But due to the use of polyurethane foam, this device often becomes clogged, and for this reason, when purchasing, you should immediately figure out how to clean the gun from dried polyurethane foam.

Cleaning the gun from dried foam

Types of tools Cleaning methods Cleaners Care instructions

A mounting gun is a necessary tool during construction or renovation. With its help, plastic windows are installed, entrance and interior doors are mounted, utility lines are sealed and other technical operations are performed. At the end of the work, it must be cleaned, otherwise the solidified solution may make the device unsuitable for further use. We tell you how to clean a foam gun using special products in different ways.

Mechanical cleaning

The mechanical cleaning method is used in the second case - when the pistol was not regularly maintained, and after several uses the foam near the connecting thread, trigger and in the channel hardened and literally turned into stone.

Removing foam that has turned to stone

The density with which it is packed under pressure from a cylinder, combined with its strong physical properties, makes the material in this case practically invulnerable to any solvents. The liquid poured inside the gun is not even able to make its way through the channel, which makes this cleaning method impossible. To do this, you need to use a mechanical method.

Note!

The mechanical method is applicable when cleaning glass from old paint , as well as when removing silicone sealant from a cast-iron bathtub .

Cleaning the bore

Mechanical cleaning involves physically removing it from the gun.

Remains are removed with a knife

You need to arm yourself with a sharp shoe or stationery knife and a very thin wire with a pointed end. Using a knife, hardened pieces are cut off and access to the hole from which the foam was supplied is cleared as much as possible.

Then the wire comes into play - the harder the metal from which it is made, the better. With careful but confident movements, the wire is screwed into the bore. The metal makes its way towards the cylinder mount. The deeper the wire goes, the easier it will be to clean the gun later with a solvent.

Advice!

It is not advisable to clean a pistol barrel using a Karcher - too much pressure can damage fragile parts.

Cleaning the cylinder and valve mount

Using the same knife, you can largely remove dried foam from the surface of the fastening and thread, thereby freeing up space for adding solvent. It is necessary to carefully remove all remaining sealant from the valve and threads, then moisten them generously in liquid.

Note!

Together with cleaning the barrel bore, you can restore the gun, even if the foam has accumulated and dried very strongly.

Types of instruments

There are household and professional designs.

- Household ones are usually represented by plastic models. They are inexpensive because they are not designed for long-term use. They are beneficial to use when renovating one apartment (several doors, windows, sealing a balcony). It is better to carry out all work promptly, within a couple of days. Then the internal cavities become clogged with sealant, and it is not possible to clean them. Therefore, this type is considered disposable.

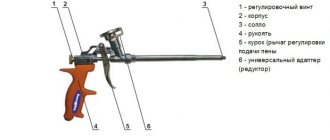

- Professional ones are made from metal. They are more resistant to chemical compounds of both the foam itself and its cleaner. Such models are more durable than plastic ones. They are a simple design: a metal barrel, an adapter for attaching a cylinder, a trigger, a handle and an adjustment screw. Depending on the manufacturing company, designs may differ slightly with different devices. But their main difference from household ones is the presence of a mechanism for regulating the quantity and speed of supply of the composition.

Structures are divided into non-removable (usually plastic), partially or completely collapsible (metal). The last two types allow you to wash the device and change worn out parts.

Foam gun

428

Buy

Cleaner for spray foam gun

The standard product is a 500 ml aerosol can into which a solvent is pumped under pressure. The main active ingredient is dimethyl ketone, to which various additives are added. Using this aerosol you can clean not only tools, but also tidy up your hands, clothes, and other surfaces.

Polyurethane foam cleaner Tytan Prof Eco

291

Buy

During work it is necessary to observe safety precautions:

- keep away from fire, batteries and direct rays of the sun;

- do not allow the container to heat above 50 degrees;

- ensure that the substance does not get into your eyes;

- when using at home, ventilate the room well;

- After use, wash your hands with soap.

Cleaners are divided into those that dissolve uncured polyurethane foam and those that work with dried solution.

The former perfectly clean canister valves, gun adapters, as well as their internal parts. Well-known companies producing this type of solvent include Tytan. They produce a kit: foam plus solvent. Many manufacturers offer solution-soaked wipes that are suitable for external treatment of instruments.

The latter act on hardened polyurethane foam, softening it for 10-15 minutes, after which it can also be washed with softening wipes. Among the manufacturers of this type of product are TechnoNIKOL and Makroflex.

Remove with acetone or other solvent

Acetone, like any other solvent, does an excellent job with construction foam that has just begun to dry out.

In this state, it is extremely susceptible to the active chemical effects of the liquid solvent.

In addition to acetone, you can use paint solvents white spirit, xylene, solvent, 646, 647, 649, 650 and P-4. Galosh gasoline, kerosene and turpentine, which have similar properties, are also suitable. Water, including hot water, does not help in cleaning at all.

Attention!

All of the above liquids have a strong, specific odor and are highly flammable. Therefore, you need to follow safety precautions when using them.

It is best to use solvents to regularly clean the gun from foam residues. Cleaning it with solvent after each use can save a lot of time at home later on.

Immediately after the work is completed, you must carefully disconnect the cylinder.

The empty cylinder must be removed

Using a clean piece of cloth, fresh pieces of foam that have not yet hardened are removed.

Another piece of rag is moistened with solvent, it is necessary to wipe the adapter (if available), the cylinder mounting collar and immediately wipe the tip of the gun.

The foam also needs to be wiped off around the trigger. If it has time to freeze there, it may make it difficult to use the gun in the future.

Also causing problems is the drying of the foam in the “barrel” of the gun - a narrow channel through which material under pressure from the cylinder is supplied to the required location.

To wash it, you need to carefully pour the solvent into the hole located in the place where the cylinder is attached.

Cleaning the gun

Possessing high chemical activity and increased fluidity, the solvent will very quickly make its way through the uncured foam, exiting along with it through the tip of the gun. The effectiveness of this method depends on how quickly the solvent is used - the more it dries, the more difficult it will be to clean it.

If the foam still has time to cool, then the solvent can be applied directly into the channel from the tip side. To do this, you can use a regular syringe with a thin needle. You will most likely only be able to use the syringe once and very quickly, because the solvent is very aggressive towards the soft plastic from which it is made. With a quick movement, you need to draw a full syringe of liquid, insert the needle into the canal the entire length and release it inside. This will greatly facilitate cleaning the expensive gun, allowing you to do it quickly and without much expense.

Harsh solvents can also be used to remove foam from metal doors and caulk from tiles.

Pharmaceutical dimexide has properties similar to solvents.

Pharmaceutical solvent

It has a destructive effect on contamination, while being absolutely safe for the skin of the hands and the fabric used to apply it to the gun. The washing method is similar to that described above. If necessary, dimexide can be used to wipe off foam from work clothes and hands from superglue.

Basic rules of care

If the tool is used for work frequently, then to extend its service life it is recommended to follow a few simple rules.

- Store the gun with a screwed-on container that still contains foam that has not expired.

- If the polyurethane foam runs out, remove the packaging and be sure to rinse the device. As long as the solution is fresh, this is quite easy to do.

- If you replace the cylinder with a product from another manufacturer, it is recommended to rinse the device. Different companies produce sealants that differ in composition. The mixture resulting from mixing them is sometimes impossible to remove.

By following these simple recommendations, you will not only preserve your working tool, but also save your time. It will take much more time to clean a gun from dried polyurethane foam than to free it from fresh solution.

A short video that clearly shows all the cleaning methods: