Wooden and laminated timber

Wood (pine, spruce, larch, oak and other species) is a classic of house construction, a favorite material for many. Wooden houses are very beautiful, many believe that they are easy to breathe in, they are strong, warm and quite durable (if the log house is made with high quality and is properly maintained, it will last for 300 years).

Photo: Irina Plotnikova

But due to the natural disadvantages of solid timber or logs (we’ll talk about them below), many choose its “upgraded” version - laminated veneer lumber. It is a kind of “sandwich” consisting of thin boards - lamellas, which are connected to each other with an adhesive composition and thus form a single conglomerate. This technology for processing wood deprives it of many disadvantages, but still, since there is no ideal building material, you can find fault with laminated timber if you wish.

We have listed the advantages of a wooden house above. We suggest going straight to the shortcomings.

- The tree is subject to shrinkage. Therefore, it is not recommended to move into a newly built log house and especially to carry out its interior decoration right away. Such a house should be allowed to stand for some time.

- Logs have a standard size of up to 6 meters. This means that if the room is wider than 6 meters, then it will be difficult to make a ceiling out of them in a wooden house. Therefore, usually the interfloor floors in wooden houses are made of beams and wood, and this affects sound insulation.

- Wood is adored by wood-boring beetles; it rots easily and easily molds (and therefore collapses). To prevent this from happening, a wooden house must be regularly treated with antiseptics, which make the material “inedible” for pests. This will incur additional operating costs.

- In order for the walls of a wooden house to be warm, you need to ensure that they are well insulated (caulked). Over time, the integrity of the caulking may be compromised; this point must be monitored during the residence process.

- Wood, as we all know, burns wonderfully. Therefore, the material must be treated with flame retardant solutions, and the treatment must be repeated every few years. Among other things, you need to be careful when using a house - a fire will break out in it and spread faster in any case than, say, in a stone mansion.

Let's move on to laminated veneer lumber. It eliminates a number of disadvantages of solid wood. Firstly, the timber has a jagged profile, and this method of connecting wall elements will better retain heat. The clear geometry of laminated veneer lumber leads to the fact that it is assembled like a construction kit - faster than, say, a house made of logs. This house does not need shrinkage; you can work with it immediately after construction, and fire and bioprotective impregnations are “poured” into the timber at the factory. So, compared to wood, laminated veneer lumber is actually easier to construct and more convenient to use - while retaining all the positive properties of wood.

Photo: rubrus.ru

And now - about the shortcomings.

- The main disadvantage of a house made of laminated veneer lumber is its high cost. The material is not cheap, so you will have to pay a lot of money for such a structure.

- And besides, no matter who would put together such a house: only specially trained specialists can do this, so in addition to the high cost of the material itself, there is also the rather serious cost of the work and the difficulty of finding a qualified team.

- Some people don’t like the fact that glue is used in the production process, which means this material cannot be called 100 percent natural.

Advantages and disadvantages of finishing with false beams

False beams are superior in decorative characteristics to any other siding, even those imitating the texture of wood. Firstly, the material is natural wood. Secondly, its outer surface exactly matches the profiled timber

However, an attractive appearance is an important, but not the only advantage of cladding.

Among the main advantages are:

- Environmental cleanliness. The lumber is completely environmentally friendly. It does not emit harmful substances and is absolutely safe for humans.

- Easy installation. You can install the panels yourself. To do this, you need to have an idea of the procedure for carrying out the work and the availability of minimal construction skills.

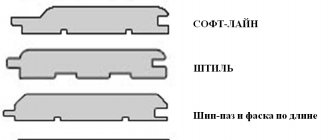

- Tongue and tongue connection system. Thanks to the presence of tenons and grooves, the lamellas are securely fastened to each other, and the entire structure is ventilated through the grooves on the back side of the panels.

- Low cost. Finished products are not much more expensive compared to artificial turf, and the installation price for all types of siding is almost the same.

- High aesthetics. A facade covered with building materials looks neat, expensive and noble, and only a professional can distinguish it from real masonry.

- Protective function. Sheathing protects walls from mechanical influences, sunlight, and natural phenomena.

- Long service life. With proper installation work and timely maintenance, the coating will last quite a long time.

- Thermal insulation and noise reduction. Cladding increases the thermal insulation and sound insulation properties of enclosing structures.

- A light weight. Thanks to this, you can cover almost any partition.

Like any other material, false timber is not without its drawbacks. The most critical disadvantages include:

- Low fire resistance. The lamellas quickly ignite; even treating the finishing surface with special compounds does not eliminate this parameter.

- Periodic care. It is necessary to regularly, every 2-3 years, change the paint layer, treat the surface with antiseptic and other means that protect the wood from precipitation, rot, and pests.

- Price of components. Unlike imitation timber, the cost of additional elements (for example, external or internal corners, decor, window framing) is very high.

Siding for exterior cladding of a wooden house

A material specially created for finishing facades. It is produced in the form of lamellas of a special profile (“herringbone” or “ship”), with locks on the long side and special perforations for nail fastenings. The slats are connected to each other with special latches and form a dense coating.

Siding is made from various materials:

- polymers;

- metal;

- cement-bonded bonding materials.

The width of the planks ranges from 10 to 30 cm, and the length is 2 to 6 m. Like wooden cladding materials, siding is installed in a horizontal position with the profile positioned in such a way that rainwater certainly flows down without getting inside the wall.

The variety of color solutions and ease of installation have determined the exceptional popularity of siding in the cladding of various types of buildings - from residential buildings to industrial, commercial and public buildings. In addition to the slats themselves, we also produce a wide range of profile parts - internal and external corners, cornices, connecting strips, etc.

The external texture of siding, regardless of the material of manufacture, usually imitates the natural pattern of wood. The slats are coated with a polymer coating or weather-resistant paint, which is also highly durable - it is quite difficult to scratch the siding by accident. All materials used to make siding are highly weather resistant and practically unaffected by moisture. The service life of siding is several decades.

Houses made of timber: how to assemble

Timber processing process

A log house necessarily involves treating the wood with various chemical compounds. To maximize the protection of wood from premature destruction and ignition, you must adhere to the following scheme:

- First, the wood is treated with a special antiseptic;

- Next, a fire retardant composition;

- Then light protection;

- At the very end, waterproofing is used.

Wiring a house made of timber

Anyone who is interested in the question of how to make a log house from timber with their own hands should know this. The first crown of the log house (or frame) should be laid level on the pre-dried waterproofing

It is important to remember that the first crown must have a larger cross-section than the others. This ensures overall stability of the entire structure.

The first crown must be laid on a backing board.

The wooden frame is fixed to the foundation with metal anchors. The box is attached to the foundation only if we are talking about a small building. Large houses with several floors will be stable due to their weight without additional fixation.

The walls of a timber house are built by laying alternate rows. For this reason, the main thing is to understand how the first crown is laid. All crowns and rows are fixed using a dowel.

All layers of timber alternate with tenons and grooves to achieve maximum strength and reliability of the entire structure. In addition, this allows you to make the corners of the building completely windproof. And this has a positive effect on maintaining heat indoors.

Connecting timber in corners and lengthwise

There are two ways to connect timber in the corners:

With remainder;

• No residue.

Moreover, for each method there are several pairing options, which depend on the method of forming the angle itself.

At the same time, there are four options for longitudinal connections:

- Half a tree;

- Longitudinal tenon on dowels;

- Longitudinal root spine;

- With an oblique lock.

The longitudinal connection method using a tenon on dowels is the most reliable. Therefore, it is most widely used when building a log house from timber. In this case, the groove manufacturing technology completely repeats the technology of corner joints with keys.

Methods of finishing a house with wood

Wood cladding of a timber house can be made with the following materials:

- block house made of pine , representing cladding panels with a semicircular shape of the front part, secured to each other using a tongue-and-groove connection, and to the facade with sheathing or to the wall with fasteners;

- plank made of larch or pine , which are planks with ideal geometry and a smooth glossy surface, allowing for butt or overlap cladding at any angle, with fastening to the sheathing or directly to the wall using special fasteners;

- boards made of larch with imitation timber or profiled pine, having excellent shapes, textures and a wide choice of colors, with a simple technology for attaching to the walls of the house or to the sheathing.

Installation of a block house

Cladding a house made of timber with a block house is quite simple; to do this, you must follow the following step-by-step instructions:

- Lay an overlapping waterproofing layer on top of the timber, gluing all joints.

- Fix wooden or steel guides 50x50 mm in a vertical position to the walls of the house at intervals of 50-65 cm so that they are evenly spaced, and the edges of the sheathing are securely fixed to them with screws or nails.

Important! All guides must be located in the same plane so that when installing the sheathing, distortions and deformations do not occur.

- Place the insulation between the guides so that it fits snugly against them.

- Sheathe the resulting structure with an overlapping layer of waterproofing with high strength and density.

- Secure wooden planks along the guides, which will serve as a frame for mounting the block house.

- Lay the first row of sheathing along the plinth with careful alignment and be sure to have the connecting tenon facing upwards. The end part of the plank must first be cut at an angle of 30°. Fasten the block house planks using self-tapping screws or nails.

- Cover the walls with a block house, sealing the joints and carefully checking the evenness of the installation (approximately after 2-3 rows).

- Install additional cladding elements at the corners of the building and at junctions with various structures.

Block house made of pine

Read more

Surface preparation

Preparation for the external cladding of the facade begins with impregnation of the timber with special anti-corrosion and fire retardant compounds. Without an insulation device, a film or a special membrane is laid overlapping the surface. Next, they are attached to the wall with a construction stapler, and the joints are taped. A plaster mesh is attached to the film. Next, it is plastered and stone or facing tiles are laid.

For other types of finishing, start insulating the external walls. After fixing the film, the sheathing is stuffed onto the frame. It is made with a metal profile, or can be made of wooden slats. The profile or batten is filled in increments of 50 cm. Mineral wool or foam plastic is placed in the cells so that 2–3 centimeters of empty space remains to the edge of the sheathing for ventilation of the facade. The insulation is covered with a windproof membrane on top and covered with a plaster mesh for subsequent plastering and stone gluing or painting.

Arrangement of vapor barrier

After the preparatory work has been completed, finishing the house from the timber from the outside, and the wood has been treated with antiseptics, a vapor barrier layer is laid. It is needed to maintain natural air circulation in the wooden walls of the house, which, thanks to their ability to “breathe,” create that unique microclimate that wooden houses are valued for. A special membrane, roofing material, or foil coating can act as a vapor barrier.

Between the insulator and the timber it is necessary to leave a small space for air masses, so wooden slats of small thickness are nailed to the outer walls, and a vapor barrier is already attached to them. The vapor barrier strips are overlapped, the edges are sealed with tape, and direct fastening to the frame slats is done using a construction stapler or nailed.

Options for exterior finishing of a log house

- vinyl siding;

- metal siding;

- block house,

- lining;

- thermal panels;

- fiber cement boards;

- facing brick;

- natural and artificial stone.

Below we will go into more detail about each material.

Vinyl siding

Properties of vinyl siding:

- resistant to any natural factors and chemical environments;

- does not fade under the influence of the sun;

- not subject to rotting and corrosion;

- withstands mechanical loads without deformation;

- frost-resistant;

- service life is more than twenty years;

- It is easy to install and requires no maintenance.

Metal siding

Thanks to this “multi-layer cake”, metal siding is perfect for façade cladding: it is durable, strong, does not burn or support combustion, and has a variety of textures and colors. All elements are equipped with special locks, which allows for quick and easy installation.

The disadvantage of metal siding is the complete lack of thermal insulation and insufficient sound insulation, as well as the instability of the paint.

It should be noted that the weight of the assembled structure is quite large. Therefore, metal siding can be installed if there is a strong and reliable frame.

Block house and lining

Larch or coniferous species are used to produce lumber. The lining is a perfectly smooth polished board equipped with fasteners. The block house, on the one hand, has a flat surface, on the other, a semicircular surface, imitating the shape of a log.

External finishing of a log house with clapboard or block house allows the house to preserve its natural color, and also provides good sound and heat insulation and protects the building from adverse factors.

Facade thermal panels

The panels are a monolithic structure, which includes moisture-resistant tiles and insulation, connected to each other with a high-quality adhesive composition.

Thermal panels have an aesthetically attractive appearance; they are available in different colors and textures. The surface lined with panels imitates a stone or tile finish. Clinker, porcelain stoneware or glazed tiles are used as facing materials in thermal panels.

Facade tiles are lightweight, so when installing them, there is no need to strengthen the foundation for the log house; finishing is done without strengthening the base.

The panels are suitable for cladding any surfaces; they are used to decorate buildings made of profiled and laminated timber, as well as log houses. Installation of facade panels is quite simple using ordinary dowels.

Fiber cement boards

- resistant to corrosion and rotting;

- fireproof, do not ignite under the influence of open fire, and do not support combustion;

- heat-resistant, tolerate any temperature;

- not susceptible to chemicals and biological factors;

- resistant to ultraviolet radiation.

Fiber cement boards are available in a variety of textures: stone, brick, granite and other materials. With their help, you can hide all the unevenness and defects of the walls; surface preparation is not required. The panels can be installed directly on the wall without installing lathing.

Brickwork

Decorating a house made of timber with brick from the outside is one of the best options. Brick is a very practical and durable material. It is not affected by bad weather, humidity, or temperature changes. Brickwork provides good sound and heat insulation of the house, which will also receive reliable protection from any mechanical and other adverse influences.

It should be noted that if you choose this option for finishing a house made of laminated veneer lumber, you will first need to strengthen the foundation, since the brick structure is quite heavy. In addition, it is necessary to ensure that wooden walls have good ventilation. To do this, small ventilation holes must be left in the lower and upper rows of the brickwork.

Decorative stone finishing

Wood and stone go well together, so you can think of a wide variety of combinations of these two materials.

Decorating the house with cord

Recently, retro style has become very popular. You can give your home an antique look using a special cord. Usually jute rope is used for these purposes. Finishing a log house with cord can be done both on the outside and on the inside of the house.

Rope finishing, in addition to decorative purposes, serves to insulate the house, and also allows you to close the caulked inter-crown seams of the log house.

Recommendations for choosing wood species

The finishing of a log house should be done with a suitable type of wood in accordance with the following recommendations:

- to finish facades with complex shapes or if wood carving is necessary, it is recommended to choose soft wood species such as cedar or pine;

- with increased requirements for the durability of the facade, it is recommended to choose hard wood (oak, larch), the service life of which is at least 100 years;

- in climate zones with high precipitation or extreme temperature fluctuations, larch is suitable;

Important! The type of wood should have an optimal price and be available for sale. This will make it possible to quickly carry out partial or complete replacement of the cladding in order to provide the required level of façade protection at minimal cost.

- in hot climates, it is recommended to sheathe facades with wood that contains a minimum amount of resin (oak);

- to increase the level of heat and sound insulation of a house, it is better to sheathe the building with materials with a minimum thermal conductivity coefficient and optimal density (larch as the main material and pine for creating decorative structures with complex geometry);

- pine is suitable for finishing houses with a minimum budget and the need to insulate walls without additional installation of thermal insulation materials.

Interesting ideas

Facade decoration is not the least important thing in modern construction conditions. It is necessary in order to hide existing defects and imperfections in construction work. Decor is also often used to update the appearance of a country house, restore it and achieve greater attractiveness. The structure can be given a Gothic, Scandinavian, Byzantine look. It all depends on desires and design imagination. An important argument in favor of decorating the facade are some practical aspects. For example, insulation.

Currently, he identifies several of the most popular preferences for decorating the facades of private houses.

Decor of curved and framed facades

As a result of recent years, there has been a noticeable increase in demand for various curved and framed facades, for the manufacture of which high-quality MDF is used. These materials can be used to decorate both the walls of a building and the corners of a country house. In addition, there are some developed technologies, following which you can install the facade of a house in accordance with any style and architectural direction that will emphasize individuality.

Provence

This style is most preferable for adherents of natural facing materials such as brick, ceramics, and stone. Predominantly the presence of light shades, in which the decor of the facade of the house is carried out. This finish is refreshed with some kind of colorful, eye-catching panel with a ceramic tile base. The façade can also be finished using decorative plaster, overlay elements or painting.

Scandinavian

The founders of this style are lovers of laconicism, the predominant absence of eye-catching decor and the presence of uniformity. Thus, the Scandinavian style of installation pursues the goal of visually increasing the space in size. This style is characterized by cladding materials such as wood, brick or stone masonry. The Scandinavian style is suitable for light and warm shades of colors and a lack of contrasts.

High tech

This style is characterized by modern origins and focuses on the use of various modern construction technologies that provide maximum convenience. The high-tech style is characterized by the extensive use of glazing in combination with different geometric shapes.

European style

The world's architectural art is dominated by a considerable number of very different design styles, including characteristic features from the Gothic and Byzantine movements. Both in Western countries and in Russia, Gothic styles and designs that came from the Middle Ages are especially popular and in demand. A popular trend is to combine the Gothic style with some other style. This style is characterized by difficulties in installing the facade.

In addition to the above styles, there are others, each of which has its own characteristic features and practical aspects, namely:

- avant-garde;

- country;

- colonial;

- classic;

- minimalism.

Very interesting and original design solutions can be obtained as a result of the correct combination of two or more styles of facade decoration. Today, there is an opinion among designers that the most original and unusual design can be obtained by combining a modern “chalet” with some additions to the classical style.

To learn how to cover a wooden house with siding, watch the video below.

Decoration of house facades

Many ordinary people have the opinion that wooden houses do not need façade finishing. Their logic is simple: a naturally beautiful and warm material does not need to be hidden behind any additional layers. In fact, properly selected finishing materials help make a wooden structure more attractive, practical and durable. What materials can be used to finish a wooden facade? The construction market offers a large selection of modern and classic technologies. But it should be noted that the following requirements apply to all finishing materials:

- attractive appearance;

- good resistance to atmospheric agents;

- the cladding should protect the wood, making the structure more durable;

- compliance with basic and/or advanced fire safety requirements;

- good thermal and sound insulation performance.

If the technology meets the described requirements, then the rest of the façade finishing options can be chosen based on your own design preferences, available budget and design features of a particular wooden house. Below we will look at the finishing technologies in demand today.

Decorative plaster

No matter how strange it may sound, such a traditional coating is often applied to external wooden walls today. But there is one limitation.

- This technology is not suitable for log houses.

- But if the structure is made of timber or SIP, then finishing the facade of a wooden house with plaster can be a good solution.

Before applying a layer of decorative composition, it is important to treat the wooden surface with products that will protect it from moisture and destructive biological factors. Finishing facades with plaster begins with attaching a layer of waterproofing. After this, a reinforcing plastic mesh is attached to the treated surface, and a layer of cement-based mixture is applied to it. The choice of decorative plaster mixture depends on the preferences of the owner. Today, mineral compositions are common, which form an attractive pattern during the solidification process. Home owners often prefer acrylic plaster. It is easy to apply and provides good natural air microcirculation. It is critically important to prepare the composition for application in strict accordance with the instructions. Mixing ready-made plasters from different manufacturers is not allowed, as their polymer and/or mineral compositions may be incompatible. Construction market experts recommend buying already colored mixtures from well-known manufacturers, as this usually guarantees the optimal proportion of color pigment.

Curtain facade for a wooden house

Finishing the facades of private houses using this technology is a relatively new, but already popular technology. It is used for cladding both new and restoration of old wooden structures. A hinged or ventilated facade allows you to use almost any material for exterior decoration, from clinker tiles to composite panels. The technology involves installing a special frame on the external walls of a wooden house. The base has special fastenings for insulation and exterior finishing. The peculiarity and main advantage of a ventilated facade is that a small air space remains between the wall and the curtain structure. This ensures sufficient natural ventilation so that moisture does not accumulate on the wood and thermal insulation and mold does not develop. Additional advantages of finishing the facade of a house using a curtain wall include the following qualities:

- technological simplicity of insulating wooden walls;

- protection against the formation of pockets of moisture;

- the ability to implement different design ideas;

- the air gap helps maintain an optimal indoor microclimate at any time of the year;

- the lightweight suspended structure can be quickly installed without transferring significant loads to the walls and foundation;

- insulation and cladding can be done independently without the use of special equipment;

- the use of mineral insulation makes the house more fireproof.

If heavy materials will be used for finishing, such as porcelain stoneware or clinker tiles, then you need to carefully calculate the load to select fasteners.

Insulation of a wooden house with Isoplat

It is very easy to insulate a wooden house with Isoplat. The plate is a dense, but at the same time elastic material. It is enough to simply press it against the wall and nail it with nails with a wide flat head. Isoplat fits securely to the base and prevents the appearance of “cold bridges”. A ventilated facade is installed on top of the slab. In addition, Izoplat slabs of 25 mm or more can be covered with plaster. Insulation in this way can be done independently without the involvement of specialists. This is the fastest, easiest and most reliable option for insulating a wooden house.

It is very simple to insulate a wooden house with Izoplat slabs

Basic Rules

When selecting materials for cladding a house from the street, be sure to remember that in order to maintain normal humidity in the rooms, the vapor permeability of the materials must decrease from inside the room to the outside. That is, the exterior finishing should conduct steam better than the wall material. Then the increased humidity, which is typical for our homes, will be removed through the walls naturally (explanations in the photo).

When deciding what is best to sheathe the outside of the house, do not forget to take into account the vapor permeability of the materials

If this principle is violated, moisture will accumulate at the interface of materials with different vapor permeability. It condenses, creating conditions for rotting and the development of fungi and mold. In winter it freezes, destroying the wall material and/or finishing. Sooner or later such a system will have to be dismantled and rebuilt.

The trouble is that only wood meets this requirement. Most other materials for exterior decoration of a house have low vapor permeability. The problem is solved in two ways:

- A ventilated facade is being installed. A ventilated gap with a width of 60 mm to 150 mm is left between the wall or insulation layer (with high vapor permeability) and the finishing. Ventilation holes are left at the bottom of the cladding at the rate of 75 cm² for every 20 m² of wall, including windows and doors. Air will enter through them. There are exit holes at the top. With this device, moisture will be removed from the wall material or insulation, and the outer cladding will protect from precipitation and perform a decorative function. The principle of finishing a house using a ventilated facade

- The finishing material is attached directly to the wall. But from the inside the wall must be protected by a layer of vapor barrier. In this case, the penetration of vapors into the wall material is prevented and it remains dry. Excess moisture is removed by the ventilation system.

Today the second option is becoming increasingly popular. Very effective thermal insulation materials have appeared that can significantly reduce heating costs. But they have very low vapor permeability (expanded polystyrene and extruded polystyrene foam). When using them, only the second humidity control scheme is possible. When choosing what to cover your house with, consider these points.

Material selection

Siding today comes in three varieties:

- fiber cement (another name is cement fiber);

- metal;

- polyvinyl chloride (for short called vinyl or simply plastic).

Vinyl siding is the most popular - it accounts for 70% of all sales.

Vinyl siding

This is explained by a number of advantages of this material:

- Low cost.

- Light weight, due to which there is no need to strengthen load-bearing structures and foundations, and delivery and installation are extremely simplified.

- The widest selection of colors and textures. PVC plastic, like any other, can easily be given any shape, which manufacturers successfully use: siding is produced that imitates wood, brickwork, straw and other materials.

- Resistant to all weather conditions.

- Sufficient mechanical strength.

When choosing vinyl siding, consider the following:

- The cheapest panels are those that imitate wood. They are also the most popular - they account for approximately 80% of consumer demand. Siding with a more complex texture may cost more.

- You shouldn’t buy cheap siding from a little-known manufacturer out of a desire to save money. Some buyers think that there is not much difference, they say, siding is just a piece of plastic. In fact, a lot depends on adherence to technology: low-quality siding does not burn evenly, but in spots. In addition, the material itself is less resistant to ultraviolet radiation, which causes the destruction of polymers.

Siding in pastel colors is considered the most preferable. Compared to brightly colored panels, it has the following advantages:

- fades less quickly and less noticeably in the sun;

- less susceptible to thermal expansion;

- has a lower cost.

Among the manufacturers of vinyl plastic, Russian, Docke, FineBer, Grand Line, Northside, Belarusian Atlantic, U-Plast, Vox, Polish Royal, Canadian Vytec, Mitten and American Elixir, Variform have proven themselves well.

Selection of finishing materials

So, we have to cover the outside of the house from timber.

For these purposes, you can use the following materials:

- vinyl siding;

- metal siding;

- block house;

- thermal panels;

- lining;

- fiber cement panels;

- brickwork.

- . Again, this material is not afraid of direct sunlight, since the plastic is resistant to ultraviolet exposure.

The photo shows vinyl siding

Today, such material is considered the most popular, but not only because it practically does not age, but because it is easy to install and requires virtually no subsequent maintenance.

- . Therefore, this material is not widely used in the finishing of individual buildings.

- . A building finished with a block house is often confused with a house built using rounded logs. The block house is made from residual lumber obtained during the manufacture of wooden beams.

Connection of block house panels

Structurally, this finishing material is very similar to lining, as there is a tongue-and-groove connection. But the block house, unlike ordinary lining, repeats the relief of the log, and therefore is widely used for cladding low-rise buildings.

This finishing material is based on polyurethane foam, so thermal panels are characterized by low heat and noise conductivity. Again, this finishing material is lightweight and easy to install. Among the significant disadvantages is the high cost of finishing.

- . The advantage of this material is not the highest price and ease of installation. You can probably handle installing this material yourself.

- X. Gradually, this finishing material is penetrating the domestic market.

Color versions of fiber cement panels

A distinctive advantage of this material is its relatively light weight with a wide range of colors; the panels, when installed on the wall, not only protect the wooden house from destruction, but also perform the function of heat and sound insulation. Installation of the panels is simple, as it is performed directly on the wall of the house without the use of lathing.

- . After all, through decorative brickwork you can protect wooden walls as much as possible from the negative effects of environmental factors. But the problem is that it is difficult to lay such masonry with your own hands, therefore, for such work, professionals should be involved.

Decorative brickwork

Installation of Block House

Let's look at how the most popular exterior cladding of a timber house with a block house is carried out.

Installation of this finishing material consists of the following steps:

- wall surface preparation;

- insulation of walls and installation of load-bearing sheathing;

- preparing panels for installation;

- installation of panels.

The panels should be mounted on smooth and dry walls. The wooden surface must be examined for areas affected by mold and mildew. Next, these places are treated with an antiseptic primer and sanded.

At the same stage it is necessary to waterproof the walls. To achieve this, the wood is treated with water-repellent compounds that make the surface of the walls more hydrophobic. As a result, during the operation of the building, mold and mildew will not appear under the layer of the block house.

Lathing on timber walls

Before installing the panels, the surface is covered with lathing. The sheathing can be made from wooden beams or from a metal profile. The primary task is to bring the surface of the sheathing to one level in a vertical plane. The installed wooden sheathing must be covered with a protective layer of drying oil or varnish.

Before proceeding with installation, the material must be kept outside for a couple of days so that it acquires the appropriate humidity and temperature.

The installation of a block house is traditionally done with the tenon facing upwards. In this case, water will not penetrate into the groove.

Installation is carried out via:

- nails (budgetary but short-lived fasteners);

- galvanized self-tapping screws (the most common fastening element);

- special staples (clasps).

Block house laying diagram

Types of timber for log houses

Three types of timber are used for the construction of a log house:

Sawn timber.

Profiled solid timber.

Glued laminated timber.

Each of these materials has its own characteristics.

Sawn timber

This is the easiest type of timber to produce. It is made by sawing logs, in fact, removing slabs from it on four sides. The simple shape and simple production technology determine the low cost of the material.

Timber is made from raw or partially dried logs. Before use on a construction site, they can be dried, but they can also be used raw, with drying as part of the log house, which avoids distortion due to the rigid fastening and weight of the elements located above.

Sawn timber can be subjected to additional processing - planing of the sides. Thanks to this, they are calibrated in width and obtain smooth surfaces ready for finishing.

The main advantage of sawn timber is its low cost. Moreover, compared to construction from logs, it produces walls with a flat surface.

The disadvantages of sawn timber are a consequence of the low degree of processing of the material:

- severe shrinkage of the frame;

- relatively large labor costs for caulking joints and subsequent maintenance of seals;

- the possibility of blowing through the seams and water flowing into them;

- tendency to warp.

Profiled timber

Profiled timber is a beam that has a special cross-section that is formed by milling. Let's evaluate the pros and cons of profiled timber. Dried timber with a natural humidity of about 20% is usually subjected to profiling. But drier material can also be used.

The section of profiled timber has several characteristic features. Smooth side surfaces with chamfers, smoothing corners and forming a linear structure of the log house wall. The upper and lower surfaces have a relief that forms a lock, which fixes the elements of adjacent crowns and helps seal the inter-crown seams. The complexity of the profile can vary greatly from one manufacturer to another. The profile of the edge sections prevents water from flowing into the seam.

Advantages of profiled timber:

- clear fixation of the crowns when assembling the log house;

- reliable and low-cost sealing of joints;

- good protection against blowing;

- reduced shrinkage, usually not exceeding 5%;

- smooth surface requiring virtually no finishing.

The disadvantages of profiled timber are the increased cost and the usual mobility of wood when humidity changes, including seasonal ones.

Glued laminated timber

Glued laminated timber is obtained by gluing together 3-8 lamellas with a multi-directional structure. For this, well-dried material and modern adhesives are used, ensuring high bond strength. After gluing, the timber is given the desired profile.

This technology offers several advantages.

- Natural restrictions on the thickness and length of parts are removed. The length can reach 20 m, which is almost impossible for a solid beam.

- By combining lamellas with different arrangements of annual layers into one “package”, possible curvatures due to changes in humidity are compensated. Glued laminated timber is practically not subject to warping.

- The shrinkage of a log frame made of laminated veneer lumber does not exceed 1-3%, which allows for faster commissioning of the building.

- Smooth walls with smooth surfaces.

This material has only one significant drawback compared to less technologically advanced analogues - the highest cost among them.

Sometimes doubts are expressed about the environmental friendliness of laminated veneer lumber due to the presence of adhesive seams in its structure. But if the gluing technology and relevant standards are followed, the effect of the glue on the composition of the air in the house is practically zero.

Interior decoration of a timber house: painting windows and doors

Before painting wood windows and doors, the surface should be prepared to ensure that the paint will apply smoothly and remain on the wood for a long period of time. To carry out the preparatory work efficiently, you may need the help of a specialist.

To begin with, they inspect the surface intended for processing, identify and eliminate possible defects. If windows and doors do not close well or are in unsatisfactory condition, the structures must be repaired before painting them. After this, the surface is cleaned of dust and sanded with sandpaper. Adjacent parts that do not need to be painted should be sealed with protective tape.

When painting interior doors in a house made of timber, the surface is first treated with a brush, which is drawn in a horizontal direction, and then the strokes are shaded, moving the brush vertically.

When decorating the interior of a log house, the paint coating on the door varies depending on whether it is smooth or paneled. Applying a layer of paint to a paneled door begins with painting the grooves and recesses of its panel. In this case, a narrow brush or a regular paint brush is used, which is held at an angle. After processing the recesses, they move on to the areas between the recesses, and then to the door strips (upper and lower). The vertical beams are painted last. The smooth door begins to be painted in the upper left corner. Then they move to the right corner, after which they gradually go down.

For the threshold you need to choose abrasion-resistant paint. To paint this element, use a wide paint brush.

To paint window and door frames, it is better to purchase alkyd-based enamels. It is necessary to work with these coatings in the morning, so that the smell from the paint has time to dissipate during the day.

Painting windows is quite a labor-intensive task, since during the processing process you should avoid getting paint on the glass. Window sashes are painted along the beams

It is necessary to pay attention to the corners, since it is in these places that gaps often remain. First, the movable window sashes are painted, then it’s the turn of the stationary sash bars.

The window sill and frame are painted last.

Door frames, as well as window frames, are covered with the same paint as the windows or doors on the outside. To allow the paint to dry completely, windows and doors are left open for two days. This ensures it dries completely and also gets rid of the smell.

The door can be varnished. However, before you begin this process, you need to decide what type of varnish is best to use for the interior and entrance doors. Since the front door is constantly exposed to atmospheric changes in the environment and temperature changes, its coating deteriorates faster. That is why to paint it you need to use a varnish that is highly wear-resistant. It is best to paint the inner door with a waterproof varnish intended for parquet.

Before painting, the door is removed from its hinges and laid on a flat surface, after which it is carefully processed with sandpaper. Both the side surfaces of the door and its leaf are sanded. The resulting dust is carefully swept away with a brush and the surface to be treated is wiped with a damp cloth, and then a primer is applied.

After the primer has dried, the door is sanded again with sandpaper and varnish is applied. It can be colored or colorless. If colorless varnish is used, then the door is first coated with stain before applying it. The varnish is applied to the surface using a brush or roller - first the first layer, and after it has completely dried - the second.

Home insulation

The next stage of finishing a house made of timber from the outside is installing insulation. To do this, a sheathing is initially constructed, in the cells of which the selected heat insulator will be placed. Today there are many materials for home insulation, the most popular, the price of which is affordable and installation is possible on your own (without special tools and certain experience), are:

- mineral wool. Environmentally friendly, non-flammable, vapor-permeable, convenient and inexpensive fibrous material, the effectiveness of which has been proven for more than one decade;

- penoplex. One of the new materials produced by polystyrene extrusion. Lightweight, safe, easy to install and inexpensive. It retains heat well, but is vapor-tight, so it requires special technology when installing a vapor barrier and organizing ventilation.

The choice of mineral wool is preferable. It is produced in rolls and slabs, the latter are more convenient for installation and are perfectly installed in sheathing cells prepared just for their size.