For many, one of the most difficult and unpleasant moments is renovating an apartment. Especially when doing it on your own, you have to learn a lot and face some difficulties. Those who have begun processing walls during renovation work are interested in the subtleties of their finishing. Putty is used as a finishing material for walls and ceilings. It helps make the walls smooth and prepare them for painting. Among the many brands, Fugenfüller putty is in great demand among buyers due to its high quality.

What is Knauf-Fugen putty

The German company is known to a wide audience in many countries around the world. Most consumers pay attention to Knauf brand products when the need arises to repair their own home. This is a dry mixture made on a gypsum basis. However, it imposes certain restrictions on its use.

Plaster does not withstand constant contact with moisture. This is especially critical in the case of direct exposure to putty and water. In addition to gypsum, the building composition contains a number of additives, which can improve the quality of the product. Some components slow down the setting of the mixture, others retain water. It is worth noting that the gypsum solution itself hardens quickly. This problem is solved by including substances that prevent moisture evaporation. As a result, Fugen putty retains its viscosity for a long time.

Both gray and white compositions go on sale, but there are no differences in properties between them. The mixture is packaged in bags of 5, 10, 25 kilograms. In order not to lose the quality of the putty, it is necessary to add the required amount of water, as indicated in the instructions.

Knauf Fugen putty is intended for interior work.

Technical and operational characteristics

The high demand for construction mixtures of the Knauf brand is due to no less high quality indicators. But before making the final choice in favor of one or another putty, it is necessary to study its properties. Despite the presence of several variations, they are all little different and are used in a similar scenario. Therefore, it is worth considering the technical characteristics of the conventional mixture, as it is more widely used:

- The grain size is 0.15 mm - this fine-grained structure allows you to create an even finishing layer. The largest fraction can reach up to 0.2 mm.

- The thickness of the laid coating is 1-5 mm. However, in most cases the layer rarely exceeds 3 mm. This creates an unnoticeable and strong base foundation.

- To ensure long service life, the room temperature should be maintained at the recommended temperature. The minimum threshold below which you should not fall is +10 °C.

- The drying time of the solution is 30 minutes. The exact interval depends on operating conditions, as well as the volume of the mixture mixed.

- The shelf life of the building material is no more than 6 months, and therefore, before purchasing, you need to calculate in advance how much putty will be needed for finishing work. But subject to storage conditions.

- Compressive strength is more than 2 MPa.

- Bending strength – starting from 1 MPa.

- Surface adhesion indicators – from 0.5 MPa.

- 1 kg of dry mixture is spent on preparing 1.3 liters of solution.

Thanks to the components of Fugen GF putty, a high-strength base is created, prepared for finishing. Fugen Hydro mixture can be used as a starting putty due to the fact that it is suitable for use in rooms where there is a constant high level of humidity. Fungi, mold and other pathogens do not develop on the finished coating.

Thanks to the plasticity of the mass, it is easy to work with

Area of use of putty

A standard gypsum-based putty composition is used for interior work. Despite this, the list of tasks is far from small:

- Sealing the seams of concrete floors.

- Professional processing of gypsum board joints (regardless of the type of edges).

- Restoration of coatings made of various materials - gypsum plasterboard, concrete, tongue-and-groove blocks.

- Treatment of the entire surface of walls and partitions

- For reinforcement - during fastening of mesh or special corners.

- As an adhesive for fastening plasterboard sheets to a leveled vertical surface.

- Creating a base coat for wallpapering.

- Filling recesses at installation points of fasteners (masking screw heads).

Attention!

Compliance with the technology of applying the material allows you to avoid many undesirable consequences. In this case, the putty does not crack, and the shrinkage rates are so minimal that it is invisible to the naked eye.

The putty composition can be used for various purposes without the risk of loss of properties

Packaging and storage

The KNAUF-Fugen mixture is packaged in paper bags of 5, 10 and 25 kg. Packaging 5 kg can also be produced in plastic packaging. Bags of KNAUF-Fugen dry mixture should be stored in dry rooms on wooden pallets. Use material from damaged bags first. Shelf life in undamaged paper packaging is 6 months from the date of manufacture, in plastic packaging - 12 months. The date of manufacture is indicated on the side of the bag. Upon expiration of the shelf life, the packaging and product must be disposed of as household waste.

Types of Knauf Fugen putties

Various types of putty are available for sale:

- "Fugenfuller" (Knauf Fugen) - standard Knauf mixture.

- Fugen GF is a composition intended for finishing works on plasterboard sheets (GKL).

- Fugen Hydro is a moisture-resistant gypsum composition for processing gypsum fiber materials.

Note!

It is advisable to use each type of putty for its main purpose, based on the type of surface.

Fugenfüller or Knauf Fugen

The standard mixture for professional processing of joints of plasterboard panels does not crack after drying. For the manufacture of the composition, only environmentally friendly raw materials (gypsum) are used, and therefore there are no harmful emissions.

Knauf Fugen GF

Fugen GF mixture completely covers the entire surface of gypsum fiber sheets. The composition itself is durable and at the same time elastic. No cracks form on the treated and dried surface. The Fugen GF option is the same standard gypsum putty, but with the inclusion of polymer additives. There is no harmful effect on the human body.

Knauf Fugen GF – for continuous puttying of GVL

Knauf Fugen Hydro

This is a moisture-resistant gypsum option that is suitable for effective processing of gypsum board joints. It is also used when installing plasterboard slabs with tongue-and-groove fastening. When dry, the putty shrinks minimally and does not crack. Due to the content of environmentally friendly polymer and hydrophobic components, the mixture is resistant to moisture.

Knauf Fugen Hydro - moisture-resistant gypsum putty for treating joints

Comparison of Knauf Fugen and Fugen Hydro putties

The main difference between Fugen and Hydro putties is that Knauf-Fugen is a regular compound, while Fugen-Gidro is a moisture-resistant mixture. Due to the inclusion of hydrophobic components in the composition, Fugen Hydro putty is used to treat surfaces of rooms with high humidity.

Otherwise, there is no difference between these types of putties. Even the areas of application are largely similar.

Nuances at work

In the process of reinforcing joints, nuances may arise that negatively affect the quality of the work performed. That's why:

- Before filling, all windows and doors should be closed to prevent drafts. If there is strong air movement, the seam will not be strong and may crack.

Crack in drywall construction - The room temperature should be more than 10 degrees. Because the joint will not be strong if the temperature was low.

Unstable drywall joint - It is imperative to reinforce plasterboard joints in a new building, because the building undergoes “shrinkage” and this negatively affects the plasterboard structure.

- Cracks are reinforced with tape using a special putty mixture to prevent their growth.

Reinforcement of cracks

Reinforcing joints is an essential step in creating a beautiful and durable plasterboard structure. The tape and the mixture used will create an obstacle to the occurrence of cracks, as well as deformation from the effects of temperature changes, high humidity, and mechanical force (hand blow).

To prevent cracking on the walls, use fiberglass.

Advantages and disadvantages

Fugenfüller Knauf putty is valued primarily due to its advantages that are difficult to dispute. Among the obvious advantages it is worth highlighting:

- The building compound is used when working with gypsum plasterboard, although the plasterboard surface is exposed to moisture.

- Due to their high strength, concrete surfaces are effectively joined.

- Environmentally friendly.

- Putty is produced in different colors.

- High adhesion, which is easily enhanced by additional primer treatment.

- Putty is applied in a different thickness range - from the thinnest to a more reliable coating. But within acceptable limits.

- The Knauf assortment contains a moisture-resistant option.

- Thanks to its fine-grained structure, the putty completely fills small cracks.

- Moderate consumption of putty contributes to economical spending on repair work.

Knauf offers three putty options to choose from, so it makes sense to consider the strengths of each individually.

Gypsum is a clean material that does not pollute the environment.

Even such a professional mixture has a number of disadvantages that must be taken into account first. This allows you to choose the only correct solution in each specific case.

One of the significant disadvantages is the high drying speed, which imposes certain inconveniences. In particular, you need to act extremely quickly and dilute small portions of the solution. With a large scale of work, this takes a lot of time. Other disadvantages:

- It is not recommended to use the material for large surface bends. When the level difference is 3 mm or more.

- Hardened gypsum coating is difficult to sand because it is very durable. At this stage, the worker requires endurance and considerable effort.

- If thin and light wallpaper is chosen for finishing, dark gaps may appear.

- The inconvenience lies in the maximum thickness of the applied layer - no more than 3 mm.

The main disadvantage is that it dries quickly in the mixing container.

Rules for working with material

To obtain high-quality results, you must follow some recommendations from experts:

- It is recommended to putty at a room temperature of at least +10°C and a humidity of no more than 80%.

- Before applying the raw material, it is necessary to pre-clean and prime the surface. Putty can only be applied to a dry surface.

- It is necessary to prepare the solution only in a clean container. If foreign substances get in, wash the instruments and remove foreign substances from the composition.

- When preparing the solution, it is not recommended to take more than 1 kg of the substance. If you lack experience, you may not have time to use up the entire mixture, which cannot be reused.

- To prepare the solution, take only clean water and pour the purchased composition into it. Start stirring after all the powder is wet. After the first stirring, wait a while and stir a second time. To avoid the formation of lumps and to facilitate the mixing process, you can use a construction mixer. The finished solution should have the consistency of thick sour cream.

- To avoid rapid hardening and the formation of a large number of lumps, a new portion of the solution is mixed in a previously washed container. The tool should also be washed after completing the application of the mixture.

- To work with joints, use a sickle mesh or a special paper tape. They increase the strength of the seams, but still do not guarantee the absence of cracks.

- When sealing joints and seams, the second layer is applied only after the first layer has completely dried.

Remains of finished material after work must be disposed of. When adding residues to a new composition, you can get a large number of lumps. They should not be flushed down the drain due to the possibility of creating a permanent clog. The remaining dry material should be stored in a tightly closed plastic bag. It is not recommended to use raw materials after the expiration date .

Choosing a quality manufacturer of finishing materials allows you to avoid frequent renovations of premises. Many professionals prefer finishing raw materials, including putty, Fugenfüller Knauf, which has long been successfully used in interior renovations. These materials have long established themselves as high-quality and durable .

Conditions and procedure for performing work

Before starting work using Knauf-Fügen putty, care must be taken to create suitable conditions. Any master needs to know this, especially beginners. The optimal temperature ranges from +10 °C to +30 °C.

Processing of plasterboard sheets should only begin after all “wet” processes have been completed, which lead to changes in temperature and humidity levels in the premises. This includes installation of self-leveling floors, plastering of walls and ceilings, installation and dismantling of windows (especially from autumn to winter).

You need to start putting putty when the surface to be treated is completely dry. Otherwise, linear deformation of the gypsum board and, as a consequence, cracking of the coating cannot be avoided.

It is also prohibited to add other components to the solution, otherwise the quality of the putty will decrease, and significantly! The manufacturer produces putties with a specially selected composition. It is undesirable to use a thickened mixture, as well as dilute it with water - this will not return the original properties.

Preparing the surface for puttying

Preliminary surface preparation is strictly necessary and neglecting this stage is highly discouraged. The first thing you need to do is get rid of the old finish - wallpaper, plaster. The base is thoroughly cleaned of other contaminants - mold (if any), grease deposits, dirt, dust. After cleaning, it is necessary to treat with a primer depending on the type of walls.

Processing the rough coating is a mandatory stage of the work.

Plasterboard structures

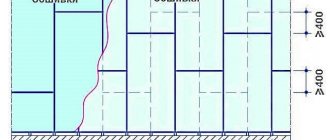

The frame is assembled according to technology, which avoids sagging of plasterboard sheets when creating ceilings or deformations of cladding and partitions. The sheets must be firmly fixed to the frame, in which the pitch of the fasteners plays an important role:

- 170 mm – ceilings;

- 250 mm – partitions.

The sheets themselves must be laid out in a staggered manner. The displacement of seams also has its own weight:

- 400 mm relative to vertical;

- 150 mm relative to horizontal.

The screw caps are covered with putty (Knauf-fugen). The end parts of the sheets should be cut at an angle of 22.5°, which is effectively achieved with a special tool (edge plane). Also, the ends must be primed with a deep penetration compound.

At the end of the preparatory stage, a primer is applied to the surface. You can use a brush, roller, spray. Wait until it dries - each type of primer has its own duration:

- Tiefengrund – 3 hours;

- Betocontact – 12 hours.

It is important to ensure that the treated surface does not become dusty again.

Seams and small recesses between sheets are coated with the composition using a spatula

Dilution of putty

Most beginners make a number of mistakes while still at the stage of preparing the mixture for surface treatment. Do not allow air to get in when mixing the mixture. For this reason, it is not advisable to use mixers or other mechanical devices. It is better to dilute portions manually. At the very least, the mixer speed should not exceed 300 - then air will not penetrate into the mixture during the mixing stage.

The kneading procedure has a number of features:

- On average, 0.8 liters of water are taken per kilogram of dry mixture. The exact proportions are indicated on the label for each Knauf product.

- The dry composition is carefully and gradually poured into a container of water for proper impregnation.

- When the mixture is poured, wait 2-3 minutes. This time is enough for the mixture to become saturated with water. Only then start stirring. If you start right away, you will not be able to achieve a uniform structure, and the putty will lose its technical characteristics.

- The temperature of the water for mixing the dry mixture plays an important role. Indicators should be kept within +5 °C to +30 °C. Due to warmer water, the moisture resistance of the mixture deteriorates and subsequently the coating will begin to crack after drying.

- It is advisable to mix the mixture manually with a spatula. Using a mixer at low speeds is important when you need to prepare a lot of solution - it is very difficult to knead such a volume with your hands (even with a shovel).

- The ready-to-use mixture should have a uniform, creamy consistency. Initially, the solution seems liquid during mixing, but you cannot deviate from the proportions and add more dry mixture. After some time, the consistency will come to the desired form.

Attention!

You should not throw the remaining putty back into the container with the prepared mixture. This shortens the lifespan of the composition, which quickly renders it unusable.

The rate of consumption is affected by the type of finishing work

Instructions for use

To obtain high-quality coverage and avoid erroneous actions, you should strictly follow the instructions. In particular, start work when the surface is cleaned and dried. You should also not allow dirt or foreign bodies to get into the putty. Tools must also be clean.

There are several ways to use the Knauf-Fügen dry mixture:

- continuous surface coating;

- installation of KNAUF-gypsum board partitions;

- processing of joints of gypsum board sheets.

Each case has its own characteristics that should be taken into account. Otherwise the work will have to be redone.

Complete puttying of concrete surfaces

The solid technique is used in case of minor unevenness. Buying expensive putties is not practical from an economic point of view. A day before the start of work, the surface is primed.

The putty is applied to the walls using a spatula or trowel. Any technique is used that is convenient. For example, cross-shaped - first follow vertical stripes, then change direction to horizontal movements for leveling. Or perform fan-shaped manipulations.

The thicker the layer, the more liquid the plaster should be.

Installation of KNAUF gypsum boards

Putty is convenient when attaching plasterboard. During installation, the solution is applied to the recesses of the slabs:

- bottom row groove;

- vertical groove from the end part.

Next, the gypsum board is pressed tightly, and the remaining remaining mixture is removed. The process is reminiscent of laying bricks using cement mortar. When the installation of the slabs is completed, the seams are sealed with fugagypsum putty.

Sealing joints of plasterboard sheets

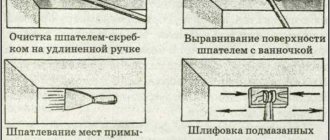

Processing of gypsum board seams is carried out in several approaches. The Uniflot composition was developed specifically for these zones. The sequence of actions varies depending on the type of edge. It can be straight or folded. Processing joints of gypsum board sheets with a straight edge:

- The seams are filled with putty to the full depth, maintaining uniformity.

- Wait until the mixture dries, then clean the surface of the closed joints.

- Cover the sheets with a leveling layer of putty mixture.

Adjacent gypsum board sheets relative to a straight edge are mounted with a gap of 5 to 7 mm. Sequence of actions in the case of a folded edge:

- To begin, apply the first layer of putty.

- A special reinforcing tape or fine mesh is applied and pressed into the putty mixture with a spatula to avoid the appearance of wrinkles and bubbles.

- A second leveling layer is applied to the dried surface.

- When the putty dries, the joints are sanded.

Note!

It is convenient to carry out the work with a 150 mm wide spatula. Moreover, it is advisable to choose a tool that has a handle in the form of a screwdriver tip, in order to tighten protruding screws at the same time.

Plastering is a simple operation that requires only time and patience

Applying putty to seams

We fill the joints of the sheets by pressing the material with a spatula with a handle adapted for screwing in protruding screws, filling and sealing the seam as much as possible. Apply the solution again to the seam from left to right (16), and then from top to bottom, again filling and compacting the seam as much as possible (17).

The European standard provides for working with the new edge with Uniflot putty, which, without additional reinforcement, provides high quality “one-pass” coupling. Use a spatula to rub the solution into the seam and level it out.

- When working with Futen we use paper tape. After the first layer of putty, apply it to the seam and “press” it into the previously applied solution with a wide (150 mm) spatula to remove voids and air bubbles (18). After drying, we putty again, covering the tape with a wider layer (19).

The seams dry after a few hours (time depends on temperature and humidity). If necessary, we sand them and prime them with colorless primer "Tifen-Grund" of deep penetration, which improves the adhesion of the coating to the base. After this, you can glue the wallpaper, but before painting you will have to do additional work - apply ready-made finishing putty “Rotband-paste” to the entire surface of the plasterboard sheets.

Tips from experts on puttying drywall joints

- We attach plasterboard sheets using technology to a metal “Knauf profile” (it is also possible to mount them to wooden blocks, but you need to be absolutely sure that the material is dry, otherwise the structure may become deformed, which will cause cracks to form). It is better to tighten adjacent screws on the mating edges not on the same horizontal plane in parallel, but with an upward-downward shift, which will help avoid deformation of the joint in the area of adjacent screws (20).

- If you fasten it parallel and twist the screw, the plaster will squeeze out and form a tubercle. When fastening with a shift, this situation will not arise. Since gypsum putty dries quickly (after about 30 minutes it begins to thicken and harden), you should not mix more than half of the box. Spatulas should be made of stainless steel to avoid oxidation.

- We carry out puttying work at a temperature of 10-30 °C. Fresh grout takes some time to dry. The main thing is that there are no sudden changes in temperature and humidity. When working with a new edge, it is recommended to use paper tape rather than mesh tape. “Uniflot” does not provide for additional reinforcement of longitudinal seams (with edges covered with cardboard), but if desired, it is possible to use paper tape for reinforcement - it will be reliable, but it will take more time and money.

- Special screws/self-tapping screws (there are several options for different jobs) will not destroy gypsum panels. They will not oxidize and will not appear as rusty spots on wallpaper or paint after six months or a longer period of time. The manufacturer guarantees high quality of work subject to adherence to technology, as well as the use of the above materials and tools.

Consumption

How much putty is required depends on the type of work. The type of surface being treated also plays a role in this. When sealing plasterboard joints, the consumption per 1 m2 of surface will be 250 grams. In the case of continuous application of putty - from 800 g to 1 kg per square area with a layer thickness of no more than 1 mm.

If you need to cover an already plastered surface, then the putty consumption will be slightly higher (0.8-1.2 kg per square area), depending on the degree of roughness of the rough coating. As for the installation of tongue-and-groove slabs, you should take into account the figure of 1.5 kg per 1 m2.

Fugenfüller

KNAUF-Fugenfüller putty is a classic of the genre, as it is the most common composition for sealing gypsum board joints. The basis of the mixture is gypsum, but there are also auxiliary additives that improve the properties of the solution.

When using Fugenfüller, it is not necessary to glue the gypsum board joints with reinforcing tape - this is confirmed by the practice of the author of the lines, although the manufacturer recommends using tape. The mixture is used not only for seams, but also for gluing gypsum board sheets, as well as for sealing large irregularities on the walls.

Packaging 25 kg, consumption depends on the width and depth of the seam, and the price starts from 300 rubles per bag. The composition is diluted manually or using a mixer.

Reviews

Choosing a manufacturer who specializes in producing high-quality building mixtures is the key to successful finishing. Most professional finishers prefer the Figenfluger Knauf mixture. There is also no doubt about the durability of the company’s materials.

Was this information useful to you? Share in the comments!