How much does groove putty cost?

Gating works

| I. Grilling for electrical wiring | ||

| № | Types of jobs | Price, rub.) |

| 22. | Putting plaster mixture on electric grooves up to 20mm on the wall | 20 |

| 23. | Putting plaster mixture on electric grooves up to 40mm on the wall | 30 |

| 24. | Putting plaster mixture on electric grooves up to 60mm on the wall | 40 |

Is it possible to use tile adhesive instead of plaster?

In the Decorative plaster section there is an article about the use of putty instead of decorative plaster. You may have read about the wet façade system, which uses adhesive compounds. Liquid wallpaper also has an adhesive base and is applied like plaster. Why not also use tile adhesive as plaster? When talking about whether it is possible to plaster walls with tile adhesive, one should consider not only the possibility of this, but also the pros or cons of such a solution, since such mixtures are more expensive than plaster ones and have special qualities, nuances of finishing work and operation.

When strictly considering the choice of materials, you need to take into account that each type has its own purpose. Today's building materials are often universal, and home craftsmen will try each type in a non-standard “field.” As a result, it turns out that dough-like masses on various bases, spread on the base, harden, form a coating that serves no worse than plaster.

So, plastering with tile adhesive is possible.

The inscriptions of manufacturers based on cement indicate the same thing. The brand manufacturer Ceresit sometimes mentions on the packaging the possibility of using glue to level the walls. Do not lose sight of the fact that some mixtures are inferior in strength to plasters. Compare technical characteristics, plasters and adhesive mixtures to get a high-quality coating.

Pros and cons of this solution

Let us list the advantages that adhesive compositions have:

- increased adhesiveness, solutions adhere well to concrete;

- being thin, it sticks to the base without sliding down;

- high plasticity, workability;

- the lifespan allows you to work with the material without haste;

- easy to make, easy to apply;

- environmentally friendly;

- resistance to temperature changes,

- mechanical strength comparable to cement plasters;

- rapid strength gain;

- Possibility of use for finishing facades;

- long service life.

In some areas, glue-based coatings as plaster are superior to gypsum compounds and putties. For example, for the bathroom these mixtures are an irreplaceable material. They do not peel off, are not destroyed by impact or pressure, and do not allow moisture to reach the walls. While plaster is wary of water and easily cracks and bursts upon impact, when applied in multiple layers it can come off layer by layer.

The disadvantages include:

- High price.

- You cannot apply adhesive masses in a layer of more than 10 mm. If more coating thickness is required to level the coating, then it is necessary to apply the mixture several times. Plasters allow the application of layers thicker than 1 cm.

- It is not convenient to work with glue. It is not intended for plastering and sticks to the rule.

Accessories for facade tiles

The presence of components is not typical for all types of facade tiles. Many types of material are laid using conventional technology and do not require additional elements. This situation is typical for small material.

If the elements are quite large in size, then it will not be easy to do without specialized parts. Typically, corner profiles are made that make it possible to carefully line the outer (in some cases, inner) corners of the house .

In addition, fastening elements such as clamps, mounting brackets, etc. can be used as component materials. For some types of material, manufacturers provide for the creation of a subsystem - a supporting structure for installation to form a ventilation facade.

At the same time, most types of tiles intended for dry installation are not strictly tied to the type of subsystem and can be installed on any planks - wooden or metal .

Types of tile adhesive

Developers of adhesive compositions keep pace with chemists, which is why many types of adhesive compositions for laying tiles are produced.

Conventionally, there are types that differ in strength and other properties:

- universal (used for repairs with an average level of tasks);

- moisture-resistant (for car washes, swimming pools, showers, kitchens, where the humidity is above average or the walls are in contact with water), for example, Ceresit SM 11 PLUS;

- reinforced (with increased strength and adhesive characteristics);

- for outdoor use (frost-resistant, withstands repeated freezing);

- for transparent tiles/mosaics (developed on the basis of white cement, therefore they can even be used for finishing);

- heat-resistant (for stickers on stoves, fireplaces).

Moisture-resistant compounds contain substances that prevent the growth of mold and fungi.

There are two forms of release of adhesive compositions:

- dry mixtures in powder form;

- ready-made viscous adhesive masses.

The basis of all adhesive tile compositions is cement. Modern tile adhesives also contain a second binder - polymers, for example, latex, polyurethane. That is, new adhesives are mineral-polymer composites. Filler – sand. 5% of the amount of all components are modifying additives (anti-fungal, anti-frost, moisture-retaining, etc.).

Frost resistance of tile adhesive intended for finishing facades can be 35 cycles. The composition of the adhesive mass determines two important characteristics:

- lifespan (average 3 hours);

- the strength of the resulting connection.

General information

It would seem that each building material has its own purpose, so tiles should be glued with glue, and walls should be leveled with plaster and nothing else. However, tile adhesive even has some advantages over conventional plaster, which we will discuss below.

In addition, many home craftsmen have successful experience in decorating walls with their own hands. But, at the same time, it cannot be said unequivocally that this can be done, since this operation has a number of its own nuances, which are described below.

Leveling the wall with tile adhesive

Today, the choice of building materials in any store is huge. When planning to make a renovation, you don’t need to look for friends who can sell imported wallpaper or scarce tiles from under the counter through connections. And you no longer need to mix cement mixtures yourself.

However, the question is often asked on forums: “Can I plaster with tile adhesive?” As a rule, the reason for such a craving for experimentation is banal savings. Firstly, it happens that tile adhesive costs an order of magnitude cheaper than plaster composition from a good manufacturer. And secondly, if you are going to glue ceramic tiles in the bathroom and have already purchased the necessary materials in stock, then plastering the walls with tile adhesive will help solve the problem of unexpected surface irregularities.

So is it possible or not?

Manufacturers of adhesive compositions based on Portland cement (for example, Ceresit) sometimes indicate on the packaging the possibility of using glue as a leveling material.

Plastering with tile adhesive, as practice shows, is fully justified if you follow the instructions for use (that is, you cannot exceed the thickness of the layer, you must wait until it dries, it is recommended to use a primer before and after application). However, when replacing one material with another, as in the case of using tile adhesive as plaster, you need to remember the differences in technical characteristics. If we compare, for example, tile adhesive SK KUARTZ and the universal TsPS M-150 of the same brand, we will see that the compressive strength of the cement-sand mixture is higher. In addition, the dry mixture is much cheaper. And, by the way, this universal plaster is used no less often instead of tile adhesive.

What if we connect?

The inquisitive mind of folk craftsmen has gone even further: on the Internet you can also find questions about mixing the two above-mentioned compositions. According to the experimenters themselves, the resulting material is resistant to cracking and durable. But the exact proportions of adding glue to the plaster are difficult to determine. After all, it is necessary to proceed from the characteristics of a particular glue and plaster mixture. Therefore, we do not recommend carrying out such tests on the walls of your own home. Especially if you are new to decorating.

Conclusion

Each material is best used for its intended purpose. But if the question arises whether it is possible to use tile adhesive instead of plaster, then our answer is - use it boldly!

You should work according to the instructions. The thickness of the layer should not be thicker than 10 mm; too thick can crack. Finishing is carried out at temperatures from +5°C to +30°C, at normal or low humidity. The working life of the finished test is taken into account. Dilute the required amount of powder.

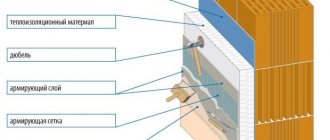

Preparing the base

Old paint, wallpaper, plaster, and dirt are removed from the walls. The strength of the base is checked with a trowel and metal fastening elements are removed. Large potholes and cracks are repaired. Then the surface is primed and a reinforcing fiberglass mesh is attached. For smooth surfaces, select a primer with sand that creates roughness. While the soil dries, prepare the glue.

Preparation of the solution

Add the amount of water indicated on the package to the dry mixture. Craftsmen often mix glue “by eye”. If there is a lot of cement in the mixture, you can add sand or other mineral filler: marble or granite chips of various fractions, small pebbles. The finished solution should be elastic and easy to work with.

Application and creation of decorative coating

To obtain a high-quality finish, the adhesive mixture is applied in small areas. The glue takes a long time to dry, so you can create any texture using a plastic trowel. Immediately apply a thick layer with a spatula, which does not require perfect leveling.

Video of creating a decorative covering from tile adhesive

The plot clearly presents the technological process. You can verify in practice that there is nothing complicated in decorating walls with an adhesive mixture. It is enough to follow the advice of the master.

General information

Mixtures for fixing tiles differ from other building compositions in their increased strength and ability to operate in extreme conditions (high humidity, vibration, temperature fluctuations). Depending on the chemical composition and consistency of the mixture, three types are distinguished:

- dry, cement-based, with resins in the composition;

- dispersive, ready to use;

- liquid nails (polymer base, used for sealing small defects, not plaster).

The cheapest and most popular to use are dry mixes. The consistency depends on the amount of added water and sand, and is regulated by the builders themselves. There are also epoxy mixtures, which contain resins and other synthetic substances that impart greater resistance to external factors and plasticity.

Dispersion adhesives are expensive and dry quickly. High ductility indicators allow the composition to be used under significant mechanical loads. Due to the high cost and difficulties when applying over large areas, it is used only for its intended purpose.

Liquid nails containing rubber are a durable material and are used for working outdoors and not indoors. The packaging resembles a tube with a dispenser. The mixture is immediately ready for use.

It is recommended to use adhesive mixtures for minor amounts of wall reconstruction work, but no more.

The choice of adhesive for its intended purpose depends on the characteristics of the room (humidity, temperature) and the type of surfaces prepared for gluing.

Types of plaster compositions for bathrooms

The modern construction market offers a variety of materials, but it is important to choose the most reliable and durable. After all, bathroom plaster should not only have high resistance to moisture, but also increased strength, elasticity, bactericidal properties, etc. Therefore, to make an informed choice, you need to familiarize yourself with the types of materials, characteristics and features of each of them.

Sanitation mixtures

Bathroom sanitizing plaster is a group of materials with high waterproofing properties for creating a base layer on surfaces before their subsequent finishing. They are also characterized by increased plasticity, but slower setting, compared to conventional cement-sand compositions. Decorative material can be applied over them after 7 days from the date of plastering.

Photo 2. Plastering walls in the bathroom with sanitizing compounds

Today, manufacturers produce moisture-resistant gypsum mixtures that are (supposedly) intended for rooms with high humidity levels. But experienced builders do not recommend using them in bathrooms, and sometimes in kitchens. This can be explained by both the low moisture resistance of the compositions and their low strength characteristics.

Photo 3. Consequences of gluing tiles to gypsum plaster in the bathroom

Facade plaster

In fact, any facade mixtures can be used for plastering in the bathroom, because they are initially produced for use not only in conditions of high humidity, but also temperature changes and other negative atmospheric influences. This determines the possibility of their use in rooms with unstable humidity conditions.

Decorative plaster

Moisture-resistant decorative mixtures are in increasing demand today. The main features are the ability to eliminate small wall defects without prior preparation and create a beautiful textured surface in any color scheme. Despite being waterproof, the plaster has good vapor permeability.

Photo 4. Combined decoration in the bathroom, one wall with tiles, the second with decorative plaster

Leveling walls with tile adhesive

Let’s say that during renovations in the bathroom, tiles were removed from the walls. There is still a layer of the previous tile adhesive on the wall, and underneath (possibly) a layer of leveling plaster. Removing a layer of glue that adheres firmly to the wall requires time, money and effort. After this, you will need to level the wall with gypsum or cement-sand mortar, and then apply a layer of adhesive.

removing tiles from walls

It’s easier and cheaper to use an adhesive mixture to level the wall without removing the old coating, and after drying, plant the tiles on a flat surface using a similar adhesive composition. Plastering with tile adhesive in this case will be cheaper. It will be enough to “correct” individual potholes a little with the adhesive mixture, after drying the “patches”, apply a thin layer of adhesive solution and level it off as a rule.

Video on how to plaster aerated concrete with tile adhesive

The work is performed in a sequence similar to the plastering sequence:

- prepare the base;

- install beacons;

- plastered once or twice;

- dried;

- perform finishing work, for example, gluing tiles.

Preparing the base

Without looking at the increased stickiness of the mass, we carefully prepare the base:

- We remove loose, fragile coating from the walls (we must remove the plaster, as well as paint, peeling plaster, wallpaper, tiles);

- we remove hardware that can become a source of rust; we isolate the remaining parts by painting them with oil paint;

- we clean off efflorescence, grease, traces of grease, soot (we remove everything that reduces adhesion);

- we repair cracks, chips (large potholes, cracks, primed, repaired with the application of a reinforcing mesh);

- remove dust;

- cover with a primer, selecting the product according to the base material (2-3 times with drying after each);

- if necessary, install reinforcing mesh;

- We set up beacons.

priming walls before plastering

Large cracks or potholes are repaired with mortar.

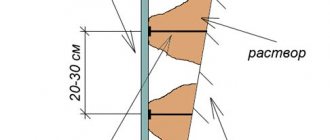

Installation of beacons

Beaconless methods can be used to level small depressions. For example, after applying the mixture, you can level it with a wide spatula or a scraper rule. But if leveling requires applying layers thicker than 6 mm, then beacons are used. Beacon strips are installed using a level using a certain technology. First, measurements are taken of the wall and the most convex point is identified. If it is not possible to knock down the protrusions here, then this point is taken as a reference point for constructing an auxiliary plane of beacons.

installation of beacons

Beacon strips can be made independently from a solution, for example, gypsum, using string beacons or standard metal beacon profiles. The distance between the beacon slats is selected from a meter to one and a half (depending on the length of the rule).

Since tile compounds are more viscous (sticky) than plaster mortar, it is generally more difficult to level them. Therefore, it is better for beginners to use a shorter tool (rules with a meter bar).

Beacons can be installed horizontally.

Preparation of the solution

Like plaster solutions prepared from dry mixtures, adhesive masses from dry powders are prepared following the instructions.

- Pour the mixture from the package (the required amount) into a container with warm water.

- Using a mixer with a nozzle, mix the components for 3-4 minutes.

- The composition is allowed to mature for 10 minutes.

- The mixing procedure is performed again.

Before work, it is recommended to find out the lifespan of the composition so as not to prepare more solution than you have time to produce.

The glue is sealed just before use. The finished composition should be covered with a lid during breaks, avoiding prolonged contact with air. The remainder of the dry mixture is sealed and stored in a dry pantry.

How to plaster with tile adhesive

Plaster the wall with tile adhesive following strictly according to the instructions printed on the packaging. Adhesive solutions containing cement as a binder work under the following conditions:

- the air temperature should not go beyond +5 - +30°C;

- the proportion of mixing water is no more than that specified by the manufacturer;

- layer thickness – no more than recommended 10 mm (see instructions);

- the diluted composition is not rejuvenated (you need to be ready to work out the prepared dough in 20 minutes);

- Each applied layer is dried before applying the next one (if tiles are not glued to it);

- some adhesives have restrictions in use or special conditions, these conditions must be met, or select a different type of adhesive;

- when applied in a layer of more than 10 mm, the hardening mass can crack; sometimes adding sand helps (but it is better not to exceed the specified thickness);

- An intermediate application of primer between coats is also recommended.

Tile adhesives are not originally intended for plastering, so the composition is usually rich (large proportion of cement), while plastering requires thinner mixtures. To make the adhesive composition suitable for plastering, sand is added. If the solution sticks too much to the trowel, it’s time to reduce the fat content.

It usually takes a day to completely harden.

The adhesive composition, unlike the plaster composition, shrinks. Having used it for leveling, you can observe the appearance of “craquelure” honeycombs when applying a primer to it before gluing the tiles. This is how the glue swells, having absorbed some of the moisture of the primer. This “decoration” will disappear when the primer mixture dries.

Tile laying technology

The tiles are laid from the bottom up in the direction corresponding to its design (especially if there is a hidden seam). The glue is applied with a notched trowel to the surface of the wall and to the tile, and the direction of the glue strips should be transverse - if the lines on the wall are horizontal, then on the tile they are vertical.

NOTE!

For most types of tiles, pre-soaking is not necessary, but the porous surface of the base must be moistened with water.