Concrete coloring – pigments and dyes

Painting concrete is a very important stage for DIYers, and many of them want to learn how to beautifully and reliably paint a self-made concrete figurine, flower vase, decorative stone (short video) and other garden products.

The issue of painting concrete products was partially discussed on the pages when making a two-color flowerpot (short video) and a small vase for a fountain.

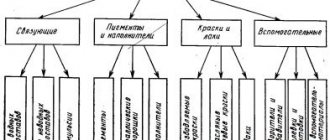

Once again, it should be noted that painting concrete (short video) and concrete products is mainly carried out in three ways: introducing a colored pigment into a dry concrete mixture, painting the finished product, and combining the two previous methods.

First method: painting concrete by introducing a colored pigment into a dry concrete mixture

In this case, mineral pigments are usually used, which are oxides or salts of various metals.

For paving slabs and decorative stones on paths, inexpensive iron oxide pigments (FeO, Fe2O3, Fe3O4, etc.) are mainly used, having brown, black, red and yellow colors.

There are organic pigments and dyes (for example, aniline), but they are less resistant to ultraviolet radiation and alkali in concrete. Their advantage is that they give the product a more intense color with low dye consumption.

Since for homemade ones the most important criterion (when making concrete decor) is the minimum cost of the product, we will dwell in more detail on the use of iron oxide pigments.

Dye selection

You don’t have to think long about how to paint artificial stone. Various types of dyes can be used for decorative coating. The most popular is acrylic, which has important properties:

- good absorption into the stone coating;

- elasticity;

- quick drying;

- increased durability and reliability;

- no fading;

- the formation of an additional protective layer from external influences.

Pay attention to: Painting metal gates at home: tips for beginners

Due to the elasticity of the water-based composition, artificial stone does not crack during temperature fluctuations. Its permeability, due to the absorption and release of moisture, protects it from destruction as a result of weather changes.

Important! When drying, the shade often changes; the result is often not quite what was intended. Therefore, the paint must be tested first.

When starting work, we recommend:

- read the composition of the paint and its purpose on the packaging;

- check that there are no clots or lumps in the solution;

- dilute the dye with primer or water.

Before painting, the decorative gypsum stone is impregnated with a universal primer or vitriol so that the acrylic layer is more uniform and adheres better. You can simplify the work by combining pigment with a gypsum composition when making stone. This will give the material the desired shade in advance. Silicone and silicate dyes are made on the basis of resins and liquid glass, which enhance their strength, make them attractive, and extend their service life. The material is impregnated with copper and iron sulfate to increase durability and strength. An additional effect is the color of the stone changing to a yellow or blue tone when the parts are immersed in the solution for two hours. In this case, the elements should not touch each other. Liquid for staining wood can give decorative concrete or gypsum stones a rich range of shades. Therefore, it is advisable to test the effect of the dye on one part before starting work. A good effect occurs when the tile is immersed in a heated solution for a few seconds. For coloring, other compositions for processing gypsum are used: tinted varnishes, impregnations and other dyes. The master himself chooses what to paint the artificial stone with.

Helpful information. Nowadays they produce compounds that give artificial stone a natural look, but they are expensive.

Comparison of color shades

Iron oxide pigments for concrete

Pigment manufacturers recommend not to exceed a dosage of more than 5%. A larger amount of introduced pigment will lead to a significant deterioration in the characteristics of concrete; it becomes less durable.

To make paving slabs last longer, 2-3% of the pigment by weight of cement is added to the solution. At the same time, it is difficult to obtain a bright color of the product and usually tiles, curbstones, and paving stones have a pale color tint.

Paving slabs

Before introducing the pigment into the concrete solution, experts in the production of paving slabs recommend diluting it in a 1:1 ratio and leaving the pigment in a deep penetration primer (such as Ceresit) for 2 hours. There are now a very large number of primers, the choice is up to the master.

In their opinion, this makes it possible to obtain a more uniform color of the product.

In some cases, for example, when using black soot as a pigment, it is necessary to dilute it in the primer, since otherwise, due to its low weight, the soot will float in the concrete solution. If you add it without diluting it into a dry mixture, as many do with iron oxide pigments, then when stirred, the soot becomes very dusty and flies through the air.

But the master may also be faced with another task - uneven coloring of concrete. It is necessary in the manufacture of artificial stone, similar, for example, to marble.

To do this, two or more multi-colored concrete solutions are prepared, as was done when making a small vase for a fountain.

Then the solutions are mixed and several turns are performed with a spatula. Using different concentrations of pigment and solution, you can get a variety of patterns and stains.

If the solution is being prepared not for modeling, but for pouring into molds, you can apply dyes mixed with cement (dry or liquid) to the front surface of the form before filling it with the prepared concrete solution. By combining these methods, very interesting color effects are obtained.

Coating Methods

Qualified construction workers use different methods of painting decorative gypsum stone:

- mass staining;

- surface application of paint;

- custom coloring to imitate different textures.

Each of them has features of the work and nuances that should be taken into account when painting.

Painting gypsum stone with a brush

To create a decorative coating for stone walls, the classic method of painting using a brush can be used. This surface method is considered the most labor-intensive, but when using an airbrush it becomes faster and easier.

An airbrush is used to apply the pigment more evenly. It is a tool that sprays paint. To adjust the saturation of the shade, it is enough to change the distance from the airbrush to the surface being treated. This technology is used when it is necessary to make smooth transitions between shades or create darker convex areas. You can use multiple airbrushes with different paints to save application time and get unusual results.

Airbrush advantages:

- creates a thin and neat colored layer;

- applies paint more accurately, which protects adjacent surfaces from unnecessary contamination;

- possibility of changing shade;

- the ability to smoothly transition from one color to another.

There are various types of sprayers available for sale. The most affordable airbrush is considered to be a spray gun. If you choose a model with a high-quality compressor, the quality of painting will not be inferior to the result of a more expensive model.

Painting in bulk with an airbrush

This method of coloring is used when independently carrying out work on the production of the material. The technology involves adding a coloring pigment to the solution. Thus, coloring occurs from within the material.

Typically, a proportion of 0.5 parts of pigment per 200 ml of water is used. The resulting mixture must be mixed with an acrylic primer. After drying, a matte varnish should be applied to the surface of the stone to secure the painted layer.

The pigment can also be added in powder form directly to plaster for casting stone. This allows you to eliminate unpleasant situations with small chips on the resulting wall: the white base will not be visible. Working with such products is also convenient, since you don’t need to be afraid that minor defects will be obvious.

The technology is considered the simplest, since the surface should not be covered in several layers. However, along with the advantages, there is also a disadvantage: the surface loses its natural appearance when painted in this way.

Applying pigment to molds

You can do it even simpler and apply the pigment inside the mold. To do this, you need to dilute the pigment and apply it to the entire form or individual areas using a brush. Gypsum solution is poured into the prepared forms. The result is a material with an unusual color.

In some videos, decorative gypsum stone is painted using impregnation, which is also applied to the molds.

Water in cement mortar

It should be noted that iron oxide pigments of different colors absorb water from the solution in different ways.

Therefore, in order to obtain a solution of the required fluidity, it is necessary to take this feature into account.

Adding excess water is also bad, as this will reduce the strength of the finished product.

In such cases, cellulose ether or another moisture accumulator is usually added to the solution, which retains water and gradually releases it to carry out the necessary cement hydration reaction.

To obtain a purer color, use white cement.

If this is not possible, then you can whiten gray cement by adding titanium dioxide TiO2 to the mixture in an amount of 2-3% by weight of cement.

Second method: we paint concrete by applying dye to the surface of the concrete product

Most often, this method is used by the majority of both craftsmen and DIYers when making figures and small architectural forms. Some people prime the surface before painting, some putty, some paint it without any treatment. These actions depend on the final surface obtained.

When making artificial stone in molds, everything is simpler. The quality of the surface depends on the quality of the form. Usually it is quite high. Therefore, additional treatment of the stone surface is not required.

It’s a completely different matter when a figure is molded on a frame and not at once, but gradually, layer by layer. If the last face layer is made from the same mixture as the base layer, it will need to be refined to an acceptable condition.

Water based paints

Let's return to painting the surface of a concrete product. Most often, water-based acrylic paints are used for this purpose.

To ensure that the paint penetrates deeper into the pores of the concrete, 10-15% acetone is added to the paint. This coating lasts longer on paths. If there are bright artificial stones somewhere in the photographs, then most likely they are painted that way.

In other cases (when there is no abrasion factor), an ordinary aqueous solution is sufficient for painting. Some artists use oil paints, but they are inconvenient to use because they take a very long time to dry.

If you impregnate a stone for a protective purpose, then you cannot use a deep penetration primer, as well as paint it with nitro paint. A thin, non-breathable film forms on the surface, which will gradually peel off with changes in temperature and humidity, sometimes with the top layer of concrete.

There are also acid dyes. They penetrate into the surface, react with calcium salts and create a unique color pattern on the surface. Depending on the composition, concentration and exposure time of the dye, different colors and shades can be obtained. A peculiarity of the use of such dyes is that the surface after treatment must be thoroughly rinsed with water, eliminating acid residues and efflorescence. It is advisable to treat the surface with a water-repellent agent after the surface has completely dried.

Unusual coloring

In addition to painting using conventional compositions, there are several non-standard options that will allow you to create with your own hands a magnificent “palace” decoration of the interiors of a house or apartment.

Under old marble

If you like the effect of aging surfaces, you can make the artificial stone look like antique marble. The painting technology is as follows:

- The purchased facing material is kept in a darkened room for 48 hours. If the artificial stone is made independently, it is pre-dried. The maximum permissible drying temperature is 55 degrees;

- Heat the drying oil. This work requires maximum caution and must be performed with protective gloves;

- Using a flute brush, the material is coated with drying oil, preferably in 2 layers. It is necessary to ensure that the stone is processed evenly, without gaps;

- All you have to do is wait a little time, and soon the gypsum surface turns out to be colored with veins, like ancient marble. It makes an excellent finish for the kitchen or fireplace area.

Under terracotta

The surface is treated to resemble terracotta using rosin and shellac varnish, which are dissolved in industrial alcohol. The principle of painting is the same as when painting marbled. The terracotta effect also appears after some time.

Creating a bronze sheen

To obtain a bronze tint on the surface, materials are prepared and actions are performed in a certain order:

- Drying oil is applied to the surface so as to thoroughly saturate the plaster with it;

- The product is dried. As a rule, this takes 8-10 hours;

- Bronze powder is mixed with varnish, then the product is treated in 2 layers;

- The material is thoroughly dried;

- Prepare a mixture: for 0.3 liters of water – 0.1 liters of acetic acid and 10 g of silver nitrate;

- A thin layer of bronze powder is applied to the surface and covered with a solution. In this case, an oxidation reaction occurs;

- The surface is wiped with a piece of velvet.

To enhance the effect, wax dissolved in turpentine is applied to the gypsum surface. This must be done until the material is saturated with the solution (the latter stops being absorbed). Facing with such a coating can be washed, but it will not lose its properties.

Painting using stain

Stain allows you to get very beautiful and unusual surfaces. You can apply it using a spray gun, but the best result is obtained by dipping the product into the solution. Warm up the stain a little, dip the gypsum stone into it for a couple of seconds, and then dry. If necessary, the product is pre-wiped.