Plastering is a rather labor-intensive process. A lot of time and effort is spent on covering surfaces with a layer. At the same time, you want the layer of plaster to lay evenly and tightly. Typically, a builder works with a ladle, throwing the mixture onto the masonry.

However, it does not lay down quite evenly. Cavities cause crumbling over time, frustrating repair efforts. Plastering when building a new home or renovating is the most difficult part of the finishing process. And the success and neat appearance of subsequent stages depends on its quality. This labor-intensive process takes days and weeks. You need skill for this.

Many people invite a specialist to help, but if the area to be treated is large (say, finishing the walls of a new house with mortar), then it will be expensive. With some skill and, of course, a great desire, you can plaster the walls yourself. The mechanical device cartouche “plaster gun” will help you with this. Applying plaster with a compressor will improve the quality of repairs, significantly speed up and facilitate the process itself, as it sprays the composition of any consistency.

Plastering walls with a compressor.

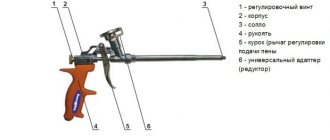

The gun for applying plaster (pneumatic bucket) is a semi-automatic device. It is powered by a compressor that supplies air to the hose. A mass flows into the funnel nozzle, picked up by a stream of air, which directs everything towards the wall. The process of working with a cartouche plastic or metal gun is not easy, but it is still easier than manual plastering.

After some time, you will not have to seal cracks in newly made plaster; if you use a cartouche device, the solution will lie tightly and evenly.

This device is a 5-liter funnel and a short barrel extending from it with a set of tips. The handle regulates the action of the cartouche device, and air is supplied under pressure through the compressor hose, due to which the composition is sprayed.

Different tips are adapted to the composition of a certain consistency. Dense ones are sprayed under air pressure of 3-4 atmospheres. This means that air escapes from the hose and seals the solution to the masonry at a speed of about 200 l/min. Using nozzles you can adjust the thickness of the jet.

The density of the composition when working with a cartouche device does not differ from the composition when plastering by hand. It should slide down the funnel like thick sour cream. A wide nozzle is placed on the barrel if the master is working with thick cement. For a thinner consistency, choose a narrow tip. The solution is added to the funnel. To cover 1.5 square meters of surface with a layer of 1 cm, 25 kg will be required.

Using a cartouche gun to apply plaster is not easy. He weighs almost 5 kg. It is difficult to keep it suspended for a long time, especially if thick cement with sand or stone chips is used.

Cement that hardens on the walls of the tank must be cleaned off periodically.

The main advantages of the hopper plastering bucket and reviews

- Affordable price.

- You can buy a shovel with a compressor attachment separately or a ready-made station.

- Quick payback by minimizing manual labor costs.

- Simplicity of design and ease of operation.

- Reliability and durability of parts, compressors break in most cases.

- To work with it, you do not need special education or skills; you need to be in good physical shape.

- The speed of plastering increases significantly, because one person controls the hopper, and the other levels the surface.

- To apply liquid adhesives and paint, you can use a portable ladle - a special gun.

- Saving solution.

- Increased coating quality and reduced risk of deformation of the treated surface.

- Adhesion increases several times.

- The device can be made directly on the construction site from available materials.

Users appreciated all the listed advantages of this tool, so the hopper bucket received only positive reviews. They especially highlighted the affordable cost, simplicity, speed and ease of operation, and saving of solution.

Cartouche plaster gun in action.

Before applying the plaster with a compressor, you need to protect your face with a plastic mask, since with strong pressure from the hose, particles of the composition can fly off to the sides with great force. Then turn on the compressor and fill the cement funnel. During operation, the nozzle of the cartouche unit should be at waist level.

The compressor works so that the mixture enters the bell, just press the starting handle. It will lie flat on the wall, will not flow from it and will not splash to the sides if the stream is directed strictly at right angles to the surface to be coated.

We direct the movement of the unit parallel to the floor. You should get a straight strip of solution. Having reached the corner, we raise the cartouche apparatus higher, so that the next strip lies slightly overlapping over the first.

This way we cover the entire wall. While spraying the solution, try to keep the cartouche apparatus at the same distance. Which deletion to choose is up to you to decide. If the solution adheres well to the surface and does not fly off in splashes, then the distance is appropriate. A cartouche gun for plaster in action means speed and quality of work.

Experienced plasterers can apply an even layer the first time. But for beginners, it is better to first treat the surface with a mixture to a thickness of 5 mm, let it set for 5-7 hours, and then apply a finishing leveling layer. Before it hardens, make the grout a rule. In a day the coating will be completely ready.

How to use the hopper?

Despite the simplicity of the design and reliability of the product, the hopper bucket must be operated correctly. This is not a spatula and manual surface treatment, and the solution is supplied under high pressure.

The ready-made solution is filled into the ladle, the compressor pumps air under a pressure of 6 atmospheres, which flows through a hose into the hopper. Now you need to adjust the supply of air mass to the nozzles. The tool is ready to spray.

Main features of the gun for applying plaster.

Hand plastering, although heavier, is more familiar to the master. Using mechanical equipment takes time to get used to. But this method has many advantages:

Saving time during repairs. In one day you can plaster 150 sq.m of wall;- Economical use of material. When applied mechanically, one layer is sufficient;

- Smooth coverage without special skills or effort;

- Possibility to rent the installation for the required time;

- Saving money on work costs;

- The density of the applied layer increases, as the mixture “sticks” into the brickwork under strong air pressure;

- The durability of the applied layer of plaster increases;

- A cartouche gun for plastering walls is convenient to use for applying decorative finishing. It is made on a gypsum basis.

By purchasing this tool, you can significantly reduce the cost of major renovations of an apartment or house. What you need to pay attention to when using a cartouche gun for plastering walls for the first time.

- If you have little idea how it works in practice, find a video on the Internet that shows how to prepare the tool, how to connect the hose from the compressor, how to fill the solution into the reservoir, and so on.

- Make sure there is an even layer of mortar on the wall. This will prevent cracks from appearing.

- For mechanical plastering, special gypsum-based mixtures are often used. They tend to harden quickly. Therefore, it is not worth preparing a large number of them at once. The composition may set before it enters the cartouche apparatus.

- The point of using a cartouche gun for plastering walls is to ensure that the cement mortar adheres tightly to the surface. This means that the air pressure in the hose must be sufficient. Excessive pressure breaks the hose or sprays the mixture from a strong impact against the wall.

- Keep the nozzle at a distance of 35-40 cm from the wall.

- Pay attention to the injectors. For training, it is better to take a nozzle that is medium in size across the hole and prepare a cement mix that is not very thick (but not liquid either). When acquiring skills, you will determine for yourself what and how it is more convenient for you to work in order to get the expected result.

Popular models

According to the 2021 rating, the most popular air devices for everyday life and private construction were recognized as models whose characteristics are given in the table:

| Brand | Receiver volume, l | Power, W | Work pressure, bar | Productivity, l/min | Lubricant type | Note |

| Hyundai HYC 2024 | 24 | 1470 | 8 | 200 | Oil | |

| Metabo Basic 250-24WOF | 24 | 1500 | 8 | 220 | Oil-free | |

| Forte VFL-50 | 50 | 2200 | 8 | 420 | Oil | Direct drive |

| Fubag Air Master Kit | 24 | 1500 | 8 | 222 | Oil-free | Very noisy, made in China |

| Abac Montecarlo L30P | 50 | 2200 | 10 | 270 | Oil | |

| Whirlwind KMP-300/50 | 50 | 2000 | 8 | 300 | Oil | Direct drive |

| Remeza SB 4/C-100 LB 30 A | 100 | 2200 | 10 | 420 | Oil | Belt drive |

A properly selected compressor for a hopper bucket will not only speed up the work, but also make the plastering process much more enjoyable. Once you become familiar with the basic selection criteria, you will be able to choose the right mechanism that will last a long time and be useful for other jobs.

Features when working with the device.

As already mentioned, most often gypsum mortar is used for mechanical plastering. There are several reasons.

Firstly, it is more elastic and fine-grained. It mixes well and slides well along the walls of the funnel. Secondly, gypsum solutions do not get stuck even in the narrowest nozzles. Thirdly, they are quickly prepared and consumed. With this mixture things go faster. Fourthly, during finishing the gypsum mixture can be tinted. Preparatory steps for mechanical plastering. Step 1. First, the surfaces are impregnated with a primer. Step 2. The walls are marked with beacons. They are installed at a smaller distance than the width of the rule so that the layer can be leveled. You can attach these beacons to cement, wait until it hardens, and start plastering.

Step 3. Prepare the compressor and cartouche gun for plastering the walls, turn on the unit and fill the container above the barrel. Bring the nozzle to the desired height and press the start handle. Further actions were described above.

Cartouche gun for plaster “matrix 57350”.

Used for applying finishing decorative plaster. There are special mixtures for this type of finish. Narrow nozzles produce a thin stream that is directed to the application site.

Decorative plaster comes in different textures and patterns.

The mixture may contain marble and mica chips. After applying it to the wall, you can work with a trowel or trowel, correcting the surface. At the same time, the stone chips move and create a certain pattern.

Structural plaster is made thick with a large content of stone chips. The result is a rough surface, which can then be painted or refined with mica coating.

The textured surface is created by a more liquid composition. It suggests a chaotic pattern. It can be applied to wet plaster using improvised means. Solutions may vary in composition. The binder can be glue, and the filler can be synthetic materials.

But more often, nevertheless, a cartouche gun for plastering matrix walls is used to apply a decorative composition to prepared plaster. This can be spraying marble chips or a colored composition. This decoration method gives the designer extraordinary scope for imagination and great possibilities in choosing wall coverings.

Decorative finishing can be carried out both inside the building and on the street side. The consistency in these cases will be different, but the finishing principle will be similar.

Cartouche gun for plaster "matrix 57350" can be used for application under any decor.

This speeds up the process of covering the wall with mortar. If you are planning to decorate a room using an unusual, fashionable technique of textured plaster, you should try to do it yourself. The price of decorative plaster per 1 square meter is about 300 rubles.

Moreover, 75% of this amount costs work. After all, it’s almost like a piece of art on the wall.

This mechanism can be used to spray thick paint and to apply glue to large surfaces (when gluing insulation boards).

In any of these cases, applying plaster with a compressor speeds up and facilitates the finishing process, allowing the composition to be applied in an even, thin layer.

Where to buy a cartouche pistol.

Compared to the benefits and benefits that come from working with this mechanism, its price seems paltry. Imagine that you can plaster an entire house or a large apartment in a matter of hours using a mechanism that costs only 2500-3000 rubles.

Having bought a cartouche machine for wall finishing, you can forget about the exhausting plaster. It requires a compressor, but if you can’t afford to spend money on purchasing one, this unit can be rented from a building materials store or construction company. It won't cost much.

The cost of the mechanism may vary depending on the material from which it is made. A plastic container for the mixture in the Matrix brand significantly reduces the weight of the device. But some models intended for primary plastering have aluminum funnels. Different cartouche devices have different numbers of nozzles. All these factors influence the pricing of the product.

You can buy a plastic cartouche gun at a hardware store or order it from a catalog on the Internet.

A sales floor specialist or online consultant will help you choose the mechanism of the required configuration and advise the brand and model depending on the purpose of the tool. data-matched-content-ui-type=”image_stacked” data-matched-content-rows-num=”2″ data-matched-content-columns-num=”3″ data-ad-format=”autorelaxed”>

Characteristics

Weight, kg 1.794 Country of origin China Air consumption (l/min) 350.0 Volume Bucket volume – 4 l Brand SPEC Product application Spraying Weight 2.0 Tip diameter (mm) 18 Product type Pneumatic hopper Product model SN-01 Packaging type Without packaging

Prices and availability may vary. Please check the exact cost and availability of goods in stores.

242,00 Male adapter 1/2 inch - quick release 293,00 Oil for Patriot compressors, 1 l 1,775,00 Dexter hose 15 m, PVC 196,00 Adapter for Dexter hose 8 mm - quick release with clamp 197,00 Adapter Dexter “female” 1/4 inch - quick release 420,00 Plastic container Sibrtech 90 l 77,00 Equation coupling, 1/2″, nickel-plated brass 278,00 Aluminum rule Trapezoid Sibrtech 1.5 m, 2 stiffeners 378,00 Aluminum rule Trapezoid Sibrtech 2 m, 2 stiffeners 57.00 Coupling 1/2″, brass 1,087.00 Spiral hose Dexter 10 m, polyurethane 27.00 Spatula 100 mm 30,580.00 Oil compressor Patriot LRM 100-480R, 100 l 480 l /min 2.2 kW Show all Related products