Sequence of painting work

To properly paint a wooden house, you need to follow the technology and sequence of actions. Painting a frame house follows the same rules as a log house.

- First of all, the surface is cleaned of dust, construction debris, and resin stains - otherwise, mixed with the paint, foreign particles will remain on the facade. If this is not the first treatment of the building, then carefully remove the previous paint and clean the surface down to wood.

- Then mechanical grinding of the surface is carried out manually or using a grinding machine. Sanding and further painting are carried out with a short break, no more than 3 days, so that the cleaned base does not have time to suffer from external factors.

- In an old house, cracks, unevenness and damaged areas are puttied. If nails or other metal elements protrude from wood, they are coated with a special primer designed for metal.

- After this, the entire surface is covered with a primer with antiseptic properties and impregnations. The primer will not only perform protective functions - after its application, paint consumption will noticeably decrease and it will apply more evenly.

- Then they move directly to painting. The paint is applied with a roller or sprayed with a spray gun. It is necessary to take into account that acrylic facade paints and varnishes are too thick and viscous - only a professional tool is suitable for them. To use household sprayers, the paint will have to be thinned, which means the layer will be thinner than the manufacturers recommend.

- Painting is done in several layers. Each subsequent layer is applied only after the previous one has completely dried. When painting with a roller or brush, apply the paint along the grain of the wood.

Tools for work

Paints are applied to the prepared wooden surface mainly using brushes. To cover large areas, rollers or spray guns and aerosol cans are used.

The main tool when painting wood is, as banal as it may seem, a brush!

In most cases, the choice of tool depends on the composition of the coating and the purpose of the product being painted. Furniture and interior items are painted mainly with hair brushes, which have a denser structure and apply a smooth layer of material.

Large surfaces outside (for example, fences, facades) are treated with synthetic brushes or rollers. Professional painters use spray guns, where the paint mixture is supplied under pressure and is able to quickly and evenly cover large surfaces.

Cloth or pad dyeing methods are used, but they are usually used for artistic, decorative color finishing of wooden objects.

Preparing the house to paint

fungus removal

If a fungus is found on the wood, then before you start painting, you should get rid of it. The fight against fungus should begin with eliminating the causes of its occurrence: increased humidity and temperature. Fungal spores are very volatile and also often cause allergies in people. The area damaged by the fungus is mechanically removed by any of the available means: a knife, a scraper, a scraper, a metal brush, etc. The shavings, sawdust, and wood dust obtained as a result of cleaning should be carefully collected and burned to prevent further spread of the fungus. The cleaned area is thoroughly washed with a washing solution and dried.

To destroy the fungus, the wood is treated with special antiseptic agents, a large number of which are available in the retail chain. Commonly available folk remedies for mold control include treatment with hydrogen peroxide, chlorine-containing bleach “Belizna”, vinegar, an aqueous solution of ammonia, an aqueous solution of borax and some others. It is also worth treating areas of wood adjacent to the affected areas with antifungal drugs, since they are most likely also infected with fungal spores.

resin removal

Resin protects the wood from rot and insects, but when painting, a large amount of resin will interfere with the adhesion of the paint to the surface. You can remove resin from wood in places where there are knots mechanically, using a knife, spatula or similar tool. If it still continues to protrude, then this place must be heated with a hair dryer and first removed mechanically, and then removed with a nitro solvent, alcohol, white spirit, purified gasoline, turpentine or ammonia-based solvent. After removing the resin, this area is thoroughly sanded. However, you need to know that it is impossible to completely get rid of resin.

surface grinding

Before applying paint, it is necessary to prepare wooden surfaces for painting. This is done by first rough sanding and then fine sanding.

Not all owners of wooden houses take on the task of sanding the facade, as they consider it a very time-consuming and labor-intensive job. However, the sanded facade looks more beautiful and impressive, and the applied paint penetrates better into the wood structure, while its consumption decreases, approaching the data declared by the manufacturer.

For rough sanding, abrasive materials with a grain size of 60-80 are used, and for final sanding - with a grain size of 120. It is undesirable to use finer abrasives, since in this case the pores of the timber will become clogged and the applied protective coatings will not be able to penetrate deeply into the wood. When switching from coarse-grain sandpaper to fine-grained sandpaper, you should not make sharp transitions, but use sandpaper with a medium-sized grain.

It is very difficult to manually clean an area as large as the walls of a house, so it is recommended to use power tools and their consumables. The surface can be processed using various types of grinders: angle, eccentric, belt, vibrating. To sand wood in hard-to-reach places, you should use angle attachments on a vibrating sander.

If the surface of the wood has previously been treated with varnish or glue, then the old paint and varnish coating must be removed. This can be done mechanically, and to speed up the process it is recommended to soften the old coating with a construction hairdryer and remove it with a spatula. Professionals also advise using specialized products for softening varnishes and paints, which are available in sufficient quantities in the retail chain. After loosening, the old coating is removed mechanically.

The wood that is to be painted must be dry and clean, so the surface after sanding before painting should be cleaned of dust using a vacuum cleaner or brush.

Sanded wood must be processed within 24 hours, otherwise the depth of penetration of primer, paint or varnish deep into the wood structure will decrease.

Preparatory stage before painting

Before you understand the technology of painting wooden products, you need to prepare them appropriately so that the paint lays evenly and adheres firmly.

Basic stages of painting wood

The very first step of the preparatory stage is stripping off the old paint. To remove the layer, you can use a grinder, a hair dryer, which allows you to soften the layer, which can then be easily removed, or removers containing reagents that help quickly separate the paint.

Next, the surface must be degreased - a solvent is applied, which will also wash away dust and greasy stains. If your product has knots or chips, you need to treat the surface with putty until it is even. The third step involves priming, which will help the paint adhere smoothly. After applying a thin layer of primer, they go through it with an abrasive, sanding it, and allow it to dry completely.

How to decorate the ceiling of a wooden house

Painting a wooden house

Very often, the ceiling of a wooden house allows your imagination to run wild. This is due to the fact that attics are often not used in wooden structures. As with any finishing work, the ceiling needs preparation, so it should be covered with an antiseptic mixture. Next, the ceiling is insulated regardless of the insulation during the construction of the house.

You can decorate the ceiling in a wooden house using materials such as:

- Wooden cladding, which occurs using lining boards, wooden panels, MDF panels

- The ceiling can be decorated with more budget options: plywood panels with a decorative coating that imitates wood

- Often a wooden ceiling is finished with sheets of plasterboard. After such covering, the wooden ceiling can be painted or wallpapered

Which color to choose

The choice of color depends only on the wishes of the homeowner. Manufacturers offer a wide range of shades. Typically, preferences depend on the design of the house and the location where it is located. To make the house visually blend with its environment, various shades of green, sand, and brown are chosen.

There are no restrictions on the choice of color, the main thing is aesthetics

To highlight a building in the area, you can use bright white, blue, and yellow. The most effective is the combination of two colors - light and dark.

A significant part of developers are more focused on the practical effect of painting, for example, dark colors attract rays, the surface heats up too much and cracks form on the wood. Light shades reflect light and do not fade longer, but dirt is more visible on them. The light gray color fades the least.

If resin appears on the wood, they prefer light dyes so that the wood does not heat up. Resin secretions are less noticeable against a background of cream, white, or ivory.

Often, paint is chosen to match or contrast with the color of the roofing material.

How to paint a wooden house with old paint

Materials and tools:

- dye;

- antiseptic;

- brush;

- metal brush;

- scraper;

- spray.

If mold, various defects, or damage appear on the covering of a wooden house, it must be painted again. Before painting begins, repair work is carried out to eliminate unevenness in the wood. Only problem areas can be painted. You can repaint the entire surface of the building.

For coloring, use a dye of the same quality as before. If the house was painted with oil paint, it is coated with oil or acrylate paint. When applying acrylate paint, the old coating must be cleaned down to the base with a wire brush. If the building was painted with acrylate paint, then it is painted with the same. Painting with oil dye is possible if the previous dye is completely removed.

First, prepare the walls, clean them of dust and pieces of paint with a scraper. After this, the walls are washed with a spray bottle. Mold is removed with an antiseptic. Damaged boards must be replaced with new ones. Removal of old paint can be done mechanically using a scraper or chemical peeling. In this case, the surface of the wood will have an ideal appearance. If necessary, sand the wood.

Secrets of decorative wood staining: techniques and tricks

City dwellers want to preserve the natural color of wood as much as possible. For those for whom wood in the house is a boring everyday thing, paint the interior lining in some unusual color. Modern paintwork materials allow you to achieve different effects. For example, textured or brushed lining, but in two colors. This technique is often used in loft style interiors.

Brushed lining in two colors is an excellent choice for decorating walls

The trick is to apply two layers of different colors. The first layer is a dark color, the second is a light or brighter color. After playing with colors and the order of their application, you can create your own version. Watch the video - how to get lining brushed in two colors.

Painting in two colors may not be the same. You can make the recesses a darker color, and only slightly tint the face (front part) or do everything exactly the opposite. The result is a striped wall made of clapboard - the effect of a slatted wall.

Selecting a pre-treatment agent

A separate category consists of impregnations, which are necessary to improve the structure and durability of wooden elements.

Such mixtures include:

Drying oil. It is applied to protect the base from any harmful influences. It is better to lay several layers to achieve deep penetration. Can be used before oil paints to reduce their consumption.

Drying oil Oxol consists of 55% natural oil component, 40% white spirit, 5% drying agent, therefore, compared to natural drying oil, its cost is lower and it dries faster

Oil. Parts that are close to the ground or immersed in it are processed.

The oil is ideal for processing wood indoors with temperature changes and high humidity.

Special antiseptics. Protect from microorganisms and insects, prevent rotting.

Universal deep-penetrating colorless antiseptic for wood Neomid

Fire retardants. Do not allow the fire to spread quickly.

Fire-retardant composition for wood Phenilax

How to protect wood

To protect boards or timber before painting, various types of impregnations are used, which are selected depending on the impact the wooden product will be exposed to:

- Antiseptic. These solutions prevent mold and various wood fungi from developing. They are used for treating surfaces in wet areas or for outdoor work. Applying these compounds before painting significantly increases the resistance of the wood structure to adverse factors that provoke the development of fungal spores. Unfortunately, all antiseptics are very toxic, so it is not recommended to use them indoors.

- Insecticidal. Impregnation of surfaces with such compounds causes the wood to become “unpalatable” to bugs. It is recommended to use insecticidal agents for outdoor buildings.

- Water repellent. Water penetrates deeply into the wood structure, causing it to swell and, upon subsequent drying, to cause various deformations and cracking. This kind of trouble can be avoided if you treat the timber or board with water-repellent impregnations. Such an impregnating agent will penetrate deeply into the wooden structure, fill all the pores and, after drying, create a durable moisture-repellent layer. It is recommended to use moisture-proofing compounds in wet rooms and for facade work.

- Fire retardant. Fire protection means must be used if wooden surfaces are located close to the source of fire (bathhouse, sauna, area near some household appliances in the kitchen or barbecue gazebo). Fire retardants significantly reduce the natural flammability of wood and allow, if not to prevent a fire, then to quickly localize and destroy the fire that has arisen. In addition, for prevention, it is recommended to treat facade walls made of wooden materials with fire retardants to increase the fire resistance of buildings.

- Combined. Solutions containing 2 or more of the above components. Combined mixtures are convenient to use when it is necessary to provide comprehensive protection of the wood structure before painting. For example, you need to protect the facade of the building from fire, bugs and high humidity. Applying each of the specialized compounds, and then waiting for it to dry and repeating the treatment again is a long and labor-intensive process. It is much easier to use a combined mixture, and it will cost much less in terms of money.

After the impregnation has been applied and dried, it is recommended to prime the wooden surface.

Requirements for paint and varnish materials for wooden facades

All paint and varnish materials can be divided into two large types: for interior and exterior work. External painting of a wooden house will help protect it from negative influences. Therefore, increased demands are placed on exterior paints. After all, operating conditions inside and outside are significantly different. The main requirement for compositions for interior work is odorlessness, environmental friendliness and abrasion resistance. Interior painting of a wooden house is faster and easier.

Requirements for compositions applied to the façade surface:

- High rates of adhesion and adhesion to the surface.

- Improved characteristics of resistance to minor damage, impacts, scratches, chips. High wear resistance.

- Weather resistance. The environment and bad weather should not affect the appearance of the facade and the quality of the paint. This includes chemical inertness to acids and alkalis.

- High levels of protection against moisture. Wood is afraid of it, so façade paint for wood should provide reliable protection to the coating.

- Resistance to temperature changes.

- They are not afraid of the influence of ultraviolet rays.

- High levels of vapor permeability, so that painting the external walls of a wooden house does not interfere with the wood’s ability to breathe.

- Be flexible even after drying. Wood tends to expand and contract under the influence of temperature changes. Therefore, the paint layer should not crack. This is achieved by the elasticity of the composition. Rubber paint on wood for exterior use has high indicators of this parameter.

- Easy to care for. Frequent washing should not be a problem.

- Resistant to fading, maintaining the original color for a maximum period of time.

If the composition meets most of the requirements, then painting wooden surfaces will be as effective as possible.

Painting work

Before painting a wooden surface, it must be properly prepared, because paint itself is not able to repair cracks, dents, chips and possible holes. The picture will come out good only if a high-quality canvas is used, and in our case, the processed base must have the appropriate appearance.

The instructions look like this:

Set of actions No. 1: wood preparation

The following tools will be required:

| Name | Purpose |

| Metal spatula | Peeling off old paint |

| Flexible spatula | Applying putty and putty |

| Sandpaper | Surface grinding |

- Remove as much of the old paint as possible with a metal spatula.

Do-it-yourself paint removal using a spatula

Advice: if the previous coating was done with oil paint, it is recommended to pre-treat it with hot air from an industrial hair dryer. As a result, the paint layer will swell and peel off, making it easier to remove.

Removing old finishes using a hair dryer

- We treat what we couldn’t remove with trisodium phosphate, which will also clean the wood of dirt.

Photo of trisodium phosphate in packaging

- We wash the surface with water.

- After the wood has dried, we repair all existing cracks, chips and scratches with regular wood putty. If there are significant defects or even through holes, then to eliminate them we use a special putty, which is better not to save in such cases.

Filling holes before painting with putty

- After the putty material has hardened, we sand along the wood fibers using 80-100 grit sandpaper, which allows us to eliminate the last remnants of the old paint layer and level the putty with the wood.

Sanding a wooden surface

- Then we go over the wood with finer 150 grit sandpaper to smooth the surface for applying primer.

Tip: It is recommended to use an electric orbital hand sander for sanding work. With it, the work will be done much faster and with better quality.

Electric orbital grinding machine

- We remove the remaining large debris with a dry rag.

Removing debris remaining after sanding work

Tip: if you have a vacuum cleaner at hand, it is better to remove all debris with it, it will be more effective.

- Then we go over the wood with a damp cloth to remove small grains that may interfere with the proper application of primer and paint.

- We seal the areas that we want to leave unpainted with special tape for paints and varnishes, which can be purchased at any specialized store. It is noteworthy that if you want to paint the areas to be sealed in a different color in the future, and not just leave them untouched, then you should cover them after priming.

Sealing areas that need to remain unpainted

- Apply primer in several layers. For dark types of wood we use gray solutions, for light types of wood – white. Sometimes owners neglect this step, considering priming to be just a waste of time and money.

This is fundamentally wrong, since the ground cover performs several important tasks:

- increases wood adhesion;

- reduces its hygroscopicity by blocking pores;

- strengthens the surface

Applying white primer to a wooden surface

Advice: it is recommended to choose a latex-based primer rather than an oil-based one, since such a solution is more elastic and less susceptible to cracking.

Sample of latex primer for woodworking

You can use a brush or spray for application; let's compare the effectiveness of these two tools:

| Tool | pros | Minuses |

| Brush |

|

|

| Spray |

|

|

Set of actions No. 2: applying paint

First of all, you should decide on the question, what is the best way to paint wood? Indeed, today in specialized stores you can find a large selection of paints and varnishes.

The main types of wood paints are as follows:

- Acrylic.

Their composition is based on ordinary water and acrylates, due to which they have many advantages:

- Operational safety. This option leads the types of wood paints for interior work, since during the hardening process it emits only water vapor, which is absolutely harmless.

- High strength and durability. After drying, a reliable polymer layer remains.

- Wide range of colors. Plus, you can easily mix the shade you want.

Water-based wood paint palette

- Easy to apply. This wood stain applies smoothly and without streaks.

- Possibility of partial touch-up.

- Alkyd. If you are considering types of paints for exterior woodwork, then this option will be very interesting, as it has increased water-repellent properties, excellent frost resistance, allowing you to withstand a drop in ambient temperature to -30 degrees Celsius, and low cost.

But there are also disadvantages:

- Relatively short service life.

- Need for a dry base. Is it possible to paint wet wood with an alkyd solution? No, which makes it possible to use them only in dry, clear weather.

- Toxicity. Indoor use is not recommended.

Example of alkyd paint

- Oily. An outdated option with many negative aspects, including high cost, toxicity and a tendency to crack.

You can also use natural dyes for wood, which only emphasize its natural texture and give it a unique shade.

Now let's move on to the painting itself:

- Dip the brush into the paint can, turn it 180 degrees and dip it again so that the solution is evenly distributed on both sides of the bristles.

Set of paint on a brush

- Apply a layer to the wood from top to bottom, without delaying the pause between strokes.

Painting wood

- Then we take a clean brush and point-fill the corners of the surface, which eliminates the appearance of smudges.

- After the coating has completely dried, apply a second coat.

Selecting paint and preparing surfaces

Tool for painting a wooden house

Everyone knows that wood is a natural material that tends to age. Therefore, let's take a closer look at how to paint the outside of a wooden house with your own hands if it is already old and has lost its appearance. But first, you should remember that the key to successful painting is surface preparation.

Surface preparation consists of preliminary cleaning the walls from dirt and dust. This is very easy to do by hosing down the base with water. If mold or mildew appears on the base of the log, then the walls of the house should be treated with special impregnations. And if you notice resin in some areas, remove it with a spatula and cover the area with varnish.

All fastener caps must be coated with metal primer solutions. When surface preparation is completed, you should leave the walls of the wooden house alone for several weeks. This is necessary for complete drying and subsequent high-quality painting.

For a log house and structure made of laminated veneer lumber, you can choose compositions from the following list:

- Antiseptic

- Acrylate paint

- Oil paint

Painting the outside of a wooden house allows you to protect the structure from the effects of external negative factors. This allows you to slow down the aging process of the log. With the help of antiseptics, they achieve excellent protection against mold. It is better to use a glazing antiseptic, which is transparent and can highlight the texture of the log. Acrylate paint is quite weather-resistant and allows the material to breathe. A good advantage is that this type is elastic, which means that during thermal deformations of logs and even laminated veneer lumber, the coating does not crack and retains its appearance.

Oil-based paints absorb well and have excellent characteristics, but a painted house will take a long time to dry and ultimately the surface may become more matte.

Beginning of work

Nowadays, with a large availability of synthetic and polymer materials for construction, when decorating rooms, pieces of furniture and creating original furnishings, wood-like painting is still used, because such colors have a better effect on the human psyche and attitude than bright and unnatural artificial colors.

This natural material has a peculiar fibrous structure, so preparing wood for painting has its own characteristics. To begin with, the surface is treated with coarse sandpaper to eliminate large irregularities and various harmful organisms that may be located in the crevices between the fibers.

Sanding old wood will renew the top layer, making it light and clean.

You may also need to use coarse sandpaper if you are renewing an old, previously painted product. For example, in such a matter as painting a table that has been in use for a long time, when removing the old coating after sanding, it is recommended to use special wash-off compounds.

After coarse sanding comes the leveling process, which is done using a spatula and special automotive putty to create a flat surface. After the entire mass has dried, it should be treated with fine sandpaper to obtain a perfectly smooth surface without cracks, dents, bumps and all kinds of burrs.

After treatment with sandpaper and putty, it is necessary to remove all fatty inclusions from the area to be painted. They may prevent good adhesion of the paint material. Degreasing is done by wiping the surface with acetone, white spirit or other liquids.

In order to paint a wooden object with high quality, obtain an excellent final result of painting and maintain the durability of the coating, during the final surface treatment, a layer of regular or acrylic aerosol primer is applied to the product.

The primer gets into the smallest pores and crevices, thereby reducing its perception of moisture and improving the adhesion of the new coating. This is especially important when painting the surface white.

Acrylic paints for wood - description

Acrylic paint for wood is distinguished by its excellent protective properties, providing wooden structures with a long service life and a decorative coating. Before it dries completely, it can be easily washed off with water if something goes wrong during the work. And after complete drying, it creates a reliable protective layer that resists external influences well, and also performs well in conditions of high humidity and sudden changes in temperature.

It features a bright palette of shades that do not fade for a long time. You can get both matte and glossy finishes

Note! In addition, the paint is safe for the human body and has no odor.

What's included

Thanks to its constituent elements, paint is characterized by its positive qualities. The basis is water, which contributes to the uniform distribution of components in the solution and further even coating of surfaces.

In addition to the water base, the paint includes:

- Acrylic is a transparent substance that is almost insoluble even at high temperatures. What makes it possible to work in the building is that it does not emit an unpleasant odor;

- Plasticizers give the solution elasticity and flexibility. As a result, when the wood shrinks, cracks do not appear on the coating;

- Hardeners, they are responsible for the time required for the paint layer to dry;

- Dyes and pigments are added in a thoroughly crushed state, which makes the resulting coating smooth and uniform;

- Matting additives create a matte effect. Most often, this option is chosen for facade decoration and fences so that they do not form glare in the sun.

Advantages and disadvantages

Acrylic enamels for wood have a number of positive qualities, but several negative ones can still be identified. These qualities will be discussed in detail below.

The advantages of enamels include:

- Resistant to natural precipitation and long-term exposure to water;

- A large assortment of colors is distinguished by the fact that it does not lose brightness over time;

- Covers products evenly;

- Does not emit an unpleasant odor;

- UV resistant;

- “Breathable”, which has a beneficial effect on the wood; fungus and mold do not form on it;

- Durable, 4-8 years depending on the brand;

- Dries quickly.

Flaws:

- It freezes in the cold, after which it can no longer be used;

- Not resistant to some solvents;

- Not compatible with other film-forming dyes;

- Expensive.

Resistant to natural precipitation and long-term exposure to water.

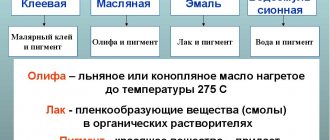

What paints are used for exterior painting of a wooden house?

Facade paints differ primarily in the composition of film-forming components. And the type of solvent, the possibility of tinting and other parameters depend on them.

Antiseptics

Antiseptic impregnations are often used to treat the walls of a house. They can also rightfully be considered full-fledged paints. Antiseptics can be glazing and coating. Glazing antiseptics create a transparent coating that emphasizes the texture and color of the wood.

Coating antiseptics create an opaque coating on the surface, but preserve the texture of the wood.

Antiseptics are very convenient for covering facades made of planed or polished wood of valuable varieties, which have their own distinct pattern and beautiful texture. Antiseptics are good because they penetrate deeply into solid wood. The compounds dry very quickly and in most cases, for complete protection, it is enough to cover the wood with two layers of impregnation. But this treatment can only be performed on fresh wood that has not been painted before.

Antiseptic impregnation should be repeated once every 2 to 3 years. But there are expensive products that can be updated every 5-6 years. As a rule, they belong to the category of azures or colored impregnations and, together with the protective one, play a decorative role. Many impregnations include substances that block ultraviolet radiation; the wood does not darken or change color after such treatment.

Acrylic or acrylate paints

The most fashionable and modern paints for external decoration of facades. Produced in the form of emulsions and dispersions, water-soluble. In most cases, the basis of such paints is acrylic resins or acrylic copolymers. Artificial or natural rubbers, antiseptics and fungicides can be added to the components. They are sold in the form of a white or transparent base with varying degrees of gloss - matte, glossy, semi-gloss.

A number of pigments and dyes have been developed for acrylic paints, with which they can be tinted to any desired color and shade. Some dye catalogs contain up to 20,000 color solutions. But when purchasing such paint, it is advisable to choose a pigment from a fan of colors from the same manufacturer. Most factories keep the chemical compositions of their paints secret, so different reactions are possible between products of different brands.

Of course, there will be no explosion, but the paint will take too long to dry, will bubble, or will quickly fade and change color. To avoid such “surprises”, it is better to buy a product from the same brand or check the paint and pigment for compatibility. Most serious stores will tell you what you can mix with what. It’s best to tint the composition right in the store, this is especially convenient if there is a tint machine and a color studio.

Acrylic paints:

- provide a wide range of colors;

- have excellent adhesion to wood;

- have no odor;

- absolutely safe in terms of fire;

- environmentally friendly and non-allergenic.

But they have a significant drawback - they are quite expensive, at least significantly more expensive than alkyd and oil-based ones.

Alkyd paints

These are well-known compounds that have been used to paint wooden walls for many years. Paints created on the basis of polycondensation resins, united under the name “alkyds,” are characterized by relatively low production costs, excellent coating ability, and a high level of adhesion to wood. Moreover, you can paint both polished, planed or sawn wood, as well as logs from which the bark has just been removed.

Alkyd paints form a dense and durable highly elastic film that responds very well to temperature changes in wood and does not crack during drying, thermal expansion or other dimensional changes. When covering wood in two layers, the film becomes waterproof and slightly vapor permeable. Therefore, it is recommended to paint only dry wood with alkyd paints.

Some manufacturers include antiseptics and fire retardants in alkyd paints. You must find out about their presence from the instructions for the paint before using it. If there are no such components, then the walls need to be further processed before painting. This slightly increases the cost of painting, but the service life of the coating and the house as a whole increases several times.

Alkyd paints are usually available in a fixed range of colors, but changing the shade is quite simple - you need to mix two or more paints in a certain proportion so that the color changes in the desired direction. The quality of the finishing coating does not change. But, as in the case of acrylics, it is advisable to use only paints from the same manufacturer for mixing.

In recent years, the world's leading manufacturers have also offered colorless alkyd paints, which are tinted in the same way as acrylic ones. This is very convenient, especially when painting a new house, when the urgent question is how best to paint the outside of a wooden house so that it stands out among its neighbors, even those built according to the same design, which is often in cottage villages.

Alkyd paints are a full-fledged competitor to acrylic paints in terms of quality. They lose only in fire safety, and even then only during storage and operation - here they require compliance with fairly strict rules of conduct with fire and heating devices. But after drying, the paint layer becomes practically non-flammable. However, due to rapid drying, the paint does not have time to penetrate deeply into the wood, which negatively affects its durability. Alkyd paints have good frost resistance and can withstand temperatures below - 300C.

Solvents for paints based on alkyd resins are white spirit, solvent and similar weak organic solvents. They are moderately toxic and flammable, which also requires compliance with safety precautions when working. Although gasoline and kerosene also dilute alkyd paints well, their use is undesirable - the color fades somewhat, and the gloss may change towards becoming more matte.

Oil paints

For a long time, oil compositions, the diluent of which is drying oil or other natural oils, represented serious competition to alkyd ones. But in recent decades, an increasing number of manufacturers have abandoned them - the paints are quite difficult to use, take a long time to dry, and the characteristics of the finishing coating are inferior to most modern compositions.

Despite their shortcomings, these paints are the most budget option. Once applied to wood, the paint is perfectly absorbed and creates a weather-resistant coating.

Recommendations for use

There are a number of tips for correctly applying acrylic substances to wood; they are not at all complicated, but knowing them will help you get the desired result. These include the following recommendations:

- Since the products differ in application conditions: indoors or outdoors. Then you should buy the appropriate products;

- Before painting, it is better to prime the wooden surface;

- The resulting color may differ from that indicated on the packaging. Since it is influenced by the number of layers applied and the color of the surface itself. Therefore, it is better to apply the product to a small area to check what color it will turn out after drying;

- It is not necessary to purchase a spray gun for painting; it is more suitable for painting large areas. It is more convenient to paint small areas with a brush, and floors with a roller;

- There is no need to paint the surface with a thick layer; more than 2 layers are applied to those surfaces that will be frequently cleaned or will be constantly exposed to mechanical stress.

Before painting, it is better to prime the wooden surface.

Wood painting technology

The technology is not complicated. First, it is worth assessing the general condition of the surface; for example, if the product exhibits high absorbency, then it must first be treated with a pigmented primer solution.

If dents and depressions are found, they are covered with putty matching the color chosen for painting. Wait until the surface is completely dry and sand the product with sandpaper. Next, primer work is carried out.

Stir the paint before applying. If it is too thick, it should be diluted with a solvent. Apply the 1st layer with the selected tool, wait for it to dry for about 4-5 hours.

Then you can proceed to applying the finishing layer if the first one looks uniform and even. The finishing layer dries in a few days.

Stir the paint before applying.

Acrylic paint outperforms many other types due to its environmental friendliness and beneficial properties. It also comes in a wide range of colors, from white to red. It is easy to use and creates an aesthetically pleasing surface appearance.

Wood painting process

Use a spray gun to apply paint to large wood surfaces. It will allow you to evenly and quickly distribute the paintwork in the required area. Rollers are also popular at home. Small, narrow or hard-to-reach areas can be easily treated with paint brushes.

Before painting the wood with varnish or paint, pour the paint into a container from where it is convenient to collect the material. To achieve the required consistency, use solvents that are selected taking into account the paint base. Consistently treat the surface of the wood, avoiding the appearance of smudges or missing areas.

Wood coloring is carried out at above-zero temperatures. Drying time depends on the paint and usually varies from several hours to 1 - 1.5 days. The number of layers is 1 – 3 pcs.

«>

Wood processing procedure

To understand how to protect lumber from aging, you need to know the structure of the wood. Deciduous and coniferous trees have different textures. In a simplified way, we can imagine that along the entire length of the trunk there are numerous elongated cells responsible for the transfer of nutritional fluid from the roots to the branches. That is why, through the end cut, moisture is most intensively absorbed into the wood at high environmental humidity and evaporates at low humidity.

In order to maximize the life of wooden buildings, it is necessary to protect the wood from the destructive effects of the environment, for which a three-level protection system is most often used.

- Protecting wood ends from moisture absorption using end products. It can be performed with all kinds of liquid impregnations and thick mastics. End products allow you to reliably “seal” the so-called pores and prevent the wood from becoming saturated with moisture.

- Protecting the surface from fungus and insect damage using antiseptic agents. Antiseptics have a liquid consistency, due to which they penetrate deep into the wood and protect it from rotting and insects.

- Protecting the surface from exposure to ultraviolet rays and precipitation using paint.

The better to paint

Paint for the facade of a wooden house can be translucent, glossy or matte. Since the natural look of wood is most attractive, glazing facade materials, which are available in the form of antiseptics, glazes or oils, are very popular.

The peculiarity of these materials is that they do not hide the structure of the wood. The materials work as impregnations, penetrate deep and create a barrier to getting wet or exposed to ultraviolet rays (UV). Despite their transparency, glaze paints are available in a wide range of colors. The most famous manufacturers:

- Renocoll (Rhenocoll) Germany.

- Teknos Finland.

If there is a desire to hide the surface of the wood, then use façade covering paints, which are divided into:

- oil - made from oils of natural origin and organic solvents;

- alkyd - produced in organic solvents or aqueous solutions of alkyds;

- acrylate (acrylic) coatings - based on acrylic and copolymers (latex, vinyl, silicone).

These paints form an opaque protective film that completely hides the wood grain. Over time, they oxidize, cease to be elastic and crack. Subsequently, the top layer turns into a powdery white substance (paint chalking process). After a few years, the layer will need to be removed completely or partially and the work done again.

Acrylic paints are more expensive and have a high degree of elasticity.

Well-known manufacturers of covering paints:

- Tikkurila (Finland).

- Alpina (Germany).

- Dufa (Germany).

- Beckers (Sweden).

- Dulux (Netherlands).

- Marshall (Türkiye).

Among the Russian brands, the most popular are “Optimist”, “Svyatozar”, “Tex”, “Yaroslavskie Krasny”.

Average paint service life:

- glazing antiseptics – 5 years;

- acrylic – 8–10 years;

- oil – up to 6 years;

- alkyd materials – 7 years.

When comparing different types of paint, consider their pros and cons:

- oil paints – have a high penetrating ability, reliably protect against moisture, but dry slowly (several days depending on the temperature), which is sometimes unacceptable for outdoor work;

- alkyd compositions - have good frost resistance, but crack over time under the influence of UV;

- acrylic - convenient and easy to use, odorless, do not lose color, a new shade is easily obtained by mixing white paint with colorants (colored dyes), but if the house is painted with acrylic paint, then in the future you can only use them.

In recent years, acrylic paints and varnishes have taken a leading place, despite their higher price. Considering how much it costs to paint a wooden house and the effort it requires, it is not advisable to focus on cheap types. It’s better to do it well once than in 2-3 years the house will look sloppy. Immediately choose how to paint the outside of a private house or cottage for a long time, even if you have to invest more.

The total cost of painting depends mainly on the size of the house. This amount will include the cost of antiseptic, putty and paint.

Finishing materials

Coating with special oils and wax for wood will help protect the wood from many negative factors. However, stain, whose price is lower, is also suitable for these purposes. Although the waxing process is quite complicated, it can be done at home.

How to use stain

Protective compounds and stain are applied to the already prepared wood in the same way as paint. A uniformly colored surface can be achieved if these materials are applied quickly and continuously so that the entire surface dries evenly. If any area dries faster, the border will remain noticeable.

In the photo - wood stain for decorative work

Each of the wooden sections is painted with stain in stages by applying in the direction of the grain. Do not wet the brush too much, otherwise drops will form on the surface. If this cannot be avoided, the drops should be thoroughly smeared, not allowing them to dry out.

You also need to ensure that at the junction of sections of the structure, the layers do not overlap each other. Considering the technological complexity of this process, you should first practice.

Waxing

The most convenient material for applying wax is a piece of cloth, but some compounds can also be applied with a brush. To create deeper color and shine, the material must be applied in two layers.

Applying wax or coating on wooden furniture for durability

Tip: It is more effective to apply wax in the direction of the grain, but this is not a necessary condition.

To treat the surface you need:

- Use a piece of soft cloth to collect wax from the container;

- start rubbing;

- when particles of coating begin to remain on the surface, the rubbing process can be considered complete;

- then the wax should dry, but not harden;

- after which polishing is carried out to ensure smoothness using a clean rag.

After a certain service life of the wooden structure, waxing can be repeated.

Protecting wood with oil

The oil serves as additional protection against adverse factors affecting the wooden surface. Whatever the oil used for processing, they are all applied in the same way.

Depending on the purpose of the surface being treated, the following oils are used:

- tung is non-toxic, so its use is ideal for treating countertops and other surfaces used for food preparation;

- Danish and teak are used for processing hardwood and outdoor furniture, giving them a special gloss;

- linseed oil is suitable for treating any surface, but requires preliminary boiling (preferably double boiling), which allows it to dry faster and eliminates stickiness.

Any of the oils is applied with a soft brush, generously moistened with the composition, in the direction of the fibers with rubbing movements, which allows you to cover large areas and penetrate deeper into the structure of the wood. After absorption, excess oil is removed with a piece of cloth. If there are no other instructions in the instructions for the composition, the wood should be left for half an hour, and then polished with a dry rag.

What is the best way to cover a wooden table in the kitchen?

How to work with varnish

Despite the fact that varnishing does not require special care, this material must be applied along the grain and in good lighting, as it is often colorless, which is why some areas may remain untreated. You should also regularly check treated areas for gaps.

Coating wooden walls inside with acrylic varnish

Tip: each section should be processed in stages, while even application of varnish is possible with smooth brush work.

Before applying the next layer, you need to take a damp cloth and wipe off the first one. This action is explained by the fact that the varnish tends to spread along the fibers of the wooden surface.

Wood paint requires protection

To obtain the required shade, paints are often mixed with each other. But before moving on to this process, you need to make sure that they have the same base, which can be either water or oil.

The paint is applied along the fibers, without overlapping the already dry and wet areas with each other. Please note that coloring alone is not enough.

The material also often requires a protective layer - wax or varnish. But before you start applying it, you need to make sure that the finishing materials used are compatible with each other.

Rating of wood paints for interior work

Tikkurila is a Finnish company that produces impeccable quality compounds for treating interior and exterior coatings.

Tikkurila Empire base

Tikkurila Empire base is a paint that is suitable for painting wooden and metal surfaces, as well as for finishing furniture. Alkyd based. Packaged in cans of 0.255 l, 0.9 l, 2.7 l and 9 l. The paint has many advantages and is ideal for interior work. It has a semi-matte effect and a slight shine. The price for a 0.9 liter jar is 700-800 rubles.

Tikkurila Empire base

Advantages:

- easy to use;

- does not flow;

- does not splash;

- the smell is weak, barely noticeable;

- little consumption;

- can purchase any color from the catalog;

- hides flaws;

- dries in 3 hours.

Tikkurila Miranol

– another high-quality paint for wooden surfaces. The price for a 0.9 liter jar is about 700 rubles.

Advantages:

- fits easily;

- no leaks;

- dries in 3-4 hours;

- large range of colors;

- dense, one layer is enough.

Tikkurila Miranol

Flaws:

has a moderate odor.

About the features of the material - in the video:

TEKNOS

is a Finnish company that cares not only about the quality of its products, but also about their environmental friendliness. The company's advanced technologies allow it to succeed in this matter.

Water-based TEKNOS biora balance has virtually no odor and is perfect for painting even a child’s room.

TEKNOS

Advantages:

- does not contain solvents;

- safe;

- practically odorless;

- matte beautiful finish;

- hides small irregularities;

- persistent.

Flaws:

high price.

ALPINA

– a German brand with a 100-year history. It produces a huge number of different products for finishing interior and exterior surfaces. The first cold water soluble paint was invented.

Alpina Aqua Buntlack is an acrylic-based paint that produces a beautiful gloss. Available in 0.7 l and 2.5 l cans.

ALPINA paint

Advantages:

- has no unpleasant odor;

- many rich colors;

- easy application.

Flaws:

expensive - 2000 rubles for 2.5 liters.

ADLER

is an Austrian paint manufacturer with a good reputation in Europe.

ADLER Lignovit Color is an acrylic paint that provides long-term protection for wooden surfaces. Prevents mold, mildew and blue stains from entering. Suitable for any wooden elements both indoors and outdoors.

ADLER

Advantages:

- reliable coverage;

- does not crack after a long time;

- little is spent.

Flaws:

price - almost 4000 for 4 liters.

ACE PAINT

is a very large and popular American company that often offers innovative products to its customers.

ACE Contractor Pro Interior Wall Paint is an acrylic paint for interior work, suitable not only for wood, but also for drywall, wood, brick and other surfaces.

ACE PAINT

Advantages:

- economical;

- does not peel off;

- covers unevenness well.

Flaws:

Sold in large quantities, more suitable for large-scale work.

SENEZH

is a Russian company known for its products for processing wooden surfaces, in which it has achieved great success.

SENEZH AQUADECOR is an antiseptic with the main task of protecting the wooden surface. There is a fairly large palette of colors.

SENEZH

Advantages:

- protects the tree as much as possible from the effects of various negative factors;

- no unpleasant odor;

- many colors to choose from.

Flaws:

- It is not always possible to achieve the color specified;

- more consumption than indicated by the manufacturer.

Types and manufacturers of facade paints for exterior woodwork: overview

Reading time: 12 minute(s) Painting the exterior of a house is necessary not only to give the facade an attractive aesthetic appearance, but also to protect the surface from external factors. Properly selected paint can protect the facade from the negative effects of moisture, wind and direct sunlight, as a result of which the building will last much longer, maintaining all its technical characteristics. In this article we will talk about what façade paints on wood for exterior use are, what they are and what qualities they should have.

What is the best way to paint the outside of a wooden house?

What kind of paint

As you know, wood is an ideal building material, which is very popular today. In order for the building to maintain its functionality, it is extremely important to carry out finishing work correctly.

The main reasons for the destruction of wooden buildings are:

- susceptibility of the material to the natural aging process;

- negative influence of external factors.

When moisture gets inside the wood, the wood fibers expand, and after drying, they narrow. Ultimately, this cyclicity leads to the occurrence of cracks.

Based on the listed factors, experts recommend using the following types of dyes for wood:

- oil paints;

- acrylate paints;

- alkyd-acrylate paints (covering antiseptics);

- varnishes and azures.

We will discuss the features of each of the above types of paint below.

Consumption per m2

The dye consumption rates are indicated by the manufacturer on the packaging for an ideal surface. As a rule, for walls it is smooth polished plaster with a double layer of primer. You can determine how much paint you will actually need by taking into account factors such as:

- surface density;

- texture;

- roughness;

- curvature;

- preliminary preparation;

- type of dye;

- tool.

That is why in each specific case, paint consumption should be calculated taking into account the existing features.

Consumption rates for 1 liter of universal wood paint are presented below:

- sanded hardwood, along the grain: 16 m2;

- wood, along the grain: 8-10 m2;

- tree, cross-cut: 4-6 m2.

Types and technical characteristics of facade paints for wood

Below we will consider the most popular types and technical parameters of facade paints for wood.

Wear-resistant

At the same time, while wood dyes for interior work are subject to strict requirements for the safety and environmental friendliness of the product, for exterior work it is allowed to use paints that release harmful chemical compounds into the air. Due to this “relaxation”, paint manufacturers can produce products with improved technical characteristics.

Attention: Exterior paints are highly resistant to weather conditions.

Another difference between such dyes is plasticity. The thing is that wooden structures used outdoors are regularly subject to cyclic freezing and thawing, as a result of which their linear dimensions fluctuate to a greater extent. That is why paints for exterior woodwork must compensate for these factors and, accordingly, have an increased level of ductility.

As for the wear resistance of the material, it equally depends on the technical characteristics of the paint and on the accuracy of compliance with the rules and application technologies.

Currently, both traditional and innovative materials are used to paint wooden surfaces of houses. The physical characteristics of paints vary depending on the chemical composition, material of manufacture and the presence of special additives.

Experts consider oil, polyurethane, alkyd and acrylic paints to be the most wear-resistant materials.

Weatherproof enamel

Weatherproof wood dyes must meet a number of the following requirements:

- protect the surface from moisture, since it is this factor that is most destructive for any tree, especially for soft wood with a fibrous structure;

- contain components that prevent the occurrence of fungus and mold;

- have components that repel wood borers and pests;

- be resistant to direct sunlight (ultraviolet radiation), otherwise color fastness will be low and the paint will fade within a year;

- maintain protective properties for five years.

The most weather-resistant are acrylic, alkyd and oil paints.

Acrylic

Acrylic paints are the best option for wood processing. They have high vapor permeability and elasticity - they retain viscosity even after complete hardening. Color saturation remains even five years after application.

Oily

Oil dyes are distinguished by their availability, popularity, cost and a wide range of color solutions. They are produced on the basis of drying oil, which provides the dye with deep penetration into the structure of the wood and, therefore, its good protection. At the same time, they lose color saturation quite quickly. It takes several hours to completely dry, so the coating application time should be selected taking into account weather conditions - so that atmospheric conditions do not prevent the paint from drying completely.

Alkyd

Alkyd dyes are based on alkyd (resin). This type of paint has a high level of heat resistance - even when heated to 90 degrees, the paint retains its original color and adheres well to the base. Alkyd paint should only be applied to a perfectly dry surface - otherwise the coating will swell and bubble. As the dye dries, it forms a thin, durable film covering the facade. It takes 10-12 hours to dry completely.

Latex

Latex wood stains appeared relatively recently. These paints are based on latex (rubber), which ensures the plasticity of the paint. Due to its elasticity, the coating allows the painted surface to breathe freely. The paints are non-toxic, so you can work with them without using respirators or other respiratory protection. During application, the dye lays down in an even layer, and as it dries it turns into a film that is pleasant to the touch. The resulting coating can be washed with soap solutions, and its minimum service life is 10 years.

Rubber

The consistency of rubber exterior paint is similar to mastic. A film resembling rubber forms on the paint layer only after it has completely dried. The dye is completely environmentally friendly, as it is based on ordinary water. The strength of the material is achieved by adding acrylate latex to the composition.

The distinctive performance properties of rubber paints are: good resistance to temperature changes, increased adhesion, increased covering ability and high vapor permeability. In addition, the material is incapable of ignition, since it does not contain any toxic components. Under standard external conditions (temperature +20° and humidity level 65%), the applied paint layer dries in 1-2 hours. The average service life of the coating is 8-10 years.

Impregnation paint for wood

The modern construction market offers a huge variety of protective compounds for wood, which can be roughly divided into several large groups. Film compounds are used for exterior work, and penetrating compounds are used for interior work. Experts also distinguish antiseptic, fire-retardant and complex impregnations, which combine both fire-retardant and antiseptic properties.

Another division - according to the main component:

- Aquatic. Available in the form of powder and crystals, diluted with water according to the instructions. They have no smell. They require pre-treatment of the wood with sandpaper and wetting before applying the composition. Do not use on dry surfaces. They take a long time to dry.

- On solvents. They penetrate deeply into the wood structure and have a strong odor. Toxic until completely dry. They perfectly protect wood from moisture, fungus, mold and insects that have penetrated into the upper layers. Apply exclusively with a brush. Available in a wide range of colors.

- In oil. They are a classic stain. They penetrate deeply into the wood, protecting it from moisture and dirt. Prevents surface cracking. Can be applied with a brush or spray.

- Lucky. In terms of protective characteristics, they are in no way inferior to paints, but allow you to leave the wood texture visible.

- Acrylic. Protect wood from blueing and blackening, as well as from mold and insects. Can be used on both treated and untreated wood. They have high decorative value and are produced in a wide range of colors. Dries within a few hours.

- Wax (or oil/wax). After their application, you cannot use any other impregnation.

Antiseptic paint

Covering antiseptics (or alkyd-acrylate paints) appeared on the construction market relatively recently. They help to significantly improve the appearance of wood. They are able to stay on the surface of the facade for at least 10 years without losing the appearance and quality of its protection.

Polyurethane

A distinctive feature of polyurethane dyes is their high wear resistance - they perform well at low temperatures, negative atmospheric influences and direct ultraviolet rays.

Before applying paint, the wooden surface must be perfectly dry - in this case, you can even do without a primer. Since the material is capable of absorbing any compounds that come into contact with it, several layers of paint should be applied, since one will not be enough to completely protect the surface. If all rules and application technologies are followed, the average service life of a polyurethane coating is more than 10 years.

Review of the best manufacturers of facade paints for wood

For clarity, let’s look at the technical parameters of the most popular and high-quality façade paints for wood.

Finnish paint

Today Finnish is a leading manufacturer of paints and varnishes. Experts consider alkyd-urethane and polyurethane-acrylate mixtures to be the best dyes of this brand.

Attention: For additional protection of wood surfaces, Tikkurila produces a number of antiseptic agents with fungicidal (antifungal), biocidal (antimicrobial) and insecticidal (against insects) properties.

Water-based paints of this brand are developed specifically for the harsh weather conditions typical of northern countries. That is why the compositions easily withstand various types of climatic loads (including the influence of precipitation and sun), as well as mechanical stress. If you follow the technology of a three-stage painting system (primer + 2 layers of paint), coating with Tikkurila materials can last more than ten years.

The dye consumption depends, first of all, on the texture of the treated area. While on a flat surface 1 liter of paint is enough to paint 9-11 m², on a rough surface the same volume will cover only 4-6 m² of area.

"Tikkurila"

The most popular series of Tikkurila paints intended for exterior finishing of wooden surfaces are:

- "Pica-Techo": base: water, impregnating oil and acrylates;

- Recommended areas of application: protection and decoration of cladding boards, exterior wood products, fences and logs;

- distinctive features: strength and elasticity, no smudges;

- consumption: 1 l per 6-9 m2;

- coating service life: 6-7 years;

- base tinting: 120 shades;

- complete drying of the paint layer: after 2-4 hours;

- average cost of 1 liter: 810 rubles.

- base: polyacrylates;

- base: alkyd substances;

"Belinka"

Slovenian-made Belinka facade paints take into account the need to protect wooden surfaces from the negative effects of fungi, mold and insects. Correctly applied coating can last 10-15 years. Dyes of this brand are successfully used to give facades various shades; in addition, they enhance the natural pattern of wood. The most popular series of Belinka facade paints intended for wood processing are:

- "Toplasur": base: alkyd substances;

- scope of application: protective finishing of sanded logs, facades of wooden buildings, window frames and door structures made of wood;

- distinctive features: absence of biocidal substances in the composition, preservation of attractive external characteristics throughout the entire period of use;

- consumption: 1 l per 10-20 m2;

- average cost of 1 liter: 615 rubles.

- base: alkyd substances;

- base: alkyd substances;

"Drevoplastic"

specializes in the production and sale of antiseptic products for wood protection. Impregnations are suitable for internal and external treatment of both planed and sawn surfaces.

The most popular compositions of this brand are:

- "Biodrev" is a covering type antiseptic. It is made on a water basis. Contains natural oils. Completely environmentally friendly and safe for humans. Provides wood with reliable protection from external factors, preserves its structural features and prevents drying out. The average cost is 307 rubles.

- "Drevotex" - used as an impregnation with a tinting effect and an antiseptic effect. It is water-based and contains additives such as acrylate dispersions, resins of synthetic origin and dyes. It is odorless and does not contain solvents toxic to humans. The average cost is 230 rubles.

Teknos

Teknos facade paints differ from most of their competitors in their high cost and long service life (30 years). Dyes of this brand are used mainly for finishing buildings made of prestigious wood.

The most popular and in demand series of Teknos finishing materials are:

- "Woodex Classic": base: organic solvents;

- distinctive features: tinting antiseptic, no smudges, ease of application;

- scope of application: primary processing of horizontal and vertical wooden surfaces, including facades, window structures, terraces, fences and piers;

- consumption: 1 l per 8-12 m2;

- average cost of 1 liter: 635 rubles.

- base: alkyd resins;

- base: oil;

"Osmo"

Osmo paints based on natural waxes and oils are used to protect and decorate wooden facades, terraces, fences, doors, windows and garden furniture.

Distinctive features of the paints of this brand are: resistance to moisture and ultraviolet radiation, environmental safety, ease of renewal and restoration, wear resistance and durability of the coating.

No preliminary priming or surface sanding is required. Average consumption of 1 liter of composition: 26 m2. Average cost of 1 liter of paint: 2900 rubles.

"Senezh"

Russian (NPO Drevozashchita) specializes in the production of high-class antiseptic and renewing compositions with a large selection of colors.

The average service life of such compositions is 10 years. At the same time, the coating reliably protects the surface not only from pests and moisture, but also from the spread of flame in case of fire. The average cost of 1 liter of paint is 266 rubles.

"Neomid"

specializes in the production of products aimed at preparing wooden surfaces. Whitening compounds are especially popular.

The most in demand materials are:

- façade paint "Neomid": base: acrylic copolymers;

- distinctive features: high adhesive properties, good transmittance and resistance to repeated deformation;

- scope of application: treatment of facades against mold and mildew;

- consumption: 1 l per 8-10 m2;

- average cost of 1 liter: 300 rubles.

- base: acrylic copolymers;

- base: alkyd resins;

"Pinotex"

produces dyes for various purposes, including separately for the treatment of window and door structures.

Experts consider the most suitable compositions for wooden surfaces to be:

- "Pinotex Aqua Protect" is a water-based decorative impregnation. It has elastic, water- and dirt-repellent properties. Emphasizes the texture of wood, is evenly distributed and ensures the material’s resistance to mechanical damage and the influence of detergents. Average cost: 750 rubles.

- "Pinotex Doors&Windows" on a water-soluble basis. Effectively fights blue stains and mold. To obtain a high-quality result, you need to apply 2-3 layers of paint. It takes 4 hours to dry one layer, 12 hours to dry completely. One liter of paint is enough to process 13 m² of planed wood and 11 m² of sawn wood. Average cost: 779 rubles.

"Dufat"

The German company produces high-quality paints and varnishes, including alkyd and acrylic compositions, colored varnishes and coatings with a large margin of safety.

The most popular universal paints are the Premium Woodflex series. Distinctive features of such coatings are: weather resistance, high adhesive properties, elasticity, resistance to the aggressive effects of industrial emissions and dirt- and water-repellent properties. As the paint dries, it forms a glossy finish with a silky effect. Average cost: 2043 rubles.

"Aquatex"

Domestic () produces several types of combined materials, including an antiseptic, moisture protection and an ultraviolet filter. Biopyrene protection is not provided.

The most popular compositions intended for wood are: decorative paints with protective functions “Aquatex” (249 rubles per 1 liter), oil and wax-based products “Aquatex Extra” (339 rubles per 1 liter) and non-washable antiseptics “Aquatex soil antiseptic "(209 rubles per 1 liter).

"Remmers"

When choosing materials for the external treatment of wooden surfaces, experts recommend paying attention to the following products of the German brand “Remmers”:

- “Hk-Lasur” - premium decorative glaze with effective biocides in its composition (1090 rubles per 1 liter);

- “Langzeite-Lasur” is a decorative glaze with increased protective properties against UV radiation (1122 rubles per 1 liter).

The average service life of coatings is from 2 to 5 years.

Wood paint colors: color range

The correct selection of color is extremely important, since the shade provides the wood not only with a pleasant appearance, but sometimes even with protection from external factors:

- light colors exhibit high resistance to ultraviolet radiation;

- gray shades do not yellow and retain the appearance of the coating, perfectly masking dust.

In addition, light shades allow you to visually increase the size of an object, so if the architectural design involves scale and grandeur, the use of light colors cannot be avoided.

What is the price

The cost of facade paint for wood depends on many factors (type of dye, manufacturer, brand, packaging, properties) and therefore can vary greatly.

As practice shows, prices for domestically produced coatings are significantly lower than for imported products. That is why you should check the cost of a specific composition directly with the seller.

Technology for painting a wooden house outside: instructions and video

The entire technology of painting a wooden house outside can be divided into three stages:

- impregnation of wood with special compounds that will protect it from rotting, fungus and insects;

- application of film-forming coatings, the main purpose of which is to reduce the flammability of the material and protect it from ignition;

- surface painting.

It should be noted that before painting work it is extremely important to carry out the necessary preparatory measures - remove all irregularities (treat them with a grinder or sandpaper), remove resin stains, and carefully fill knots and cracks with a specialized solution.

How to properly paint wooden houses is shown in detail in the following videos:

Where to buy wood paint for exterior use?

In Moscow

In Moscow, you can buy facade paint for wood in such organizations as:

- “World of Colors”: official website: https://www.mirkrasok.ru;

- address: Moscow, Ivan Franko street, building 48, building 5;

- telephone.

- official website: https://www.krasko.ru;

- official website: https://www.kraski.ru;

In St. Petersburg

In St. Petersburg, the following stores sell facade paints for wooden surfaces:

- Petrovich": official website: https://petrovich.ru;

- address: St. Petersburg, 6th Verkhny lane, building 12A;

- telephone.

- official website: https://olvia-color.ru;

- official website: https://kraskinadom.ru;

Thus, a properly selected coating not only gives wooden surfaces an aesthetically pleasing appearance, but also extends their service life. That is why it is so important to follow all the rules for the selection and technology of dye application.

Did this article help you? We would be grateful for your rating:

What color to paint the outside of the house: photos and recommendations

Once the type of dye is selected, all that remains is to choose the color. Traditionally, either shades are chosen that correspond to valuable types of wood, or tones that are more radically different.

So, in Scandinavia they prefer cold shades of light colors - white, gray, bluish or greenish colors, which go well with the “cold” nature around.

However, bright, juicy colors also look great in an “icy” environment – apparently by contrast.

For those who prefer the natural color of wood, it is better to choose relatively light colors - from golden to ocher. Darker ones (walnut, old oak, mahogany, ebony) require a contrasting finish so as not to look too gloomy.

When designing the exterior of townhouses and cottage communities, some designers suggest using contrasting bright colors for neighboring buildings - they believe that this enlivens the atmosphere and helps distinguish individual buildings.

Choosing paint to paint the lining white

The following types of paints are used to process panels:

- Oily;

- Acrylic;

- Water-based.

Oil paint

It is a mixture of vegetable oils, organic fillers and alkyd resins. The advantage of oil compositions is their high drying speed and resistance to natural factors.

After application, the paint dries within several hours. After drying, it forms a glossy or matte film on the surface. The surface film increases the resistance of the lining to abrasion and damage.

White oil paint is used to paint various elements of buildings and structures. The main disadvantage of oil compositions is the uneven distribution over the surface. Over time, small cracks appear on the surface of the panels. Therefore, oil paints cannot be applied in a thick layer.

Acrylic paint

Acrylic compositions are a mixture of aqueous dispersion and polymer substances. To dilute acrylic, use ordinary water. When dry, it forms a waterproof film. Acrylic paint does not contain harmful or toxic substances.

The advantage of acrylic paints is their high drying speed and uniform distribution over the surface. The freshly applied composition is easily washed off with water. The dried layer is removed using special means.

The disadvantage of acrylic paints is that they darken after drying. White lining loses its whiteness over time. To restore the white color, re-dying is required.

Water-based paint

It is a mixture of water, pigments and polymer particles. For dilution, clean cold water is required. To apply to the lining, a brush, roller or spray is required.

The advantage of the paint is its high drying speed and easy care of the painted surface. The water emulsion is easily removed with warm soapy water.

A significant disadvantage is low moisture resistance. Therefore, water-based paint is used for cosmetic repairs of dry rooms.