Enamels: properties and scope

Enamel coatings refer to both liquid and paste-like materials, the base of which is diluted in solvents. Moreover, it should be noted that solvents can be either synthetic (White Spirit) or natural (turpentine).

By and large, almost any enamel is a pigmented varnish. Below are the most common types of finishing enamels:

- phenol-oil;

- alkyd;

- polyurethane;

- epoxy;

- acrylic, etc.

Despite such a variety of different enamels, alkyd enamel is mainly sold out on the Russian market. It is widely used not only for external, but also for internal work.

Enamel PF-115 is a bestseller. If you plan to protect metal surfaces outdoors from aggressive environmental influences, then PF-115 is the best option.

This is interesting: UV curing paints - application

The main difference between paints and enamels

Do not forget that paint differs from enamel primarily in that the pigments themselves are dissolved in drying oil, and not in a solvent. At the same time, the paints still have high protective qualities.

However, they are used mostly indoors. The purpose of the premises is not very important. They can be both residential and industrial. For finishing facades, it is still better to use alkyd enamels.

There is also a classification for paints - adhesive, mineral, enamel, etc.

As far as one can see, the essence of enamel and paint is close, but there are still several differences. You need to choose a paint coating based on your own criteria (what is required from the coating - durability, color, etc.).

- Do you know how and what to paint indoor walls with?

- Recommendations for painting surfaces using a roller - https://postroyka.org/kak-krasit-valikom/

The video will describe all the negative aspects of alkyd paints. Especially recommended for viewing by non-professionals:

How to choose a laser level

How to make screw piles

Basic information

Requirements

Requirements for the use of enamel and paints, regardless of their purpose:

Hiding ability is the ability to make the color of the material that will be processed invisible.- Adhesion – the adhesion of paint and varnish material to surfaces.

- Environmentally friendly.

- Wear resistance – resistance to high humidity, as well as mechanical damage.

First of all, paints are used to impart a specific color. Enamel is a similar paint and varnish material, but it will include the addition of a varnish agent. It turns out that the difference between paint and enamel lies in the composition. The choice will depend on the application.

Purpose and application

The properties of paints and enamels will depend on the substance added to form the film, as well as what exactly the pigment is and how much it has. Adding pigment gives the following characteristics:

- Adds color.

- Improves protection against external factors.

- Reduces swelling coefficient.

- Improves thermal stability.

- Reflects ultraviolet rays.

- Enhances anti-corrosion characteristics.

Metal powders are used as pigments. For an ideal indicator, wear-resistant additives of the organic type are azo dyes, speckles and phthalecyanite agents.

Please note that enamel compositions are used both for interior painting of premises and for facade treatment. The material is characterized by excellent stability and long service life.

Composition and characteristics

Enamel is a paint and varnish material that consists of additives, sand, metals, and also subject to heat treatment. The main difference between enamel-type paints is their increased degree of durability. Such compositions consist of pigments and various additives that will be converted into a protective layer; as fillers, they usually use a varnish composition or other substances with similar characteristics. The difference between oil paint and enamel is that the first is made from drying oil, where similar target types of fillers are added. Enamel mixtures based on drying oil are classified as paints and varnishes, and there is no specific difference between the materials. It is very difficult to determine the difference between enamel and oil paints.

In addition, some manufacturing companies try to create the illusion of a large selection of their products, and assign different names to paints and varnishes, taking into account the properties that should be emphasized. That is, in order to emphasize strength and shine, the manufacturer can call the coating enamel, although this is not at all true. If we consider the difference between oil paints and enamel, we can define it as follows - paint enamel with the addition of drying oil is called enamel, and with the use of linseed oil it is called paint.

Please note that in order to be able to determine how oil solutions differ from enamel-type mixtures, you should analyze the composition, which differs in the base and the additive used in the role of mixing.

Terminology and composition

First of all, it must be said that there is nothing in common between enamel and paints and varnishes. Enamel is a glassy formation that includes quartz, alkali metal oxides, pigments and other components. After application to the base, these components are thermally treated, resulting in a very durable, wear-resistant protective layer. Unlike paints, which are applied to the surface of the product, enamels are fused. Examples of the use of enamel include enamel cookware, enamel-coated bathtubs, some types of ceramics, etc.

Paint is a broader concept than enamel paint composition. The first enamel paint and varnish compositions appeared after chemists learned to modify pentaphthalic drying oil with alkyd resins. Unlike enamel composition, ordinary paint and varnish material is made on the basis of linseed oil (natural drying oil) brought to a boil. The difference in composition is noticeable even in the markings: on cans of enamel paints there is always the abbreviation PF (pentaphthalic), but simple paints contain the MA (oil) index. Enamel paint differs from ordinary paint in its smoother and more durable coating.

Enamel paint is liquid or paste pigments, the medium of which is a solution of film formers in organic solvents. A varnish, alkyd resin or other substance with similar physical and chemical characteristics is usually used as a film former. When the enamel paint and varnish material dries, an opaque film remains on the surface, differing in different cases both in color and texture.

As for the gloss of the coating, this indicator depends not only on the film former, but also on the additives included in the paintwork materials, and therefore some ordinary paints shine much more intensely than enamel paints.

It is worth mentioning such a characteristic feature of the enamel composition as a pungent odor. For ordinary paints, an unpleasant strong odor is not at all necessary, especially if they are water-based: the odor may be absent, weak or even aromatized.

Applying alkyd enamel to oil paint

Repainting window sashes is often done using the old base.

Important! It should be understood that the technology for applying paintwork materials involves complete cleaning of the base from old coatings. This is a condition for the most durable, long-lasting and beautiful protective layer that will fit well and serve for a long period of time. The success of the event depends by 60 percent or even more on the degree and quality of foundation preparation.

Now we will tell you how to apply enamel to paint with your own hands, and for convenience we have compiled instructions:

- We check the surface of the old coating for strength. If it peels off and comes away easily from the frame, it is best to remove it. If the coating is durable, then it should be washed from dirt and dust and sanded with coarse sandpaper;

We check the old finish for strength.

- After this, sweep away the dust and shavings, and wash the surface with water and soda. Don't forget to rinse the solution thoroughly with warm water. After this, wait for it to dry;

Add baking soda to the water and wash the windows.

- Open the jar, slightly dilute its contents with solvent or white spirit (1 - 2%) and mix thoroughly;

Lightly dilute the product with white spirit and mix.

- We apply the material in three thin layers, each new layer after the previous one has completely dried. It is better to apply the second and third layers thicker, without thinning. (See also the article Facade finishing - types.)

Carefully apply three layers of coating with a brush.

Important! Wear a respirator, gloves and safety glasses; alkyd coatings are toxic, especially during application and drying.

Water

Water-based paints are those mixtures whose base solvent is water. The drying process occurs due to the evaporation of water, as a result of which all film-forming substances come closer to each other and create a monolithic coating.

Kinds

Water-based paints come in very different compositions - it all depends on the filler substance:

- Silicate.

- Cement.

- Latex.

- Acrylic.

Peculiarities:

- Such solutions are used mainly for interior finishing work, since under the influence of various natural factors the coating quickly collapses.

- The drying speed of water-based paints is very high - one layer can set from 10 minutes to an hour or two (depending on the filling component).

- Aqueous solutions interact well with any finishing materials - they can be applied to rough finishes, wallpaper, wall panels, wood.

- They can be used in rooms with varying degrees of natural light, as they do not fade or turn yellow under the influence of ultraviolet radiation for up to 5-20 years.

- Since there are no organic solvents in the composition, water-based paints are usually odorless, safer and more environmentally friendly than any other types of compositions.

- Water-based coatings usually do not crumble, crack or peel if the layer thickness and application technology are followed.

- The finished finish based on water-based paint is “breathable”, so a comfortable microclimate is maintained in any room, and problems with “standing” air, fungi and mold are less likely to arise.

- The base color of water-based paints is white, but with the addition of color pigments you can get any shade of the buyer’s choice. This allows you to embody any artistic ideas when decorating your interior design.

This is interesting: How to properly dilute paint with hardener

Enamel

It has a very thick consistency. After its application, a fairly smooth coating with a beautiful glossy shine is formed, resistant to external chemical and mechanical influences. Enamel is produced on the basis of varnish; it also contains zinc oxide and other additional substances. Depending on the binding component, there are several types of such paint.

Acrylic

Today it is considered the most popular and in demand among users. This is easily explained by its following characteristics:

- It can be either transparent or multi-colored;

- resistant to fading;

- short drying period - up to two hours;

- suitable for any materials, perfectly protects metal from rust;

- environmentally friendly;

- The created coating “breathes” well.

Important! Acrylic enamel is perfect for external and internal finishing work. At the same time, it fully retains its beneficial properties and is extremely resistant to any adverse effects.

Acrylic enamel is suitable for painting metal in conditions of high humidity or constant heating Source oxidom.com

Alkyd

It is made on the basis of alkyd resins, alcohols, polybasic acids, which have undergone preliminary heat treatment. This composition determines its main characteristics:

- dries quickly;

- resistant to variable humidity and temperature, various chemicals;

- affordable (cheaper than the popular acrylic);

- easy and quick to apply with a roller.

In its liquid state, alkyd paint has a specific, rather pungent odor. This should be taken into account before starting finishing work.

Alkyd enamel can be matte, glossy and even semi-matte, therefore the scope of application of this type of paint is almost limitless Source kraski-net.ru

Details

Consumption per square meter

Calculation of product consumption will depend on the conditions for applying the paint layer. However, the difference can be quite large. To process materials in one layer, approximately 0.1 to 0.14 kg of product per square meter is required. When calculating the average consumption rate, it is necessary to take into account the quality of the surface being treated, the viscosity of the paint and varnish, the location of the painting (street or apartment), and also the painting method (brush or spray gun).

The main differences between paints and enamels

To determine what the differences are between enamels and paints, you should compare these types of paints and varnishes. enamel compositions are used to treat surfaces, creating a thin glass film. In addition, they will be subject to processing at elevated temperatures. Paints will have lower protective properties, in contrast to the same enamels.

Important! The difference between paints and enamels is hardness and also elasticity. Enamel mixtures will have better performance properties. Enamel compositions do not lose their initial characteristics when exposed to external negative factors.

Advantages and disadvantages

Paint and varnish coatings, which are used in the decorative treatment of wall surfaces, are valued for a large number of advantages. Main advantages:

- Rapid polymerization will ensure high drying speed of coatings.

- Easy to process and safe, the materials have virtually no unpleasant odors, and the emulsion fumes are non-toxic.

- Wide range of colors, high coverage and thin-layer coatings.

- Excellent grip and versatility on all types of material.

- Beautiful appearance after decorative treatment.

- The tightness of the coating, which protects the wall surface from mold and corrosion processes, which will increase the service life of the material that will be processed.

It should be noted that rapid polymerization can only occur at positive temperatures.

The difference between oil paints and enamels

Paint and varnish oil mixtures are used for facade and interior work, for painting and priming various building materials. The compositions can be applied to wood walls as the first layer for further enamel coating. Taking into account the manufacture of paint and varnish products, two types can be distinguished:

- Thickly grated - before you start painting, the composition should be diluted with turpentine or drying oil.

- Liquid grated - the composition will be ready for use immediately after opening the jar.

Oil paints are not used as often as the final layer, because they will have some disadvantages:

- Long drying time.

- Insufficient coverage and poor abrasion resistance.

- The drying oil contained in the composition will, after a while, give a yellowish tint to the surface.

- A thick layer will not allow air to pass through, and this will lead to cracks on the surface.

- Toxicity of products made on the basis of synthetic drying oil.

The differences between enamel and paint are clear, but oil paints are popular due to their relative cheapness and versatility of use. The use of oil-type compounds on the surface is not subject to mechanical stress, and allows the coating to be used for a long time. The features of the paint and varnish coating will be determined by the area of application and the main purpose - the compositions can be used to treat almost all surfaces, and at the same time they will perform the function of protection. But such enamel indicators are much better.

How does enamel differ from oil paint?

When carrying out repair work on covering various surfaces with paints and varnishes, the consumer is faced with a choice: purchase enamel or oil paint. These coloring agents are the most popular. In order not to make a mistake with your choice, you need to understand what the difference between them is.

Enamel

The term “enamel” has several meanings, united by common features.

In its original scientific meaning, this is the name given to a durable glassy layer that covers various surfaces and performs a protective function.

For example, tooth enamel or glaze applied to metal and secured by firing. The manufacturing material is glass powder, which melts when fired and forms a fairly durable coating.

In another sense, this term denotes a special type of paint that has a fairly thick consistency and gives an even, durable and glossy finish. These types of paints are produced on the basis of high quality varnish, containing drying oil and zinc oxides.

Their similarity to ceramic enamel is due to the fact that the painted surface in appearance resembles ceramic glaze. This type of paint has high protective properties, is resistant to abrasion and weathering. It can be applied after priming to almost any surface, including polyurethane foam and glue-sealant. There are several main types of enamels:

- Acrylic (they are used to paint furniture, floors, walls, windows, indoor doors, since they dry quickly, are non-toxic and safe in case of fires).

- Alkyd (best used for outdoor work, can be applied to wood and metal, not recommended for painting floors, takes a long time to dry and has a pungent odor that is toxic and lasts throughout the drying period and for some time after, so it requires ventilation even after complete drying).

- Nitroenamel (this type of paint is easily recognized by the smell of acetone, it is distinguished by the rapid drying process of the painted surface - within an hour, it cannot be applied to surfaces painted with oil paint - the old layer peels off, it is fire hazardous).

Oil paint

Oil paints are a type of paint and varnish product based on drying oils of vegetable or synthetic origin. It is a dispersion of drying oil with a pigment substance and special additives. The color range is very diverse.

It is used for external and internal work, for painting and priming wooden surfaces, and is also suitable for concrete, plastic, and metal. Applied to a wooden surface as a primary coat, it can serve as an excellent primer for enamel. Based on the manufacturing method, there are two types of oil paints:

- Liquid grated . The composition of this paint is ready for use immediately after opening the container.

- Thickly grated (pasty). Before you start painting, this type of paint must be diluted with drying oil or turpentine. When adding drying oil, the painted surface will have a gloss; if you add turpentine, the surface will be matte.

Oil paints can be applied to the surface in various ways: using a brush, roller, spray. Oil paints are rarely used as a final layer when finishing surfaces, since they have some disadvantages, namely:

- Low hiding power and abrasion resistance.

- Drying time (from six hours to several days).

- The toxicity of some oil paints made on the basis of unnatural drying oil makes its use undesirable inside residential premises.

- When applied in a thick layer, oil paint does not allow air to pass through to the painted surfaces, which can lead to cracks in the coating.

- The drying oil contained in the composition gives the color a yellowish tint over time, which spoils the appearance of the surface.

However, this type of paint is in demand due to the relatively inexpensive cost of the product and the versatility of its use. Its use on surfaces that will not be subject to mechanical stress makes it possible for the coating to last for quite a long time. If applied correctly, it will last at least seven years.

The production technology for these types of paints is similar: binder base and pigment . The similarity between enamel and oil paint is due to their scope and purpose: they are applied to almost all surfaces and perform a protective function. However, the protective properties of enamels are higher; they are more resistant to sunlight, temperature changes, and precipitation.

The main difference between oil paint and enamels is their composition. Since the base of enamels is varnish , such paint has a sharper odor in contrast to oil paints, which are based on drying oil .

During long-term storage, the pigment substances of oil paint settle, forming a dense layer at the bottom of the container, so before use it is necessary to thoroughly stir the drying oil and the settled pigment until a homogeneous mass is obtained.

It is not recommended to store oil paint after opening the can; the settled pigment hardens and the paint becomes unusable. Enamel can become thick during long-term storage; before use, it is enough to dilute it with a solvent.

Source: https://vchemraznica.ru/chem-emal-otlichaetsya-ot-maslyanoj-kraski/

Minuses

Application of this composition in very humid rooms can lead to the appearance of whitish stains on surfaces, as well as various stains. This can be explained by the fact that the evaporation of acetone included in the paint occurs extremely quickly, which cools the surface. To eliminate this harmful effect, you need to use a solvent that is not very volatile. Finishing work must not be carried out indoors with humidity levels greater than 70%.

Very serious disadvantages are toxicity and flammability. You can only work with such substances using respirators, in well-ventilated areas or outdoors.

If necessary, it is permissible to dilute the nitro paint with acetone or special licensed nitro solvents.

Purpose and use of wood enamels

A tree, after prolonged exposure to various atmospheric phenomena (rain, snow), begins to gradually lose its visual appeal.

Over time, cracks may appear on its outer part. In addition, if a tree is constantly exposed to moisture, then fungi, moss and even mold may appear on it, which poses a considerable danger to human health. The use of enamels to protect the facades of wooden buildings allows not only to protect wood from moisture and prevent its premature destruction, but also to eliminate or mask the negative consequences that appear on the surface of wooden buildings due to adverse atmospheric influences. For example, enamels for exterior woodwork can not only significantly extend the life of a structure, but also eliminate all imperfections that have appeared on the surface of the wood during its operation.

Wood enamel makes it possible to disguise and eliminate the loss of the natural shade of wood. In addition, the use of enamels makes it possible to prevent the occurrence of various cracks or even small deformations on the surface of the wood.

The main task of enamels and other paints and varnishes that are used to color wood is to provide reliable protection for its surface and repel water. Enamels also have the following beneficial properties:

- Prevents drying out and cracks on the wood surface.

- Repels harmful insects.

- Preserve the decorative characteristics of the building.

It is worth noting that enamels used to paint wood have increased resistance to abrasion. Therefore, if you follow all the rules and nuances for painting wood, you will have to replace and update the already applied enamel no more than once every few years.

Types of enamel coatings

There are many varieties of enamel compositions. Only the most common ones are listed below:

- Nitrocellulose. They contain cellulose nitrate, pigmenting substances, additives, fillers and solvent. Most often used for painting metal, concrete and wood. Packaged in cans and aerosol cans. A characteristic feature is a pungent acetone smell. Without preparation in accordance with technological instructions, combination with other paints is unacceptable.

- Organosilicon. Such compositions can be applied to materials and surfaces of all types. The characteristic qualities of silicone enamel coatings include moisture resistance, increased strength and wear resistance. This type of paint and varnish materials can only be combined with dried acrylic coating.

- Pentaphthalic and glyphthalic. They belong to a subtype of oil paints and are made from combined and synthetic drying oils after modification with alkyds. This type of paintwork material is compatible with polyurethane-alkyd, acrylic and epoxy compounds.

- Acrylic. They are a latex-based aqueous dispersion. Acrylic enamels can only be combined with paints and varnishes that are water-based. However, it is also possible to combine with other types of paints, subject to appropriate preparation.

- Urethane and alkyd-urethane. They are characterized by very high strength and wear resistance. Such compositions can be applied to surfaces painted with oil, epoxy or pentaphthalic paints.

How is enamel different from paint?

Very often, when purchasing paint and varnish materials, you can come across the names - enamel or paint. How are they different?

Vapor permeability

Enamels and paints create films of different types: alkyd and oil-based coatings, dull, impervious to steam. And water-dispersed coatings create a breathable coating.

This parameter separates the use of enamels and paints:

— mineral surfaces require vapor permeability (fine-porous materials tend to equalize their humidity with the environment), otherwise condensation will collect on the side of the coating adjacent to the base and the coating will begin to peel off. This is exactly what happens with the walls in the entrances, which are almost always covered with enamel.

— metal surfaces require insulation from external influences; the less moisture and air penetrates the metal, the less it will oxidize (rust). In this case, it is more advisable to use enamels.

— wood can change its geometric dimensions up to 8% throughout the year. those. Elasticity is also an important parameter. Enamels do not have elasticity and will begin to crack on wood, but the coatings created by enamel are mechanically stronger and harder. Water-dispersion paints are more elastic and less durable.

Types of enamel compositions

Nowadays, many different types of enamel coatings are made. Here is a list of the most common enamels:

- nitrocellulose. They consist of cellulose nitrate, fillers, solvents, special additives and pigmenting components. They are typically used for painting wood, concrete and metal surfaces. Available in liquid form, as well as in cans and aerosol form. Nitrocellulose enamel has a pungent odor of acetone. Most of these mixtures cannot be mixed with other paint products;

- organosilicon. They can be used to treat all types of surfaces. This enamel is characterized by high moisture resistance, wear resistance, and excellent strength. These paint and varnish products are combined with dried acrylic compounds;

- glyphthalic and pentaphthalic. These oil-based paints and varnishes are made from different types of drying oil, which is modified with alkyd substances. These mixtures are most often combined with epoxy, alkyd enamel paint, as well as acrylic products;

- alkyd-urethane and urethane. They have one of the highest levels of strength and wear resistance. They can be used to treat surfaces that already have a layer of pentaphthalic, epoxy or oil paint mixture;

- acrylic. These are water-dispersed compositions based on latex. Acrylic enamels are perfectly compatible with water-based paints and varnishes. They can also be combined with other types of paintwork materials, only after special training.

The complete list of different types of enamels and other paint and varnish products is much larger. To view the full list of mixtures, you can read special tables that indicate the compatibility of materials, their names and properties.

Important! You should never apply oil mixtures to nitro enamels, since nitrocellulose compositions immediately begin to curl after contact with solvents that are not part of their composition. After mixing these two types of paints and varnishes, the applied layer begins to swell and bubbles appear on it.

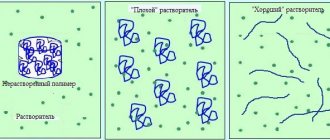

Paint is a water-based suspension

It's like a solid in a liquid. Water-dispersion, water-emulsion, water-acrylic paints are water-based.

: Porcelain tiles for parquet - features of choice

Enamel is a solution based on organic solvents

Enamel is pigments in liquid or paste form. Their medium serves as a film-forming solution in an organic solvent. Alkyd resins or varnish are used as a component for film formation.

After complete drying, a dense film is formed on the product or structure.

Attention! It is the amount and type of additives that make simple oil paints shine more than enamel paints.

Enamel paints and varnishes have a strong, pungent odor. This is one of the main differences from water-based paints. A pungent odor is not typical for them. It may be completely absent.

What else should you know?

- All enamels have higher protective properties than oil and water-based paints.

- If a question arises regarding the compatibility of acrylic and alkyd enamel, then there is such a nuance: two-component compositions cannot be applied to one-component ones, but vice versa, they can. In the first case, the destruction process will be irreversible, in the second, the finished coating will be strengthened. If, for example, acrylic or alkyd aerosol paint for ceramics is used, then it is often a one-component composition. A composition based on another substance can be applied on top of such a coating.

- An important nuance to remember when changing interior design: nitro enamel cannot be applied over an oil paint coating.

- Any solutions, especially oil paints, must be thoroughly mixed before use. And if the pigments in the oil solution settle tightly and stick to the bottom of the container, then such a mixture is no longer suitable for use.

- If the enamel has been stored for too long, it can be brought to the desired consistency with a suitable solvent before use. This will not reduce the quality characteristics.

- It is important to store water-based paints under the conditions prescribed by the manufacturer, since if these solutions freeze, they cannot be used further for their intended purpose.

When deciding which paint is best to buy for specific purposes, do not be afraid to consult with specialists. You will always be provided with such qualified assistance in the “Na, Stroy!” store if you need to buy paint or enamel in Blagoveshchensk. Here you will definitely like the range of products from reliable manufacturers, and the cost of various types of finishing materials!

Compound

Enamels are solutions of pigments in film formers – alkyd resins or varnishes. If oil paints are made on the basis of vegetable oils, then enamels are a modification of pentaphthalic or glyphthalic drying oils. Since they are made from alkyd resin, compositions based on them are called alkyd.

The organic solvent in enamels is most often white spirit. Therefore, if you don’t know how to dilute alkyd enamel, use it. To give the paint special properties (anti-fungal, anti-corrosion), various additives are introduced. The fillers are finely ground sand, granite and marble chips.

The difference between enamel and oil paint is noticeable in appearance. The first one is more shiny and smooth. Pentaphthalic solutions, resistant to abrasion, are used in everyday life for painting floors. Glypthal enamels are used on a production scale to create a protective film on metals.

Melamine-formaldehyde drying oils are used less frequently in production. The first ones are intended for treating surfaces exposed to high temperatures (up to +175°C). Alkyd-styrene compounds are used mainly to protect metal and wood.

The difference between enamel and acrylic paint in composition and technical characteristics

The most common types of materials used in repairs are acrylic and alkyd, which are more advanced types of oil-based enamels.

Although they are often confused, they differ radically in composition:

- Alkyd. Compared to enamels, these paints dry faster and form a protective film on the surface. It contains polyhydric alcohols, for example, glycerin and orthophthalic acid;

- Acrylic. They are produced on the basis of plexiglass, with the addition of components that improve the properties of oil paints.

Difference between acrylic and alkyd paint. Which is better

Many car owners, when they bring their swallow for painting, ask me, what kind of paint will you use? Alkyd or acrylic? But when I ask them in response, what is the difference between them? Hanging up... Now let's try to figure out what's what.

Here it is, acrylic.

What is alkyd paint?

Alkyd automotive enamel is a derivative of oily alkyd resin. The alkyd type can be called a more modernized version of oil paints.

They are characterized by a similar mechanism of hardening and formation of a surface film (which, by the way, is somewhat stronger, but less elastic). Alkyd paints consist of polyhydric alcohols (for example, glycerin) in combination with orthophthalic acid.

Actually, the word “alkyd” comes from a combination of the words “alcohol” (alcohol) and “acid” (acid). Alkyd paint for cars has been used for painting for decades and has managed to prove its positive qualities.

It is used to give an updated look to the body due to the ease of application to the surface and the wide variety of color shades in the palette. It polymerizes quickly and does not require several layers, but requires careful surface treatment before painting.

Do not forget that rapid setting leads to the formation of a thin film, which, under all environmental conditions, does not allow the entire applied layer to dry quickly and evenly in depth, so special hardeners are now added to the car paint composition.

Alkyd paint for metal protects the surface from aggressive external influences and, as a result, from corrosive processes, but it is short-lived. The big advantage of this type of coating is its low cost. To completely paint a car, such enamel is used very rarely, as it requires additional varnish and polishing.

There is also a completely matte automotive enamel; it is used either for local repairs before varnishing, or as an independent decoration for parts on which shine is not needed.

What is acrylic paint?

Paints may contain various additional components designed to improve certain properties (add elasticity, speed up drying). Unlike alkyd paint, the surface of acrylic paint retains its original appearance much longer.

The enamel can be either glossy or matte.

- High reflective characteristics of the painted surface;

- Short period of time from application to complete drying;

- Resistance to mechanical stress;

- Low shrinkage when painting.

Basic properties

- Life time.

Unlike alkyd paint, the surface of acrylic paint retains its original appearance much longer. It is advisable to renew alkyd paint about once a year, since oxygen and ultraviolet radiation intensively destroy the surface layer of paint. Acrylic coating, subject to surface preparation and paint application technology, can last for years. - UV resistance.

Acrylic practically does not change the properties of the surface film under the influence of sunlight, that is, it does not fade, does not turn yellow and does not acquire a “matte” appearance (it also changes). Alkyd compositions are not so reliable in this regard. - Drying process.

Alkyd film dries relatively quickly, and after just a couple of days it fully performs its protective and decorative functions. The acrylic film completes its formation approximately a month after application to the surface. In this case, the coating should be protected from mechanical influences until it is completely dry. - Mechanical stability. The longer process of forming an acrylic film is compensated by a higher level of resistance to mechanical stress (deformation, scratches).

- Decorative properties.

Alkyd compositions are distinguished by a more diverse range of shades and halftones, as well as generally brighter colors. On the other hand, acrylic paint lasts longer and does not require regular updating.

The moral of this story is that tractors and tanks and all sorts of pieces of iron can be painted with any of these paints)))) But to paint our personal cars we use only acrylic paints.