Preparation and application technique

Before you putty the base, it must be thoroughly dried and prepared.

You should not even try to apply putty to old paint or wallpaper - such repairs will not last long. In order for everything to be done efficiently and without unnecessary losses (both time and finances), it is necessary to strip off all the old finishing. After which the base is cleaned of dirt, dust and degreased. Walls and ceilings made of highly absorbent materials must be additionally primed. No matter how high-quality the leveling mixtures are, the final quality of the work depends on the correctness of their preparation and application. The main rule here is to follow the precise proportions specified by the manufacturer and the kneading technique.

Small quantities of leveling solution can be mixed by hand. However, using a mixer will be much more effective. Especially when it comes to large volumes, which are unlikely to be mixed without special equipment.

When kneading, the dry mixture is poured into the water, but not vice versa!

The amount of solution should be calculated based on the amount of work that the repairman will have time to complete in one and a half hours.

Another important point is the application technique. This is especially true for beginners who have no experience working with putty mixtures.

Everything will be much easier if you follow certain rules:

- In the work it is necessary to use two spatulas, one for applying the mixture, the other for the main work of distributing the putty. To capture the composition from the container, a narrow tool 80-100 mm wide is used. As for the wide spatula, its size should correspond to the area of the surface to be puttied.

- In order for the mixture to lie as evenly as possible, it is necessary to select the right combination of putty thickness, angle of inclination of the working tool and pressing force.

After all the work is completed, it is necessary to sand the walls (ceiling) and you can begin finishing.

How to choose?

Before starting finishing work, it is necessary to study the building materials market. A wide range of products and the rapid introduction of new technologies can be an obstacle for novice builders on the path to updating the interior. The correct putty will help level the surface and remove all defects. Technical factors of the work will help you choose the necessary product from a huge assortment:

- at the stage of eliminating unevenness and filling large cracks, a starting putty with a large grain size is used (layer thickness - up to 10 mm);

- after 24 hours of drying, you can begin applying a fine-grained topcoat (base for wallpaper and paint);

- the choice of material (dry mixture or ready-made solution) is one of the important stages of finishing work.

The choice of putty is influenced by the type of surface on which it is applied, the type of planned decorative finish, and the temperature and humidity of the room. For basic leveling it is necessary to use coarse material, for final work - fine-grained solutions. Universal putty is an intermediate solution for filling cracks and final leveling.

The price range plays an important role when choosing a solution. The cost of putty depends on several factors:

- packaging volume;

- composition;

- type of readiness;

- additives used;

- the presence of special properties (improved performance characteristics, increased thermal insulation, special texture and decorative properties of the surface);

- country of origin.

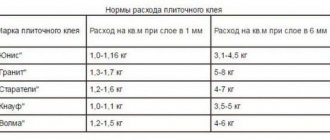

Accurate calculation of the amount of material required is a necessary stage of finishing work. Having determined the area of the room and the consumption of putty per 1 sq. m, you can accurately calculate the volume of putty for finishing work.

- time until thickening - the higher this indicator, the longer it is possible to use the solution;

- manufacturer's warranty period – storage time of undamaged packaging;

- recommended layer thickness - the larger it is, the higher the mixture consumption;

- environmental indicators;

- fire resistance;

- terms of Use;

- recommendations for storing the solution;

- Application method: manual or using special tools.

Finishing putty

Among the mixtures for fine finishing, the finishing putty “Starateli” has become widespread. It contains small gypsum particles, so the applied layer will be even and perfectly smooth. Among the company's assortment there are different types of finishing agents, and each of them has a high level of adhesion to building substrates. They eliminate unevenness in the base layer, covering even the smallest imperfections. The thickness of the finishing putty layer is usually about 0.5 cm. It is prepared in not too large portions, since it hardens quickly due to the gypsum base.

Basic putty

The most popular among professionals is the basic putty “Prospectors”. It is suitable for external and internal work, is characterized by high moisture resistance, and is applied in a layer of up to 0.8 cm. The base mixture contains cement, so it can be used in a wide variety of works, for example, as a base for painting external walls.

Information about the manufacturing company

was formed in Moscow in 1992 and initially was only engaged in the production of ready-made putty. Later, the range of truly high-quality products was seriously expanded; a whole list of dry building mixtures was introduced into it. In a short period of time, the company organized high-tech production, introduced computerized control systems and established a powerful sales system.

The recipe for “Starateli” putties uses only selected raw materials and safe components, while the prices for the goods remain quite affordable. Many putties can be used in the most difficult climatic conditions, and all of them are of guaranteed stable quality. Now the company has 15 production lines in the Moscow region and 4 branches in other regions of Russia, producing more than 80 types of goods for various finishing works.

A few words about the manufacturer

The story began in 1992. The company was initially focused on the production of ready-made putties; subsequently, the product range began to expand. In the 90s of the last century, this area of the construction market was not yet developed, so it was necessary to use the experience of European manufacturers. The company learned from the mistakes of others, introducing its own technologies and implementing a computerized quality control system.

Currently, the company works according to its own recipe, using only high-quality raw materials. This helped us become the largest manufacturer and supplier of ready-made dry mixes.

Application Tips

Before applying the putty mixture, the manufacturer recommends treating the base with a primer (also from).

After the soil has dried, use a spatula to fill all existing depressions with the solution. After this, the solution is leveled

When carrying out work, it is important to observe the temperature regime (optimal - 10-30 degrees). You should also not perform puttying work in direct sunlight.

Typically, the “Starateli” putty gives a flat and smooth surface that does not require additional sanding, but if necessary, the surface or any section of it can be easily sanded with fine sandpaper.

Final finishing of surfaces (pasting with wallpaper, applying a paint layer or decorative plaster) is possible only after the final putty layer has dried.

If it is necessary to seal the seams between sheets of drywall, then first you need to use a spatula to fill the gaps between the sheets with material and attach reinforcing tape along the seam. Pressing it directly into the seam, use a spatula to remove excess putty from the drywall. When the solution has dried, you can begin applying the next layer. And this must be done until the seam is completely level with the surface of the drywall sheet. In the same way, the putty mixture is applied to the areas where the sheets are attached.

To learn how to putty walls yourself, see the following video.

Application method

PVA-based putty is applied only to the plastered surface or over the base. This type of putty cannot be applied in a thick layer, so it is not suitable for leveling and sealing cracks. The surface for finishing should be carefully prepared.

- If there are greasy or oily stains on the surface, they are removed using organic solvents. Significant gaps and cracks can be sealed with sealant using a construction gun. The base must be cleaned of dust. As a primer, you can use diluted PVA glue with water in a ratio of 1 to 4.

- To apply the putty, you need a wide spatula that allows you to cover a significant area of the wall. In this case, the tool should be used clean, since dried grains leave grooves on the surface. PVA-based compositions usually do not separate, but it is recommended to stir them before application. This can be done using a construction mixer and a special drill attachment.

- The floor must be covered. The PVA solution absorbs well, and it will be difficult to remove stains from the floor. For protection, you can spread plastic wrap and secure it with masking tape. Despite the frost resistance of the putty itself, it is recommended to apply it in a warm room at a temperature of 20-30 degrees Celsius.

- The putty should be applied in a thin layer of 0.5 mm. There can be up to 4 layers in total. It is dangerous to make it too thick: the material cracks when it dries and can break off in pieces. When the layer dries, you need to sand it with a polyurethane float to obtain an ideal surface. Many reviews from builders say that you don’t have to wait for complete drying, this will make sanding much easier.

- After complete drying, you can apply a decorative layer. If this is painting, you can additionally apply a primer made from diluted PVA. For wallpapering, a primer is not needed; its function will be performed by wallpaper glue.

Types and characteristics

Currently it produces the following types of finishing compositions:

- “Finishing putty”;

- “Facade finishing putty”;

- “Finishing Putty Plus Moisture Resistant”;

- “Ready putty Superfinish”;

- "Finish putty KR".

“Finishing putty” is a dry white gypsum mixture used for plastering indoor surfaces.

The composition includes modifying additives.

The recommended thickness of the applied layer is 0.3-5 cm. The material consumption, subject to this condition, will be 900 g per square meter of surface.

Can be applied to plastered, concrete and brick substrates for subsequent painting or wallpapering.

The use of this material in places where there will be contact with food or drinking water is not permitted.

This type of putty is applied to a dry, clean and strong base. If the base has crumbling or unreliable areas, they should be removed. Gypsum and other hygroscopic substrates must be pre-treated with a primer.

The putty solution is prepared at the rate of 400-580 ml of water per kilogram of dry matter.

This type of material is sold in containers of 5, 12 and 20 kg.

“Facade finishing putty” is a mixture for carrying out plastering work mainly on the outside of the building. The material is also suitable for interior work.

The functionality determines the following properties of this product: frost resistance, weather resistance, resistance to cracking.

The facade-finish mixture includes white cement, modifying additives and fine natural filler.

The finishing coating can be applied to cement, concrete and reinforced concrete bases for subsequent application of decorative plaster, painting and wallpapering.

Suitable for application in damp areas. Not recommended for use in areas where food contact is expected.

The recommended thickness of the applied layer is from 0.3 to 3 mm. Consumption is kilogram per square meter with a putty layer thickness of 1 mm.

The solution is prepared at the rate of 320-400 ml per kilogram of dry powder.

The prepared solution remains viable for three hours from the moment of mixing.

Packaging – only in bags of 20 kg.

“Finishing Putty Plus Moisture Resistant” is a white polymer-cement plastic material with increased moisture resistance.

Can be applied to substrates covered with gypsum plaster, concrete and plasterboard.

The thickness of the putty layer recommended by the instructions is 0.3-3 mm. Material consumption – 800 grams per square meter (layer thickness 1 mm).

The base for applying the solution is prepared in the same way as finishing putty.

The solution is prepared at the rate of 350-400 ml per kilogram of dry powder.

The prepared solution remains viable for six hours from the moment of mixing.

“Ready putty Superfinish.” This material is a ready-made putty mixture in the form of a paste.

Its composition includes: reinforcing fibers, a polymer binder, fine fillers, antiseptic fractions and modifying additives.

Ready-made paste is used only for interior work in rooms with normal humidity levels. Apply to plasterboard bases, gypsum plaster, tongue-and-groove boards, fiberglass. The subsequent coating can be in the form of wallpaper or a paint layer.

The recommended maximum thickness of the applied putty layer is 2 mm. Paste consumption with a putty layer of 0.3 mm is 500 g per square meter.

Adhesive ability of the material is up to 0.5 MPa.

Drying time for a 1 mm layer of putty is 4 hours.

The base for applying the solution is prepared in the same way as finishing putty.

Packaging – in plastic buckets of 7 and 15 kg.

“Finishing putty KR” is a finishing polymer highly plastic material for interior renovation. Recommended for use in dry rooms only.

Can be applied to concrete, gypsum-based plaster, but is most suitable for treating drywall. The boiling white color of this material and good covering ability significantly save the cost of subsequent painting of the treated surface.

It is recommended to apply this type of putty with a layer of 0.3-3 mm. Material consumption per 1 mm of layer with an area of 1 sq. m. will be 1.1 kilograms.

The finished mixture of KR putty has an increased vitality indicator - the solution can retain its properties for 24 hours from the moment of preparation.

Technical characteristics and consumption

When selecting a specific material, you need to pay attention to its properties and technical parameters, which must correspond to the chosen field of application. Some putties are used to level out serious differences, eliminate significant defects, and after drying they do not shrink or crack, even when applying a thick layer. Other products are applied in a thin layer, as they are intended for final leveling and finishing of surfaces.

The average technical characteristics of “Starateli” putty pastes are as follows:

- recommended temperature for application - from +5 to +30 degrees;

- drying time of the layer - 24 hours at a temperature of about +20 degrees;

- adhesion - from 0.25 MPa;

- frost resistance - from 30-35 cycles;

- viability of the finished mixture is 1.5-24 hours (depending on the type of putty).

Material consumption is usually 1.1 kg/sq.m. m with a layer thickness of 1 mm. When diluted, 1 kg of dry mixture requires about 0.3-0.36 liters of water.

Facade-finish

The mixture has an ideal composition, is intended for outdoor work, and perfectly eliminates unevenness of any level of complexity. Finished surfaces withstand contrasting weather changes. The prepared solution is suitable for use for no more than three hours. The basis for the manufacture of façade and finishing products is a gypsum composition, the main characteristics of which are non-toxicity and safety.

Can be combined with surfaces made of wood, plasterboard and other materials.

- High hardness.

- Weather resistance.

- Possibility of grinding.

- When structures shrink, it does not move away from the base.

- It has a beneficial effect on the microclimate.

- High adhesion. Moreover, the mixture fixes finishing materials so firmly that it can be used as an assembly adhesive or as stucco for finishing.

Kinds

There are quite a few varieties of putties on sale. They are designed for various purposes and have certain technical characteristics. The principle of working with these putties is approximately the same.

provides several types of putties.

- Basic mixture for interior decoration. Using this material, the surface is leveled and a solid basis is created for subsequent finishing processes. Before applying putty, the wall surface must be thoroughly cleaned of various contaminants.

- Facade dry mixture. A distinctive feature of this putty is its resistance to high humidity. Thanks to this property, the façade mixture is ideal for finishing external wall surfaces. The main advantage of the material is that the applied layer of solution dries quickly.

- Finishing putty. When performing the final stage of finishing work, a finishing mixture is used. This coating is applied to the starting layer of putty. In some cases, the finishing mixture is used for decorative finishing of the surface or as a base coating for wallpapering or painting walls.

- Leveling mixture. Sometimes there are quite large unevenness and chips on the wall surfaces; in this case, it is better to use leveling putty to level the wall. Builders can prepare a solution of the consistency they need, varying it flexibly.

Description

The basic putty “Starateli” is a dry mixture of white cement, which expands the scope of use and speeds up the time it takes to complete the work. If we compare with plasters based on gray Portland cement, the described composition has a light beige color, so finishing can begin immediately after the starting putty has dried.

If we consider the product in terms of composition, then “Prospectors” can be classified as dry plasters. However, one of the important differences here is the plasticity that is characteristic of putties. This indicates versatility. The mixture combines moisture resistance and leveling properties, which are characteristic of gypsum putties and plasters.

Using the “Starateli” basic putty, you can take advantage of another important advantage, which is the possibility of gluing wallpaper without additional puttying of the starting layer. This allows you to save money and time.

The described mixture contains purified sand, the fraction size of which is 0.4 mm. The recipe calls for the addition of gypsum and ground clinker. The mixture also contains additives that prevent shrinkage and improve elasticity, and also help repel moisture. The mixture contains polymer plasticizers and additives.

The starting putty is a modified mixture, because marble flour, fine sand and cellulose ethers are added to it, which helps retain moisture and allows the composition to be applied in a layer of up to one centimeter.

Option Prospectors of the Kyrgyz Republic

Product code: 068.255.000

Shelf life: 12 months Technical regulations (STANDARD, TU): TU 5745-017-11779802-2003 Certificate of conformity: provided upon request of the buyer Fire certificate: not certified Sanitary-epidemiological certificate: not certified

Characteristics

| General characteristics | |

| Category | Gypsum putty |

| Brand/Manufacturer | Prospectors |

| Series | FINISH |

| Application area | for interior work |

| Color | white |

| Manufacturer country | Russia |

| Specifications: | |

| Base temperature, °C | 30 |

| Water consumption, l/kg | 0,58 |

| Time to use the finished mixture, min. | 60 |

| Minimum layer thickness, mm | 0,3 |

| Maximum layer thickness, mm | 5 |

| Mixture consumption per 1 m² with a layer thickness of 10 mm | 9 |

| Packaging options | |

| Packaging, kg | 5 |

| Product unit weight, kg | 5 |

| Product unit volume, m 3 | 0.001000 |

We draw your attention to the fact that all the above characteristics of the product are for informational purposes only and do not constitute a public offer as defined in clause 2 of Art. 437 of the Civil Code of the Russian Federation. For detailed information about the characteristics of this product, please contact our sales department staff or the Russian representative office of this product.

The base is a polymer composition. Provides high quality puttying. Packing of KR compositions is packaging from 3 to 20 kg, which is practical for small volumes of repair work and convenient when calculating the repair budget. Apply to ceiling surfaces and interior walls in one or several layers.

Each subsequent layer is applied after the previous one has completely dried. A layer of 0.2 to 3 mm is allowed. Consumption on average is 0.5-2.5 kg/m² - depends on the thickness of the layer, so with a thickness of 1 mm - 1 kg/m². It is worth carefully studying the operating instructions that the manufacturer indicates on the packaging. The durability of the finished KR putty is one day.

Finish Plus

According to its composition and scope of application, the polymer mixture KR is divided into:

- Acrylic - for facades and interior decoration, the surface is beautiful with a mirror effect. It performs the functions of protecting and decorating walls. Execution technique: the shape of a design is pressed or cut into the raw putty, or certain strokes are applied using tools. Acrylic putty is used by interior designers and decorative artists to finish walls and ceilings. For plasterboard bases, an acrylic finishing mixture is indispensable.

- Latex - for interior work, applied with a thin layer of high strength and ductility with astringent characteristics. To prepare putty in the winter, take a mixture at room temperature. Prepare the composition to the consistency of a paste, taking into account that it is used within one hour. The ratio of water and putty is 1:1. The surface to be applied must be dry after the previous finishing steps. Latex finishing compounds are characterized by the rapid release of moisture, so a water sprayer will be useful in the work.

Sale (-53%):

Finishing putty “Prospectors” - features

Prospector finishing putty or another type is of high quality and is produced using modern technologies. It is produced by the Moscow company of the same name, which is distinguished by the production of high-quality building materials at reasonable prices. When creating Starateli polymer putty, modern European equipment is used.

The products are dry mixtures characterized by a high level of plasticity, making them universal for use. The base putty is light beige in color. The mixtures are moisture-resistant and have leveling properties, which are more pronounced in Starateli gypsum putty.

The products are dry mixtures characterized by a high level of plasticity, making them universal for use.

The mixtures have the following technical characteristics:

- Operating temperatures vary from +5 to +30 degrees;

- Consumption per layer up to a millimeter thick is 1.1 kilograms per square meter;

- The shelf life of the prepared mixture varies from one and a half to 24 hours, depending on the type of product;

- The adhesion index is not less than 0.25 MPa;

- Frost resistance up to 30-35 cycles.

The components of the mixtures can be:

- The cement is white or standard;

- Natural fillers;

- Polymer and modifying additive elements;

- Reinforcing fibers;

- Antiseptic substances.

The shelf life of the prepared mixture varies from one and a half to 24 hours, depending on the type of product.

Advantages and disadvantages

Like any product, Prospector polymer putty has its positive and negative sides. To decide whether to choose this particular brand, you need to study them. The advantages are:

- Containers of various sizes are produced, which allows you to purchase the required quantity;

- Long shelf life, up to 12 months, but must be stored according to the rules, the place must be dry;

- Fast drying rate, allowing to shorten the repair period;

- High strength index;

- Reasonable price.

KR and other putties also have disadvantages, these include:

It is advisable to apply the putty material at temperatures above +11 degrees; when temperatures are lower, the drying period becomes more difficult

This is usually important when working outdoors; Resistance to ultraviolet radiation is not high, so additional treatment with protective agents is required. Containers of various sizes are available, which allows you to purchase the required quantity.

Containers of various sizes are produced, which allows you to purchase the required quantity.

Advantages and disadvantages of putty

Mixtures of the “Starateli” brand have many positive qualities:

- sold in finished and dry form in a large assortment - you can choose a product for any occasion;

- have a variety of packaging, which allows you to accurately calculate the required amount of material;

- have a long shelf life, without any special requirements for conditions;

- dry quickly, which speeds up repairs;

- allow you to create a high-strength coating that is resistant to adverse factors and durable;

- have an affordable price.

Among the disadvantages, it is only worth noting that putties are not recommended for use at low temperatures indoors or outdoors, so it is better to transfer finishing work to the warm season. The mixtures can be called practical and easy to use, which increases their popularity and puts them on a par with well-known world brands.

How to apply, nuances of using the composition

Before applying putty material, the surface must be well prepared. If there is an old coating on the wall, then it must be removed, otherwise the new finish will not last long.

When the previous finishing material is removed, they proceed to cleaning the wall and degreasing it. If the base is made of absorbent material, then apply a primer first; it will reduce the waste of other mixtures.

Even a high-quality mixture will not be able to give a good result if the preparatory work is carried out poorly or it is prepared incorrectly. When preparing the solution, strictly follow the instructions specified by the manufacturer.

It is better to mix the components in plastic buckets, because you need to cook in small portions, which will last for an hour and a half of work. It will be easier to wash such a container to prepare a new portion. If the volume of the mixture to be prepared is small, then manual mixing is possible; for larger quantities it is advisable to use a construction mixer to make it easier to prepare a homogeneous mixture.

If the volume of the mixture to be prepared is small, then manual mixing is possible; for larger quantities it is advisable to use a construction mixer.

After initial mixing, wait 5 minutes and mix the solution again. Apply the solution according to the rules described below:

- When working, you will need 2 spatulas, the first with a size of 80-100 mm, the second wide should be selected based on the area of the room. The mixture is taken onto the narrower one, then transferred to the wider one and distributed over the surface;

- During work, they determine what inclination of the tool is best to do, what thickness will be made and the pressing force;

- Typically, 2 layers are required, each must dry before applying the next mixture; priming is carried out before the second.

At the end you get a flat wall that needs to be sanded.

Typically, 2 layers are required, each must dry before applying the next mixture; priming is carried out before the second.

How to calculate consumption per 1 m2

Calculating material consumption requires knowledge of the area being processed. The average consumption depends on the type of product chosen; it is indicated on the packaging. For example, for basic ones it is 1 kilogram per 1 square meter.

Calculating material consumption requires knowledge of the area being processed.

Prospector putties have proven to be a high-quality product that is easy to work with. To carry out a good repair, it is necessary to carry out preparatory work, and only then apply a putty layer; the composition should be selected based on the working conditions and the task at hand.

Working with putty

If you have putty on your hands from the company Starateli, the work ahead of you will be quite easy. Preparing the mixture is not difficult even for a beginner.

Working with the material includes three stages:

- Surface preparation;

- Preparation of the solution;

- Applying the mixture.

Now we will consider each of these stages in more detail.

Surface preparation

Everything is standard here. If plaster was used, surface treatment will be quite simple. It’s a little more difficult with a brick and concrete base, for example.

Your task is to get rid of traces of oil and old paint, clean the areas, and achieve the required degree of dryness. Wood and plaster must be primed. The plaster is not necessarily treated with a primer, although this action will not be superfluous.

Preparation of the solution

In order for the putty and plaster to stick well to the surface, you need to follow simple rules when preparing the solution. Due to this putty and plaster, miners will show their best qualities. Prospectors prepare the finishing putty approximately according to this scheme.

- For 1 kg of mixture, you need to add up to 400 to 580 milliliters of water, kept in advance to reach room temperature. It is not recommended to dilute the dry mixture with cold tap water.

- The solution is mixed manually or using a drill with a special attachment.

- Stir until a homogeneous mass is obtained, which should be left to infuse for about 10 minutes. After this, the solution is actively mixed again.

- The prepared kilogram of the mixture is suitable for use within an hour. After this, the solution can no longer be applied. Therefore, calculate in advance how much putty you will need per hour of work.

Application

The application rules are not much different from the use of any other putty. The same finishing coat from Vetonit is applied in the same way. But we still recall the main points:

- The tool used is a steel spatula;

- After drying, the applied layer is treated with abrasive meshes;

- The indoor temperature should not be below 10 degrees Celsius.

Putty from the prospector company is a high-quality material, a mixture with excellent characteristics, which allows you to perform finishing on any surface. This putty has an ideal price-quality ratio. This explains the high level of trust in the company Starateli from consumers.

Features and Specifications

Repair and interior decoration of any room involves the purchase of various finishing building materials. Among the huge assortment, it is sometimes very difficult to choose high-quality and inexpensive putty. In this case, consultation with experienced repair and interior decoration specialists will help. According to experienced specialists, production putty is the best option.

Basic

The basic mixture is very popular and in high demand among buyers. This material is used for finishing both internal and external wall surfaces.

The basic putty is resistant to high humidity and is applied to the surface in a thin layer, no more than eight millimeters thick. The presence of a substance such as cement in the mixture significantly expands the scope of use of this material. In some cases, covering the surface with base putty is used as a base for painting walls.

Finish

The finishing mixture “Starateli” is also widely used for finishing work in various premises. The finishing putty “Starateli” is deservedly considered one of the best mixtures of this kind. The developers tried to select the smallest particles for it, creating an impeccably smooth surface. This material contains gypsum. This component gives the solution certain properties.

This brand has several varieties, but each of them has excellent, unsurpassed adhesion. Thus, the finishing composition is able to cover any deformations of the base layer and easily applies to a variety of building materials. Builders can prepare a solution of the consistency they need, varying it flexibly.

The finishing solution is applied in an even layer, no more than five millimeters thick. You should not prepare a large amount of solution at once, since the finished mixture tends to dry out quickly.

Finishing putty KR, created on the basis of PVA, is a high-tech mixture with excellent characteristics, suitable for interior decoration of rooms with low humidity levels. Crystal white putty is made on a polymer base. The manufacturer provides 20 kg packaging. The applied layer of this material has excellent adhesive properties and dries quickly. When finishing wall surfaces with the finishing solution KR, the temperature in the room must be above zero.

The “Finish Plus” mixture is made on a polymer base, which includes cement. This putty is used for interior decoration as a leveling layer on the surface of concrete, plastered and plasterboard walls. This material is resistant to high humidity, so this putty can be used for finishing any premises. This cement mixture in bags has mostly positive reviews.

Peculiarities

Domestic finishing putty is quite popular and in demand. Its main feature is that it provides a high degree of adhesion to the surface to which it is applied. This has a positive effect on long-term operation and also guarantees complete protection against delamination of the coating or the appearance of cracks.

An important advantage of the finishing putty “Starateli” is its excellent quality. The company offers high quality products that compete well with well-known European companies. The production of “Starateli” brand products is carried out on modern equipment using the latest technologies. The quality of production of dry mixtures is subject to automated control at every stage, starting with the selection of raw materials and ending with the delivery of finished products to warehouses.

has been producing putty for 25 years, and is constantly in search of new recipes to create improved repair compounds that are characterized by excellent technical and operational parameters. The manufacturer uses exclusively the best raw materials, which are purchased from trusted suppliers with an excellent reputation. Production equipment is constantly being modernized, which has a positive effect on the quality of manufactured products.

Finishing putty “Prospectors” has the following characteristics:

- Simplicity and convenience in preparing the mixture. You must carefully read the instructions and mix the dry mixture with water according to it. To create the finished putty, it is not necessary to use a special tool, because it can be mixed manually.

- The putty mixture can be given the required viscosity by simply increasing or decreasing the amount of water.

- The finishing mixture guarantees the creation of a smooth surface, since it immediately lies on the base without the formation of lumps or cracks. With its help, you can easily hide the imperfections of the previous layer.

- The high elasticity of the mixture has a positive effect on the application of the composition. The process is carried out quite easily and quickly. The finished mixture is very convenient to apply to the surface, since it does not stick to the spatula and does not form “tracks”.

- The plaster layer hardens very quickly after application. Complete drying takes two to six hours. The exact time depends on the thickness of the putty layer applied.

- Processing of the finished surface is characterized by ease. After drying, you can correct unevenness by sanding with fine sandpaper or mesh.

- Excellent hygroscopicity of products. The building mixture perfectly absorbs and releases moisture, and also allows air to pass through.

- Increased wear resistance. The finishing putty is characterized by a long explication period.

- The finishing putty comes into contact well with various building materials of any brand. Regardless of which manufacturer’s putty mixture was used to make the base layer, the product can be used for the finishing coat. Excellent adhesive properties guarantee excellent adhesion to any base.

- Safe, environmentally friendly substance. The company provides documents for each of its products that confirm that the manufactured products comply with hygienic and sanitary standards established in Russia and Europe.

- The putty is available for sale both in ready-made form as a solution, and in unprepared form as a dry mixture. Each buyer independently chooses which option is most convenient.

- The products are available in a variety of packaging. For dry mixture, a bag designed for 5, 12 and 20 kilograms is used. The ready-made solution is sold in buckets. Containers of 7 and 15 kilograms are available for sale.

- The putty can be stored for a long time. The manufacturer gives one year for storage, and it can even be stored in rooms with low air temperatures.

- The company's products are characterized by ease of storage and transportation.

- Affordable cost is an undeniable advantage.

Putty “Prospectors” for finishing work also has disadvantages. After preparing the mixture, it must be used immediately for work, since it begins to harden very quickly and is no longer suitable.

Types of putties and their composition

All materials in the “Prospectors” series can be divided into base (cement), gypsum and polymer. You can select a suitable putty from the general list.

Ready superfinish

Polymer-based composition in a plastic jar. Sold in ready-made form. It has a snow-white color and contains finely ground fillers with a fraction of up to 60 microns. To increase strength, it contains reinforcing fibers and modifiers. Thanks to antiseptics, it does not support the proliferation of microorganisms. It is used in rooms with low or normal humidity, excellent for gypsum plasterboard, fiberglass, walls with gypsum plaster already applied. Widely used for wallpapering and painting.

Facade-finish

Facade putty “Starateli” is made on the basis of cement, natural fillers and various modifiers. Suitable for exterior, interior, wet rooms, walls and ceilings, easily adhered to concrete and reinforced concrete walls. Suitable for painting, decorative plastering, wallpaper. The features of the putty are:

- applied in a layer of 0.3-3 mm;

- crack-resistant;

- frost-resistant;

- weatherproof;

- perfect white.

Facade finishing putty Starateli 20 kg

Facade

Available in the form of a dry mixture. It is characterized by a high level of resistance to moisture, so it is excellent for finishing external walls and other structures. The finished layer, up to 1 cm thick, dries quickly, has an even light beige color, and perfectly levels concrete, foam concrete, aerated concrete and other types of bases. Also used for working on bricks and cement plaster. Withstands up to 50 defrost/freeze cycles.

Basic white and basic gray

Base mixtures for internal use. Designed for rough leveling of walls and ceilings in order to create a reliable basis for finishing. Made on the basis of cement, polymer additives, formula improvers, modifiers

Before applying the base compounds, it is important to prepare the base well and remove all types of contaminants from it that reduce the reliability of adhesion to the finishing layer. The purpose of the mixtures is varied:

- for facades and interior surfaces;

- for any humidity level;

- for all types of mineral bases - concrete, brick, reinforced concrete, aerated concrete, foam concrete;

- for vertical, horizontal structures.

Finishing - fast-hardening leveling

Contains fine fraction gypsum, as well as improving additives. Suitable only for rooms with low and normal humidity. Smoothes out minor imperfections and prepares walls for final finishing. It is perfectly applied and reliably adheres to bases made of gypsum, plasterboard, cement, reinforced concrete, and concrete.

Finish CD

It has a snow-white color and is sold dry in packages of 20 kg. The composition includes the finest mineral fillers, special polymer components, as well as PVA glue. It is used for finishing cladding of walls, ceilings, and other indoor structures. Not suitable for rooms with high humidity. It dries quickly, firmly adheres to different types of building bases, but is best suited for working with gypsum bases, drywall, concrete and reinforced concrete. The finished coating will be so smooth that you can stick the thinnest wallpaper on it or use it for painting.

Finish Plus moisture resistant

Cement-polymer based putty. Applied in a layer within 0.3-3 mm, it forms a perfectly even, smooth, white coating. Plastic, does not shrink and does not crack after drying. It is not afraid of moisture due to its high level of moisture resistance. Can be used outdoors and indoors. Perfectly levels walls made of mineral materials, plasterboard.

Plaster leveling

Designed to eliminate various types of irregularities, chips, cracks, and pits. Allows you to reliably seal defects on mineral bases, previously plastered walls and ceilings. Prepares structures for painting, gluing wallpaper, seals seams between plasterboard sheets, cracks and other damage to gypsum boards, fills joints in concrete structures and between prefabricated elements. Suitable only for interior work in dry rooms.

Types of brand, how to choose, description and technical characteristics

Prospector finishing putties are available in various types, all of them have their own properties and features. The company has expanded its range, and experts divided the putty mixtures into three types:

- Basic;

- Polymer;

- Finishing gypsum putty Prospectors.

Prospector finishing putties are available in various types, all of them have their own properties and features.

"Finish putty"

Finish types are among the best types of similar products on the construction market. The smallest particles are used in the composition to obtain an even coating. Gypsum is also used as a component. The resulting degree of adhesion is high.

This type is able to cover the imperfections of the base layer, creating a perfectly leveled surface. Suitable for creating a base for painting and wallpapering. The composition should be applied in a thin layer, not exceeding 5 millimeters. It does not cost much to prepare the solution at once, so that it does not have time to harden when processing the wall.

This type is able to cover the imperfections of the base layer, creating a perfectly leveled surface.

"Facade-finishing putty"

It is distinguished by a non-toxic and safe composition, which is based on gypsum. Suitable for use outside the building, withstands exposure to natural factors. The prepared solution must be used within three hours. Can be used for wooden, plasterboard and other substrates.

Properties:

- High degree of hardness;

- Good resistance to environmental influences;

- Grinding tolerance;

- When the building shrinks, it continues to adhere securely to the façade;

- Excellent adhesion, can even be used as an adhesive solution for installation work.

It is distinguished by a non-toxic and safe composition, which is based on gypsum.

“Finishing Putty Plus Moisture Resistant”

This type can be used for interior and exterior work. It stands out for its moisture-resistant properties, which allows it to be used in rooms with high humidity.

The color of the mixture is white, the coating can have a layer of 0.3 to 3 millimeters. It is based on a polymer composition that has plastic properties. Suitable for concrete and plasterboard substrates.

It stands out for its moisture-resistant properties, which allows it to be used in rooms with high humidity.

"Ready putty Superfinish"

Starters Superfinish putty is also based on polymers and fine-grained fillers up to 60 microns. Additional components included in the composition: reinforcing fibers, modifying additives and antiseptic substances.

Designed for use inside a building, in rooms where the humidity level is normal. Can be used on gypsum plaster, plasterboard sheets, fiberglass. The result is a surface without unevenness, suitable for painting and wallpapering.

It is always better to choose products of the same brand, for example, if necessary, use Starateli finishing plaster.

The result is a surface without unevenness, suitable for painting and wallpapering.

"Finishing putty KR"

Finishing putty KR is made from polymers. Suitable for work inside the building, in rooms where there is no high humidity. Can be applied to walls and ceilings. The best application would be under a plasterboard base or gypsum plaster. But work on concrete and reinforced concrete is allowed.

The minimum packaging volume is three kilograms, finishing putty KR 20 kg Prospectors - this is the maximum volume that is on sale. Breaking down formulations into different volumes helps you purchase the required quantity without overpaying for excess.

The best application would be under a plasterboard base or gypsum plaster.

Application technique

For beginning craftsmen, the process of applying putty is very difficult. Here are recommendations to avoid problems when working:

- The drying speed of the mixture confuses slow puttyers. After all, the main principle of applying the starting composition of Prospectors is that the surface is puttied in one approach. The mixture is applied to the walls in parallel strips, so that one strip is layered on top of the previous one before it begins to set. Otherwise, the surface will not be smooth. The stripes go in any direction: vertically, horizontally or diagonally.

- The work is performed with at least two spatulas. A narrow 80 or 100 mm spatula is used to scoop up the solution from a container, and they work with wide spatulas. The width of the working spatula is selected depending on the surface area.

Work tool

It is important to achieve a uniform layer thickness. Without the skill, this is difficult to achieve.

The master does this reflexively, but the beginner will have to constantly monitor the angle of the spatula and the pressure applied. You need to “feel” the optimal combination of mixture thickness, angle of inclination and pressing force of the spatula. Too small an angle will result in a thick and uneven layer. Excessive pressure will cause the putty to squeeze out along the edges of the putty knife and create unwanted streaks. After the first layer is applied, the putty must dry completely. Typically, at normal humidity, this requires 24 hours. During this time, no excess moisture will remain in the thickness of the putty. Before the second application of the starting composition, the surface is primed again. This will prevent the second layer from drying unevenly and improve adhesion. The last layer before wallpapering is sanded with mesh No. 60 and No. 80.

Expert advice:

https://youtube.com/watch?v=videoseries

All tools used are cleaned with water immediately after completion of work. The dried mixture can only be removed mechanically, which can damage the spatulas.

Ready-to-use building mixtures have speeded up many works and made them less labor-intensive. And the simplicity of their preparation and application has allowed many home craftsmen today to independently carry out repairs at a professional level.

How to prepare a finishing solution?

Properly preparing the finishing solution is a very important point, since it determines how high-quality the coating will be and the ease of working with the finished solution. The most important point in this process is careful observance of all necessary proportions and uniform mixing of the solution.

You should follow the advice of experts when mixing the solution.

- To prepare the mixture, it is better to use a plastic container in the shape of a cylinder. The smooth walls of the container are much easier to clean after finishing work.

- Pour the required amount of water into the prepared container, then, stirring constantly, gradually add the mixture, which will avoid lumps.

- A small amount of solution can be mixed by hand. If finishing a room requires a significant amount of ready-made mixture, it is more advisable to use a mixer. The putty consumption must be calculated in advance before starting work.

- It is necessary to take into account the fact that the solution must be mixed twice. The dry mixture is poured into a container with water and mixed thoroughly. Next, you need to let the solution stand for a while and stir thoroughly again.

Each package of dry material contains detailed instructions in which you can find the exact proportions of water and putty to create a high-quality solution, and a precise description of each stage of mixing the mixture. Therefore, before mixing the solution, you need to carefully read the instructions. Only if all parameters and conditions are met will a solution of the required consistency be obtained.

Dry building mixtures “Starateli” are practical and quite easy to use. The use of these materials greatly simplifies the process of interior decoration.

In the video below you will see the difference in the use of gypsum and finishing putty.

Mixing the solution

The correct proportions and uniformity of mixing will make applying the solution convenient, and the coating will be smooth and durable.

Inexperienced craftsmen talk about poor elasticity of the solution or uneven drying. This is due to incorrect kneading technique.

- For the solution, it is better to take a plastic cylindrical container with a smooth inner surface of the walls. The dishes can be easily washed after the next batch of kneading.

Using a plastic bucket and mixer

- First, water is poured into the container, and the dry mixture is poured into it. This sequence must be followed, since otherwise you will have to deal with dry lumps.

- A small amount of the mixture is mixed by hand, but it is only possible to mix 3-4 kg of putty efficiently using a mixer. The amount of solution is calculated from the amount of work that the master will complete in 1.5 hours.

- The second important point is that the putty is mixed 2 times. After pouring the mixture, it is mixed with a mixer until the dry lumps are completely wet. After this, the solution is allowed to stand for 3-5 minutes and the procedure is repeated. A break is needed so that the dry lumps are completely saturated with moisture, after which they are finally broken up with a mixer.

Features of putty

Depending on the composition, different versions of “Starateli” putties differ greatly from each other. Most of them are based on mineral components (white or gray cement, gypsum, etc.), and also contain reinforcing fibers, antiseptics, fillers, modifiers, and polymer additives. Thanks to the modern formulation, putties are characterized by the following properties:

- Plastic. Any material is easy to apply, spreads in a thin layer over the surface, does not run off, and does not form roughness. It fills all the unevenness and cracks well, which increases the density and strength of the finished coating.

- High adhesion. Putties reliably adhere to many building substrates, including unprimed ones.

- Waterproof. After drying, the product does not have large pores, so the resulting film will not only be durable, but also moisture resistant.

- Environmentally friendly. All “Starateli” putties are safe and do not emit harmful substances, including when heated and burned.

- Resistance to negative factors. The materials are resistant to ultraviolet radiation, wind and precipitation, and chemicals.

- Versatility. The product line includes products for facades, interior work, leveling and finishing. In addition, putties adhere well to concrete, brick, stone and other substrates, so they can rightfully be considered universal.

Putty mixtures from Starateli

All putty pastes can be easily sanded after drying, resulting in a perfectly smooth finish. They are sold in bags of 5 and 20 kg, as well as in plastic buckets of 7-15 kg. The shelf life of the compositions is 1 year.

Manufacturers

The following domestic brands of putty mixtures are widely known:

- Ceresit;

- "Prospectors";

- "Volma";

- "Bolars";

- VGT;

- "Foundation 30".

The construction brand Ceresit belongs to the oldest German concern Henkel, which located its factories in Russia. For finishing facades made of mineral materials, the plant produces cement putty Ceresit CT 225. It is applied in a durable thin layer of up to 3 mm in white or gray color, supplied in 25 kg bags.

specializes in the production of dry mixtures for construction and finishing works. The line includes 3 types of cement putties for exterior use: facade white, facade gray and facade-finish.

Domestic produces dry façade putties based on Portland cement. “Volma Aquastandard” and “Volma Aquastandard light” with reinforced fibers allow you to make a leveling layer up to 1 cm. Sold in bags of 22 kg.

is engaged in the production of three types of dry products for puttying external walls. These include facade, facade-finishing and leveling products. Suitable for leveling up to 1 cm of plasterboard, aerated concrete, brick and concrete surfaces. Packaged in 5 kg, 20 kg and 25 kg. Bolars also produces ready-made polymer putty “Empire Façade” for painting, supplied in 8 or 28 kg buckets.

VGT Enterprise LLC produces ready-made facade acrylic compositions of the Bau master Shelton and VGT brands. The versatility of the putty allows it to be applied to different types of surfaces in a layer of up to 7 mm. It is characterized by a short hardening time - 8 hours. Available in 3.6 kg, 7.5 kg and 18 kg buckets, as well as in 50 kg barrels.

Under the brand name "Osnovit" we produce façade putty "Osnovit Bassilk PC 30 MG" based on cement. Sold in bags of 20 kg in white and gray. It has water-repellent properties with reinforced additives.

Popular foreign manufacturers of facade finishing materials are the German concern Knauf and the European brand Weber Vetonit. Knauf facade putties are produced on a cement base. “Knauf Multi-Finish” is designed for finishing external walls with a layer of up to 5 mm. An advantage when using is the low consumption per 1 sq. m. Has good adhesion to plastered surfaces.

Cement and acrylic putty Vetonit is a high-quality composition for leveling facades with a layer thickness of up to 0.5 cm. The Vetonit assortment includes a large selection of decorative texture mixtures for facades.