Celsius.

Important! When going to purchase this material, you must make sure that the seller has a certificate. If the fire resistance of gypsum plasterboard cannot be documented, then it is better to refrain from purchasing. In addition, suspiciously low prices should sow doubts. We have already written above that the cost of a fire-resistant sheet is approximately twice as much.