The relevance of the use of plaster mixtures

Before you begin decorative finishing, the base must be prepared. This stage of construction work includes the creation of one or another architectural plane. According to experts, plaster mixture is rightfully considered a universal material. Using mortar, walls and ceilings can be given a strict or arbitrary shape. At the same time, only a minimum set of tools is required from additional means - a primer composition and possibly a reinforcing mesh or fiberglass.

The main advantage of using plaster over other building materials is its solidity. The water-containing solution is capable of filling even minor cracks with pores and large differences. The dry residue is characterized by high mechanical compressive and peel strength, and has a low coefficient of thermal expansion. That is, the applied layer of leveler, subject to the technological process and recommendations from the manufacturer, will retain its shape for a long time and withstand loads from decorative finishing and environmental operating conditions. This applies to both premises inside heated buildings and facades in the residential and industrial sectors.

Finishing of the facade - can be carried out both on the base material and on the insulation Source lalafo.com

The applied layer of leveler additionally strengthens the base, improves the performance of structures in terms of fire resistance, acoustic properties, and thermal insulation. The formed coating from mixtures of gypsum and cement from StroyMoment can be used for almost any type of decorative finishing: puttying, painting, tiles, artificial stone, tiles and porcelain stoneware. In addition, plastering can be done independently - without having much experience in repair work.

Ready mixes

You can make the plaster mortar yourself or purchase a ready-made mixture. Van will only need to add water to get a ready-to-apply product. It is not surprising that most novice builders prefer to choose this option.

Ready-made mixture for walls eliminates errors when mixing components. You will never confuse the proportions due to ignorance of the specifics of using a particular brand of cement for plastering walls with mortar. Therefore, if you do not have extensive construction experience, it is best to choose a ready-made mixture for finishing.

As an example of a finished substance for wall finishing, consider KNAUF-Rotband. The material is produced by one of the most respected construction brands. Therefore, the price per bag is appropriate. Now you can find bags with the following weight:

- 5 kg,

- 10,

- 25,

- 30.

The choice is quite large, so you can choose the packaging that is ideal for your needs. This wall treatment substance is made in Germany. Moreover, the company has been improving its product over the past 50 years. It is not surprising that KNAUF-Rotband is well known throughout the world.

The company's product range also includes other gypsum-based substances. But their density is too high to apply materials to the ceiling. Therefore, most builders prefer KNAUF-Rotband.

The substance has the following characteristics:

- Provided that the layer thickness is one centimeter, the consumption of the substance per square meter will be eight and a half kilograms.

- The maximum possible layer thickness is five centimeters. The only exception is the ceiling. Plaster of more than 1.5 cm cannot be applied to it.

- Professional builders do not make the KNAUF-Rotband layer thinner than half a centimeter.

- In seven days the substance hardens. But this time period largely depends on humidity.

- The product is excellent for finishing walls made of different materials. Most often it is used when it is necessary to plaster walls or ceilings made of concrete, brick or polystyrene foam.

- KNAUF-Rotband is excellent for application on smooth surfaces. At the same time, the substance does not perform very well when sealing joints on drywall.

- The use of the substance is allowed both in rooms with normal humidity and in bathrooms or kitchens.

- The color of the substance varies over a fairly wide range. You can choose white, gray or even pink. This does not affect the performance characteristics in any way.

- KNAUF-Rotband can be stored for no more than 6 months.

These are the main technical characteristics of a substance, which largely determine the features of its operation. The ready-made solution allows you to avoid finishing the walls with putty. The most important advantage of KNAUF-Rotband is the absence of seams on the walls, even when applying a thick layer of plaster.

Overview of the characteristics of cement plaster

The basic component in the composition is a cement binder such as Portland cement. This is ground clinker made from clay and limestone, mixed with a small amount of gypsum (up to 5%) and mineral additives (up to 15%). The plaster mixture also includes purified sand of fine and medium fractions) and plasticizers with modifying additives.

It is common for such mixtures to cope with moisture and high mechanical loads. This is justified by the water resistance of cement and the strength provided by the binder component and quartz filler.

Cement plaster SMK 21 – standard bag 25 kg Source kenga.market

Let's consider the basic characteristics of the material using the example of facade cement plaster SMK 21 from StroyMoment:

- Compressive strength . The dry residue is able to withstand pressure of about 7 MPa while maintaining quality indicators and shape.

- Peel strength . On the part of the finishing material, the permissible load is equal to 0.4-0.5 MPa.

- Density _ A cubic meter of the applied layer after drying in the case of SMK 21 weighs about 1700 kg. As a rule, the figure exceeds 1850 kg.

- Water absorption . The coating transmits about 5% moisture per day under direct contact conditions. Taking into account additional finishing, the indicator can be reduced to zero.

- Frost resistance . After 28 days, freezing and thawing of the plaster is possible without disturbing the technical condition of the leveling layer. The declared number of cycles is 35. In practice, the value reaches 50 units.

Most cement mixtures have similar basic characteristics to the sample considered. Also, Kolmiks LLC specialists recommend paying attention to additional properties that are important for the correct choice of materials:

- consumption in kg/sq.m - usually indicated for the formation of a coating with a thickness of 10 mm, but there may be other values;

When applying facade plaster by machine, the consumption is usually less Source remontik.org

- temperature for installation – from +5 to +30 degrees Celsius (ranges from 15 to 25 are considered ideal);

- complete drying - up to 28 days in optimal conditions without accelerating additives (StroyMoment produces mixtures with additives, so the period can be 3-7 days per 10 mm layer);

- single-layer application without reinforcement - an average of 25 mm;

- shrinkage , subject to the permissible limit, is an average of 2 mm/m.

In addition, experts note that cement is characterized by a relatively short service life. Since the plaster contains high-strength Portland cement, it is worth paying attention to the production date of the material. The quality characteristics of SMK 21 remain unchanged for 12 months in sealed original packaging.

To prepare a solution for 1 kg of dry mixture, approximately 0.2 liters of clean (preferably tap) cold water is required. The working time of the resulting mass is at least 2 hours (without additives accelerating hardening). Wet grinding (grouting) is possible within 3-4 hours. The next layer can be applied after a day or a week, followed by wetting and priming the surface.

The next layer is applied after some time (indicated in the instructions) Source potolok-exp.ru

Advantages and disadvantages

Cement plaster stands out from its analogues due to its versatility of use. This applies to temperature and relative humidity conditions. As a rule, the material is used to align walls with ceilings outside the building, in unheated and damp rooms.

The choice in favor of mixtures is made due to:

- high strength;

- moisture resistance;

- inertness to biological activity (fungus, mold, bacteria);

- durability (tens of years);

- relatively low cost.

However, against the backdrop of advantages, the following disadvantages stand out:

- shrinkage (absent only when the permissible limit is reduced);

- prolonged drying (accelerating the process with additional heat and increased ventilation is unacceptable);

- rough surface (explained by the sand content, which is why StroyMoment uses a fraction no higher than average);

- low adhesion to smooth (grinding) concrete, polymers, tiles, paint, glass, wood.

- high probability of cracks due to violation of the rules for mixing the solution and work technology;

Plaster coating cracked as a result of violation of work technology Source wp.com

Relatively high consumption is also noted (QMS has 21 indicators below average).

When applied in multiple layers with a reinforcing mesh, it is possible to increase the coating thickness to 70 mm. But such a volume of plaster has a noticeable weight, which does not always have a positive effect on load-bearing structures and foundations. Therefore, cement mixtures are often used only as a rough leveler.

Overview of the characteristics of gypsum plaster

The basic component of the mixtures is gypsum. This is a natural mineral that undergoes heat treatment before grinding. The maximum value of the applied layer depends on the fraction of the resulting grains. Also added to the composition are solid fillers of natural or synthetic origin, plasticizers and modifying additives. The content of additional ingredients may exceed 20% of the total volume of the dry mixture.

A distinctive feature of gypsum plaster is the rapid increase in strength with the release of heat. This property is especially relevant for urgent repairs of cracks, fixing communication wires and channels, beacon profiles.

White gypsum solution Source remelle.ru

It is also worth noting the low resistance to moisture. Therefore, the main application of the composition is in rooms with proper ventilation and constant relative humidity not higher than room temperature (on average 60%).

In lines of gypsum plasters, it is worth paying attention to the filler fraction. There are three types:

- With large filler the limit reaches 60 mm . The composition is applicable only for rough repairs of walls, corners and slopes. It is possible to level structures in rooms with variable humidity and facades. But it is recommended to first check such mixtures for water absorption. It is also recommended to additionally treat the base and the formed coating with protective primers.

- Medium-grained is acceptable for forming a layer up to 40-50 mm thick . It is used for subsequent finishing with lightweight facing materials (wallpaper, polymer-based panels).

To level the ceiling, the middle fraction is often used Source kraski-net.ru

- Fine-grained is applied in a layer of up to 0.8 mm . The composition is relevant for finishing leveling of lightly loaded walls and ceilings.

The basic indicators of the material from suppliers have similar parameters, so let’s look at them using the example of universal gypsum plaster SMK 25 from StroyMoment. Due to the fine fraction of the filler, the plaster is suitable for manual or machine application to walls and ceilings.

Gypsum plaster SMK 25 - 30 kg in a bag Source otzovy.ru

Here are its characteristics:

- Compressive strength . The dry residue is able to withstand pressure of about 4 MPa while maintaining quality indicators and shape. This is slightly higher than the average value of 2.7-3.5 MPa.

- Peel strength . On the part of the finishing material, the permissible load is equal to 0.3 MPa; the sample has an indicator increased to 0.4 MPa, which is important for wall cladding with thin tiles or artificial stone based on gypsum.

- Density _ A cubic meter of the applied layer after drying weighs on average 1200 kg (for SMK - 1080 kg).

- Vapor permeability . The coefficient exceeds 0.15 mg/m*h*Pa. This indicates good breathability of the material, which is important for the indoor microclimate.

- Frost resistance . The property is not considered, since the use of the mixture is limited to heated rooms. There are exceptions with modifying additives.

Additional properties look like this:

- Temperature for installation – from +5 to +30 degrees Celsius.

- Primary hardening - on average a day for every 10 mm (after hardening, short-term additional ventilation is acceptable). Full set of strength according to standards - up to 7 days.

- Single-layer application without reinforcement – 20 mm (for the sample – from 5 to 50 mm).

Applying plaster to a wall made of aerated concrete Source otzovik.com

- Consumption in kg/sq.m when forming a coating 10 mm thick – 8 for machine application, 10 for manual application;

- shrinkage if the permissible limit is observed.

To mix the solution per 1 kg of dry mixture, about 0.45 liters of clean water is required. The working time of the resulting mass is no more than 1 hour (often 40 minutes). Wet sanding (grouting) is possible within 15 minutes after the start of setting. The next layer can be applied after 2-3 hours or after two days, followed by priming the surface.

Pros and cons of cement mortars

Thanks to the following characteristics, cement plasters are so highly valued among experienced and novice craftsmen:

- Mechanical strength. This indicator is a kind of calling card of cement plasters. Thanks to it, coatings are strong, reliable, and able to withstand direct mechanical impact.

- High adhesion. Even if a monolithic concrete surface is being finished, special preparatory measures are not necessary. It is enough to use a special primer or additives.

- Moisture resistance. Thanks to this characteristic, the materials can be used for finishing walls and ceilings in damp rooms. In addition, it is cement compositions that are most often chosen for facade work.

- Price. The relatively low prices for cement compositions make them attractive in the eyes of buyers.

Cement plaster is highly valued by both beginners and professionals

You should know! You cannot choose between materials based on cost alone. It is recommended to find out the consumption of each of them and calculate the required amount of mixture in advance.

The main disadvantage of such solutions is the inability to treat plastic, painted or wooden surfaces. Their finishing requires serious preparatory measures, which increase the overall cost of the work. This type of plasters has a significant specific gravity, which makes it more difficult to work with; it is practically not applied to ceilings. This same feature requires an accurate preliminary calculation of the material and layer thickness, since a large amount of material can overload the walls. The application process is quite labor-intensive and takes place in several stages, after each of which it is necessary to interrupt work for a certain period of time. It is necessary for the solutions to dry; the total duration of work can reach 1 month.

Modern mixtures contain many different components that completely or partially eliminate the above disadvantages.

Work on plastering walls with cement-based mortar can take a long time

Video description

In this video, watch an overview of the characteristics of four different gypsum mixtures:

Advantages and disadvantages

Gypsum plaster is easy to work with. The working mass is characterized by plasticity, which simplifies the process of forming a smooth and even coating. If you follow the rules for mixing the solution and carrying out installation work, the risk of cracks is reduced to zero.

The advantages of the material also include:

- the surface can be brought to a “mirror” state, which is important for painting or wallpapering without additional putty;

Gypsum plaster can be used to create a mirror-smooth surface for painting. Source interiorno.ru

- it is possible to increase the layer with reinforcement to 50 mm (for SMK 21 to 60 mm);

- relatively low consumption and weight per cubic meter;

- short setting and drying time;

- there is adhesion to mineral bases and wood;

- good breathability;

- environmental Safety.

The disadvantages of gypsum-based mixtures include three significant points:

- fragility (cracks and crumbles from vibrations, splits from impact);

- high water absorption (softens when wet, becomes loose and does not recover);

- quick hardening (you have to knead in small portions and clean the bucket before each kneading)

- risk of gypsum destruction upon contact with cement tile adhesive;

- relatively high cost .

Another drawback occurs relatively rarely, since use in dry rooms is limited. Gypsum does not prevent the development of rust and biological damage. Corrosion, mold and mildew appear through the leveling layer over time.

Before using plaster, it is necessary to exclude signs of corrosion and mold Source furanflex.ru

Gypsum-lime material

This building material has found its application in the field of finishing wooden and stone surfaces, as well as cornices. It is not used on concrete foundations. Internal cladding of ceilings and walls is what lime-sand plaster is suitable for. It is used extremely rarely for outdoor work.

A gypsum-lime mixture is a material in which gypsum acts as a binder. It is introduced in the following ratios:

- sand, gypsum, lime – 2:1:1 (for spraying);

- sand and gypsum – 2:1.5:1 (for soil);

- lime and gypsum – 1:1 (for the finishing layer).

Lime-sand plaster sets in approximately 30 minutes. Prepare it in small portions and do not store leftovers. The mixture is kneaded until it becomes sour cream. As a result, the solution should be thick and not flow off the spatula.

Lime-gypsum plaster is distinguished by excellent pliability and smoothing characteristics, and in addition, excellent adhesion to stone and wood. However, it hardens quite quickly, which is why it is prepared in small portions. Distinctive features of the material include reduced water resistance.

Comparative analysis of multicomponent mixtures

Plaster mixtures based on cement and gypsum have only three things in common. The materials are in greatest demand among leveling mixtures due to their relatively low cost. The compositions are used for finishing vertical structures and ceilings; application to surfaces with high mechanical load is unacceptable. The third point is the possibility of multi-layer application, due to which the limit on coating thickness increases to 6-7 cm.

Otherwise the plasters are different. The table presents a brief analysis of the comparative characteristics of materials, which was carried out by specialists from Kolmix LLC.

| Comparison criteria | Gypsum mixture | Cement composition |

| Conditions of use | Heated, dry rooms with proper ventilation. | External and internal works. |

| Labor costs | The plastic mass is easy to apply and distribute over the surface. But they catch on quickly. Additional treatment with preventive agents is required to improve inertness to rust and biological activity. | Due to the high sand content, the solution is slightly crumbly and has relatively less stickiness. But the working time exceeds 2 hours. Reinforcement and the use of strengthening primers are recommended. |

| Surface | It can be smoothed to a state that is suitable for wallpaper and painting. | The coating turns out to be rough; it is not recommended to use it for pasting. Additional puttying is performed more often. |

| Strength | The fragile layer is destroyed by vibration and shock loads and is not suitable for hanging household appliances or furniture. It is not recommended to carry out subsequent cladding with porcelain stoneware, stone and tiles due to the relatively low tear strength. The cycle of full strength gain is up to 7 days. | It is highly resistant to various loads. It is permissible to level the walls for any type of decorative finish. The cycle of full strength gain is up to 28 days. |

| Density | Cement plaster weighs significantly more compared to its gypsum counterpart. Therefore, when forming a leveling layer of large thickness, mixtures are often combined (first a rough finish, then gypsum-based). The mineral composition explains the good adhesion between solutions. This will create a solid basis for hanging interior items and reduce the load on the structural elements of the building. | |

Experts also note the different effects of mixtures on humans. Cement plaster contains alkali, and the binder component generates a lot of dust.

Therefore, it is important to work with a respirator, goggles and gloves, and take into account a possible allergic reaction to the composition. You can work with gypsum plaster without personal protective equipment. The material is safe for health.

Cement dust Source sazhaemistroim.ru

Classification

Compositions are divided into groups according to different criteria: by type of finish, purpose, composition.

Conventional plasters are used for:

- Leveling wall surfaces after construction from any materials: wood, concrete and foam concrete, brick.

- For repairing and sealing irregularities and cracks in structures.

- To create a soundproofing and fireproof layer.

Decorative ones are used to create a finishing cladding: they contain mineral chips, pigments and plasticizing additives.

According to the main substance of plaster there are:

- Plaster;

- Cement;

- Calcareous;

- Clay.

The main ones are gypsum and cement plasters; lime or clay is mixed into them in different proportions depending on the place of application.

Which plaster to choose - gypsum or cement - it all depends on the place of application and the expected load on the walls.

Work technology

Leveling structures using cement and gypsum-based plaster from StroyMoment is carried out according to similar principles. Work begins with preparing the base. It must be clean, durable and dry. To do this, the wizard performs the following actions:

- dismantle the old decorative covering;

- eliminate weak areas, open cracks with further strengthening, priming and filling with mortar;;

- remove foci of rust, fungus, mold, followed by preventive treatment;

- degrease oily stains, wash off chalk and lime, make notches on a smooth surface;

- cover the base with an adhesive primer (additional functionality is selected according to the condition of the structures and their operating conditions).

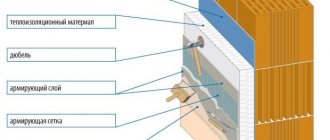

The next step involves applying a leveling coating. If the differences are significant, then the reinforcing mesh is first strengthened and orientation beacons are installed according to the rule.

Reinforcing mesh for plaster Source stroyscan.ru

To work with the solution, use the following set of tools:

- equipment for machine application (if such a method is planned);

- a construction mixer or drill with an attachment for coarse mortars and a container for the working mass;

- trowel, ladle, facade trowel, falcon, grater or rule (at the discretion of the performer).

At the final stage of plastering, the surface is grouted. The process is performed manually using a grater. The platform can be metal, with a polymer lining or made of polyurethane foam. After complete drying, grinding is carried out using abrasive materials with coarse grains.

Video description

This story clearly shows the whole process of plastering walls with the installation of beacons according to the rule:

Plastering using reinforcing mesh

In the case of a cement mixture, the company’s specialists must carry out reinforcement, since the coating is prone to cracking. In other cases, a mesh is used if the base is weak or the applied layer exceeds the limits established by the manufacturer of the mixtures.

The metal sheet on mineral structures is secured with dowel nails.

Installation of metal mesh Source kraski-net.ru

For convenience, the fiberglass mesh can be secured from above with hardware without significant tension. The edges are connected to each other with an overlap of up to 15 cm. It is important to completely cover the reinforcing material with a thin layer before applying the leveling layer. This will prevent bends and damage to the monolithic protection, and it will be easier to distribute the solution.

Which plaster to choose depending on the type of base

If the surfaces do not have serious defects and are not heavily littered, then it will be enough to simply apply one layer of gypsum plaster. In this case, we are talking about walls in panel houses, as well as plasterboard coverings. For such purposes, it is recommended to use solutions with polymer additives that increase the viscosity and adhesion of the material.

On a note! Walls made of lightweight cellular concrete require pre-treatment before applying gypsum compounds. This is not necessary for ordinary walls.

If the walls are built from brick or cinder block, then it is better to use cement-based starting mixtures. The fact is that such building materials rarely have ideal geometry; in addition, the evenness of the masonry is also rare. In addition, such coatings require preliminary priming, and if a large layer of cement plaster is used (more than 5 cm), the installation of reinforcing mesh is required.

Rough finishing of brick walls is best done with cement compounds

After the leveling layer dries, the surface becomes rough, porous and grainy. To smooth it, gypsum finishing solutions with fine filler are used. They will fill every crack and pore, resulting in a more uniform finish.

Briefly about the main thing

Cement-based plaster is used for indoor and outdoor work. The coating is highly durable and resistant to moisture.

Disadvantages of the cement composition include difficulty of application, high weight and high risk of cracks.

The gypsum-based mixture is only suitable for finishing inside a dry, ventilated and heated room. Characteristic properties of the coating are quick drying and smoothness.

The disadvantages include relatively low peel strength, fragility, and instability to moisture. It is also less inert to biological activity and corrosion. But the composition is environmentally safer.

Before applying a cement-based mortar, it is recommended to install a reinforcing layer. When increasing the maximum thickness of a single-layer coating when using both mixtures, it is necessary to use a metal or fiberglass plaster mesh.

Additionally

The exhibition of houses “Low-Rise Country” expresses sincere gratitude to the specialists for their assistance in creating the material.

– manufacturer of high-quality dry mixtures for construction and repair “StroyMoment”.

Website: stroumoment.ru

Email:

Tel: +7 (499) 705-67-37

Ratings 0

Read later