Once upon a time, carrying out major renovations in a private house or apartment required a lot of time: saving the required amount, selecting high-quality materials, hiring professional workers. Today, everyone can cope with this task on their own. Practical sheets of plasterboard are best suited for repairs and insulation of premises. Various interiors, expressiveness of rooms - your imagination is limitless. The easiest way to make partitions is from gypsum plasterboard. But, unfortunately, after installation, the sheets of drywall will not create a pleasant atmosphere in your apartment - existing chips, cracks, joints, and protruding screw heads will spoil the overall picture. But there is a way out - putty. A high-quality putty will solve all the problems that arise. The question arises - how to putty drywall ?

Why putty drywall?

Nobody wants to work extra hard, waste precious time on unnecessary work, so we often wonder - is it possible to do without finishing putty, because it is much easier to putty only with rough putty? Yes, in some cases it is possible, but not in all.

Every time after working with drywall, we have to seal the joints, hide the screw caps, and smooth out any unevenness that arose during installation. Also, long-term storage of gypsum boards or improper transportation can also make their own adjustments.

, which is one of the flagships of our market for the production of drywall, makes it possible to avoid puttying gypsum board sheets when using them under wallpaper or tiles, not counting only the corners, joints and the screw heads themselves.

They achieved this goal with the help of a special primer - water-dispersion paint diluted with water. This primer on the surface of the sheet being processed turns into a thin film layer that combines perfectly with any type of adhesive, and also protects the drywall from damage if the wallpaper breaks.

Therefore, the question of how to putty drywall is irrelevant if you choose.

How to prepare walls

First of all, it is necessary to inspect the surface of the plasterboard walls. Make sure that each self-tapping screw is screwed in well and that the head does not protrude on the surface. Often this is simply not noticed, and as a result, red spots can appear through the finish. Check the degree of screw-in of the screws using a spatula. They are used along all the seams and joints where the screws are located and you will undoubtedly feel if one of them protrudes a little. The protruding screw needs to be screwed in deeper. They are usually embedded 1 millimeter into the drywall.

Do-it-yourself plasterboard partitions: step-by-step instructions

Screws that are screwed in very deeply must be twisted, since under a certain load on the drywall they will not be able to hold it properly. Remember - the screws must be inserted to a depth of no more than one millimeter so that the integrity of the cardboard layer is not compromised. Check drywall walls for dents, deep scratches or other defects. These places need to be puttied more carefully until the wall surface is leveled.

Each subsequent layer of putty must be applied after the previous one has completely dried.

Using a primer for gypsum boards

There are a number of significant advantages to drywall primer. Firstly, it helps adhesion of adjacent materials, which greatly reduces the occurrence of bubbles and peeling of wallpaper or tiles. Secondly, it is distributed evenly over the entire surface, which helps reduce material consumption.

Primer is always used when finishing rooms, especially when working with drywall, because with its help we improve adhesion with putty and reduce glue consumption when gluing wallpaper. In addition, a primer is also used after the starting putty, so that the finishing layer will stick better, otherwise you may encounter some problems, such as rolling or falling off.

It is best to choose primers depending on the type and stage of work. It is better to use putties that have deep penetration properties.

Step-by-step instructions for performing the work

When you have finished installing plasterboard sheets , you will have to further finish them. If you plan to paint, puttying the drywall should be done in at least two stages.

The technology for puttingtying drywall is as follows:

- Be sure to apply a primer with deep penetration properties to the drywall.

- We seal the holes left by the screws.

- We putty the joints.

- We putty internal and external corners.

- Apply primer for gypsum boards.

- Finish the surface with starting putty.

- We sand the rough edges.

- Apply primer to drywall.

- Puttying with finishing composition.

- We cover the walls with primer for final work.

And now we’ll find out what kind of putty to putty on drywall. Both polymer and gypsum are used. Polymer putties are used for final finishing, as they help level the surface. Gypsum, on the other hand, can be both starting and finishing, depending on the size of the grains.

Putty for drywall comes in different types - ready-to-use, or dry, requiring dilution with water. Of course, it is better to use the first one, so you are guaranteed to protect yourself from lumps that can arise if the dosage is not correct, but it is also much more expensive.

Tools and materials

Before starting work, you need to prepare the following devices:

- putty knife;

- paint bath;

- grater;

- sharp painting knife.

The main thing in this matter is the spatula. Without it, do-it-yourself drywall putty for painting is simply impossible. Its width should be 50-60 mm, then it will be possible to work out the joints and crevices, since a lot of putty will be required. To reinforce and putty seams, you need to take a wider tool. To apply the finishing putty, use the largest spatula up to 500 mm wide.

The tool must have a perfectly flat surface. Otherwise, the applied composition on drywall will form an uneven surface, making it visually unattractive.

Also, the spatula must be completely clean, free of dust and other contaminants. Preparing drywall for painting requires a certain order of work. Below we will consider this process in detail and step by step.

Prime the surface

Even before puttying, you need to prepare the surface of the drywall in advance as a dry and clean material. We remove dust and various contaminants using a vacuum cleaner or a damp cloth. Prepare the primer and lubricate the walls using painting tools.

For rooms with high humidity, it is recommended to choose a special primer to prevent the formation of mold.

Basically, drywall is primed with one layer, but if necessary, it can be duplicated, as, for example, in the kitchen or bathroom. The following finishing steps can be started only after the applied layer has dried.

How to mix putty correctly and quickly

To make a high-quality putty mixture, you will need a drill with a mixer. A mixer is a special attachment with which the entire mass of water and dry mixture will be mixed. Pour water into the bucket approximately to the middle and pour out the dry mixture so that its level is slightly higher than the water level. Using a drill with a mixing attachment, we begin to mix everything thoroughly.

If you see that the putty mixture is too liquid, then you need to add more putty into the bucket. The mixture must certainly be neither thick nor liquid. It should stick to the spatula and at the same time be elastic. If you make a thick mixture, it will be harder to work with and your hand will get tired.

DIY plasterboard ceiling installation

Seal seams and screw heads

To seal seams, special compounds Fugenfuller, Knauf Uniflot, Knauf-Fugen, as well as their analogs are used. These types of putties dry out very quickly, so it is recommended to dilute them in small doses.

It is best to apply the putty with a small spatula on the heads of the screws; at the same time, you can cover the seams.

The edges of gypsum boards have their own characteristics: along the edge the edge is thinned, and across it is straight. Of course, butt joints are somewhat more difficult to seal, but more on that later.

Cut seams

You can putty plasterboard with a straight edge in the places where the sheets are cut and joined only by treating them first. It is necessary to moisten the edges of the plasterboard with water, and after wetting the gypsum, make small grooves at an angle of 45°. This work is best done before priming.

Lubricate the resulting joints with a primer, and when dry, fill the seam with putty. It is best to use two spatulas 10 and 20 cm. The first, smaller one, distributes the mixture. The second, larger one, removes the excess. It is very important to fill the seam well, so that you get a small bump protruding above the plane. If this happens, then everything was done correctly.

Lubricate the seam again using freshly prepared putty. The thickness of the new layer should be about half a millimeter. After this, we attach pre-soaked paper tape to the seam for reinforcement. Use a spatula to remove excess putty.

It is necessary to ensure that there are no wrinkles on the paper tape. Once again we collect the excess composition and distribute the remaining putty with a thin ball.

What if it’s like this: first tape, then putty?

Some are chasing to save time and money by simply applying glue to the gypsum board or a self-adhesive mesh, or sickle tape, or paper tape. In this case, the junction remains unfilled. Such a connection will come out with warped wallpaper and cracks. In this case, saving is inappropriate. If you apply the right technology, then plasterboard walls will not let you down when wallpapering.

By the way, serpyanka and self-adhesive have significant drawbacks. Serpyanka cannot maintain the necessary rigidity, it is deformed and stretched. Fabric fibers interfere with finishing, sticking out with small wrinkles. The self-adhesive mesh comes apart immediately, without strengthening anything.

Puttying external and internal corners

Puttying the corners of drywall is an important and crucial finishing step. They are finished using metal Shitrok and aluminum corners, paper tape and serpyanka. When finishing internal corners, reinforcing tape or sickle tape is usually used. The principle is the same as in finishing seams. The joint is puttied, paper or sickle is attached on top, and excess compound is removed. Then the corner is finished again with the thinnest layer.

Perforated aluminum corners are used to finish external corners. It is cut at an angle of 45° or slightly less. The 90° angle is not used. This is done so that the metal does not bristle during work.

To attach the aluminum corner, putty is applied in small doses at an equal distance of about ten centimeters. The corner is pressed, its position is checked, the excess mixture is removed, bringing it into an even plane in relation to the entire surface. After the putty has dried, the edges are sanded, if necessary, putty again.

The Sheetrock corner is more convenient to use as it has a paper base. It is stiffer than paper tape and, unlike aluminum perforated corners, does not lead to sudden changes with the rest of the surface.

Puttying joints

Make a small depression at the joint.

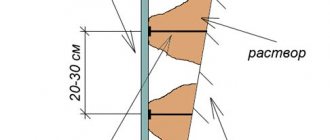

When processing gypsum plasterboard walls, special attention should be paid to the joints between individual sheets. On their sides there are special chamfered recesses designed for filling the joints with putty and reinforcing tape.

Sometimes, after cutting the sheets, the chamfered edges are cut off and the gypsum board joints turn out straight, without indentations. In this case, you will have to make the indentations yourself using a knife or a special finishing plane.

Using a sharp knife, cut the cardboard covering along the entire joint of the sheets, and pass along the gypsum base with a plane. As a result, in the area of the seam there should be a depression of 2-3 mm and a width of about 5 cm, running along the entire joint. For more information on how to seal gypsum board joints, watch this video:

In some cases, simplified preparation of joints is used: the edges of the sheets forming the seam are simply cut at an angle of 45 degrees. But this option does not allow the use of reinforcing mesh, as a result of which the sealing of the seam is not so strong.

Seam reinforcement

Secure the serpyanka to the layer of putty.

After this, you can begin reinforcing the seams with serpyanka tape. It is usually produced in the form of a self-adhesive mesh, rolled into narrow rolls. There are two ways to reinforce joints with serpyanka. In the first case, it is glued to the seams immediately before puttying, in the second, the mesh is embedded in a freshly applied layer of putty using a narrow spatula.

Gluing the serpyanka should start from the very top of the ceilings. The adhesive tape is carefully unwound and pressed firmly to the surface of adjacent plasterboard sheets. The joining seam should be located exactly in the middle of the sickle tape.

The second method, with the mesh deepening into the already applied putty solution, is considered preferable by many finishing craftsmen. In this case, the reinforcing mesh is located in the middle of the putty layer, working more efficiently.

Choosing putty for seams

To seal joints, buy basic mixtures.

To make high-quality sealing of joints, you should choose the right putty composition. All putty mixtures, regardless of the material of manufacture, are divided into two large groups - base and finishing putties.

Basic putty mixtures are intended for rough leveling of surfaces, as well as for sealing relatively large wall defects - cracks, sinkholes, chips, etc. Their distinctive feature is the use of coarse-grained components as a filler. The result is a strong bond between the filler and the binder component, allowing the mixture to be applied in a sufficiently thick layer of up to 5-7 mm. The surface treated with basic putty appears rough and rough to the touch.

Finishing mixtures are intended for final leveling of the surface. They consist of a fine fraction of filler, due to which the treated surface is smooth and suitable for final decorative processing - painting, wallpapering, applying a thin layer of decorative plaster.

To putty joints between plasterboard sheets, only basic putty mixtures are used. Only such a mixture, due to its strength, can reliably seal the joints between individual gypsum board sheets.

If the room is humid, then gypsum mixtures will not be suitable.

Basic putties are most often made on the basis of cement, and coarse quartz sand is used as a filler. Such mixtures are suitable for use in rooms with high humidity, since cement, after hardening, is not afraid of dampness. Basic putties made on a polymer and gypsum basis can also be found on sale.

Gypsum mixtures, unlike cement ones, are not recommended for use in wet rooms - bathrooms, toilets, kitchens, since gypsum itself is very hydrophobic and swells, cracks and deforms when in contact with moisture. Polymer compositions can be either moisture-resistant or damp-resistant.

Information regarding this can be obtained from the instructions for use on the package.

Applying putty to seams

To apply the putty composition to the joints you will need the following tools:

- drill with mixer attachment;

- container for diluting the mixture;

- putty knife.

Cement and gypsum putty compositions are most often supplied for sale in the form of dry mixtures, and polymer ones in a ready-to-use form. This is due to the rather complex technology for diluting polymer putties and the need for its strict adherence.

A construction mixer or drill with an attachment will make mixing the mixture easier.

To prepare a solution from a cement or gypsum dry mixture, you should read the instructions from the manufacturer, which indicate the proportions of its dilution with water. The required amount of clean water at room temperature is poured into the container. After this, the dry mixture is added to the water and mixed with a drill with a mixer attachment.

If necessary, add dry mixture or water to the container to obtain a solution of the desired consistency. The finished solution should resemble thick sour cream - be plastic enough and at the same time viscous so as not to form smudges after application to the wall.

Apply the solution to the seam using a spatula. The width of the spatula should be slightly wider than the groove formed by the edges of the plasterboard sheet (50 mm on each side). You should start filling the seam groove from the floor, moving the spatula from bottom to top. In this case, the spatula should be firmly pressed against the drywall to avoid bumps and sagging. For a detailed master class on seam processing, watch this video:

If they form, they must be removed immediately, otherwise it will be much more difficult to do this after the solution hardens.

Applying the finishing compound

When the base putty has completely hardened, you can begin treating the walls with a finishing plaster solution. Finishing putty compounds are intended for the final treatment of walls immediately prior to painting. Finishing mixtures are most often made using gypsum or polymers. The finishing solutions are prepared in the same way as the base ones, strictly following the instructions from the manufacturer.

To apply finishing putties, you will need two spatulas - a narrow one and a wide one. Using a narrow spatula, scoop the solution from the container and distribute it evenly over the working plane of the wide spatula. After this, the solution is applied over the entire surface of the wall to be treated in a thin layer, using wide sweeping movements. For detailed tips on finishing gypsum board walls, watch this video:

Work should begin from one of the upper corners so that drops of mortar from the spatula do not fall onto the already plastered surface. As a final touch, the putty surface of the plasterboard is treated with fine sandpaper and primed again. The wall surface is now ready for painting with any paint and varnish compositions.

Preparing walls covered with gypsum board for painting, although it has a number of features, can be done with your own hands. The most important thing is to approach the work as responsibly as possible, since the quality of its decorative finish depends on the correct preparation of the wall.

Sanding corners and joints

Sanding is delicate and very dusty, so you should take precautions. You really need to curtain it with a damp cloth - this will prevent dust from penetrating into other rooms. It is also good to cover the floor with wet rags or wood shavings.

If the previous work was carried out carefully and in compliance with technology, then grinding will take a little time.

First, all protrusions are cut off. Then the actual grinding begins. A sanding mesh with a mesh size of 180-200 is attached to the block. They do the work. For better grinding, use oblique light. But if you plan to use wallpaper, you can sand it even less conscientiously.

It is necessary to use personal protective equipment - goggles, respirator, gloves. This will save your health.

After sanding, prime everything again, since settled dust will interfere with further work.

DIY drywall putty

To enjoy your home walls to the fullest, it is better to putty the drywall. Your home will acquire a presentable and well-groomed appearance. In addition, contemplation of uneven walls can negatively affect the psychological climate within the family. Puttying plasterboard walls is a responsible undertaking. It happens that the owner himself, an unprepared and impressionable person, undertakes the repairs. He faces a lot of questions. The first question: how to putty drywall, what tools to use? You will need two spatulas - a large one, with a blade length of 40 cm, and a small narrow one. GKL putty is carried out in several stages. Which putty should I choose for drywall at the first stage of work? First use the starting one. It is applied in a thick layer of 5 mm to hide all the flaws and irregularities.

Question two : how to putty drywall correctly? Let's answer - it's a simple matter. Using a small spatula, apply some putty along the edge of the large spatula. Then, pressing the spatula against the wall, we distribute the putty. Repeating in this way, we putty the plasterboard walls. Then carefully level the surface. The better the alignment, the less sanding will be required. After the putty has dried on the drywall, we begin sanding. Clean the surface from dust and prime it. We use a primer with deep penetration. Let it dry again and move on to further work.

How to putty drywall at the second stage? You need to apply finishing putty. What kind of putty is up to you. It can be based on gypsum or polymers. Finishing putty is diluted thinner and is more difficult to use. In order to properly putty plasterboard walls and get an ideal surface, it is best to pre-prime the walls and then everything will be at its best. The technology of work itself is similar to the first stage. The difference is that the putty is applied in a thin layer and quickly leveled. After the putty walls have dried, they begin sanding. This is done with fine sandpaper attached to a block. For a completely smooth surface, use side or bottom lighting, preferably an LED lamp. It will help identify the smallest irregularities.

Nuances at work

To get a good result from the work done, you must adhere to the following recommendations:

- Plasterboard puttying for painting is carried out at temperatures from +5 to +30 degrees.

- Avoid direct sunlight when leveling.

- To prevent the putty from forming cracks after application, it is important to follow the work technology. A common mistake is an incorrectly prepared solution.

- Cracks can form when applying the mixture in a layer of more than 1.5 mm at a time. Only the use of a primer at each stage of work will allow for a thin application.

- Be sure to wait until the putty has completely dried before applying the next layer.

- Do not allow drafts in the room.

Well, in addition to following all the technology for applying the material, its high quality remains important, so purchase putty only from trusted manufacturers.