Types of corrosion

Metal rust treatment is carried out taking into account the degree of damage to the surface. Defects that arise may be:

- shallow corrosion spots spreading over the entire surface area, but not penetrating deep into the metal;

- small dots with deep penetration into the metal;

- through corrosion damage;

- subfilm type, occurring under the protective coating and causing it to swell.

Corrosion can manifest itself in different ways Source texturepalace.com

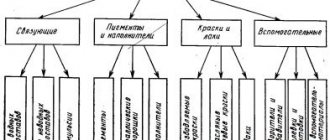

Compositions used

Treatment of the metal base is carried out with universal and special compounds. Each of them has its own characteristics that determine the possible area of use. When deciding what to paint metal with, you should take the advice of professionals and also evaluate the features of each type.

Universal

To protect the metal base, paints are most often used:

- Epoxy . They are based on silicone resins mixed with a hardener. Ensure the formation of a strong and durable coating with a sufficient level of corrosion resistance. Due to their high toxicity, they cannot be used for interior work. They place increased demands on the order of application.

- Oily . Composition based on organic matter. Apply to a pre-primed base. The pungent odor and the presence of toxic components make it possible to apply oil paint only in a well-ventilated area.

- Alkyd . A universal composition suitable for use inside and outside the building. Can be applied to a flat surface without prior priming.

Protection and decoration of metal surfaces Source kraski-net.ru

See also: Catalog of companies that specialize in paints and finishing materials

- Acrylic . Composition with a polymer base. Easy to apply. Non-toxic. Before application requires careful preparation of the base.

- Rubber . Designed primarily for outdoor use. Used to protect roofing material and other surfaces exposed to precipitation.

Attention! Before starting work, it is worth figuring out how to paint metal so that the coating is continuous and of the same thickness, and how to prepare the base.

Specialized

If corrosion stains have already appeared on the surface, a specialized product will be required. It is quite difficult to choose the appropriate composition on your own. It is worth taking the help of professionals. They know what and how to paint rusty metal, taking into account the operating conditions of a particular product. The choice is made in favor of the following compositions:

- Applied directly to rust without prior preparation. They have an epoxy base. Ensure the formation of a reliable film that prevents further destruction of the metal base.

Can be applied directly to rust Source neomoney.com.au

Painting of metal structures.

In order to give a metal product a beautiful appearance and protect it from environmental influences, it must be painted.

Painting protects against corrosion and also increases the service life of the product. Painting of metal structures takes place in two stages and there are several painting methods. Primer stage. What is a primer and why is it needed? The product must be primed so that the paint lays down in a thin and durable layer. To begin with, the product or structure is cleaned of rust and any remaining paint and dirt is removed. The surface is also degreased. This is done so that the enamel adheres and holds better. If you skip this step, the paint will bubble up and soon peel off. They also pay attention to weather conditions. The best option is air humidity of at least 80%, and the temperature should not fall below +5 degrees. Do not forget that the surface must be dry. By following these simple recommendations, you will get an excellent result at this stage, which will lead to high-quality coloring in the future.

Let's move on to the second stage. This is, directly, the painting itself. Previously, only oil paints were used for metal. Today, other types of paint designed for different types of materials have appeared on the market. These are enamels, acrylic paint and paint that contains zinc. It prevents the formation of corrosion on metal and increases service life.

There are several ways to paint metal products. There are also several options for painting tools. First, check how the paint will adhere to the surface. For this they do a test. Apply paint to a small, pre-greased and primed area. We wait for complete drying and see the result. If everything is satisfactory and the paint has applied well, paint the entire surface.

Now let's look at the tools. Use a brush to paint small and hard-to-reach areas that require special attention. Then the rest of the surface is painted with a roller. First paint the corners and edges, and then everything else. The paint is also applied in 2-3 layers for a better look. And the thinner the layer, the better the appearance. If you only need to paint small areas or update the appearance of the product, use an aerosol. It applies a thin layer and dries quickly.

The need for painting metal structures arises both primary and secondary. Regulated requirements for painting metal structures in accordance with GOST and SNiP are aimed at protecting products from the negative environment, UV radiation, chemical exposure and temperature changes. The applied layer of paint and varnish material prevents the formation of rust. In addition, it helps to improve the appearance of metal structures and products. You need to know how to apply paint correctly and what you need to know about this technology.

Preparatory stage

Metal processing before painting must be carried out with special care, since various defects will become noticeable over time. It will be quite difficult to correct the situation later. The work is performed in the following sequence:

- Cleaning the base from dirt, dust, and remnants of the old protective coating. The presence of even small areas is unacceptable.

Mechanical cleaning of the base Source haip.info

- Degreasing the metal base to increase its adhesion with mandatory protection from dirt. It is performed in three stages: using a degreaser, soap solution and water.

- Puttying . It is carried out if there are visible defects on the surface and after treating the area with an anti-corrosion compound. Provides leveling of the base.

Attention! Rust-affected areas are cleaned mechanically or using special products. The surface prepared for painting must be dry and clean.

Painting technology

To apply paint to a metal surface, use a roller, brush, or spray gun. The algorithm of actions directly depends on the tool. Use a roller to paint large, even surfaces. The brush is chosen for complex or relief areas. The spray gun is relevant for large metal surface areas.

When using a roller:

- the paint is diluted with a solvent, achieving a consistency that facilitates easy distribution over the surface, and poured into a tray;

- the instrument is immersed in paint, ensuring sufficient wetting;

- roll the roller over the surface, making back-and-forth movements;

- form 2 – 4 layers.

Powder painting of metal structures: price per linear meter⭐⭐⭐⭐⭐

The cost of painting metal structures directly depends on the volume of the order and deadlines. The client can order urgent painting, which will cost a little more, but can be completed within 24 hours.

Thanks to the coating, the metal product becomes less susceptible to corrosion, and this is the main problem of all metal products. Prices for painting metal structures are traditionally affordable, and the scope of application of powder coating extends to massive objects and products (cars, ships), and to small household appliances or parts.

Powder coating of metal structures, the price of which is adequate for the work done, includes unloading and loading work, as well as packaging with stretch film.

Powder painting of metal is a universal method, suitable for almost any type of metal structures. It can be used:

- for profile painting;

- metal furniture (park tables and benches);

- parts of cars, motorcycles, ships, carriages;

- small objects (grids, gates, canopies, forged products).

The price of powder coating of metal structures will not depend on the choice of color on the RAL scale, and attractive shades can give the product a presentable and competitive appearance.

The material for powder painting depends on the conditions where the metal structure is intended to be used in the future. Outdoors, they require deeper protection, so painting is done with polyester substances that are resistant to moisture and ultraviolet radiation. Indoors, painting with epoxy compounds is sufficient.

Video description

Watch the video to get acquainted with the main intricacies of the process:

Important! Application of the next layer begins after the previous one has dried.

When painting with a brush, the tool is immersed in paint to 1/3 of the length of the bristles. The composition is applied to the surface, making movements in one direction. First, a certain amount of paint is applied to the base and then rubbed onto the metal surface.

When using a spray gun, it is possible to maximize painting productivity. Due to the low absorbency of the metal surface, increased demands are placed on the operator’s qualifications in terms of smoothness and speed of movements. The layers are applied in parallel.

Briefly about the main thing

Corrosion on a metal surface can manifest itself in different ways. Timely painting will prevent the appearance of rust or will not allow it to develop further. For coloring, universal and specialized compositions are used. Some can be applied directly onto the rust, while others require careful preparation of the metal base.

To paint a metal surface, use a roller, brush and spray gun. The choice of tool depends on the characteristics of the substrate being painted. To obtain a high-quality protective coating, the composition is adjusted to the desired consistency and applied in several layers.

Ratings 0

Features of preparation for the technological process

The process of painting metal structures requires careful preparation. This seemingly simple type of work involves going through several stages:

- cleaning metal structures from old layers of paint and various types of contaminants;

- surface primer, which acts as a binding layer between it and the paint;

- degreasing, which must be carried out in case of presence of fat or oil contamination on the surface, polymer painting or painting by dipping.

Modern technologies make it possible to combine several preparatory stages of the process of painting metal structures into one. Craftsmen have at their disposal products that combine the qualities of both paints and primers. In addition, they have an additional function that allows you to transform existing rust on the surface.

Sometimes you can hear the opinion that a primer is quite enough to protect metal structures from corrosion. You can agree with him if the product is applied to the surface in several layers or we are talking about non-ferrous metals. The disadvantage of this solution is the lack of an aesthetic component that is obtained by coloring.