Composition and properties

The basis of aerated concrete adhesive is high quality cement and fine sand. High strength and moisture resistance are ensured by special polymer additives (plasticizers) and mineral components included in its composition.

Thanks to additional elements, the adhesive mixture has the following properties:

- excellent thermal insulation, which prevents freezing of load-bearing walls, since the glue is applied in a thin layer and is not inferior in thermal conductivity to aerated concrete itself;

- moisture retention, so the mixture dries evenly and the seams never crack;

- high adhesive strength of materials (adhesion), which is provided by the polymers included in the composition;

- after hardening, no shrinkage occurs;

- excellent plasticity - when applied to the surface, it fills all the pores and voids present in the concrete, which increases the strength of the structure.

The aesthetic side plays a big role - seams made from the adhesive mixture are thin and neat, unlike seams made from cement mortar, which are always rough and thick, and such walls require additional finishing.

Masonry with cement mortar Source avatars.mds.yandex.net

Masonry with adhesive mixture Source avatars.mds.yandex.net

Popular manufacturers and brands

- Colmix. Produces Stroy Moment SMK-10. Used in winter. Contains antifreeze additives. Consumption of approximately 20 kg of substance per cube of cellular concrete.

- Volma. Produces an adhesive called Blok.

- Henkel. The company produces Ceresit brand mixtures. There are formulations for winter and summer use.

- Craps. Kreps KGB mixture is produced. Can be used in winter, but at temperatures not lower than -10°C. Apply a layer 2 mm thick. After preparing the working solution, it can be used for another 4 hours.

- Aerok. Cellular concrete with glue from this manufacturer can be laid in winter and summer. Operating temperature from -15°C to +35°C. Consumption per cubic meter is approximately 15-18 kg, when applying a 3 mm layer.

Before you find the desired adhesive mixture, you need to understand the characteristics of their composition and operational differences.

| Brand name | Technical description |

| The main component is cement with polymer additives. There is a separate option for summer and winter construction work. The optimal layer thickness is limited to 1-3 mm. After drying, it is not afraid of moisture and severe frosts. |

| Most often used for porous surfaces. Laying should be carried out at a temperature not lower than 5, but not higher than 25 degrees Celsius. The finished object is able to withstand temperature changes in the range from -30 to +70 Celsius. Once prepared, the solution must be used within the first 4 hours. |

| Can be used for both internal and external masonry using grooved and grooveless gas blocks. It is considered a beneficial economical option for thin-seam laying of partitions. Plastic and frost-resistant. |

| It is characterized by a gypsum binding composition and has increased adhesion. Used for leveling surfaces. Environmentally friendly composition. |

| Cement serves as the base, and organic modifiers and fillers allow the use of glue under conditions of thin-layer masonry with maximum thermal insulation. For example, adhesive for aerated concrete blocks Ceresit ST21 is better suited than others for working with cellular concrete. |

| It features an environmentally friendly composition without toxic additives, which is suitable for external and internal work. |

| One of the best solutions when working with porous aerated concrete. Increased adhesion is due to the presence of polymers, and plasticity is due to modifying additives. An important feature is that the position of the blocks can be adjusted after installation within 20-25 minutes. |

| High quality results of winter work at a relatively affordable price. Dried seams remain invulnerable to atmospheric factors, which means there is no risk of cracks appearing in the seams. Easy to apply. |

| The presence of special modifiers in the composition determines the frost resistance of the solution. Can be used for all types of blocks as well as slabs. |

| It is used in thick-layer aerated concrete masonry methods at any operating temperature. Also suitable for leveling walls and for laying ceramic tiles (finishing). |

| It is distinguished by its multicomponent composition, where, in addition to cement and polymers, there is also quartz sand. The identical composition of aerated concrete blocks allows the creation of monolithic reinforced structures. |

| The adhesive solution is used to increase the thermal insulation properties of masonry and protect walls from freezing. Can be used both in winter and summer. It is resistant to moisture and sudden temperature changes, and is plastic. |

Only if you follow the correct storage of the adhesive mixture and the procedure for preparing the solution can you count on a high-quality masonry result. Adhesive foam is used for small-scale repair work.

What is

Glue for aerated concrete blocks is produced in the form of a dry powder, packaged in paper bags, usually 25 kg. Each manufacturer indicates how much liquid is required to prepare the solution; it is important to strictly observe the proportions so that when mixing the glue does not lose the necessary qualities. On average, 1 bag contains about 5.5 liters of water.

The glue must be stirred in portions, it hardens quickly Source vanna-prosto.ru

Types and types of glue

For laying aerated concrete blocks, 2 types of adhesive mixtures have been developed:

- Thin layer adhesive. It is used for laying gas blocks that have a flat surface or slight deviations from the geometric shape. It is applied in a thin layer of 2.5-4 mm - this thickness is enough to ensure high adhesion strength.

- Thick layer adhesive. Its masonry joint has a thickness of 10-15 mm. Used when laying materials with uneven surfaces and chips. Using the thickness of the seam, the blocks are leveled in height, and existing defects are reduced to a minimum.

According to technical characteristics, glue is produced in 2 types - winter and summer.

See also: Catalog of house projects made from aerated concrete blocks

Winter glue

The winter type contains special modifiers, which increase the frost resistance and plasticity of the mixture. It takes longer to dry than summer, but the high adhesive strength is maintained.

Laying can be carried out at air temperatures down to -10-12 C. These qualities are especially valuable for regions with a harsh climate, where winter lasts 6-9 months. Frost-resistant glue is universal - it can be used at any time of the year.

This is what a seam made from winter glue looks like Source nedvio.com

Summer glue

Summer glue is made from Portland cement, which is white in color. After hardening, seams made from this glue do not darken and remain white, the walls look neat and there is no need to apply additional finishing.

This is what a summer glue seam looks like Source montazheco.ru

See also: Catalog of companies that specialize in facade materials

However, summer adhesive mixtures can be used at air temperatures not lower than +5 C. At temperatures +4 and below, the glue loses its elasticity and adhesive properties.

Reference ! Gas silicate blocks are a building material that belongs to the class of cellular concrete. Despite the fact that with aerated concrete they are different in composition and production technology, the adhesive for aerated silicate blocks is usually used the same as for aerated concrete blocks.

Masonry made of gas silicate blocks Source i1.photo.2gis.com

TOP 10 best brands of glue for gas silicate blocks

To choose a good option and not make a mistake, you need to focus on the rating of glue for gas silicate blocks, which we have prepared especially for you. There are many current offers on the market, and below is a list of the most popular brands of dry concentrate.

Zabudova

A universal mixture, often used for use in winter. It contains a special substance that prevents freezing even at very low temperatures. According to reviews from builders, this glue is easy to apply. In addition, the product has a fairly low competitive price, thanks to which it is very popular in the market. Most consumers believe that this is the best adhesive for gas silicate blocks!

Prestige

This domestically produced composition is also resistant to frost. Suitable for laying cellular blocks and whole slabs. The advantage of this option is the speed of preparation. However, the price of Prestige is slightly higher than that of Zabudov.

Bonolit

Another winter option for concentrate. It is valued for its environmental friendliness - the adhesive for gas silicate blocks "Bonolit" does not contain toxic substances. It is absolutely harmless to health. Accordingly, the cost of such glue is higher than that of competitors in this segment.

Eunice Uniblock

This glue has gained great demand due to its inherent advantages:

- excellent thermal insulation characteristics;

- increased moisture resistance;

- resistance to temperature and pressure changes;

- environmental friendliness, absence of harmful impurities;

- durability and high strength of masonry;

- The optimum ratio of price and quality.

AEROC

A distinctive feature of Aeroc adhesive concentrate is its increased installation strength. Also suitable for cellular blocks. The application technology requires low consumption - a very thin layer of this polyurethane adhesive (from 1 to 3 mm) will provide good adhesion for the walls.

Among the advantages of Aeroc are also its vapor tightness, moisture and frost resistance.

The finished composition is suitable for use within two hours, unlike glue from competing companies. But its cost is much higher.

Will win

A multicomponent mixture, this adhesive for gas silicate blocks contains cement, quartz sand and modifiers. The distinctive properties of Pobedit are its manufacturability and plasticity - it does not form a sticky layer on tools, hardens quickly and is not susceptible to moisture. The price of such mounting adhesive is low.

Aerostone

Concentrate with a cement base and polymer substances in the composition. The manufacturer (Dmitrovsky plant) produces glue in two versions of Portland cement - gray and white.

Ilmax 2200

This option is used for laying porous blocks - gas silicate, foam concrete, expanded clay. Has increased resistance to frost. This mixture can be used in the temperature range from +5 to +25°C, and the performance characteristics allow the mixture to remain unchanged at temperatures from +70 to -30°C. The prepared composition can be used within 4 hours.

CERESIT ST21

The most famous construction brand. Ceresit supplies high quality mixtures for a wide range of construction work. The composition of the adhesive is cement with the addition of organic modifying substances and mineral fillers. It involves application in a fairly thin layer, which makes this mixture option economical.

KNAUF LM 21

Another well-known manufacturer of building materials and dry concentrates. The composition for gas silicate blocks from the Knauf brand has a gypsum base that provides a strong, hermetically sealed connection. Also, Knauf mixtures are environmentally friendly, easy to prepare and apply. And the world famous brand and impeccable quality make the price of this product high.

In the construction of modern buildings, block technology is increasingly used. To achieve optimal adhesion of gas silicate, it is necessary to choose an adhesive that meets all quality requirements and not make mistakes in calculating the quantity. By observing all the parameters necessary for working with the concentrate, as well as the manufacturer’s instructions, the finished masonry will be durable and strong under any operating conditions. And remember that the cost of glue for gas silicate blocks is not responsible for its quality!

How to prepare glue

Before you start preparing the adhesive solution, you should carefully study the manufacturer’s instructions, which indicate the required proportions for this type of product. In order for the adhesive mixture to be of high quality, it is important to follow these rules:

- The water for mixing should be warm.

- The dry mixture is poured into water, and not vice versa (then the mass will be homogeneous, without lumps).

- To obtain the mixture of the correct consistency, use a construction mixer operating at low speed.

- If work is carried out in winter, the glue must be mixed in a heated room, and it must have a temperature of at least +10 C.

- Do not use the mixture for longer than the specified time - the working time with summer glue is 30-40 minutes after mixing, the winter composition must be used within 2-3 hours.

Professionals prepare the solution in 2 stages - after the first kneading, wait 2-3 minutes, then knead again and begin applying to the surface of the blocks.

Attention ! The surface of aerated concrete blocks must be cleaned of dirt and dust, otherwise the adhesion will not be strong.

Mixing the adhesive mixture using a construction mixer Source www.accbud.ua

Glue consumption per 1 m3

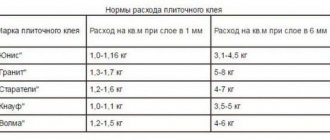

On the packaging, the manufacturer always indicates the glue consumption for aerated concrete blocks per 1 m3. On average, it is 20-25 kg per 1 m3, if the seam thickness is 2.5-3 mm. The following factors can increase consumption:

- weather conditions - in winter, consumption is always higher than in summer;

- incorrect calculation of the amount of solution - if the mixture has hardened, it can no longer be used;

- unprofessionalism of builders - inexperienced craftsmen can significantly increase the developer’s costs by applying an excessively thick layer of glue to the blocks.

To reduce the consumption of glue for aerated concrete blocks by 1 m3, it is important to choose high-quality building material for construction - the smoother the surface of the block, the less glue needs to be applied for strong adhesion.

How to lay aerated concrete blocks - step-by-step instructions

Laying walls made of aerated concrete blocks is somewhat different from work carried out using sand mortars. The main rule that is observed during work is to apply the adhesive only to a carefully prepared surface of the block. It should be free of dust, ice and other foreign substances. The main stages of work consist of the following steps:

- inspection and cleaning of blocks,

- preparation of adhesive composition,

- applying the solution to the blocks,

- installation of blocks and their alignment,

- cleaning masonry from excess glue.

It is worth noting that preliminary moistening of aerated concrete blocks during work is not required. However, in hot weather it may be necessary to slow down and stabilize the hardening of the mortar. It is advisable to cover the finished masonry with a tarpaulin or burlap until the glue has completely set.

Adhesive foam for aerated concrete blocks

As an alternative to dry adhesive mixtures, specialists have developed polyurethane foam adhesive for aerated concrete.

Cylinders with glue foam Source avatars.mds.yandex.net

Foam adhesive is a foaming mass that is packaged in sealed containers. A construction gun is used for application.

Composition and characteristics of foam adhesive

The basis of the glue in the cans is polyurethane, which is foamed using a gun. It is a moisture-resistant polymer known to be durable and resistant to acids and oils. Foam adhesive creates a rigid and durable attachment, while being heat-resistant.

Briefly about the main thing

Adhesive for aerated concrete blocks is a modern alternative to cement mortars, as it surpasses them in chemical properties and technical characteristics.

Glue for gas blocks is available in summer and winter. The choice should be made taking into account the climate of the region and the season of construction work.

Foam adhesive in cans has high adhesive strength, but is only suitable for working with even blocks and for 1-2 storey buildings.

Ratings 0

Types of glue for gas silicate blocks

Dry adhesive concentrates for gas silicate are divided into two types. Depending on the season in which the masonry is supposed to be laid, white and gray mounting adhesive (the color of Portland cement) is available on the market.

What kind of glue are gas silicate blocks placed on?

- White type (is summer). Suitable for use in the warm season. The main advantage of white Portland cement adhesive is its aesthetic appearance when cured. Therefore, this composition is also used for interior work in order to save on finishing.

- Gray look (traditionally an option for winter). However, its application is universal - it is perfect for masonry at any time of the year. The gray Portland cement composition has anti-frost functions and can be applied at temperatures down to -10°C.

In order to avoid cracks and errors, experts recommend using a frost-resistant composition in the temperature range from +5 to -15°C.

Gray glue concentrate is more finicky to work with, unlike the summer version. To achieve optimal masonry strength, certain recommendations should be followed:

- Bags with dry composition must be stored in heated rooms.

- The solution should be applied in a warm room, diluting it with water at room temperature (not lower than +20°C).

- The temperature of the finished composition for application should not be lower than +10°C.

- The prepared composition is suitable within half an hour.

When laying gas silicate blocks with glue in the winter, the finished fastening must be covered with dense PVC material or tarpaulin to prevent deterioration in the quality of the seams when moisture freezes.

Another option for glue offered on the market is foam glue in cans. When applying this composition, a special construction gun is used.