The need to degrease the surface

Contamination of surfaces varies greatly in degree - with a weak amount of impurities is 1 g / square meter, with a strong one - more than 5 g. Whatever the degree, degreasing is required before carrying out repair work. If this is not done, grease and dirt will reduce the adhesion of the finishing material to the surface, therefore, the quality of the work will be low.

You should not count on how long the product will last - it will be short. For this reason, the use of degreasers for processing glass, wood, metal, plastic, and other coatings is mandatory.

Degreasing agents

If a person decides to paint a surface in a house, apartment, or country house, any suitable product is used for degreasing, which is applied to a lint-free microfiber cloth or other suitable material.

This method is not suitable if preparation for painting the car body is required. Of course, it is better to entrust the cleaning and painting of a car to a professional who will do the job efficiently. In some cases, you can remove the grease film and protect the car body from corrosion with your own hands.

White Spirit

Almost every car enthusiast has the organic solvent White Spirit, and repair shops use it regularly. White spirit is intended for the initial treatment of the body, after which it is practiced to apply alcohol mixed with orthophosphoric acid to remove residual contamination. The solution is prepared by combining substances in a certain proportion.

Using white spirit you can safely clean car parts; the composition will not harm the metal surface. Low cost is another plus. The downside is the strong smell. Some car owners replace the solvent with trichlorethylene, but it should not be used on aluminum alloys - there is a risk of fire.

Gasoline, acetone, other analogues

All of these products are good solvents for grease, mastic, and paint. Diesel and kerosene have a rather dense structure and are difficult to clean, but their composition is suitable for degreasing.

After using kerosene, gasoline, or solvent, you will have to use an enhanced wash to remove all traces. It is undesirable to use acetone for treating cars - some types of it can cause harm to the metal.

Antisilicone

Antisilicone is a colorless liquid, a remover for removing silicone, grease, and oil. This substance is intended to remove contaminants from steel, aluminum, stainless steel, plastic, galvanization, and varnish coatings.

It is applied to the surface, then wiped with a dry cloth or paper towel. You need to wear a mask and gloves when working, and the room must be ventilated.

Antistatic

The surface can be degreased before painting using an antistatic agent. It is especially effective to do this on plastic, which attracts dust due to its ability to become electrified. It will be difficult to remove the grease film, but after treating the surface with an antistatic agent it will be much easier.

Alkalis

The preparations in this group contain detergent chemicals with an alkaline effect. They can wash away any contaminants, including grease. Usually used in everyday life.

To clean plastic and concrete, a roller is used for application. Before painting a car, use alkalis with great care, then rinse the surface thoroughly with water and dry the parts. Do not apply large amounts of product or create strong foam.

Ultrasound and other methods

A new method of surface cleaning is the use of solutions coupled with baths with an ultrasonic field. The method is suitable for degreasing small parts whose surface is uneven, has complex curves and includes various mechanisms (for example, watches). Due to the high cost, the method is not suitable for large products.

There is a method of electrochemical degreasing. It is also carried out in baths where gas is supplied from electrodes. Surfaces are cleaned with chemical solutions using current. Typically, such processing is used in production and industry.

Usage

Now that it is clear what a solvent is, its use is also worth considering. So, a solvent, the composition of which includes chemically active, even in some sense toxic substances, is used to work (for dilution or dissolution) with acrylic paints, enamel, varnishes, ordinary paints (including those applied in several layers) and flushing fluids).

The described substance is often found on construction sites, because it is used to dilute alkyd, paint and varnish, petroleum-polymer, oil compounds (for example, mastic, bitumen), and solvent adhesive. When diluting paints with solvent, it turns out to make a more viscous substance, that is, to thicken a paint solution that is too liquid.

The solvent will also be useful for those who work with rubber, urea-formaldehyde oligomers, polyesters, and oils. Due to the presence of paraffins, the solvent leaves a glossy film after processing. The substance in question is used to make insect repellents in the home and garden. Despite the fact that this active substance does not have a harmful effect on the crop, after treatment with solvent-containing fertilizers, vegetables or fruits should be washed in plenty of running water.

Solvent is also used for the production of fertilizers Source plodovie.ru

By the way! Solvent adhesive, resistant to acid attack and firmly connecting surfaces, also contains rubber.

How to degrease plastic

Plastics are one of the largest groups of materials, containing a variety of types of plastic. Gasoline, acetone, and vinegar are perfect for a number of plastics; other materials will immediately become unusable from such substances. Universal compounds are also not always suitable for plastic.

For plastic car parts, only special products are used, which are sold in relevant stores and are suitable for plastic and rubber. At home, you can try applying white spirit to the material. An antistatic agent will be 100% safe; most products can be degreased well with vodka.

The procedure for degreasing plastic before gluing it is as follows:

- Wipe off the dust with a (dry) cloth, if necessary, wash to remove obvious dirt, and dry.

- Soak a rag with solvent.

- Gently scrub the surface.

- If in doubt, try scrubbing a small area of the product first.

How to degrease iron before painting

Painting a car body or its individual components is a rather complex process from a technological point of view, which occurs in several stages, including preparatory stages, which include degreasing the metal surface. And the question immediately arises: how to degrease metal before painting?

Why do you need to degrease metal before painting?

Degreasing metal before painting is necessary for one purpose - to ensure normal adhesion of the paintwork and metal.

Although, by and large, during a complete repainting of the body or complete repainting of body elements, the paint is applied to the automotive primer.

Thus, the degreasing process must ensure adhesion of the primer and metal.

Essentially, adhesion is the sticking of one material to another. Moreover, adhesion is at the molecular level.

And if between the molecules of one substance and the molecules of the metal surface there are molecules of other substances, adhesion will be very poor.

And over time, the layer of paint will begin to fall off from the slightest vibrations.

Various oily substances of any nature, various organic matter, dust, etc. – all this will reduce the process of sticking (adhesion).

In addition, adhesion is affected by a thin oxide film, which looks like a small coating of rust on the metal.

Therefore, this coating also needs to be removed or converted into more stable chemical compounds that will not interfere with the adhesion of the paintwork.

Theoretically, you can use any chemical compounds that are capable of removing fatty and organic substances from the surface of the metal.

An integrated approach to the degreasing process uses active compounds that prevent the formation of corrosion and convert rust into a stable compound.

Some connections work worse, some better. This is especially true for serious oil contamination.

The following degreasers are used: kerosene, white spirit, nitro-based solvents, degreasers based on complex alcohols, etc.

It is not recommended to use motor gasoline as a metal degreasing agent.

The fact is that gasoline contains a fairly large amount of various oily substances, which, instead of the removed oil film, will give their own oil film, which will not be noticeable, however, the process of paint adhesion will be very poor. This oil film seems to be invisible, but in fact, it is present.

As for the integrated approach to degreasing, at the first stage, after the metal has been cleaned and dust has been removed, a product based on phosphoric acid is applied. Phosphoric acid reacts with iron oxides (which form the basis of rust). And turns these oxides into completely different compounds.

The oxide deposit appears literally immediately, only becoming visible after a certain time.

And it is better to eliminate it immediately and, in addition, create a thin layer of moisture-resistant compound. It is not for nothing that compounds based on orthophosphoric acid are called rust converters.

Features of degreasing with certain compounds

Some of the products that are used for degreasing, for example, nitro-based solvents, can not only remove grease film, but also corrode some paintwork. Therefore, if local paintwork repairs are underway, it is advisable not to use such solvents, as they can corrode the paint near the area being treated.

In such a situation, it is better to use white spirit or solvents based on complex alcohol compounds. Although nitro solvents have no effect at all on some types of paintwork.

Technology for degreasing metal before painting

A product based on orthophosphoric acid is applied to the metal surface to prevent corrosion from having the slightest chance.

The next step is applying the solvent itself. All solvents are sufficiently volatile, so there is no need to remove anything.

The degreasing agent is applied with a dampened rag, and dust is removed at the same time. You need to degrease the metal before painting the car or applying a primer.

If you then delay the painting process, dust will again collect on the metal.

All work on degreasing the metal surface must be carried out in rooms where there is ventilation. The vapors from these liquids are quite toxic.

It is imperative to use a respirator, otherwise, if you inhale the vapors, you can quite possibly get poisoned. Liquids are quite active, so you need to wear protective gloves and cover your eyes with safety glasses.

Rubber gloves are used. Any solvent that gets into the eyes can cause a chemical burn to the mucous membrane.

Degreasing metal before painting

How to degrease metal before painting? The right decision is a guarantee of quality results. The development of technology provides a wealth of choice, but this event should be approached responsibly.

Necessity of procedure and methods

Degreasing is a process during which the often invisible layer of oil or fat is completely washed away from the surface.

Contaminants reach the substrate in a variety of ways. All products that are prepared for paint application undergo this treatment.

This procedure can be performed using various methods, not all of them are suitable for home use. The quality of the result and the complexity of the work depend on the correct choice of means.

There are several basic cleaning options that can be performed separately or in combination, which allows you to achieve the desired result even with heavy contamination.

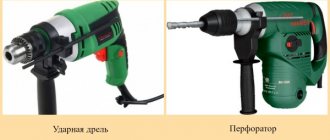

- Mechanical.

This method is labor-intensive and time-consuming. Used to obtain a rough base that gives better grip. The layer of contamination is removed using electric and manual tools. This option does not give an ideal result, so it is often complemented by other methods. For mechanical cleaning, you can use a grinder or drill with special attachments, a hand-held metal brush, as well as ordinary sandpaper. - Chemical.

The most popular method to degrease the desired element. This is explained by the fact that the work process does not require much physical effort and does not take much time. During this procedure, the selected liquid product is applied to the surface. Depending on the degree of exposure, the substance washes away oils and fats or destroys their structure. Chemical degreasers are divided into two main types: organic and inorganic - Electrochemical. This option is subject to special conditions that are only available to industrial enterprises. The bottom line is that the base is exposed to an electric charge and certain chemicals. The method allows for complete cleaning, but any deviations from the technology lead to damage to the processed metal.

At home, a good result can be achieved using chemical compounds; a mechanical method is used as a preliminary cleaning procedure. This allows you to paint the metal surface without further problems.

Simple degreasing products

Various substances are used for work. Each option can be harmful to health, so metal cleaning is carried out in compliance with safety measures, wearing special clothing, goggles and a respirator.

The following options can be used as a degreaser:

- White Spirit. This composition is considered the simplest and most affordable; it is ideal for use at home or in the garage. You can purchase it at any hardware store. The substance removes dirt in a short time, but if the layer of fat is particularly persistent, the procedure may require more time and does not always end in complete success. White spirit has a pungent odor, which suggests ventilation.

White spirit is an organic, toxic and flammable solvent that removes grease well, but leaves a film on the surface.

- Acetone. Use with great care as it may react with some metals and compounds. This results in surface damage.

Acetone effectively removes grease stains

- Kerosene. For degreasing, a pure composition is used, as free from impurities as possible. This option is used as a last resort. For work on large areas, it is better to avoid it, since kerosene is very difficult to wash off. An alternative is high-octane gasoline.

Kerosene, like white spirit, tends to leave a film that impairs the adhesive properties of the surface

- Soap solution. This option is suitable for working with fragile metal products. It is important to wash off the mixture completely after use.

Regardless of the composition chosen, at the end of the process it is recommended to wipe the base with a clean damp cloth and then dry.

On a note! It is better to avoid solvents and other caustic compounds, since the impact on the coating is sometimes detected only after time.

Special formulations

It is through the use of special solutions that the best results can be achieved, but not all of them are commercially available. When applying them, increased safety precautions should be observed.

The most common options:

- Trichlorethylene. This solvent is designed to work with different materials, suitable for cleaning ferrous metals. Allows you to remove even stubborn oil and grease stains before painting. But it cannot be combined with water.

Trichlorethylene is a non-flammable and fireproof synthetic solvent recommended for degreasing ferrous metal products

- Tetrachlorethylene. It is considered best for elements made from an alloy of aluminum and magnesium. Unlike trichlorethylene, the composition does not react with these metals.

Degreasing metal

In addition to grease and dirt, metal often contains rust, paint, and sealant residues. For metal processing you should choose white spirit, acetone, gasoline.

The procedure is as follows:

- Remove rust, paint, sealing residues with a grinder, manually, grinder, sandpaper - in any convenient way (the bathtub in the house is treated with a sponge and soda). It is better to clean large areas with a power tool.

- Moisten a cloth with solvent and treat the product until completely clean. If the parts are small, you can simply immerse them in solvent.

- After complete drying, you can apply primers and paints. Those areas that cannot be painted should be covered with double-sided tape.

Wood products

Wooden products must be cleaned of varnish and paint before painting. At the first stage, you need to clean the wood as thoroughly as possible with a wire brush, sandpaper, or a plane. The latter is used to remove the top layer if the paint is deeply ingrained - with high-quality work, you don’t even need to degrease the surface.

For wood, special products and universal solvents are used; they are applied with a roller. There is no point in using gasoline. After applying the composition, you can easily clean the surface and then proceed to painting.

Purpose and use of metal degreaser

Any metal product requires preliminary cleaning of the surface from various types of contaminants, including grease. There are the following degreasing methods:

- mechanical - used when it is necessary to provide a rough surface for painting. The process is quite labor-intensive, requiring the use of various grinding brushes or wheels;

- electrochemical – effectively cleans metal products from fatty films, regardless of the thickness of the contamination. However, this cleaning method is acceptable only on a production scale, where there are specially equipped premises. If the cleaning technology is violated and the degreaser is overdosed, the product may be damaged, since the strength of the metal may be impaired;

- chemical is the most optimal method of degreasing. The process can be performed in production as well as at home.

It is also worth noting that it is best to use a chemical method of cleaning the metal surface from fats immediately before painting in well-ventilated areas, since the specific smell of anti-corrosion agents and degreasers is very toxic, which in itself is harmful to human health. It would not be superfluous for the employee to use special protective devices that will prevent possible poisoning by chemical vapors.

It is necessary to degrease metal before painting, since many types of paint and varnish products will not be applied evenly if the surface of the product is not cleaned. Before finishing paint treatment, the metal product is cleaned from existing stains and contaminants.

Remedies before gluing

The choice of degreaser for the materials being bonded will depend on what materials are being used. This can be ordinary household chemicals, alkali, alcohol, or organic solvent. For rubber, isopropyl alcohol is suitable. The main thing is not to apply products to wet surfaces - upon contact with water, many substances give an unpredictable reaction or become ineffective.

There is nothing complicated in degreasing and subsequent gluing and painting of products. It is important to familiarize yourself with the necessary information, purchase a suitable solvent - then all work will be completed efficiently and without consequences.

After degreasing is completed, you need to drop a couple of drops of water onto the surface: if the liquid becomes flat and spreads, the cleaning is done perfectly.