Not every object can be painted with the usual tools, such as a roller or brush, and sometimes it is not even possible to use professional compressor equipment. In this case, an airless paint sprayer is used. This equipment allows you to positively influence the efficiency of the process, so it is often used in industrial production, for painting vehicles and in car repair shops.

What is an airless spray gun

An airless paint sprayer is a device that operates on the principle of spraying liquid mixtures. Thanks to its characteristics, the coloring composition is evenly distributed and dries in the shortest possible time.

The main advantage of this unit is the high-quality result and the absence of difficulties during operation. This contributes to the widespread use of the device in enterprises and for domestic needs.

The main advantage of this unit is the high-quality result and the absence of difficulties during operation.

Advantages of airless painting

- Provides material savings. Moreover, the rationality of the method consists not only in fewer paints and varnishes. Each layer of paint becomes thicker, which means fewer layers need to be done.

- An airless sprayer prevents excess paint from being sprayed into the environment, thereby reducing overall pollution.

- Thanks to the high spray speed, small foreign particles and air do not have time to get into the paint.

- Coloring occurs evenly.

- The painting process takes less time.

- Convenient when covering large areas, the result is savings in effort.

- Reducing the amount of solvents used in the paint and varnish composition, since the painting apparatus can work with thick compositions.

- An electric paint sprayer does not require a compressor.

Types of devices

A spray gun is a device for quickly painting a surface. The dyeing apparatus is of the following types:

- Manual unit powered by electricity. Manual painting equipment is small in size, but very effective, and it does not require a lot of paint when refilling. All these advantages make it popular for a variety of jobs, but such a device is not intended for painting a large area;

- Stationary device. This unit is used mainly by qualified specialists for painting large-scale objects and complex parts. Since this equipment requires a large amount of paint, it is most often used in production.

A spray gun is a device for quickly painting a surface.

Description of the technology principle

This type of coloring involves the use of a special device with which the dye is applied to the plane in the form of a stream. The paint is crushed without compressed air, which is why this technology got its name.

The essence of painting is as follows:

- Painting materials are sprayed using hydraulic pressure;

- the dye mixture is brought to the spray nozzle and flies out from there at high speed;

- particles of the working composition slow down due to the hydrodynamic effects of the environment;

- the paint applies to the surface much more economically and evenly than when using a standard spray gun.

Airless spraying is mainly used to treat large structures and large surfaces. Using a spray gun, you can easily apply fire-resistant, textured, alkyd and latex compounds, as well as primers when processing concrete, wood, metal and other materials.

Design and principle of operation of the device

The painting apparatus operates both pneumatically and electrically, is equipped with an upper or lower tank, and in some cases the coloring solution is supplied from a pump. The principle of operation of an airless sprayer is as follows: pressure squeezes the paint composition into the hose through a small diameter nozzle, and then a clearly marked spray occurs. The unit is excellent for painting plastic and aluminum products. The safety of workers during work is guaranteed by the safety system built into it.

The presence of a filter eliminates the possibility of equipment breakdown while working at a dusty or dirty site. The basis of the device is an electric motor, which supplies the coloring composition to a cylindrical cermet nozzle. The safety bracket protects the device from unplanned start.

Varieties:

- Due to its compactness, the electrical apparatus is usually used for domestic needs;

- The most efficient unit is one that runs on gasoline. The downside of the device is the exhaust;

- The pneumatic device is intended for production.

The safety of workers during work is guaranteed by the safety system built into it.

Application area

Equipment such as a high-pressure airless spray gun is widely used in large enterprises where there is a need for regular painting of large objects without small elements.

The scope of application of such coloring extends to the following industrial productions:

- Car service;

- Automotive factories;

- Car parks;

- Furniture workshops;

- Enterprises for the production of windows and doors;

- Railway service;

- Shipbuilding.

The scope of application of this coloring extends to automotive service.

Pros and cons of an airless spray gun

An airless compressor for painting evenly distributes the paint and varnish over the surface, thereby increasing the quality of the coating. The pressure action allows the paint splatter to move through the air without turbulence, improving performance.

The main advantage of this method is the saving of paints and varnishes and time. In addition, no special surface preparation is required.

The disadvantage of working with a spray gun is the inability to paint a surface whose shape has complex elements, otherwise the product will be painted unevenly. So, the convex parts of the surface will have beads, and the smaller elements will become shagreen.

Upon completion of work, the equipment must be completely cleaned, otherwise it will adversely affect the quality of the coating.

An airless compressor for painting evenly distributes the paint and varnish over the surface, thereby increasing the quality of the coating.

The working process

To use this spraying method, the equipment must be set up correctly. Otherwise, the desired result cannot be achieved. Before work, it is necessary to adjust the spray gun and be sure to check its effect on a newspaper or sheet of paper. To do this, you need to pull the trigger and try to spray the composition. Once large streaks of paint form, you should stop pressing and observe their condition.

Spray painting process

If the device has been configured correctly, excess paint will begin to flow down evenly. If uneven spreading is detected, it is recommended to change the consistency of the mixture or the pressure in the spray bottle. If heavy drips appear during operation, you need to reduce the pressure. If the paint spot is not bright enough, then you need to make the material less viscous, preferably using a solvent. After this, you can start working directly.

Professionals recommend tilting the spray gun to the right, left, and also lowering and raising it. This method will allow you to achieve high-quality painting of any element. After completing all the work, it is recommended to clean the equipment thoroughly so that even small grains are not left in it. After cleaning, it must be lubricated with a special product that should not contain silicone.

Which spray gun is better: air or airless

Many people are interested in whether an air or airless spray gun is better. This issue can be resolved by considering the advantages and disadvantages of each type of instrument.

Aircraft:

Spraying the paint mixture treats the surface in a thin layer, creating a high-quality coating. The disadvantage of this type of painting is the low pressure, which does not allow the jet to reach the desired area.

Spraying the paint mixture treats the surface in a thin layer, creating a high-quality coating.

Airless device:

High-pressure airless machining freely applies paint, thereby increasing painting performance. The disadvantages of airless painting include the inability to process complex surfaces, because with this method of painting the structural parts will not be completely painted.

Scope of application of air tools. The device is intended for small production, where there is a need for frequent replacement of the mixture, and a high-quality result is required. An airless spray gun is used primarily in large-scale production for products of simple shapes.

High-pressure airless machining freely applies paint, thereby increasing painting performance.

Advantages and characteristics of paint spraying equipment

Many surfaces in domestic or industrial conditions can be painted manually. However, the result will most likely leave much to be desired. Airless painting has the following advantages over manual application of the composition:

- very high labor productivity, automatic equipment allows you to increase the speed of work several times;

- making a high-quality layer on the surface of the part and eliminating the heterogeneity of the substance on the surface;

- the ability to paint surfaces in hard-to-reach places thanks to spraying the composition to the smallest splashes;

- the absence of streaks and stains is achieved due to the fact that the tool does not come into contact with the surface.

If you choose the wrong tip for the device or set the wrong spray speed, there may be a risk of leaks and sagging. They can also appear when painting parts of complex shapes. With careful adjustments this will be completely unnoticeable.

When choosing a device, it is important to pay attention to the tightness of seals, channels and cavities. This will avoid leaks. The connection point between the device and the hose must be equipped with a rotating mechanism for ease of operation.

Useful! It would be useful to have a blocking shut-off valve and an additional fine filter.

How to choose the best airless spray gun

Many people are concerned about which device is better; maybe it’s worth purchasing a cheaper option or it’s better to give preference to an expensive model. First, you should study the assortment, considering the highest quality and most popular options.

If you plan to use equipment to carry out large-scale work, then you should choose products from well-known, well-established manufacturers, for example, spray guns from Bosch.

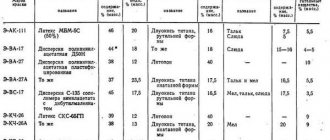

Professional equipment always has a large diameter. Bosch brand devices are designed for spraying 200-500 ml/min. It is also worth taking into account such characteristics of the units as the maximum possible viscosity of the paint, so for a water-based emulsion, a tool that can apply 50-80 Din paint and varnish is suitable.

When using a do-it-yourself airless painting machine on small surfaces, a tool equipped with a nozzle with a diameter of less than 0.8 m from well-known foreign manufacturers Bosch or Wagner, or a domestic model, will be sufficient.

It is worth choosing products from well-known, well-established manufacturers, for example, spray guns from Bosch.

Equipment selection criteria

When choosing a tool, you should consider the diameter of the nozzle. Thus, products with a torch diameter of less than 80 cm, consuming a minimum of paint and varnish mixture, and a power of 400-1000 W are suitable for household use, and professional devices with a paint and varnish consumption of 200-500 ml/min are suitable for enterprises.

For water emulsion you will need a tool with a power of 50-80 Din.

Another indicator is a comfortable handle, a spray power regulator, components for the nozzle, and it is also desirable that the noise level of the device be minimal.

When choosing a tool, you should consider the diameter of the nozzle.

Famous manufacturers

The most popular products from foreign companies are represented by the Bosch and Sturm brands; among domestic manufacturers, the most popular brands are Kalibr, Zubr, Grako and Wagner. Each of these brands produces both a line of professional equipment and devices for household use. When working with a water-based mixture on small surfaces, models with low power produced by the German company Bosch and the Wagner brand are sufficient.

The most popular products from foreign companies are represented by the Bosch and Sturm brands.

Technical information

In fact, the operating principle of an airless spray gun is not as complicated as it might initially seem. A conventional pump, powered by an engine, supplies liquid material through a special hose to the device. There, the composition is divided into microscopic particles, after which it falls under pressure onto the surface to be finished. (See also the article Finishing with decorative plaster: features.)

The basic operating diagram is presented.

Requirements

When processing large objects, it is difficult to maintain a certain distance between the surface to be painted and the gun, therefore, in such cases, special nozzles should be used, the price of which is low.

Other requirements for the equipment are presented below.

- The tightness of channels, seals and cavities must withstand pressure from 25 to 30 MPa to prevent leaks.

- The connection of the hose to the gun should be made using a rotating mechanism, which will make it possible to rotate the tool.

- The presence of a device designed to block the shut-off valve is a prerequisite, because there is always the possibility of accidental pressing.

- The equipment must be equipped with a replaceable fine filter, otherwise frequent blockages are possible.

This is what a fine filter for a spray gun looks like.

Attention! It is recommended to install a special plastic nozzle on the head of the device to protect your hands from accidental contact with a jet of paint and varnish material.

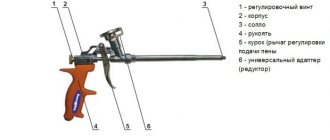

Device structure

- The sprayer body is most often made of plastic or aluminum, since these materials can withstand chemically aggressive environments. This element contains the remaining parts.

- The safety system ensures safety when using this tool. Thus, the master will be protected from accidental actions.

- A fine filter is necessary to protect against the penetration of very small dust particles. This makes it possible to extend the life of the equipment and prevent clogging.

- The handle is an important part that is needed to hold the device. Ease of use depends on its shape. Its length should not be less than 15 centimeters.

- The rotating mechanism is a small drum with which you can perform rotational movements when working with airless equipment.

- The safety guard acts as a safety feature that can prevent the trigger from being pulled unintentionally, such as when the pistol is dropped.

- The trigger powers the device. To begin the painting process, you need to press down on the bottom of the part until it touches the handle.

- The safety nozzle is also related to safety precautions and therefore must be used during operation. With its help you can close the main rod.

- The nozzle is a cylindrical product that performs an essential function. The spraying efficiency depends on its geometry. The rod is usually made from a metal-ceramic alloy.

- The nozzle cleaning device allows you to quickly remove dried composition, which is required in some cases.

Read also: How does an electronic injection pump work?

The structure of a device for applying paint.

Drive types

There is a classification of such devices, which is based on the energy used for the operation of the device. The choice is usually made depending on the conditions of use. In some situations it is convenient to use one model, and in others it is convenient to use a completely different one. (See also the article Types of finishes: options.)

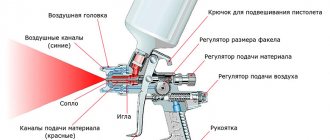

Product drawing with pneumatic drive.

- The airless electric spray gun is powered by a mains voltage of 220 or 380 volts. It is characterized by mobility and high efficiency in the presence of power lines. Disadvantages include the inability to carry out work in fire hazardous areas.

- The gasoline unit operates on a combustible mixture. It allows you to carry out painting operations where there is no electricity, which means it is an autonomous device. However, during operation there is a need to remove combustion products.

- The pneumatic analogue is more often used in industrial sectors for processing large-sized structures where there are problems with exhaust. Paint coatings can be applied even indoors, observing safety precautions.

Diagram of the electrical product.

Important! Modern models of spray guns for painting have a set of adjustments that simplify the work. These settings include: changing the speed mode of the piston, setting the amount of material supplied and the shape of the jet.

Working with an airless spray gun

First of all, the base is prepared; for this, old paint and dirt are removed. Then the tool is set up, for this purpose paint and varnish material is poured into the tank, the mode is adjusted and the device is checked.

The functionality of the tool is checked as follows: press the start button and spray directed at a cardboard sheet located vertically relative to the jet. If vertical streaks form on the sheet, this means that the tool is not configured correctly, which means that the consistency of the coloring composition needs to be changed. For large drips, it is necessary to reduce the spray power. If the color is too rich, the mixture must be diluted with a solvent.

During operation, the tool must be kept at its original level. After painting each area, the surface is checked. When the device is switched off, the pressure is released using a lever. Upon completion of work, the device is cleaned.

After painting each area, the surface is checked.

Of course, an airless spray gun is an excellent solution when carrying out construction and repair work, both at the enterprise and at the household level. However, it should be borne in mind that not all models of this equipment are intended for beginners. Also, when purchasing a tool, you should take into account the volume and complexity of the work performed. However, working with such a device is much easier, faster, and most importantly, the result will be much better.