Causes of wear and tear on chimneys

There are a large number of reasons that lead to wear and tear of the chimney.

- corrosion that occurs due to the impact of combustion products and flue gases on the masonry and other materials of the chimney;

- wind, humidity, precipitation, excessive heat;

- shortcomings in the design and construction of the pipe itself;

- unqualified intervention in the chimney system;

- when using the structure for other purposes, for example, when connecting artificial ventilation, the risk of destruction of the chimney increases;

- transition from one type of fuel to another;

- technologies, including “wet cleaning”, aimed at protecting nature;

- strong air injection from the boiler.

When using metal elements during construction, erosion may occur, which is also caused by unfavorable meteorological factors.

Metal chimneys

The coating of a colored chimney is a durable polymer composition that fulfills all the tasks of protecting the structure from destructive atmospheric influences. It does not fade, does not emit toxic substances, does not become thin, does not crumble, and retains its protective and aesthetic properties for many years, not being inferior in strength characteristics to external stainless steel pipes.

Painted sandwich pipes are suitable not only for the actual chimneys of heating systems, they are excellent for installing natural ventilation in a building (cottage, country house, utility house or bathhouse). Also for natural ventilation, colored single-circuit pipes are offered, which will continue the selected color scheme indoors or in places that do not require insulated elements.

The lead time for production and assembly of colored chimneys is 7-14 days, depending on the workload of the line, the chosen color, and the seasonality of the order. By ordering chimneys before the main season (before June), you will receive a chimney in a shorter time.

We can also offer you delivery options and professional chimney installation. (For more details, please call).

The cost of colored sandwich chimneys largely depends on the material and thickness of the inner pipe, however, a colored sandwich is significantly cheaper than chimneys with an outer stainless pipe, and differs from a sandwich with a galvanized outer pipe by less than 20%.

For more detailed prices for all products, see the full price list. Marking of colored chimneys in the price list is Ral or Ral p/o.

Thus, at a very affordable price you get not only a reliable and durable chimney, but also the opportunity to further decorate your home, emphasizing its modernity and novelty.

We suggest you familiarize yourself with how to paint pine furniture. How to paint pine doors with your own hands? Selecting covering paints based on composition

This option is most often installed in buildings and boiler rooms, as it is relatively lightweight. In production, the product is less common, since its cost is high, and the height of industrial pipes can be very significant.

Metal chimney

- The boiler room chimney is painted by climbers. For repair work, the product is equipped with brackets according to the standards, but given the height of the structure, only a specially trained person can carry out painting. The photo shows climbers painting a chimney.

- Compositions that can provide corrosion protection are used for work. Organosilicon paint and varnish coatings are most suitable for this. This option has a noticeable impact on the overall repair cost, but can withstand very high temperatures - from 330 to 700 C, and is absolutely insensitive to moisture and the action of acids and alkalis. The coating is smooth, so it even has a dirt-repellent effect.

- Painting of metal chimneys is carried out in accordance with GOST standards established for a boiler room or enterprise.

Painting an industrial chimney

This structure consists of an inner pipe made of galvanized or stainless steel and a thick concrete outer pipe.

Steel chimney on a brick base

Structures of this type are usually found in industrial boiler houses, since they are designed for a monstrous load and a large volume of exhaust gases, as well as for a very complex and aggressive composition of the exhaust gas.

- Painting of concrete structures according to SNiP standards is also necessary, and is also carried out by climbers - here the height is usually very high.

- The estimate for painting a concrete pipe includes not only the work itself and the cost of paint, but also the price of additional funds. Concrete is a complex material. After a long period of use, its strength and hardness become uneven, the outer layer begins to peel, so when painting it is necessary to take into account the material’s tendency to deform.

- Heat-resistant enamels are used for coloring; the best option is silicone. However, here it is necessary to include primers in the estimate. This is a necessary element when working with concrete: the material is too porous, instead of ensuring good adhesion, the top layer simply absorbs the coloring composition, and this will lead to the need for re-painting, and, therefore, increased costs.

The standards for painting chimneys according to GOST do not regulate the composition and quantity of enamel. The only requirement is that it must be fireproof and heat resistant.

Materials for painting chimneys

To paint chimneys, it is necessary to select materials that match those from which the structure is made. They must withstand high temperatures and be resistant to external factors and weather conditions.

Most often, primer coatings are used before applying paint to the surface. The best option is gray enamel KO-8111. It can withstand high temperatures and cope with corrosion.

A good paint for a chimney is OS-12-03 enamel. If signal coloring is necessary, red or white colors are chosen. If this is not required, then you can purchase any other shade.

Organosilicon paints and varnishes are best suited for painting structures.

They are expensive, but justify their cost due to the following advantages:

- fire resistance;

- withstand high temperatures,

- resistant to moisture, acids, alkalis;

- have a smooth coating, which adds dirt-repellent properties;

- neutral to oxidation;

- have low surface tension.

In addition, when choosing, you should pay attention to the following parameters:

- the time during which the mixture dries (with long-drying options there is a risk of damage due to exposure to external factors);

- nominal viscosity;

- validity.

With the correct choice of paint and varnish material, the service life of the chimney increases. When painting with such materials, be sure to wear a respirator, gloves, and thick clothing. The compositions are toxic and can cause harm to health if safety precautions are not followed.

How to choose the right paint

The final result of coating a furnace with paints directly depends on the correctness of its choice. Heat-resistant paint for the stove is selected taking into account the following requirements:

- Firstly, the heat resistance limit of paints and varnishes must be at least 300 degrees. The best solution may be heat-resistant metal paints for furnaces that can withstand temperatures above 600 degrees. Sauna stoves do not heat up that much, but a reserve will not be superfluous. It can be a guarantee that the decorative finish will last for a long time. In most cases, the packaging of such paints and varnishes contains the inscription: “Heat-resistant paint for stoves and fireplaces.”

- Secondly, fireproof paints for stoves have appropriate certificates certifying their quality and ability to withstand high temperatures. You should not trust sellers in this matter. They may simply make mistakes or strive to make money.

- Thirdly, when deciding how to paint iron stoves in a bathhouse, you need to take into account that the paintwork material should not contain substances hazardous to health. When heated, evaporation from the surface occurs tens of times faster. If the paint is of poor quality and contains dangerous components, they will certainly enter the respiratory tract and cause poisoning.

Paint for metal stoves is sold not only in ordinary cans (to apply it you will have to use a roller, brush or spray), but also in spray cans. If you want to paint the stove as quickly as possible, then it is preferable to use the second option.

Step-by-step instructions for painting a chimney

For work you will need the following tools and materials:

- brushes or rollers for painting;

- metal brush for cleaning the surface;

- acetone or other degreasing liquid;

- primer;

- paint and varnish composition suitable for the chimney material.

For chimney painting to be effective, the following steps must be followed:

- Calculation of the area to be painted. This step is necessary to calculate the amount of materials needed.

- Cleaning up. It is necessary to remove from the base anything that can interfere with painting and also affect the quality of work: old paint, grease, dirt, etc.

- Primer. Needed for better adhesion of paint to the surface.

Painting is the final stage in which the paint coating is applied. If marking coloring is necessary, you should be guided by the following standards corresponding to paragraph 1 of Art. 51

Air Code of the Russian Federation:

- Pipes with a height of up to 100 m are painted with horizontal stripes from 0.5 m to 6 m of white and red colors (at least there must be 3 stripes).

- For structures over 100 m, the size of the strips should be from 1/7 to 1/21 of the entire height of the object. The outer stripes should be red.

The paint is applied in 2-3 layers so that the thickness is 40-60 microns. The consumption for 1 layer of coating is 120-150 g/m².

Metal surfaces

Metal pipes are usually made of stainless steel, which is least susceptible to corrosion. However, any structure must be prepared before painting, otherwise painting on metal will not last long enough.

The work is as follows:

- Use a wire brush to remove dirt and old paint.

- Wash thoroughly and dry the base.

- Treat with a degreaser.

- Apply a corrosion inhibitor mixture.

- Cover with 2-3 layers of primer.

- The last stage is coloring. It is better to paint along the perimeter from top to bottom.

The main thing is the anti-corrosion coating, which increases the service life of the structure. Also important is the treatment of sealing seams - in these places the pipes are most susceptible to destruction.

Brick chimneys

Brick is used less frequently for construction. But such structures still exist.

- It is worth tightening the bolts on the connecting clamps.

- Remove traces of old stains.

- Wash off dirt.

- Restore the plaster if there is damage.

- Apply primer (2 layers or more).

- After drying, you can start painting. It is worth applying 2 layers of paint to the brick to make it stronger and brighter.

Ceramic pipes

The most heat-saving option for building chimneys is ceramic structures. They consist of a ceramic pipe, an insulating layer and metal or foam concrete layers.

The technology for painting a ceramic pipe depends on what the insulation layer is covered with:

- foam concrete should be painted in the same way as brick: clean, wash, restore damage (if any), apply primer and paint;

- the metal layer is processed according to the scheme for painting a metal pipe: cleaning, anti-corrosion composition, primer and painting itself.

Here you can choose a paint with a lower coefficient of resistance to high temperatures (since the insulating layer that is part of the structure reduces it).

Made of reinforced concrete

Reinforced concrete pipes are painted in the same way as metal ones. The main thing is to apply an anti-corrosion compound and choose a paint that is resistant to temperatures (otherwise such a coating will not last long).

As when working with a metal structure, you need to clean it from dirt, apply an anti-corrosion compound, primer and paint coating.

With proper preparation and painting, a protective layer is formed on the pipe that protects the structure for 5 years. In addition, the protection period depends on external factors and weather conditions, proper operation of the system and timely repairs.

Painting a stainless steel chimney

Without proper care, chimneys can become completely unusable and require equipment replacement. Preventive maintenance of such pipes includes cleaning, inspection for structural defects, and checking connections.

Example of colors for painting chimneys.

One of the most important conditions for long-term operation of structures is the painting of chimneys, which protects the surface from the effects of atmospheric phenomena, temperature changes, moisture, and corrosion. Due to the large assortment of paints and varnishes (paint and varnish materials) and the high cost of painting work, it is important to follow the painting technology and use suitable paint and varnish materials.

Chimneys often wear out prematurely for various reasons. The main ones can be called:

- lack of proper care, including preventive repair work, cleaning, removal of soot, soot and ash and elimination of cracks;

- lack of necessary major repairs with replacement of grout;

- violation of the operating conditions of chimneys, change of fuel;

- application of new resource-saving technologies, wet cleaning systems;

- excessive suction of cold air along the “boiler-pipe” path.

Destructive environmental factors, temperature changes, high humidity and excessive precipitation, severe operating loads and disruption of operating conditions contribute to the destruction of smoke structures.

Types of chimneys.

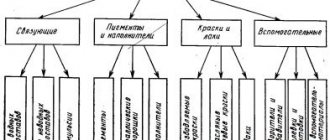

Depending on the type of chimneys, their preventive maintenance is carried out. Chimneys can be classified into several groups depending on the material of manufacture:

- metal;

- reinforced concrete (monolithic);

- brick;

- ceramic.

The technology for painting pipes depends on their type, operational features and condition.

Metal chimneys are mainly made from stainless steel, the choice of this metal is due to its corrosion resistance.

Steel pipes are characterized by mechanical strength, durability and ease of use (the smooth walls of a steel pipe do not accumulate soot and do not require frequent cleaning).

In addition, steel chimneys adapt well to any heating devices and are easily installed in an already constructed building.

Construction of a self-supporting chimney.

Painting a metal chimney consists of two main stages:

- preparatory work;

- direct application of paintwork.

Preparatory work consists of removing the old layer of paint from the surface of the pipe with spatulas or metal brushes. If ideal surface cleaning is required, special acid solutions are used.

After removing the old paint, the corrosion areas are covered with an anti-corrosion solution, then the rust is removed. The surface, if necessary, is degreased and coated with a primer. After two hours, paint is applied.

Such pipes are used mainly for industrial purposes, in production to remove any, even highly aggressive, gases.

Reinforced concrete pipes come in different designs, but in any case they consist of a reinforced concrete shaft and additional elements (anti-corrosion coating, brick lining, gas outlet shafts made of metal, plastic or ceramics, monolithic lining made of lightweight concrete, etc.).

When painting such pipes, the surface is prepared, including the removal of old paint and varnish coatings and rust, dust and contaminants. Then a primer layer and a special heat-resistant colored organosilicate enamel are applied.

After it dries, an environmentally friendly and low-flammability coating is formed, ensuring uninterrupted operation of the equipment for 15 years.

Elements of insurance for industrial mountaineering.

Until recently, such pipes were the most popular type of chimney due to the versatility and availability of bricks and the durability of the structure.

At the same time, a brick chimney has a significant mass, requires the construction of a foundation, and takes a lot of time and effort during construction.

A brick chimney requires careful maintenance; in former times they were constantly whitewashed so that the soot was more noticeable at possible cracks.

Painting a brick chimney includes the following steps:

- tightening bolted connections of metal clamps;

- applying plaster to areas of damaged brickwork;

- washing and removal of soot, soot, ash;

- surface primer;

- painting (two colors - white and red).

The paint is applied in two layers, which ensures the durability and durability of the paint and the richness of the colors.

The choice of red and white colors for painting is determined by designation standards for increased attention.

We invite you to familiarize yourself with a DIY bathhouse at the dacha: design, construction and arrangement of a bathhouse (video 130 photos)

Painting a brick chimney is carried out either using a high-pressure apparatus or traditional rollers.

Signal colors for pipelines.

In addition to reinforced concrete, steel and brick chimneys, their ceramic analogues appeared on the Russian market in 2004.

Such pipes consist of ceramic fireclay pipes, an insulating layer and an outer layer of foam concrete or stainless steel. There are glass chimneys that are moisture resistant and non-corrosive.

However, glass chimneys are not common due to their high cost and high installation costs.

Large diameter chimneys are painted using the industrial climbing method.

Chimneys should be painted with silicone enamels. For external painting of pipes, it is recommended to use KO-8111 enamel as a primer layer.

It is used under conditions of exposure to high temperatures (up to 600°C) and aggressive environments (petroleum products, oils, chlorine ions, salt solutions, etc.).

Heat-resistant enamel KO-8111 is also used for painting fireplaces and stoves.

For signal painting of pipes, silicate enamel OS-82-03 is used.

OS-82-03 is an organosilicate mixture used for anti-corrosion protection of various surfaces (metal, concrete, reinforced concrete) used in environments with high temperatures up to 500°C. This enamel is also resistant to aggressive substances, including petroleum products and industrial oil.

Painting of chimneys is carried out by specialists using professional equipment. However, painting a home chimney can be done with your own hands.

This will require gloves, a brush or roller, fireproof paint and primer. It is advisable to choose high-quality paint and beware of fakes, because the performance properties and service life of the chimney depend on the paintwork material.

You should definitely pay attention to the expiration date of the paint.

Before directly applying the paintwork, the surface of the pipe is cleaned of dirt, old paint and degreased with a solvent or acetone.

After this, the pipe is coated with a primer and left alone until completely dry, then paint is applied in 2-3 layers.

During repair work, be sure to use gloves and a respirator.

Gusevsky Andrey Anatolievich

Painting stainless steel is not an easy task. You must first decide what to paint the stainless steel with and then apply a high-quality coating. After all, if you do not follow certain rules, then the coating will quickly peel off.

Today we will tell you how to paint stainless steel without missing anything. Also in the video in this article and photos you can get additional information that will allow you to do everything efficiently and quickly.

Painting stainless steel is a process where the key role is played by a carefully prepared surface, and not by the stainless steel paint itself. So when doing the work with your own hands, you must adhere to certain rules; instructions for this are outlined below.

Attention: If the surface that was prepared was not cleaned very thoroughly and there are defects, then such paint on stainless steel will peel off quite quickly.

- Before painting stainless steel, it must be processed with a conventional grinding machine with a special attachment. Sandpaper is selected with medium grain. The speed is set to maximum. Metal processing using a machine is carried out with smooth movements with little pressure, which will allow you to achieve excellent results and save a lot of time.

- Upon completion of treatment, the surface must be degreased using alkaline compounds or special acids. One of the most effective and cheapest ways to degrease is to use a four percent solution of water and soda.

- To paint stainless steel, it is possible to use regular automotive paint with a hardener. Although its price is steep, it is best suited for this purpose. Do not forget that hardeners are added in large quantities, which will allow the paint to set and dry faster.

- Paint is applied to the surface using a spray gun (see Selecting a spray gun for painting). The use of a paint roller and brush is strictly unacceptable. If stainless steel is painted with one coat of paint, this can cause the coating to quickly peel off the surface.

- Stainless steel paint is never applied in one layer. There must be at least two of them. To enhance the effect, the paint is coated with varnish, this will protect the surface from mechanical damage.

Mandatory conditions that must be adhered to when painting metals susceptible to corrosion:

- Stainless steel paint should never be applied in high humidity. Air humidity should not exceed eighty percent.

- The operating temperature can be from 50C to 350C.

- The surface to be painted must be absolutely dry and free of grease.

If you showed interest in advance and turned to specialists, then you were probably advised to use powder paint.

The secret of the paint coating method is that the paint is applied using a spray gun (see How powder painting is done).

Next, the coating is subjected to heat treatment in a special chamber at a temperature of two thousand degrees Celsius.

Causes of wear and tear on chimneys

During prolonged exposure to high temperatures from 280 °C to 620 °C, the strength of materials decreases and they become less resistant to corrosion. The main reasons that lead to premature destruction of the chimney:

- new technologies aimed at protecting the environment, especially the “wet cleaning” system;

- too much air injection through the boiler-pipe system is also a negative factor;

- frequent or sudden changes in operating conditions;

- work in violation of design conditions;

- frequent change of fuel types.

Painting pipes is considered an effective protection against destruction. It is important to choose paint and varnish materials wisely in order to protect metal and reinforced concrete structures. It is necessary to take into account the operating conditions and surface features.

Video description

Heat-resistant paint made of liquid glass.

Colored heat-resistant enamel can be made from turpentine (PF-283), varnish and gouache of the desired shade. Mix the ingredients with a brush or wooden stick in a container until smooth. If you do not add paint to the mixture, the composition will turn out to be an inconspicuous matte finish.

Industrial solutions

Good heat-resistant enamel is offered by the Hansa brand, which can be found in 16 shades. The product is produced both in traditional liquid form and in aerosol form. When heated to 800 C, the substance does not lose its qualities. The paint and varnish material is used when working with metal, suitable for stainless steel.

Coloring process Source cement46.ru

Russian offers heat-resistant enamel designed for protective painting of metal equipment, including potbelly stoves and chimneys. Advantages of the product:

- operation at high temperatures (from -60 to +1200 C);

- anti-corrosion properties;

- does not emit toxic substances;

- resistant to aggressive environments;

- palette of 23 colors.

Heat-resistant paint for stoves Source grodno.elcon.by

produces paints created on an organosilicon base. Very strong enamels can withstand temperatures up to 600 C. The products are offered in 520 ml aerosol cans.

If the potbelly stove is placed in a bathhouse, then it is better to give preference to special enamel for metal “Termal” (). The paint is made on the basis of alkyd resin. If the stove is heated to 200 C, the newly painted surface will harden within an hour. Available in silver and black colors.

Paint selection

The choice of paint composition primarily depends on what material the chimney is made of, because paint for bricks will not be able to fully protect the metal from adverse conditions. Therefore, before purchasing a paint and varnish product, you should carefully read its characteristics and find out what materials it is intended for. But there are also uniform requirements for all paints and varnishes:

- Drying time. A very important parameter for outdoor work, because with a long drying time, the applied coating can be damaged by weather conditions.

- Temperature range. It is necessary to take into account the approximate temperature of the gases passing through the pipes and the minimum temperature drop in the region.

- Conditional viscosity. The optimal indicator would be 36 conventional degrees.

- Validity. It is determined how long the protective qualities of the dye are maintained.

If all indicators are selected correctly, then a dense thermal and moisture-resistant film is formed on the pipe surface, which will last for a long time.

Popular paints and varnishes have the following properties:

- resistance to degradation caused by oxidation;

- resistance to aggressive atmosphere;

- low surface tension;

- water-repellent ability;

- corrosion resistance;

- heat resistance.

The maintenance-free service life increases to 15 years thanks to these indicators. It is for this reason that paint and varnish materials are used to protect many objects:

- household and industrial heat exchangers;

- pipelines with superheated steam;

- chimneys;

- collectors.

All heat-resistant paints and varnishes in liquid form are highly toxic, and when applying them you must use protective equipment (respirator, gloves and clothing covering the skin).

A good composition for strengthening the surface are organosilicon materials with high moisture-repellent properties, which also have good adhesion to various building materials.

To paint the outside of chimneys, the following coatings are suitable:

- The best option for priming the surface is gray enamel KO-8111, which has increased heat resistance.

- For bright signal painting, OS-12-03, red and white paints are usually used.

KO-8111 paint perfectly withstands temperatures up to 620 °C, so it is often used when painting pipes of boiler houses and other industrial facilities. It is ideal for external anti-corrosion work on heating and water supply pipelines. This enamel is also used for painting steam lines and other process pipes.

KO-8111 enamel has good moisture resistance and is also resistant to temperature changes. As the temperature increases, the paint applied to the surface even becomes stronger.

For bright signal painting of pipes, red and white paint is applied to the dried, primed surface. This composition is applied in two or three layers, and the paint layer is 35-55 microns thick, with a consumption of 125-160 g/m2 per layer.

Organosilicon paints and varnishes are also considered a suitable material for painting. They have a lot of advantages:

- Synthetic polymers have high durability and resistance to damage and abrasion.

- The use of this material guarantees increased durability of the coating, since organosilicon paints are unique in their heat resistance. They are able to withstand long-term operation at temperatures up to 720 °C.

- This paint and varnish material has low surface tension. It forms a coating that has high weather resistance as well as reduced retention of dust and dirt.

These materials are used to paint:

- car mufflers, various engine parts and even jet engine nozzles;

- heat exchangers, manifolds and pipelines;

- metal and brick pipes of stoves in houses, saunas.

Once the silicone paint dries, it forms a very durable coating. It is fire resistant and has many other protective properties.

Now there is an abundance of silicone paints and enamels for metal and brick pipes. When choosing coatings, it is important to understand their protective capabilities.

How to choose paint for a chimney and paint it

Regardless of what material the chimneys are made of, they are all subject to increased stress: from the outside to atmospheric influences, from the inside to high-temperature gases. Painting chimneys will not only give them an aesthetic appearance, but will also extend their service life. But before painting, you need to select a suitable dye and carefully prepare the surfaces for painting.

Causes of wear and tear on chimneys

During prolonged exposure to high temperatures from 280 °C to 620 °C, the strength of materials decreases and they become less resistant to corrosion. The main reasons that lead to premature destruction of the chimney:

- new technologies aimed at protecting the environment, especially the “wet cleaning” system;

- too much air injection through the boiler-pipe system is also a negative factor;

- frequent or sudden changes in operating conditions;

- work in violation of design conditions;

- frequent change of fuel types.

Painting pipes is considered an effective protection against destruction. It is important to choose paint and varnish materials wisely in order to protect metal and reinforced concrete structures. It is necessary to take into account the operating conditions and surface features.

Paint selection

The choice of paint composition primarily depends on what material the chimney is made of, because paint for bricks will not be able to fully protect the metal from adverse conditions. Therefore, before purchasing a paint and varnish product, you should carefully read its characteristics and find out what materials it is intended for. But there are also uniform requirements for all paints and varnishes:

- Drying time. A very important parameter for outdoor work, because with a long drying time, the applied coating can be damaged by weather conditions.

- Temperature range. It is necessary to take into account the approximate temperature of the gases passing through the pipes and the minimum temperature drop in the region.

- Conditional viscosity. The optimal indicator would be 36 conventional degrees.

- Validity. It is determined how long the protective qualities of the dye are maintained.

If all indicators are selected correctly, then a dense thermal and moisture-resistant film is formed on the pipe surface, which will last for a long time.

Popular paints and varnishes have the following properties:

- resistance to degradation caused by oxidation;

- resistance to aggressive atmosphere;

- low surface tension;

- water-repellent ability;

- corrosion resistance;

- heat resistance.

The maintenance-free service life increases to 15 years thanks to these indicators. It is for this reason that paint and varnish materials are used to protect many objects:

- household and industrial heat exchangers;

- pipelines with superheated steam;

- chimneys;

- collectors.

All heat-resistant paints and varnishes in liquid form are highly toxic, and when applying them you must use protective equipment (respirator, gloves and clothing covering the skin).

A good composition for strengthening the surface are organosilicon materials with high moisture-repellent properties, which also have good adhesion to various building materials.

To paint the outside of chimneys, the following coatings are suitable:

- The best option for priming the surface is gray enamel KO-8111, which has increased heat resistance.

- For bright signal painting, OS-12-03, red and white paints are usually used.

KO-8111 paint perfectly withstands temperatures up to 620 °C, so it is often used when painting pipes of boiler houses and other industrial facilities. It is ideal for external anti-corrosion work on heating and water supply pipelines. This enamel is also used for painting steam lines and other process pipes.

KO-8111 enamel has good moisture resistance and is also resistant to temperature changes. As the temperature increases, the paint applied to the surface even becomes stronger.

For bright signal painting of pipes, red and white paint is applied to the dried, primed surface. This composition is applied in two or three layers, and the paint layer is 35-55 microns thick, with a consumption of 125-160 g/m2 per layer.

Organosilicon paints and varnishes are also considered a suitable material for painting. They have a lot of advantages:

- Synthetic polymers have high durability and resistance to damage and abrasion.

- The use of this material guarantees increased durability of the coating, since organosilicon paints are unique in their heat resistance. They are able to withstand long-term operation at temperatures up to 720 °C.

- This paint and varnish material has low surface tension. It forms a coating that has high weather resistance as well as reduced retention of dust and dirt.

These materials are used to paint:

- car mufflers, various engine parts and even jet engine nozzles;

- heat exchangers, manifolds and pipelines;

- metal and brick pipes of stoves in houses, saunas.

Once the silicone paint dries, it forms a very durable coating. It is fire resistant and has many other protective properties.

Now there is an abundance of silicone paints and enamels for metal and brick pipes. When choosing coatings, it is important to understand their protective capabilities.

Stages of work

Having chosen what to paint the pipe with, you should not immediately apply the paint. It is necessary to carry out preparatory work and select the necessary materials. You may need:

- brush (if the pipe size is large, you can use a roller);

- metal hard brush;

- acetone or other degreaser;

- primer;

- selected paint composition.

Further work will vary depending on what the chimney is made of. Chimneys are made from:

- metal;

- bricks;

- ceramics;

- reinforced concrete.

Before starting work, it is recommended, if possible, to stop the gas supply to the chimney and allow the pipe to cool to ambient temperature. This will not only reduce injuries (the risk of getting burned on a hot surface) and the toxicity of the paint and varnish composition, but will also allow the dye to form a more durable film when it hardens.

Metal surfaces

Pipes are made mainly of stainless steel and have recently become the most popular in private homes. They are installed not only on gas boilers and water heaters, but also on brick-built stoves. Stainless steel chimneys are durable and comfortable. Their main advantage is ease of installation. But before painting stainless steel, the surface must be prepared. To do this, do the following:

- clean the metal from traces of old coating, dust and other contaminants using a metal brush;

- wash and dry thoroughly;

- treated with a degreaser;

- apply an anti-corrosion mixture (if the soil contains anti-corrosion additives, then this step can be omitted);

- after drying, the chimney is covered with 2-3 layers of primer.

When the primer is dry, you can start painting. Painting is carried out along the perimeter and starts from the top.

Anti-corrosion protection is of great importance for the service life of the chimney. At high operating temperatures and aggressive environments, the protective paint layer must be resistant to these harmful factors. Therefore, painting chimneys is a necessity.

Brick chimneys

Nowadays brick is less popular, but until recently chimneys were made mainly of it. But how to paint brick? First of all, the structure must be prepared:

- tighten loose bolts on the connecting clamps;

- remove old paint or lime;

- wash away soot, soot and dirt;

- restore the damaged layer of plaster (it is not necessary to completely change it, just apply the mixture to the damaged areas and wait for it to dry);

- Apply at least 2 coats of primer (more is allowed).

After the primer has dried, you can paint. It is recommended to apply paint on brick in 2 layers to ensure greater strength and color saturation.

Ceramic pipes

This is a construction novelty consisting of a ceramic pipe, a layer of insulation and finishing made of foam concrete or metal. It is considered the most heat-saving.

The painting method depends on what the insulating layer is covered with:

- foam concrete is processed using the same technology as brick;

- the metal is painted in accordance with the rules for painting a metal base described above.

When choosing dyes for ceramic pipes, heat resistance does not play a big role, because the insulation layer reduces the heating of the outer surface.

Reinforced concrete

In private houses, reinforced concrete structures are extremely rare; most likely, this will be an industrial pipeline running through the site, delivering gas or water to the house. You will have to choose a color for it not according to your taste, but in accordance with the requirements of the marking color.

The process of protection and finishing is carried out in the same way as when processing and applying paints and varnishes to a metal chimney. The main thing is not to forget about anti-corrosion treatment and degreasing, because the uninterrupted supply of utilities depends on the safety of the pipeline.

If the paint is selected in accordance with all requirements and all processing steps are followed, then after the composition dries, a durable non-toxic film will be obtained that will protect the structure for 5-15 years. The period of protection depends on atmospheric influences, the internal temperature of the chimney and the quality of the purchased paint and varnish.

Stages of work

Having chosen what to paint the pipe with, you should not immediately apply the paint. It is necessary to carry out preparatory work and select the necessary materials. You may need:

- brush (if the pipe size is large, you can use a roller);

- metal hard brush;

- acetone or other degreaser;

- primer;

- selected paint composition.

Further work will vary depending on what the chimney is made of. Chimneys are made from:

Before starting work, it is recommended, if possible, to stop the gas supply to the chimney and allow the pipe to cool to ambient temperature. This will not only reduce injuries (the risk of getting burned on a hot surface) and the toxicity of the paint and varnish composition, but will also allow the dye to form a more durable film when it hardens.

Metal surfaces

Pipes are made mainly of stainless steel and have recently become the most popular in private homes. They are installed not only on gas boilers and water heaters, but also on brick-built stoves. Stainless steel chimneys are durable and comfortable. Their main advantage is ease of installation. But before painting stainless steel, the surface must be prepared. To do this, do the following:

- clean the metal from traces of old coating, dust and other contaminants using a metal brush;

- wash and dry thoroughly;

- treated with a degreaser;

- apply an anti-corrosion mixture (if the soil contains anti-corrosion additives, then this step can be omitted);

- after drying, the chimney is covered with 2-3 layers of primer.

When the primer is dry, you can start painting. Painting is carried out along the perimeter and starts from the top.

Anti-corrosion protection is of great importance for the service life of the chimney. At high operating temperatures and aggressive environments, the protective paint layer must be resistant to these harmful factors. Therefore, painting chimneys is a necessity.

Brick chimneys

Nowadays brick is less popular, but until recently chimneys were made mainly of it. But how to paint brick? First of all, the structure must be prepared:

- tighten loose bolts on the connecting clamps;

- remove old paint or lime;

- wash away soot, soot and dirt;

- restore the damaged layer of plaster (it is not necessary to completely change it, just apply the mixture to the damaged areas and wait for it to dry);

- Apply at least 2 coats of primer (more is allowed).

After the primer has dried, you can paint. It is recommended to apply paint on brick in 2 layers to ensure greater strength and color saturation.

Ceramic pipes

This is a construction novelty consisting of a ceramic pipe, a layer of insulation and finishing made of foam concrete or metal. It is considered the most heat-saving.

The painting method depends on what the insulating layer is covered with:

- foam concrete is processed using the same technology as brick;

- the metal is painted in accordance with the rules for painting a metal base described above.

When choosing dyes for ceramic pipes, heat resistance does not play a big role, because the insulation layer reduces the heating of the outer surface.

Reinforced concrete

In private houses, reinforced concrete structures are extremely rare; most likely, this will be an industrial pipeline running through the site, delivering gas or water to the house. You will have to choose a color for it not according to your taste, but in accordance with the requirements of the marking color.

The process of protection and finishing is carried out in the same way as when processing and applying paints and varnishes to a metal chimney. The main thing is not to forget about anti-corrosion treatment and degreasing, because the uninterrupted supply of utilities depends on the safety of the pipeline.

If the paint is selected in accordance with all requirements and all processing steps are followed, then after the composition dries, a durable non-toxic film will be obtained that will protect the structure for 5-15 years. The period of protection depends on atmospheric influences, the internal temperature of the chimney and the quality of the purchased paint and varnish.

Powder painting of chimneys for stoves and exhaust pipes

In everyday life, this method of applying paint on stainless steel cannot be used. The heat-resistant powder composition is applied with a spray gun. After its application, the stainless steel is placed in a chamber where the temperature is raised to 200°C. A film is formed that is resistant to external influences. The film can be glossy, matte or imitate different surfaces.

The applied layer will be even. The result will be a large selection of color shades. Only removable items can be painted in this way. The bulky product is not painted with powder material at the installation site. The new coating is not afraid of direct sunlight. The process is called waste-free. The material dries in 30 minutes.

The technological process itself has advantages:

- Economical consumption of dye, since it is applied in one layer.

- High adhesion is especially important for stainless steel.

- The remaining powder is not thrown away, but used for the next time.

- Painting is done quickly.

In everyday life, painting is also not carried out after which an oxide film is formed. Steel is processed using plasma at a low temperature. The process requires certain conditions to be met: the presence of oxygen in the atmosphere. Although the metal remains unchanged (matte and shiny), covered with an oxide film, it changes color.

Through them, combustion products are removed. Such devices must be kept in good condition.

Powder painting technology is used to protect them from harmful factors.

Chimney system of the building

Installation of individual stoves is practiced in private courtyards or in houses.

There they play the role of a heating source or hearth on which you can successfully cook.

They must have a chimney.

The chimney is a system that removes fuel combustion products at high temperatures. This exhaust system plays a huge role in the house:

- Removes fuel combustion products;

- Provides insulation of building structures from hot gases so that they do not catch fire;

- Serves as protection for building structures when they are exposed to aggressive condensate falling in the pipe. Over time, acids destroy building materials and soot penetrates into the masonry, which leads to damage to finishing materials.

Painting a metal chimney

Each of the chimneys has a specific shape to retain heat and remove smoke. To ensure the effectiveness of such a system, the use of an air labyrinth is practiced.

This preserves the main function of removing gases after combustion, and it becomes possible to regulate the time during which the outgoing flow moves through the pipes. It is important to prevent the walls of the chimney from becoming covered with condensation.

The presence of an air labyrinth promotes active heat collection to increase the efficiency of the combustion center.

To construct a building, you need a project that includes many drawings and calculations. They specify the dimensions and type of materials from which the construction will take place.

We invite you to familiarize yourself with DIY sauna benches drawings

And at the initial stage, it is important to choose the material for the ventilation pipes and stove chimney.

To make the right decision, decide where and what equipment you will install, what main task is assigned to this or that pipe - this will greatly simplify your task.

Brick pipe

Its design depends on what material is chosen to create the chimney.

The traditional solution is to use brick as a material for the manufacture of furnace exhaust systems.

In this case, it is permissible to use only solid ceramic bricks, and not silicate and concrete. They are not resistant to high temperatures and acids.

Ventilation system in a residential building

It is important to take care of the evenness of the walls of the inner surface of the chimney masonry, to eliminate mortar drips, and to completely fill the seams.

To build a stove chimney, it is important to use clay mortar. Due to its low strength, the use of this type of construction is suitable for one-story buildings.

Brick chimneys have a large mass; they take heat from the gases that escape and retain heat for a long time.

Metal chimneys

Recently, metal chimneys have become increasingly popular. With their help, boilers, stoves and fireplaces that operate using solid fuel are connected. It is customary to take pipes from a material such as black steel.

The wall thickness of such pipes should not be less than 2 mm. Then the heat resistance indicators for them will be at least 1000 °C.

Sometimes it is practiced to use portable stoves, which are compact and versatile in use.

They consist of an oven, a hob and a place to dry clothes. You can take such stoves with you on a camping trip. They are lightweight and multifunctional.

Such stoves also have chimney ventilation systems.

To ensure that the stove chimney lasts as long as possible and is not damaged by corrosion and rust, powder painting is practiced on the metal. It proves its practical effectiveness.

Roofing snow retainers are a high-quality alternative to liquid paints - powder coating. Basic equipment for painting - where can powder-polymer technology be used? Read in this article.

Powder coating of the chimney

Free painting of 2 samples

Painting of 2 customer samples in any color according to the RAL catalog **

| Name | Cost of painting |

| Chimney painting | from 30% of the order value |

| Additionally | |

| There is a surcharge for colored candy polishes | from 2800 rub. |

| Painting in two colors | +100% |

| Chemical and organic contamination, as well as traces of metal corrosion more than 10 microns | from 10% of the order value |

| Prefabricated and oversized products | individually |

| Urgency of order execution | individually |

| Painting more than 2 layers (primer, varnish, paint, etc.) | 100% layer |

| Minimum order value | 1500 rub. |

The cost of painting includes:

- Primary color painting

- Application of powder varnish (glossy, matte)

- Removal of fittings/installation

- The final cost of the service is determined only upon inspection

The chimney is an important element of the heating system of a private home. Without it, the operation of a stove or hood will be impossible, since combustion products are removed from the premises through it. Painting chimneys is an opportunity not only to keep them in good condition, but also to achieve their appropriate aesthetic characteristics. They are important for the exterior of the house, since a chimney made of stainless steel and having a corresponding appearance is not always able to fit into the existing color scheme.

Powder painting of a chimney is a service that you can order at. By contacting us, you can count on professional-level assistance with all that it implies: high quality of the coating received, European-quality service.

Brick chimneys

Elements of insurance for industrial mountaineering.

Until recently, such pipes were the most popular type of chimney due to the versatility and availability of bricks and the durability of the structure. At the same time, a brick chimney has a significant mass, requires the construction of a foundation, and takes a lot of time and effort during construction. A brick chimney requires careful maintenance; in former times they were constantly whitewashed so that the soot was more noticeable at possible cracks.

Painting a brick chimney includes the following steps:

- tightening bolted connections of metal clamps;

- applying plaster to areas of damaged brickwork;

- washing and removal of soot, soot, ash;

- surface primer;

- painting (two colors - white and red).

The paint is applied in two layers, which ensures the durability and durability of the paint and the richness of the colors. The choice of red and white colors for painting is determined by designation standards for increased attention. Painting a brick chimney is carried out either using a high-pressure apparatus or traditional rollers.

Signal colors for pipelines.

In addition to reinforced concrete, steel and brick chimneys, their ceramic analogues appeared on the Russian market in 2004. Such pipes consist of ceramic fireclay pipes, an insulating layer and an outer layer of foam concrete or stainless steel. There are glass chimneys that are moisture resistant and non-corrosive. However, glass chimneys are not common due to their high cost and high installation costs.

Do you need chimney painting?

Painting steel chimneys is a service that is ordered for a number of reasons, which can be grouped into three large groups:

- to give the appropriate appearance;

- to extend service life;

- in accordance with the requirements for the protection of air transport facilities.

Painting as an element of aesthetics

We are often approached by clients who don’t like the look of a stainless steel chimney, which spoils the appearance of not only the roof, but the entire house. Therefore, they want to paint it the same color as the roof, so that it visually blends with it.

Sometimes it happens differently: the customer, on the contrary, wants to highlight the chimney pipe as a separate element! In this case, we paint it in one of the colors of the house's exterior, contrasting with the color of the roof.

Painting to extend service life

Any, even the most durable steel begins to rust and collapse under the influence of external aggressive environments. Every second, the chimney of any home is exposed to negative influences of various natures, including thermal, chemical and mechanical. Powder coating of a stainless steel chimney will, without exaggeration, extend its service life significantly. Thanks to it, a reliable coating will be created on the steel surface, which will prevent its direct contact with moisture and other destructive factors, which will extend its service life.

Requirements for the protection of air transport facilities

Painting of steel chimneys located at facilities located near airfields is a legal requirement. This applies to pipes whose height is 50 meters or more. The painting should be distinctive and in appropriate colors so that pilots will know that there is a high-rise structure in front of them.

Painting metal chimneys

The metal chimney is very functional and has a long service life. But if the material is not taken care of, the pipe will lose its aesthetic appearance. In addition, a metal pipe may cease to fully perform its functions - removing gases and providing traction. Dirt, rain, sun, exposure to acids and soot - all this negatively affects the condition of the metal pipe, rust appears on it, the metal is destroyed, sometimes so much that individual parts of the pipe simply have to be replaced. This is troublesome and expensive, and regular painting of metal pipes will help extend the service life and avoid premature additional costs.

Specialists know how to properly care for a metal pipe. This is not an easy task, since the work is carried out at high altitude. However, our team of industrial climbers has everything necessary for this: permits for dangerous high-altitude work, professional gear and equipment, experience in such work.

Technology of painting a metal chimney

Our employees will take on work of any complexity. If you take preventative measures regularly, then most likely you can limit yourself to cleaning the chimney, stripping off peeling paint and applying a new coating. But this is not always enough.

Dust and sand settle on pipes, and this is inevitable. Industrial climbers can easily remove such contaminants and clean the inside of the pipe from soot deposits and chemical residues. These works are carried out using mechanized tools, because the area of contamination is too large to do it manually.

Painting metal chimneys

Next you need to remove the old paint. Under the influence of moisture, winds and sun, paint cracks and peels off. In such areas, the coating must be cleaned so that the new paintwork material lays evenly and firmly. Often, specialists resort to the use of special sandblasting equipment or industrial sprayers of acid-containing solvents. If the metal pipe is in good condition, then spot removal of peeling paint can be done manually - with scrapers and brushes.

Why is powder painting of a chimney the best solution?

The price of painting a chimney with TermoColor is low, but the benefits are significant. For a very reasonable fee, you will receive a product that not only looks great, but also has a coating that is called “vandal-proof.” The fact is that it is not susceptible to the effects of:

- high and low temperatures;

- temperature changes;

- shock and wind loads;

- physical and mechanical influences;

- moisture.

The operation of such a coating can be carried out in a wide temperature range: −60°C to +120°C. At the same time, it will not lose its functionality and will retain its integrity and original aesthetic characteristics. Moreover: it does not fade under the influence of direct sunlight, so the pipe will retain the brightness and saturation of the original color scheme for years.

All this cannot be said about any other type of painting, and that is why prudent owners choose powder painting.

Special paints and varnishes for the oven

- natural drying oil;

- varnish;

- silicone enamel;

- heat-resistant paint.

These compositions are produced industrially and are available for free sale. But some materials can be made independently; we will also talk about them in our article.

We invite you to familiarize yourself with our detailed analysis of how to insulate a steam room in a bathhouse.

Only natural drying oil is used. Its distinctive quality is that it does not change the color of the brick, but only makes its shade darker. It is used only for painting a red brick stove in a bathhouse; the stove must be lit and run for at least 2 hours, after which it can be painted. We do not recommend using it indoors - here the stove heats up less and the drying oil may not dry out.

Many owners of private houses ask the question of what varnish to coat a red brick stove with. And this is not surprising, since the transparent glossy coating effectively transforms the appearance of any interior element. To paint stoves, a special varnish of the PF-283 type is used in equal proportions with turpentine, which makes it possible to obtain a decorative layer with increased strength characteristics.

Photo 5. Example of a varnished stove

Note! The main feature of using varnish is the ability to add dry gouache to the composition and give the coating the required shade.

- excellent adhesion to brick base;

- good strength;

- moisture resistance;

- long service life.

Among the shortcomings, only a small selection of colors can be noted.

Heat resistant paint

The main advantages are resistance to high temperatures (up to 600 °C) and a wide range of shades. They are used for painting steam pipes, so if you have not yet decided how to cover a red brick stove, then heat-resistant paint will be the ideal solution.

Contacting TermoColor is a good decision!

Powder coating is impossible without special equipment. We have a powerful production and technical base, which allows us to carry out the relevant work at a decent professional level. Our clients have the opportunity to take advantage of a number of significant advantages:

- Short deadlines for work;

- Possibility of painting in more than 200 colors on the RAL scale;

- Affordable cost of work;

- Guarantee of high quality of the resulting coating.

How to paint a brick chimney?

A brick chimney is an integral part of the stove, which becomes unusable without proper care. Painting a brick pipe, done properly, will ensure the durability of the structure. The paint and varnish coating will protect against atmospheric temperature changes, the influence of humidity, and corrosion processes. At the same time, the aesthetically designed external finishing of the pipe will decorate the appearance of the building.

Repair and painting of chimneys in Yaroslavl and the Yaroslavl region

It has long been impossible to imagine many types of modern production without chimneys. Pipes remove gases, combustion products of various fuels, and also provide the necessary traction, so the condition of the pipes must be monitored no less carefully than any other equipment. will help you take care of your pipes: industrial pipes from boiler houses and thermal power plants will always look great and perform their function smoothly! Our specialists have extensive experience in repairing and painting pipes in Yaroslavl and the Yaroslavl region, and professional climbing equipment and high-quality equipment allow us to carry out the work safely and flawlessly.

Repair and painting of metal chimneys in Yaroslavl

Why paint a metal pipe? First of all, you need to remember that repairing and painting metal pipes in Yaroslavl will preserve their appearance. If the surface is covered with a layer of dirt and soot, if layers of paint are falling off, then, naturally, the pipe makes an unpleasant impression. Secondly, steel pipe is highly susceptible to corrosion if it has not been treated properly. A rusty pipe will not last long, so painting steel chimneys is necessary to extend their service life and save on premature replacement.

Repair and painting of metal pipes in Yaroslavl

How, for example, is painting of iron pipes in boiler rooms done? Usually it is necessary to replace the entire existing layer of paint, so the pipe is cleaned with special solvents, removing dirt, grease, and paint. The surface must be degreased and treated with an anti-corrosion compound to protect the metal. If rust has already appeared, our specialists will clean and also treat the affected area. After this, they begin painting with special enamels, some of which, by the way, already contain anticorrosive. Painting is done in two layers, applying the second after the first has completely dried.

Repair and painting of reinforced concrete pipes of boiler houses in Yaroslavl

Reinforced concrete pipes require no less care, since metal reinforcement also corrodes, and concrete deteriorates over time. Repair and painting of reinforced concrete pipes in Yaroslavl should be carried out by professionals, because attention to detail is important here. The work begins by removing the layer of old paint - completely or partially, using both acidic solvents and a variety of brushes and scrapers. Then the surface is inspected for damage: protruding rusty reinforcement, collapsed concrete.

Repair and painting of reinforced concrete pipes in Yaroslavl

You cannot start painting without making repairs! We will definitely treat the metal parts with compounds that prevent rust, and also restore the concrete. After this, you can carry out painting work on the prepared surface. It is not necessary to prime the pipe if the paint already contains a primer: thanks to this, painting concrete chimneys will require less time.

Repair and painting of brick industrial pipes in Yaroslavl

Brick pipes are found quite often: alas, many are sure that brick is an almost “eternal” material and do not even think about possible damage. Now brick has been replaced by stronger and more durable metal structures, so we can safely say: your brick pipe is many years old. Even the highest quality brick, the best plaster and paint cannot withstand dirt, sunlight, frost, or moisture. Our specialists know how to repair and paint brick pipes in Yaroslavl, and will be happy to help you!

Repair and painting of brick chimneys in Yaroslavl

First of all, you need to get rid of the old paint: it is best removed using high-pressure machines. Then we will check the condition of the masonry: if there are damaged areas or fallen plaster, repairs will have to be made. And only after that we will proceed to priming and painting itself. In addition, we will definitely tighten the crimp clamps that become loose over time.

Types of paint

For a brick pipe, only heat-resistant or enamel paint compositions are suitable, which, when properly applied to the surface, ensure the durability of the coating for 10 years. An option is to use a special varnish, the protective decorative properties of which are less and last 3-4 years. Each type of coating has pros and cons, for example:

- Heat-resistant paint has vapor permeability, decorative, electrical insulation, protective properties, is reliable, and does not wear out for a long time. Resistant to high temperatures, lies evenly along the surface, protects the chimney from corrosion, oxidation reactions, temperature changes, and atmospheric phenomena. Disadvantages - specific odor, long drying period, aggressive composition.

- Enamel - affordable, has water-repellent qualities, richness, and a variety of shades. When dry, it creates a dense coating that is resistant to atmospheric changes, mineral oils, and high temperatures. The only drawback is the pungent odor that persists for several days.

- Heat-resistant varnish is used for protective painting of brick and other surfaces that are subject to heat. Creates a coating with high resistance to moisture, water, temperature changes, protects the surface of the brick from efflorescence, giving a neat appearance. The downside is the short service life.

Return to contents

How to choose?

To carry out high-quality painting of a brick chimney, which should retain its protective and decorative properties for a long time, it is necessary that the paint and varnish materials meet the following requirements:

- They had a high level of adhesion (adhesion of surfaces of dissimilar solid and liquid bodies) - the coloring composition must be absorbed by the structure of the brick, providing protection from fluctuations in temperature and humidity.

- They were vapor and water permeable - they removed excess moisture from the surface, but did not allow drying out.

- They were resistant to ultraviolet rays - they retained their color for a long time and did not fade in the sun.

When choosing paint for a chimney, you need to pay attention to its features.

- The mass fraction of non-volatile substances should not exceed 17%.

- The optimal indicator of conditional viscosity at air temperatures from 0 to +20 ° C should be 36 s.

- Important points are the drying time, the operating temperature range, and the shelf life.

Return to contents

Home Remedies

The chimney can also be treated with homemade coloring agents. For example, brick is ground into small crumbs and sifted in a sieve until a homogeneous mass is obtained. Then it is mixed with homemade milk, village milk and egg whites. The solution should look like liquid sour cream. It is applied with a wide brush, covered with drying oil or, if a shiny surface is needed, with varnish. Forms a heat-resistant and durable brick-colored coating. To prevent the painted brick from getting dirty, it is recommended to apply a layer of whipped egg white. This heat-resistant paint protects brickwork from moisture and dirt.

How to properly paint a brick chimney?

The quality and durability of the varnish coating is greatly influenced by appropriate surface preparation. Only the tidied, repaired areas need to be coated with the paint composition. Old pipes are damaged first of all. The reason is the influence of water, wind, time. In addition, the solution that holds them together becomes unusable.

Basically, only plaster is sufficient to treat a damaged surface, but restoration of damaged masonry may be necessary. Thus, the bolted connections on the clamps may become loose, since chimneys are high-rise structures that are subject to vibrations. As a result, the trunk tilts and destruction is possible, to prevent which these connections need to be tightened.

After restoring the brickwork, it is worth cleaning the outer surface of the pipe (wet, household washing) using special equipment, and sometimes manually, to remove dirt, soot, soot, and ash. Loose layers of paint can be effectively removed using a sandblaster or acid solvent. The better this work is done, the smoother the new coating will lie and the longer it will last.

The cleaned surface is coated with a primer. Coloring compounds are applied on top of it. To ensure color saturation, durable and long-term preservation of the flooring, the paint must be applied twice. For structures such as a brick pipe, devices are used that can operate in high pressure mode, and rollers are also used. Paints and varnishes are applied by spraying to the surface.

Types of chimneys

The photo shows several product options

Depending on the type of pipe that needs finishing, a number of preventive measures are selected.

These designs come in the following types:

- Monolithic or reinforced concrete;

- Metal;

- Ceramic;

- Brick.

The method by which chimneys are painted directly depends on the type of product itself, its wear and tear and the characteristics of the operating conditions.

Metal chimneys

Metal chimney

Metal type chimneys are mainly made of steel. This metal is preferred due to its resistance to corrosion, and in addition, steel chimneys are strong, convenient and durable products.

Painting a chimney boiler pipe, which is made of steel, consists of only two stages of work;

- Preparatory activities. The list of such works includes removing the old finishing coating using a spatula or a metal brush. After the layer of old chimney finishing has been removed, areas with corrosion should be treated with anti-corrosion agents. If necessary, the metal is also degreased and primed;

Advice. If complete removal of the paint layer is necessary, then specialized acid removers should be used.

- Application of paint and varnish coating.

Monolithic structures

Furnace gas outlet design

Such designs have found their use mainly in industrial facilities.

Chimneys made of reinforced concrete consist of a barrel and additional elements, which can be:

- Brick lining;

- Monolithic lining from light types of mortar;

- Anti-corrosion coating;

- Metal gas exhaust trunks;

- Plastic gas exhaust barrels;

- Ceramic gas exhaust barrels.

Instructions for painting elements of this type are as follows:

- Removing old coating, dust, dirt and rust;

- Applying a layer of primer;

- Coloring.

For such painting, chimney paint is used, which is a heat-resistant colored enamel that creates a coating with excellent adhesion and high moisture and heat resistance.

One of the heat-resistant paint options

Note! Using this material, an environmentally friendly and non-flammable coating is created, which will ensure the quality of the chimney for the next 15 years.

Brick pipes

Brick finishing

Until recently, it was structures of this type that were most popular due to the availability and versatility of such a material as brick.

Painting brick chimneys involves performing the following types of finishing work:

- Tightening of bolted connections on clamps;

- Treatment with plaster of places where masonry is destroyed;

- Wet washing and removal of soot, soot and ash;

- Application of primer;

- Application of paint and varnish coating.

Advice. The paint should be applied in two layers in order to ensure color saturation, as well as the durability and longevity of the created coating.

Painting of such structures is carried out using equipment operating in high pressure mode or with paint rollers.

Ceramic pipes

Example of a ceramic chimney

In addition to reinforced concrete, brick and metal structures, their ceramic analogues have recently appeared on the market. Such products are ceramic fireclay pipes, a layer of insulating material and external finishing made of stainless steel or foam concrete.

Powder coating of stainless steel

The NAYADA company offers powder painting of stainless steel in Moscow. We paint steel products of any configuration up to 7 meters in length; we use only high-quality coatings from DuPont, AkzoNobel, Pulver, Primatek and other well-known manufacturers. Stainless steel painting using modern equipment is completed within 3-4 days; if necessary, an urgent order can be completed within 1 day.

Powder painting of stainless steel is the best way to decorate and protect metal products against corrosion, since steel surfaces have low adhesion to liquid paints and varnishes. The finished powder coating adheres firmly to steel, lasts up to 30 years, does not peel off with constant contact with water, and retains its rich color when exposed to the sun. In addition, powder paint forms a perfectly smooth, aesthetic coating - without streaks, bubbles, craters and other cosmetic defects.

The equipment we have allows us to powder coat large metal products.

Oven dimensions: 2.1m x 1.4m x 7m

How is stainless steel painted?

First stage. Before painting, the metal is degreased in baths using special chemicals.

Second phase. For painting, the product is placed in a special chamber, where coloring powder is applied using electrostatic sprayers. As the paint particles pass through the spray gun, they become electrically charged and are uniformly attracted to a neutral, grounded metal. This technology for painting stainless steel is ideal for products with complex configurations, since the paint penetrates into all their corners and recesses.

Third stage. The metal structure with sprayed paint is placed in a polymerization oven, where, under the influence of heat, the powder particles are fused with the steel structure and with each other. As a result, a durable and uniform decorative and protective coating is formed, resistant to any external influences.

Powder painting of stainless steel at NAYADA

Our company offers a rich color palette of paints. You can order one-color or two-color painting of metal products in any shades from the RAL catalog. The original color effects such as metallic, super gloss black, gold chameleon, as well as imitation of natural wood, stone, and crocodile skin look especially expensive and beautiful. All types of coatings are given a three-year guarantee: if the paint peels off during this time, we will carry out a second set of painting works free of charge.

Cost of painting stainless steel

The price of painting stainless steel products depends on the surface area and shape of the metal products; below is the price list for painting flat and profile products. There is no additional charge for loading and unloading, chemical preparation of metal and packaging of finished products.

| Order quantity | Cost of painting, incl. VAT (20%), rub * | ||

| when painted according to RAL scale | when painting with ANTIK paint | ||

| Artist's paint | Customer's paint | ||

| 14.5–100 m 2 | 255.00 | 217.00 | 288.00 |

| 101–500 m 2 | 243.00 | 208.00 | 275.00 |

| 501–1,000 m 2 | 232.00 | 197.00 | 262.00 |

| 1,001–5,000 m2 | 221.00 | 187.00 | 249.00 |

| 5,001–10,000 m2 | 211.00 | 179.00 | 238.00 |

| more than 10,000 m2 | 201.00 | 171.00 | 227.00 |

Reviews

expresses gratitude to Pokras.ru LLC for fruitful cooperation. We believe in maintaining existing business relationships and hope for further mutually beneficial cooperation. We wish you successful development and achievement of new heights in business.

Maybes RUS LLC expresses deep gratitude and sincere gratitude to POKRAS.RU LLC for the impeccable and timely painting of our equipment. Thanks to the competent approach and well-coordinated work of the team of POKRAS.RU LLC, our company successfully presented its equipment at the 20th International Exhibition Aqua-Therm Moscow 2021. We express confidence in maintaining the existing friendly relations and hope for further mutually beneficial and fruitful cooperation.

Harutyun Rafikovich, the Laser Systems company and I personally express our gratitude to you for the high quality and efficiency of the work on painting our products, completed under invoice No. 5008. We would like to thank the powder coating specialist Nika for the attentiveness and highest skill he showed in completing our order. Special thanks to Vasily Ivanovich for his help and support.

I recently painted a frame from a Land Rover D2 at NAYADA, I really liked it, if there are discounts I’ll paint mine next year