The variety of types of linoleum allows it to be used for different purposes. Linoleum often becomes the basis in home interior design, as well as in commercial buildings. In most cases, this coating refers to rolled PVC coverings, while natural linoleum occupies only a small share of the flooring materials market. PVC linoleum has high aesthetic and quality characteristics. And if all the nuances of installation technology are observed, the coating acquires a long service life.

One of the most important questions that arises before installation:

Is it necessary to glue linoleum?

Note

Those who risk laying the covering without fixing it face:

- fungus formation

- waves on the carpet,

- bubbles with folds,

- damage when moving furniture.

If we consider harder PVC coatings, then unevenness and swelling can be observed in those places where the coating does not have a strong bond with the base. Such areas are the first to suffer from wear and tear.

Soft household coverings are subject to change in size due to fluctuations in humidity and temperature. During the winter season, when the rooms are heated, linoleum shrinks. If the coating is not glued, then gaps will form between the joints. With the onset of spring and increased air humidity, the linoleum stretches again and then bubbles appear on the surface, which are almost impossible to fight.

To avoid defects when installing the floor covering, it is recommended to use the adhesive method.

Is it worth gluing

There are three ways to lay flooring:

- gluing to compounds offered in stores;

- flooring with the canvas secured with skirting boards;

- fastening with construction double-sided tape.

It is recommended to fix linoleum with glue if the room size is more than 20 square meters. Long-term guarantees are issued for glued materials. Felt material is also offered in a wide range.

It is necessary to glue the canvas if the room has large furniture that moves frequently. This will eliminate the risk of deformation of the floor covering. Thanks to gluing, the wear of the material can be minimized, so it will last longer. Even non-professionals can do this.

During the off-season, linoleum can stretch or shrink as it is affected by sudden changes in temperature and high levels of humidity. You can avoid such troubles if you attach the linoleum with glue.

It is necessary to apply glue at the joints of the panels, covering every centimeter. These areas need a strong connection, otherwise they will begin to lag.

How to choose glue for linoleum?

When selecting glue, you should pay attention to:

- type of base

There are two types of bases - absorbent and non-absorbent. Absorbent materials include concrete, wood, cement screed, gypsum screed, chipboard, fiberboard. Non-absorbent materials include old linoleum, PVC coating, laminated parquet, ceramic tiles, marble, granite, metal and various polymer coatings.

To determine the type of base, perform a simple test. Drop some water on the floor and see if it is absorbed or not. Carry out the test even if you are sure of the type of base. For example, treating a loose base with a film-forming primer turns it into a non-absorbent one. It is quite difficult to determine this visually.

- type of coating

Household (heterogeneous) coatings have a heterogeneous structure, several layers and retain their appearance for a long time; the thickness of the protective layer varies from 0.12 to 0.3 mm. They are used in low-traffic areas, such as bedrooms and living rooms.

Commercial (heterogeneous and homogeneous) coatings are much more resistant to stress. The thickness of the protective layer of such materials is already more than 0.4 mm. Coatings are used in corridors due to high traffic and in any commercial facilities such as offices.

Removing glue from linoleum

Often during repairs, glue gets on the surface of the canvas. It is usually not easy to wipe it off when it is dried, so it is important to get rid of the stain before it hardens. The easiest way to remove fresh glue is with a soap solution. Add a little liquid soap to warm water or dissolve soap shavings. Wipe the floor with a soft sponge. Kerosene is often used for the same purpose.

If the glue has dried, you will have to use more aggressive agents. But many of them leave stains on the surface and spoil the material. It is recommended to first try on an inconspicuous area of the floor - for example, in a corner, near the baseboard. It is best to use gasoline, kerosene, or, in extreme cases, white spirit. The use of acetone is strictly not recommended! Work must be carried out wearing a respirator and gloves, and then thoroughly wash the floor with soap.

Removing superglue from the coating is even more difficult. You need to buy a special product designed for cleaning glue - Moment Antiglue, Contact. If they are not available, use gasoline. The composition is applied for 5-10 minutes, then wiped off with a napkin. The softened stain is also carefully scraped off with a hard spatula. Due to the risk of damage to the material, it is better to be careful when gluing the coating, this will help to avoid problems.

Adhesives for PVC coatings are divided into groups:

- Adhesives for continuous bonding

Water-dispersed compositions are the most common today - they are universal for laying most types of coatings and, in addition, are absolutely safe. Such compositions are applied directly to the base. This technology requires less time and less glue.

The recipe for adhesives depends on their specialization. For coatings with special properties, the adhesive composition is noticeably different. For example, adhesives for conductive coatings not only perform adhesion functions, but also form part of the conductive system. When working with PVC tiles, a special adhesive is required, which allows for a longer open installation time. And if the composition turns out to be insufficiently heat-resistant, then with increasing temperature and mechanical loads, the joints of the tiles may become detached from the base.

- Adhesives for fixation.

Unlike adhesives for continuous gluing, fixing compounds have average adhesive ability and at the same time high permanent stickiness. Used for laying PVC tiles and modular carpet tiles. The fixation is applied with a roller, which is much easier than applying with a spatula, and does not require additional skills. The clamp allows you to easily dismantle sections of the coating. Due to this property, such compositions have become popular primarily in offices and rented premises. Quick removal of a section of coating provides quick access to communications and allows you to save on repairs. After all, at any time the tile can be replaced with a new one.

Advantages of laying on glue

- The service life of the coating increases. The service life when laid with glue will increase by 4-6 years.

- Aesthetics improve. Without glue, linoleum will quickly become unusable, cracks and defects will appear.

- The level of safety and operating comfort increases. It is easier and safer to move on a flat, fixed surface. Less chance of falls and injury.

- There is always the possibility of dismantling and reusing linoleum in another room. If the adhesive is properly prepared and the installation technology is followed, the coating can be easily removed without special equipment and consumables.

- Linoleum is protected from water getting under it, which prevents the development of mold.

How to glue linoleum to a concrete base

The concrete surface should be cleaned with a vacuum cleaner, cracks and irregularities should be covered. To glue linoleum to concrete, we recommend pre-treating the base with a primer for better adhesion.

Gluing linoleum to a concrete base at home is not difficult. It is enough to follow all the principles of technology. The room where the work is carried out must be well checked, the temperature is not lower than 15°, and the humidity is within 5-10%.

The glue is selected taking into account the primer. When treating the base with a film-forming primer, the adhesive composition should be selected for a non-absorbent base.

Types and characteristics of glue

The choice of adhesive depends on the surface on which the installation is being made and the type of coating itself. At the moment, linoleum adhesives are presented in dispersion and reaction compositions.

Dispersive

This type includes water-soluble compounds containing cellulose acid, acrylic, latex, rubber, chalk. They are the safest for health, do not emit a smell, and have good elasticity. They are used for natural and PVC linoleum on different types of bases - felt, fabric and foam.

Adhesive for commercial and semi-commercial linoleum, water-dispersion

The presence of water in the composition causes some restrictions: dispersion adhesive can only be applied to an absorbent base, in dry rooms where the temperature does not fall below 15°C and the humidity does not exceed 60%. The adhesive layer must not be allowed to freeze, as this will cause the material to lose its elasticity and begin to crumble.

Special water-dispersion adhesive for PVC coatings

The group of dispersion adhesives includes:

- acrylate glue - a mixture based on acrylic resin. It is characterized by high adhesion and viscosity, which ensures excellent adhesion of the coating to the floor. Can be used for homogeneous and heterogeneous linoleum with jute and synthetic base;

- Bustilate is a synthetic water-soluble composition with latex, chalk and cellulose thickener. It has high tear strength and elasticity, best suited for thick linoleum on a dense felt base;

- humilax – the composition is based on a mixture of rubber and latex, thanks to which the adhesive is easy to apply, has high elasticity and adhesion to various types of surfaces. Suitable for natural and synthetic linoleum with felt and fabric backing.

Dispersion adhesive for natural linoleum

Reactionary

This type combines two-component compositions containing polymers and epoxy resin. Bonding of surfaces occurs as a result of a chemical reaction, which is caused by mixing the components. This type of glue contains a solvent, therefore it has a pungent odor and is a flammable substance. The advantage of such compositions is the absence of shrinkage, plasticity and resistance to moisture, and they are used mainly for sealing joints between sheets and repairing damage.

Two-component epoxy-polyurethane adhesive for linoleum

Three types of two-component glue are available, differing in their consistency:

- type A is the most liquid, used for all types of linoleum on a rigid basis. It is used to seal joints when laying a new coating, as it forms an almost invisible, but very strong seam. It takes about an hour to fully cure;

- type C - a viscous transparent composition, used for sealing open seams on used flooring. Capable of closing gaps up to 4 mm;

- type T - paste-like composition for fastening seams on PVC linoleum with a polyester base. Intended for professional use, so it is rarely used by home craftsmen.

Advice. When applying these compounds, you must do everything very carefully, because glue that accidentally gets on the canvas will melt the top layer of the coating and leave a noticeable mark.

Popular brands of adhesives for linoleum

| Name | Main characteristics |

EXPERT Glue Bustilat | Suitable for gluing artificial surfaces to concrete, wooden floors, chipboard, OSB. Used for PVC linoleum on a jute base and felt. Consumption per meter of area is 500-600 g with continuous application, dries within 24 hours at a temperature of 20 ° C |

PVA glue “Universal” | Thick composition with the addition of latex. It has a wide range of applications, suitable for felt-based linoleum when laid on chipboard, OSB, wood, and concrete screed. Consumption per square meter is 200-500 g. Drying takes 24 hours at a temperature of 18-20°C |

Clay Polynom 105 | Acrylic composition for all types of linoleum, regardless of the base. Can be used on any surface. Consumption for continuous application is about 300-400 g/m2, drying time is at least 12 hours |

Homakoll 208 glue | Viscous polymer composition for roll coverings on fabric, pile and foam bases. Used only on moisture-absorbing surfaces - concrete and cement screed, plank floors, chipboard, OSB. Consumption for continuous application is 300-500 g/m2 |

Thomsit L 240 D glue | Acrylic paste composition intended for gluing natural linoleum to absorbent substrates. Can be used on heated floors. When applied continuously, the consumption is 450 g/m2, complete drying time is 72 hours |

Frost-resistant adhesive for natural linoleum

How to glue linoleum to OSB (OSB) board

The main property for which OSB boards are loved by installers is their strength. It is also an excellent material for leveling the floor.

Oriented strand board is an absorbent substrate. Homakoll 208, Homakoll 228, Homakoll 248 adhesives are suitable for laying rolled linoleum.

Putty is recommended only for joints and screw fastenings.

Calculation and selection of linoleum

To be convinced of the popularity of linoleum, it is enough to turn your attention directly to the assortment of construction stores. In most of them you can find a huge selection of this particular material, which is offered to potential buyers at a relatively competitive price.

The type of linoleum should be selected according to the markings on it. From these two numbers you can understand two factors: for what room the coating is intended and the intensity of the load that it can withstand during operation. Marking according to the principle of placement in the room is divided into the following indicators:

- Number 4 – for enterprises;

- Number 3 – for offices;

- Number 2 – for living rooms.

The intensity is marked with numbers from one to three and in increasing order, depending on the endurance of the material. However, designating a class in this way does not mean at all that, for example, linoleum can be laid for a house only with the designation 21-23. Much depends on the functionality of the room; for example, class 31 would be preferable for the kitchen, since it is easy to clean and is most tolerant of mechanical damage. The better the class, the higher the cost.

Please note that class and decorative features are not the only important considerations. When choosing linoleum, most buyers pay attention to its qualities regarding insulation and sound insulation. To do this, you need a coating that has a foam base.

Tips for choosing and laying linoleum from the video manufacturer

If you are planning to independently calculate the future floor covering, you need to take into account a number of certain indicators, such as the width and length of the product, its type, the length and width of the floor. The cut part of the covering must cover the floor completely, since when laying, the linoleum is not subject to any tension at all. Based on these data, you can calculate the minimum amount of material required.

How to glue linoleum to a wooden floor

The gluing technology is no different from previous ones. The most important thing is to level the wooden floor and clean it thoroughly. Any water-dispersed adhesive for absorbent substrates can be used as an adhesive composition. Also suitable are universal adhesives homakoll 208 and homakoll 164 prof with increased stickiness, regardless of what primer the base is coated with.

Recommendations for choosing and using glue

So, the main criterion when choosing an adhesive is the type of subfloor. Absorbent and non-absorbent substrates use different formulations, and if you use the wrong adhesive, a strong bond will not work. Absorbent surfaces include cement and concrete screed, solid wood, plywood flooring, chipboard, fiberboard, OSB.

Wood is a highly absorbent surface

Linoleum is glued to them with water-soluble compounds, but this also has its own nuances. Board materials such as plywood, fiberboard and others can become deformed from excess moisture, so for them you need to choose thick adhesive mixtures with a minimum water content. For a concrete floor, the consistency of the glue is not particularly important.

If the floor is concrete, the consistency of the glue can be any

Floors lined with natural stone, porcelain stoneware, and tiles are considered non-absorbent. Here, water-soluble compounds will be ineffective, since there is nowhere for moisture to escape, and high-quality adhesion between surfaces will not work. For such bases, reaction adhesives are used, when applying which it is necessary to take precautions - use protective gloves and masks, ventilate the room.

If the floor has tiles, it is better to use reaction adhesive

You need to buy glue along with or after linoleum to make sure that the composition is suitable for this particular coating. The glue packaging always indicates what types of linoleum it is suitable for and what the coating base should be. Be sure to check the expiration date, because expired glue will not hold the canvas. It is best to buy adhesive compositions in construction supermarkets or large stores where there are conditions for proper storage of such materials. This is especially true for water-soluble adhesives, which completely lose their adhesive properties after freezing. The exception is special dispersions with frost-resistant additives: they can withstand 3 to 5 cycles of freezing and thawing without losing their basic characteristics.

Universal adhesive fixer for linoleum and carpet Axton

Information about the glue is always on the packaging

This is what linoleum glue looks like

In order not to overpay, before purchasing you should calculate the required amount of glue. To do this, you first need to take measurements of the room and calculate the total coverage area. As a rule, consumption varies between 200-500 g per m2 (this is influenced by the type of working surface and coating base). For example, a fabric or felt base requires more glue than foam and rubber, and a plank floor requires more than a concrete screed.

To reduce glue consumption, it is recommended to prime the floor. Glue should be purchased with a small supply so that you do not have to interrupt installation and go back to the store.

Primer concrete-contact

Acrylic primer for wood floors

The photo shows the process of priming a wooden floor under linoleum

Advice. You cannot mix glue of different brands, even if the name of the composition is the same. Each manufacturer has its own manufacturing technology, so the compositions may differ in the number of components, drying time, peel strength and other characteristics.

Linoleum and glue must be kept in the room where the covering will be laid for at least 24 hours. Work should be carried out at a temperature not lower than 15°C and air humidity not higher than 75%. In this case, the humidity of the floor base should not exceed 8% for wood and 2% for screed.

Let the linoleum sit at room temperature for 24 hours

Immediately after applying the glue, you cannot lay linoleum; you need to let the composition dry a little for 5-10 minutes (the exact drying time is indicated on the packaging). Also, you should not apply glue in a thick layer: this will not make the fabric stick better, and excess glue will appear as thickenings and bumps on the surface of the linoleum.

How to glue linoleum to fiberboard on the floor

Fiberboard is an excellent underlay that is often used to level floors. If the room is dominated by dry air and there are no temperature fluctuations, then this coating will be a good base for linoleum. And considering that fiberboard is easy to install and has a low cost, we can safely say that this material is a favorite among installers.

To glue linoleum to fiberboard, use the universal adhesive homakoll 164 prof with increased stickiness and long open working time, or the more economical homakoll 208. And in rooms with high traffic, you can use adhesive for semi-commercial linoleum homakoll 248.

All of them have a thick consistency and are conveniently applied with a spatula.

Do I need to glue linoleum?

Installation can be carried out without additional fixation or with double-sided tape. These methods are suitable for installing a large-area solid canvas. If the coating consists of several stripes, it is better to apply it with glue. Otherwise, bubbles may appear on the linoleum, and the edge will protrude upward.

Glue improves the adhesion of linoleum to the base, which extends its service life, minimizing the likelihood of water getting under the coating and the development of mold and mildew.

Without glue, you cannot lay canvases in the kitchen, bathroom and other rooms with high humidity. It is also impossible to do without mixtures where large, frequently moved furniture will be used.

How to glue linoleum to plywood

Any base under linoleum must be strong, level and dry. Laying sheets of plywood is often chosen as one of the methods for leveling the floor. After installation, the plywood is sanded to remove burrs, the screw heads are puttied, as well as the seams between the panels.

With proper preparation of plywood sheets, the base becomes durable and moisture resistant. After cleaning the base, the linoleum is spread and left for 2 days to acclimatize.

A suitable adhesive for gluing linoleum to plywood is a water-dispersible adhesive for absorbent substrates.

Advice from professionals

- In living rooms with a small area, to save glue, it is enough to apply it only near the threshold, additionally securing the canvas with a strip.

- In a room of no more than 10 square meters. and without a lot of traffic, you can use double-sided tape.

- When installing yourself, you need to apply the glue gradually, covering small areas. On each of them it is necessary to carefully press the linoleum to the base.

- When laying directly on concrete, without an additional insulating layer, it is better to install an additional heating system or make thermal insulation of the screed from plywood or OSB boards with a layer of waterproofing.

- If there are communications under the linoleum that must remain freely accessible, do not use heavy-duty adhesives. It is better to choose means for temporary fixation. If necessary, the canvas can be easily removed.

How to glue to old linoleum

Installation of linoleum should be carried out on a rigid, level base. And for this case, old linoleum will not be a completely suitable substrate, since the material is flexible and soft. We recommend that you first dismantle the first layer, prepare the base, and then lay a new one. Laying linoleum on an old coating risks the formation of mold and repetition of the defects of the previous layer.

The practice of laying linoleum on linoleum still exists. If you still decide to do this, make sure that your coating has not lost its elasticity and is not damaged, otherwise the coating should definitely be dismantled.

For gluing linoleum, glue for non-absorbent substrates is suitable, for example, homakoll 268 for residential sectors and homakoll 164 for commercial sectors.

Gluing methods

It is possible to lay the coating efficiently if the surface material is taken into account. The base for gluing is carefully prepared.

- Must be durable. Fallen pieces of concrete and peeling wooden boards are removed.

- Dry. On a wet base, high-quality glue adhesion is impossible.

- Smooth. Any difference or unevenness after installation will become even more noticeable.

- Clean. Any debris left on the floor will ruin the appearance of the linoleum.

It is necessary to ensure the correct temperature conditions. The air must warm up to at least +18 °C, and its humidity cannot exceed 70%. If installation is done in winter, it is better to keep the linoleum roll in the house for several days.

If there are creases on the canvas, the rolls are rolled out and laid out at room temperature for at least five days. When the linoleum is leveled, it is adjusted to the size of the room. The excess near the walls is cut off with a knife, leaving a small allowance of up to 1 cm. The installer’s further actions will depend on the type of floor.

On the concrete floor

If there are minor defects on the concrete floor, they are rubbed with a mixture of sand and cement. If there is a significant difference in height, the floor is filled with cement screed. You can start gluing only after it has completely hardened. If there is no time for the screed to dry completely, the floor is leveled with polyurethane-based self-leveling mixtures. A day after leveling the surface, you can begin laying.

It is best to glue linoleum onto a concrete base with mastic.

The canvases are laid on the floor, their edges are bent, the glue is applied in an even layer to the concrete, the material is pressed to the base and carefully smoothed. At the final stage, the joints are sealed.

On a wooden floor

The strength and evenness of the base is checked. If necessary, squeaky floorboards are fixed and height differences are detected with a level. If there is no such need, you can immediately begin installation.

Plywood will help smooth out minor unevenness.

Before gluing to fiberboard sheets, check whether the heads of the nails that secure the boards to the floor protrude from above. The caps should be deeply recessed into the material, and the joints between the plates should be puttied and sanded after the putty has dried.

Linoleum is attached to chipboard and OSB with Bustilate or PVA. The fixation to ordinary plywood is the same as the fixation to a wooden floor.

On old linoleum

You can lay new linoleum on the old one without preparing the base. The old material will provide additional heat and sound insulation. Dispersive substances are suitable for adhesive compositions. They have good adhesion and are applied with a spatula. The thickness of the layer should not exceed 0.2 cm. After applying the mixture, the canvas is pressed tightly to the base and carefully straightened.

You cannot lay a new coating on top of dried out or severely deformed linoleum, since over time it will become unusable.

Is there a difference between gluing linoleum in an apartment and in a country house?

In country houses in rooms with high traffic, such as the kitchen and corridor, it is advisable to use linoleum of at least class 32, which is much more resistant to various mechanical influences. Homakoll 248 or Homakoll 148 is used with this coating.

For bedrooms, household linoleum in combination with homakoll 208 and homakoll 268 glue is suitable.

Which is better to choose linoleum for an apartment?

Which linoleum is best for an apartment? Manufacturers produce two types of coating:

- Natural. The classic type, which is made from a resin mixture, flax oil, wood flour, wax and other natural ingredients. All these fillers are mixed in construction mixers, turning into a viscous mass similar to dough. This mixture is rolled out onto a fabric base (for example, linen or jute). This coating is safe for health, environmentally friendly and expensive.

- PVC. Household PVC linoleum is made from thermoplastics coated with a protective layer. Often the base is foamed PVC, while other brands have synthetic felt. Durable, resistant to mechanical damage, easy to maintain and resistant to moisture.

Useful tips

Algorithm for performing operations:

- Linoleum is laid out for acclimatization for 1-2 days;

- the base is prepared (cleaned of dust and dirt, cracks are sealed, the surface is leveled);

- primer is applied;

- linoleum is cut in place (leaving gaps around the perimeter between the canvas and the walls);

- linoleum is glued;

- pressed and smoothed (to remove air). Adhesive compositions must reliably fix the linoleum, prevent it from shifting, the appearance of fungus, bubbles, ensure the removal of the coating (if necessary) and not destroy the base.

How to glue correctly: step-by-step instructions

The technology for installing natural and vinyl elastic coatings is in many ways similar, so here we will give a description of working with PVC coatings with some remarks. First you need to prepare a set of auxiliary tools. You will need:

- Construction vacuum cleaner for cleaning surfaces from dust;

- Knife with hook for cutting linoleum. You can use a regular construction knife with replaceable blades;

- Steel ruler or level;

- Tape measure and marker;

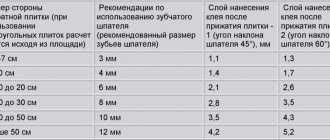

- Notched trowel or short-haired roller for applying glue;

- Lapping board, weighted or regular rolling roller for smoothing linoleum to the base;

- Double-sided tape and cold welding glue for fixing seams;

- Skirting boards with fittings, as well as decorative metal or PVC thresholds.

It is necessary to glue indoors when:

- Air temperature not lower than +15 °C;

- Base temperature – from +14 °C to +25 °C;

- Relative air humidity – up to 75%;

- The humidity of a concrete or cement-sand base is up to 4%, anhydrite – 0.5, dry prefabricated screed – up to 8%.

Don’t forget to give the covering time to acclimatize when spread out - at least 24 hours during warm periods and up to 3 days during cold periods. Natural linoleum is left indoors in the form of a vertically standing roll for the same period.

If the base meets the requirements for strength, moisture, evenness and hardness, then you can begin laying linoleum with glue.

Checking the base for levelness.

Work order:

Preparing the base floor

Includes:

- Checking the base for evenness. All pits and cavities must be filled with repair mixtures, and tubercles and protrusions must be cleaned to the general surface level;

- Turn off the floor heating system at least 3 days before the start of work;

- Cleaning the surface of old coatings, paint residues, bitumen and oil stains, dust, soot, soot;

- Priming with a primer appropriate to the base - waterproofing, strengthening, improving adhesion and equalizing absorbency.

Natural and vinyl linoleum products can be laid over old ones using special adhesives (Forbo 522 Eurosafe Star Tack, UZIN KE 2428, etc.). But only if the coatings have a dense structure, a thickness of up to 2 mm and an undamaged surface.

Linoleum fitting

If the flooring material is laid as one canvas, then the canvas must be placed tightly against a flat wall and leveled. You can temporarily fix it around the perimeter with double-sided tape. Carefully cut off the excess, taking into account the compensation gap of 5-10 mm, and also cut along the external and internal corners. Cutting is carried out in the following way: the covering is pressed to the point where the wall and floor meet, it is cut crosswise, then it is carefully folded back, and the excess is cut off.

Adjusting linoleum when laying.

When laying several canvases you must:

- Combine decor correctly. In case of a blurred pattern without clearly defined boundaries (marble chips, cork, flock, plain), it is recommended to lay PVC-coating canvases reversely (that is, in opposite directions), and natural ones - in one direction. Products designed to look like wood or tiles are also laid one-sided, taking into account rapport.

- Form a tight joint. To do this, the vinyl layers need to be laid with an overlap of 2-5 cm, pressed to the base with a metal ruler and cut through both layers with a knife. When working with natural linoleum, the technique is slightly different: the ends are trimmed with a slightly inclined knife so that when the panels are combined, they touch with their upper sharp edges. During the fixing process, the edges are slightly wrinkled and form a tight seam without the slightest gaps.

How to cut linoleum at home

At first glance, it may seem that cutting linoleum should not cause any trouble. This is due to the opinion of high density and the fact that it does not deform at all when cutting. However, the cutting process requires some attention, especially when a perfect cut is needed to obtain a perfect seam in the future.

Edge cutting of linoleum will not cause any trouble; a simple shoe knife will help with this. It is not so important here whether the seam is even or not. Even if the edges of the cut turn out to be too crooked, they will later be hidden with the help of skirting boards near the walls.

It is worth noting that even the most seasoned craftsmen will not be able to cut linoleum perfectly even. The main rule of cutting is to first cut one piece, then fit another to fit it. To prevent future gaps between the pieces intended for joints, you should overlap each other and cut them off at the same time.

You can cut it with various tools, depending on which one seems most convenient. For example, a large utility knife with interchangeable blades is suitable. Moreover, the frequency of their change should be regular; cutting with a dull knife should not be allowed.

There is even a special knife for linoleum, which has special curved fixed blades. Thanks to this structure, they can cut any type of material. You can also use a specially designed flooring knife. Thanks to it, you can easily cut a straight line. If the tools listed above are not at hand, you can use a construction knife.

Preparation for gluing linoleum

This stage includes all the preparatory work that needs to be done so that all subsequent work can be carried out comfortably and the result will be of high quality.

Initially, the room needs to be cleared of all unnecessary things:

- Take out all the furniture;

- Remove old baseboards;

- Remove slats and other items on the floor.

Next, begin preparing the materials and tools that will be needed to level and improve the quality of the old coating.

You will need:

- Gloves;

- Cold welding adhesive;

- Masking tape;

- Putty knife;

- Knife.

When all of the above steps have been completed, you can begin to work on connecting the old canvases together.

To do this, you need:

- Apply masking tape in the places where the panels are connected. This is necessary so that the glue does not spread over the entire surface.

- Cut the tape along its entire length with a knife to create a cavity between the coatings for filling with cold welding glue.

- Start applying glue; the process will be more convenient if you use a pointed tube.

- Leave it all for 10-15 minutes, then remove the tape.

- Wait until the glue has completely dried and begin leveling the surface. This can be done using a sharp knife, which cuts off the excess and protruding parts of the seam.

After all the work done, the surface must be cleaned and degreased. This concludes the preparation stage.

What to glue

Before laying linoleum, you need to figure out what to glue it with. If the room is small, lay household linoleum in one piece on a smooth base (sheet material, old linoleum, etc.), you can fix it with double-sided tape. It is secured securely, but due to thermal expansion, humps may form between the tape strips. Therefore, if you glue linoleum, then use glue.

There are two types of adhesives:

- Glue, which, after drying, creates a rigid connection between the floor and the coating (the most famous and often used when laying linoleum is PVA); wet gluing, applied with a roller or brush (for absorbent substrates);

- dry gluing applied with a spatula (universal, including for non-absorbent substrates);

Linoleum adhesive is applied with a roller or spatula

The first option is more familiar to us, but when changing the coating you have to suffer for a long time, tearing off the coating and glue residues from the base. The fixation holds the “shift” no less reliably, but allows you to easily re-lay it several times (from 5 to 8 depending on the composition).

Fixations

Fixations are used for laying household and semi-commercial linoleum. If we talk about the price per liter, then fixation is much more expensive. But its consumption is much less (100-180 g/square), so gluing one square meter will be cheaper. From all points of view, this is the best option. Here are some normal fasteners to work with:

- Homakoll 186Prof (Homakoll) is a universal fixing composition for repeated re-gluing of flexible floor coverings.

- Fobo 541 Eurofix Anti Slip - fixation for materials with vinyl or bitumen backing on an absorbent or non-absorbent substrate.

Fixation for linoleum allows you to change the coating several times without replacing the “sticky” layer - Fobo 545 Polaris is a fixative adhesive for residential and public premises with medium load (any substrate in terms of absorbency).

- Arlok 39 (Arlok 39) is a fixing adhesive for flexible floor coverings, including linoleum.

There are other manufacturers, new products appear every day. But, before purchasing, read the instructions carefully. See that it can be used on your base, with your type of coating.

Adhesive for linoleum

You should definitely not use solvent-based glue (neoprene). Technologies have changed so that such glue produces a color change (red spots appear). This glue can only be used to glue marmoleum (a material based on natural ingredients).

If you decide to use glue, here are the brands that give good results:

- Forbo 522. Adhesive with high adhesive ability for rolled floor coverings, can be used in rooms where there is furniture on casters. Suitable for gluing linoleum onto linoleum or for heated floors. Apply with a notched trowel, consumption 220-270 g/m2.

- Polynomial 105. Designed for gluing household and semi-commercial linoleum without a base or on a foam base. Apply using a notched trowel. Consumption 300-400 g/m2.

How to lay linoleum - with glue or fixation - you decide for yourself - BOLARS LinoleumFix. Suitable for gluing commercial linoleum on a PVC basis, semi-commercial and household - on a pile basis, on fabric or on a foamed bottom layer. Can be used for gluing to heated floors. Apply to concrete, gypsum-sand screed, cement, plywood, fiberboard and chipboard. Consumption 400-500 g/m2.

If you need to save money, household linoleum “with a pile”, on a jute or foam base, can be glued to PVA or Bustilat M. If it is placed on concrete, screed or other similar coating, first the glue is diluted with water (1 to 1), and the surface is primed with this composition (maybe twice). Then PVA or Bustilat is applied and the coating is rolled out “on wet”.

How to glue linoleum joints

There is a special glue for joining linoleum joints. It is called “cold welding for linoleum”. These are small tubes with a sharp spout, with which the composition is filled directly into the joint. It does not so much glue as it dissolves adjacent areas of the coating, creating a sealed seam.

There are two types of cold welding for linoleum:

- type A - for connecting freshly laid sheets (for example, SINTEX H44, Werner Muller, Tytan (Titanium);

- type C - for repairs (if you need to fill a split seam, a burst fabric, etc.).

How to join linoleum at joints - cold welding glue

When laying linoleum, naturally, type A is used. Pay attention to the instructions for use. They come in different types and require different drying times.

If you haven’t worked with cold welding for linoleum joints before, practice first on scraps. Once you have mastered the technology and understand what and how to do, you can start gluing joints indoors.

One more point: the glue for joining linoleum joints does not polymerize until it releases harmful substances. Therefore, windows and doors are opened in the room, providing ventilation. It’s better to work with gloves, and a respirator won’t hurt.

How to join linoleum together

A very important point in laying linoleum with your own hands is the correct joining of its parts. The flooring material itself can be laid in any way - using glue, using adhesive tape or fixing it with skirting boards, provided it is perfectly even. The joints require the use of special glue.

First of all, before you start gluing the joints, you need to wear gloves, since the glue for this action is poisonous to your hands. It is also advisable to protect your respiratory tract by wearing a respirator, as the glue may be toxic. To prevent the possibility of glue getting on the front surface of the linoleum, you should first apply wide double-sided tape to the joint, as if gluing the two halves together.

After this, you should run a knife clearly along the joint, cutting the tape. In this way we make a hole for injecting glue. We pour glue into the resulting gap, now, even if it accidentally gets on the edge of the linoleum, it will remain on the surface of the tape, which is then removed. The tape should be removed after 15-20 minutes. The complete junction of the different parts will occur after an hour.

This joining method is called cold welding. It is considered the most dense and durable, even if it is subject to frequent use. The most important thing is to follow the technology, as well as the instructions for using the glue.

Joining linoleum using cold welding video

It is preferable to make short seams, since the shorter the joint, the less noticeable it is. Of course, it will not be possible to achieve a perfectly flat base for laying linoleum; therefore, if you cover the entire floor with a coating at once, defects will appear over time. This can be avoided by gluing the joints using segments of 50 or 70 centimeters. As a result, you will get a perfectly flat surface, provided you wait for the glue to dry after each soldering.

Laying methods

The coating is attached to the concrete base in different ways:

- No glue required. The material is held only along the perimeter by the baseboard and the fixing strip near the door;

- On tape. The flooring is attached with double-sided adhesive tape intended for construction work. Laying on tape is quick. During the installation process, you can glue individual strips;

- For mastic or adhesive. This method gives the most reliable results. Installation is labor-intensive, but allows you to forget about floor repairs for a long time.

When to glue linoleum

Before gluing linoleum to the floor, you should consider all the pros and cons. Attaching to the base makes sense if the material is spread for a long period of time. Short-term repairs involve installation without glue. When deciding on fixation, you need to consider the size of the room. In a spacious room it is not easy to fix the material without glue. In this case, the use of a binder is a reasonable solution.

What glue to use

Each type of coating is suitable for a specific binder composition. How to glue linoleum to the floor so that it sticks securely? When choosing a composition, you need to take into account the nature of the base, the type of surface, and the amount of further load on the floor. For fixation use:

- Dispersion glue. The product does not have a strong odor and is suitable for coating on a fabric, heat-insulating basis;

- Reaction composition. The adhesive is moisture-resistant, not afraid of sudden changes in temperature and difficult operating conditions;

- Bitumen mastic. The product is suitable for coating on a woven base;

- Synthetic adhesive containing artificial resin, rubber. The composition is well suited for material without a base.

Applying glue between joints

When gluing is not recommended

Fixing the material to the base is contraindicated if:

- The area of the rooms does not exceed 20 square meters. The material is spread in one large piece and secured with a plinth;

- The base is loose and unstable. Fixation to an unreliable screed is not recommended;

- The floor was painted, but the paint was peeling off in some places. Glue should not be used due to a possible reaction between the glue and the old coating. The floor may become stained;

- The basis is a screed, even a modern one;

- The floor is shaky, not strong, there are creaking floorboards.

Bonding joints using special equipment

Options for fixing linoleum

And yet we need to figure out the question of whether it is necessary to glue linoleum. There are only two main ways to fix the material on the floor: with or without glue. Among the advantages of the adhesive fastening method is better coating strength. During use, the coating does not swell, does not ripple after furniture is moved, and there are no dents left on its surface from the legs of a table or cabinet.

Among the advantages of the adhesive fastening method are better coating strength

The fixed material remains perfectly smooth during operation and lasts longer. The coating is durable, the seams are securely fastened.

But this method has its drawbacks. First of all, you need to choose only high-quality glue. If it does not meet the requirements, then after a while it will begin to crawl to the surface. In addition, adhesive fastening is suitable only for those who are not eager to change the interior of the apartment every year, since linoleum is glued, as they say, tightly. Removing the old coating to replace it with another will be problematic. Therefore, you should think carefully about whether you need to glue linoleum.

Among the old fastening technologies without glue - fastening with ordinary nails

Among the old fastening technologies without glue is fastening with ordinary nails. Despite the significant development of technology, the good old method is still alive and is still used along with the more modern one - fastening the sheet using skirting boards.

However, glueless technologies are gradually becoming obsolete. They are no longer popular among professionals. Why will become clear almost immediately after the start of operation. Even a slight movement of the furniture will cause the surface of the material to wrinkle; it will have to be constantly adjusted. And waves are a characteristic feature of a glueless connection. Therefore, even if the room is small, according to experts, the question of whether to glue linoleum is no longer relevant. The answer is unequivocal - “Yes”.

Important! One of the best ways is to attach it to bitumen mastic.

This method is good when there are any defects on the screed, and the question arises of how to glue the linoleum, since neither glue nor tape is suitable in this case. Mastic is a good option for gluing linoleum in spacious rooms.

Mastic is a good option for gluing linoleum in spacious rooms

It is recommended to glue the material onto a floor without a base using mastic based on synthetic resins. To work with material based on felt or fabric, especially if it needs to be glued to a wooden floor, types of mastic are used:

- Biscuits;

- DFK;

- Acrylax;

- Syntalax.

Bituminous mastic will additionally serve as waterproofing

Bituminous mastic will additionally serve as waterproofing. But before application, it is necessary to coat the floor with a layer of primer to improve adhesion.

How to lay linoleum with your own hands

In order for self-laid linoleum to be pleasing to the eye, not to swell or wrinkle, it is necessary to fulfill several mandatory points. The first is related to the preparation of the foundation. You already know that it should be even. In addition, it must be dry and clean. No dust or any grease or other stains. We collect everything with a vacuum cleaner, remove stains with a suitable product, and dry everything thoroughly. We do all this carefully: dust impairs adhesion to the base, and debris particles will eventually appear through the coating.

Before laying linoleum, prepare the base

The second mandatory condition: before laying linoleum, it must “rest” for some time in a straightened state. Preferably at the installation site. It is rolled out and left for at least 2 days, but better - for 5-7 days. So it straightens out and takes on “working” dimensions. After this you can start cutting.

How to trim

Let's start with how to cut linoleum. There are two options - a knife and scissors. Both can work normally, they just have to be sharp.

Some people find it more convenient to use a stationery knife, but a shoe knife or a sharp kitchen knife will also work, although there are special ones. They have a retractable blade, like stationery knives, but their handle is curved and the blade almost does not bend.

Knives for linoleum

On a utility knife, the ridges that hold the blade must be iron. In this case, the blade is more elastic and there is less chance that the cut will go to the side. It is precisely because the blade can “lead” that some craftsmen prefer powerful scissors. To make cutting easier, they make an incision, and then, without making cutting movements, they simply rip the coating along the intended line.

Now about where to trim. Roll out the linoleum so that it extends slightly onto the walls. If there are several canvases, an overlap of at least 5 cm is made at the junction. If there is a pattern, lay out the canvases so as to achieve a match. Then the connection point will not be noticeable.

How to cut linoleum

The linoleum is cut in the corner, the joint remains overlapped and is trimmed after gluing the main part. The canvas is pressed to the floor and cut off with a knife or scissors. Please note that if work is carried out in a cool room, in summer the coating will increase in size due to high temperatures. If you cut the canvas close to the wall, in the summer a roller will form near the baseboards. Later, at lower temperatures, it can stretch, but in the summer it spoils the appearance. Therefore, when cutting, retreat from the wall about 1 cm.

Glue to the base

If you decide to lay linoleum without gluing, it is usually fixed along the baseboards with double-sided tape. The same material is glued in the door area. In this case, turn away the edges and stick tape on the base. We return the edges to their place and carefully level the coating. After making sure that it lies flat, without distortions or waves, remove the protective tape from the adhesive tape and glue the covering.

If you work with glue, you act a little differently. Roll the covering up to half its length. The composition is applied to the floor (strictly according to the instructions). If there is a joint, a strip of about 35 cm wide without glue is left on both sides of it. After waiting the time prescribed according to the instructions, the linoleum is rolled out again and pressed well.

Roller for rolling linoleum

The technology requires a pressure roller - a heavy cylinder (about 50 kg in weight), movably mounted on a handle, which squeezes out air and presses the coating to the base, ensuring good adhesion. If there is no roller, take a plastic smoother, which is used when gluing heavy wallpaper, and press everything well with it. You can use a board wrapped in felt or felt or something similar.

Then glue the other side. If the canvas was laid in one piece, we can assume that the installation of linoleum is completed. All that remains is to secure the baseboards. If there are any joints, we continue.

Seam processing

If there are two or more canvases, the seams will need to be processed. There is a simple way - take a T-shaped metal strip and secure it at the joint (attached with screws or dowels, depending on the type of base). The method is not very aesthetic, but reliable. This is exactly what they do if two pieces of linoleum with different colors are joined under the door.

It is better to connect two pieces of linoleum of different colors with a plank

A more aesthetically pleasing way is to use cold weld linoleum glue. First you need to trim off the excess material at the joint. We take a metal ruler (a level or a rule will do), apply it at the joint, cut both sheets along it with a knife, and remove the excess strips. It is very important to cut through both sheets at once. In this case, if the pattern is chosen correctly, the connection is imperceptible, since the two canvases match perfectly. If the base under the linoleum is hard, you can put something soft under the joint - a piece of felt, linoleum, etc. Then it will be easier to cut both sheets at once.

How to cut so that the linoleum joint is perfect

We unscrew the non-glued parts of the coating along the seam, apply glue, wait, if necessary, the time according to the instructions, glue the coating in place, and roll it with a roller. We wait the time required for the glue to dry (according to the instructions).

Next, we take cold welding for linoleum joints and wide masking tape. We glue the joint with this tape, then use a utility knife to cut it along the joint. This is necessary to protect the coating from accidental contact with the composition. It is chemically active and will melt the coating, leaving an unsightly stain. The next steps are:

- Open the glue. It has a nozzle with a needle, we screw it onto the tube.

- We insert the needle at the very beginning of the seam, gently press the tube until a spot of glue with a diameter of 3-4 mm appears on the masking tape. After this, we slowly move the needle along the cut, making sure that the amount of glue squeezed out is the same throughout.

- Having filled the seam, wait 15 minutes (see the instructions for the exact time), after which we remove the tape with excess glue.

How to join linoleum discreetly

If everything is done correctly, the joint is almost invisible. There is no need to test it yet - several hours are required for final polymerization. But that's all. Linoleum is laid and you know how to lay it yourself.