Types and composition

Adhesive “Moment Installation”, depending on the main component in the composition, can be divided into 2 groups:

- The first includes substances with synthetic resins and solvents in their composition, but they are characterized by increased moisture resistance and high strength. The packaging is marked MP.

- The compositions of the second group are made on the basis of an aqueous dispersion of polyacrylate. The chemical composition is neutral, suitable for working with plastic. Adhesives are marked MV.

Advice! To get acquainted with all the information of interest regarding the selected adhesive composition, you can open the technical information sheet. This sheet is presented on the official resource. There you can find information about any Moment Montazh product.

Depending on the markings and abbreviations, the Moment brand mounting adhesive is divided into the following types:

- “Express MV-50” belongs to the category of acrylates, as symbolized by the MV marking. It is used to work with various materials, including wood, plastic, metal, ceramic, plaster and others. Suitable for external and internal gluing. Capable of fastening window sills, baseboards, decorative parts.

- “Super strong MV p-70” also belongs to the subgroup of acrylic adhesives, but does not contain solvents. Suitable for working with various raw materials, even PVC and foam. But it will not be able to glue Teflon, polyethylene, polypropylene surfaces. The additional letter “P” in the marking indicates the transparency of this glue, and the number 70 is the adhesive strength in kg/m². Even large and heavy parts can be held together with glue.

- “Express Decor MV-45” is a white mounting adhesive from the acrylic category, suitable for gluing various decorative parts from different materials.

- “Universal MP-40” is an assembly adhesive that is used for fastening wooden, stone, brick, marble, even glass bases and is washed off very easily.

- “Extra-strong MP-55” is a “Moment” assembly adhesive, which is made from polyvinyl acetate and carbon resins. High-strength adhesive is used for the installation of heavy, metal, wooden, ceramic, and plaster structures. They can even glue PVC, chipboard, and MDF. The description of this glue has a distinctive property - the instant formation of a film on the surface. It will protect the bonded surfaces from dust accumulation. When the materials are bonded to each other, the film breaks down, providing a strong and perfect bond.

Advice! When working with this glue, you must immediately ensure a neat connection of the two surfaces, since movements will only disrupt the strength of the adhesion. The best adhesion is ensured by the initial contact of the bases.

Specifications

Rubber-based mounting adhesive “Moment” has the following main technical characteristics:

- Contains harmful volatile substances that emit a characteristic odor. When working, it is necessary to create good ventilation in the room.

- Moisture resistance and frost resistance down to -40°C.

- It is a construction and installation substance and performs the functions of a sealant.

- Suitable for joining smooth and non-absorbent materials.

- There are types that are distinguished by instant adhesion.

- Can be stored at -20…+30°C.

- Shelf life 1.5-2 years.

- Can be found on sale in tubes and cartridges weighing 125-400 g.

- Operating temperatures -12…+ 35°С.

- The hardening period is 10-30 minutes depending on the variety.

- Complete setting after 1 day, maximum period 7 days.

- Can be cleaned using white spirit.

- Most of the variety is produced in the form of a beige mass.

Technical characteristics of water-based construction adhesive:

- No pungent odor.

- Frost resistance and water resistance -20°C.

- Versatility - glues any materials.

- Necessary condition – 1 surface must be moisture-absorbent.

- Store at temperature +5…+30°С.

- Shelf life: 1.5 years.

- Available in convenient tubes and cartridges weighing 125-400 g.

- Suitable for indoor and outdoor use.

- Working period 5-15 minutes.

- The frozen seam can be painted with acrylic paint.

- Great initial grip force.

- Excess liquid glue can be removed with a damp cloth. Available in the form of a white mixture, after drying it becomes transparent.

It is important! In construction stores you can find a huge variety of Moment glue liquid nails. To choose the right type for certain types of work, you need to study the technical specifications or ask a consultant for advice.

On video: Liquid nails “Moment installation”.

Adhesive liquid nails: types and applications

The scope of application of liquid nails glue during installation is quite extensive, but their main purpose is to fix any wall panels and similar materials. The highlight of this glue is its elasticity even after complete drying. And this is what is necessary for gluing large products that undergo thermal expansion. It is elasticity that allows the material to expand and contract freely without the risk of tearing away from the surface. Liquid nails glue is unique in this regard.

How to use liquid nails

Today, Moment liquid nails glue is produced in ten varieties:

1. “Instant Grip” is an almost universal glue. It can be used to connect both porous and non-porous surfaces - it easily copes with plastic, metal, brick, concrete, wood, ceramic tiles and many other materials used in construction.

2. “Express Decor” – works well with plastic, wood and polystyrene. In practice, it has been widely used in the installation of ceiling moldings made of foam plastic, all kinds of decorative friezes and panels made of PVC, polystyrene and other lightweight materials.

3. The moment of installation “for mirrors” - the name of this glue speaks for itself. It is able to connect a mirror or glass to any type of surface indoors.

4. Liquid nails Installation moment “Super strong transparent” - produced under the DGII marking. It can be used to glue wall panels made of wood, PVC, and cork. It does an excellent job with plastic and MDF skirting boards. According to the manufacturer, it can even be used to secure a door in the opening and install a window sill.

5. “Super strong” montage moment. It differs from its transparent brother only in its nondescript color.

Types of glue moment liquid nails

6. Installation point “Super strong plus” is a modified version of the two adhesive compositions described above. Added to all other qualities is the ability to be used outdoors – it sticks to everything and to anything.

7. “Very strong” – used in connections of heavy structures. If we are talking about reliably gluing a heavy object, then it is difficult to come up with a better solution than this type of liquid nails. In practice, this glue has shown itself to be excellent when working with bamboo wallpaper and slabs.

8. Installation moment “For panels” - used for installing any types of panels on concrete, plasterboard, brick, wood and any other base.

9. “Universal” - intended for everything and at the same time for nothing. In principle, it’s difficult to say anything bad about this type of liquid nails - in fact, it is an average glue that is mainly used for gluing light and medium weight materials to any type of surface.

10. “Express” – glues quickly and efficiently. Designed for use both indoors and outdoors. Quite often used for finishing facades with gypsum or cement artificial stone.

Adhesives liquid nails photo

Liquid nails: instructions for use

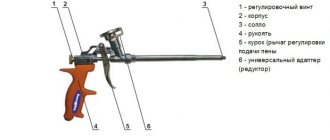

In fact, Moment Installation is unpretentious to use, but, like most similar adhesive compositions, it has a lot of nuances. And the first, most basic of all, is the need to use a special gun; without it, squeezing liquid nails out of a cylinder is tedious. The gun is inexpensive and is sold in any hardware store at a very affordable price - as a rule, we are talking about $4-10.

The liquid nail gun is quite simple to use. The metal tongue located behind the handle of the gun is pressed with a finger, after which the piston-pusher is pulled back, thereby making room for the glue bottle. When the cylinder is installed, the piston is pressed back in exactly the same way. Now everything is simple - swing the trigger and squeeze out the glue.

Gun for liquid nails photo

Many people have a question: how to open liquid nails? It's really simple. You don't wonder how to open a tube of toothpaste or hand cream, do you? There are two types of blockage of this glue - in the first case, you will have to cut off the sealed part of the plastic tube with a knife, and in the second case, if we are talking about tin or paper cylinders, you will additionally pierce the protective film located deep in the spout with a long nail. This protection is necessary so that the glue has time to reach the consumer without losing its qualities.

Okay, that's all lyrics, let's get back to the technology of using glue. Moment installation of liquid nails. As elsewhere, work on gluing something using liquid nails begins with preparing the surface - dust, dirt, and loose paint must be completely removed. The surface of the walls and the glued material (if it is porous) must be covered with a layer of primer to increase the adhesion of the materials.

Liquid nails instructions for use

When the surfaces are dry, you can begin gluing them. Liquid nails are applied to one of the surfaces in two ways - either in continuous stripes or dotted. It is necessary to choose the application method based on the type of product. For example, it is better to glue long panels, such as PVC plastic or MDF, point by point, but the ceiling plinth will adhere more firmly if the glue is applied in a strip.

Liquid nails application photo

Did you apply glue? Now we take the glued product and connect it to the base of the wall. Press tightly, if necessary, lightly tap with your fist and tear off the product. For what? The glue should dry out within 5-7 minutes. There is no escape from this – this is the lack of technology. If you want to glue surfaces, as they say, “tightly,” then you should not ignore this point. When the glue has dried, the panel is put in place and tapped well with a fist. This, in principle, is the whole technology - now you know how to use liquid nails. Installation moment and you can safely get to work.

And finally, a few tips for sloppy craftsmen - removing liquid nails not in a frozen state is tantamount to smearing them on the finished surface, thereby ruining it. First, wait until the glue dries, then carefully cut it off with a sharp blade - these are the instant liquid nails.

Author of the article Dmitry Vorokhov

Hello, dear visitors of our site! Today we will talk about liquid nails “Moment installation”. In addition, we will look at what other products this company produces and what exactly are they - liquid nails? Let's find out how much such products cost today.

How long do liquid nails take to dry?

Liquid Nails

The adhesive composition “liquid nails” is often used when performing repair work. Thanks to its excellent technical characteristics and properties, this installation material is used by both professional builders and craftsmen who prefer to do all the homework themselves.

Types of material and technical characteristics

What are liquid nails? This is nothing more than a special assembly adhesive, which differs from ordinary glue in its composition. The difference is due to the inclusion of a small amount of fine filler, which ensures the reliability of the connection of various materials during installation or construction.

Liquid nails are produced in two types:

- water-based (acrylic);

- based on organic solvent (neoprene).

Depending on the base, the technical characteristics of liquid nails vary significantly.

Liquid neoprene nails are different:

- possibility of application for a huge number of surfaces made of various materials;

- harden quickly, reliably glue surfaces, easily withstanding significant loads;

- can be used at low temperatures (down to -40°C).

At the same time, organic-based liquid nails have a strong unpleasant odor and are toxic, so you need to wear a protective mask and rubber gloves when working with them.

Water-based adhesive has the following features:

- can be used to connect porous materials;

- non-toxic

- does not have an unpleasant odor;

- fireproof.

Liquid water-based nails do not tolerate freezing and are not recommended for use in high air humidity.

How long does liquid nails take to dry? Most modern brands are quick-drying and set in literally 20-40 minutes. Even if a mistake is made when connecting the surfaces to be glued together, during this time it can be completely corrected. The final drying time for the composition is 24 hours.

Application area

Liquid nail glue, according to the instructions for use, can be used to work with various materials:

- wood;

- glass;

- aluminum;

- drywall;

- natural cork;

- plastic materials.

Often, inexperienced craftsmen have a question: is it possible to glue ceramic or polymer tiles to liquid nails? The answer is yes. Moreover, some brands of glue can be used as a sealant for bathrooms, windows, door frames and many other important elements.

Advantages and disadvantages of the material

The popularity of liquid nails, including for ceramic tiles, is due to the impressive list of advantages of the material, among which several main ones stand out:

- waterproofness of polymer compounds - even moisture getting inside the seam will not affect the condition of the tile;

- high strength throughout the entire service life - after drying, liquid nails glue the surfaces “tightly”;

- power - some brands are able to withstand loads of up to 80 kg/cm2, which makes it possible to glue together large elements of sufficiently large mass;

- resistance to environmental influences - between surfaces glued with liquid nails there is no formation of rot, rust, or mold;

- ease of application of the composition - it is possible to use a special gun, which significantly increases the speed of work;

- convenience - the glue is completely ready for use, it does not need to be diluted or kneaded;

- cleanliness - no dust or dirt is generated when performing work.

At the same time, one cannot fail to note the obvious disadvantages of liquid nails, namely:

- a relatively short period of time (20-40 minutes), during which the position of the bonded surfaces can be adjusted;

- high cost of the material compared to conventional adhesives;

- lack of packaging variability - most manufacturers produce liquid nails in small (300-50 grams) tubes.

How to work with the material

The scope of application of liquid nails glue is not limited to interior work. Due to moisture and frost resistance, some compositions can also be used for outdoor work.

In any case, before purchasing and starting work, you must carefully read the instructions and strictly follow all the rules and recommendations of the manufacturer.

In general, instructions on how to use liquid nails are as follows.

First of all, the surfaces to be glued should be thoroughly cleaned and degreased - there should be no dirt, dust or grease on them. The surface must be dry and hard.

It is more convenient to apply liquid nails using a special gun: small dots, stripes, snakes, mesh. The surfaces are given the required position relative to each other, they are pressed tightly against each other and held for several minutes. If the gluing area is large enough, the surface can be tapped with a wooden or rubber mallet to increase the pressing force.

As a rule, liquid nails are completely dry after 24 hours, after which the surface can be used for its intended purpose or its mechanical processing can be continued.

How to remove liquid nails

Often, when performing repairs, glue is applied not only to surfaces, but also to hands, clothing, and the front side of the building material. To remove the composition, you must prepare in advance a damp rag or sponge, soap, warm water, solvent, scraper, Vaseline, and vegetable oil.

Removal from clothing

You can quickly remove any adhesive that gets on your clothes using Secunda anti-glue.

Another equally effective method is to heat the fabric with a hairdryer or iron and then cool it in the freezer. In this case, the composition loses its characteristics and can be easily removed from clothing.

If the material does not fade from exposure to acetone, then you can use it. If the glue has not cleared after the first application of acetone, then the treatment should be repeated the required number of times. To prevent the fabric from sticking to the table, it is recommended to place a sheet of paper under it, and to quickly remove stains, you can use an unnecessary toothbrush.

Removal from materials

Liquid nails are removed from the surfaces of the elements to be joined using a damp sponge, soft spatula, or white spirit.

If the glue has already set or dried, it can be removed with a blade or a hard spatula, or wiped off with fine sandpaper.

If the glued materials need to be separated, it is recommended to heat them to a temperature of 60°C, at which the glue becomes liquid again.

Removal from the skin surface

Acrylic liquid nails can be easily removed from the skin of your hands with liquid or laundry soap.

Neoprene compounds are removed from the skin with Vaseline or vegetable oil.

From the many brands from dozens of manufacturers, it is sometimes difficult to choose a high-quality adhesive composition. Which liquid nails are better must be decided in each specific case, namely: the material of the surfaces to be glued, the conditions of their use, the magnitude of the static and dynamic load exerted on the element.

Review: Liquid nails Moment Installation MV-100 - Dries quickly, odorless, reliable.

Advantages:

White color, no odor, quality, ease of use, versatility.

Flaws:

no and cannot be.

Good day everyone.

We always have liquid nails at home. A very useful thing, as it turned out. How could we manage without it before, because liquid nails are such a universal thing. It is used constantly and everywhere.

Even crafts for school can be done using liquid nails. It turned out to be very convenient. Liquid nails Moment Installation MV-100 are practically odorless. They dry quite quickly.

This glue is white in color. It is best to use nails for interior work. Suitable for plastic and MDF, wood and chipboard.

Liquid nails Moment Installation MV-100 are very reliable. The main thing is to follow all the rules for gluing. We even had the opportunity to glue artificial stone to the walls using these nails. One has only to apply nails to one of the surfaces and apply them to the other, the objects are securely glued together. It is recommended to press for 15 minutes. But this is not even necessary. Of course, it all depends on what you are gluing.

I give examples of what can be glued using liquid nails Moment Installation MV-100. I glued the artificial stone directly onto the wallpaper myself. It grabs instantly, holds on - you can’t tear it off.

The platbands of the interior arch are also held on with liquid nails. Here we had to fix it for 15-20 minutes to be safe.

Decorative molding is also held on with liquid nails. Here everything is simpler than ever. If you couldn’t glue it evenly, you can tear it off in the first minutes and correct the situation.

If you are doing repairs, liquid nails will always come in handy. A very necessary and useful thing. Much more convenient than glue, as it has a thicker consistency and no odor. It also dries faster.

I recommend it and thank you for your attention.

Usage time: constantly

Cost: 300 rub.

Year of manufacture/purchase:2015

General impression

.

They dry quickly, are odorless, and reliable.

Proper use of liquid nails

The first question that arises among consumers who first purchased this product is how to open liquid nails . Blockage of assembly adhesive can occur in two ways. In the first case, the sealed part of the plastic tube is cut off with a knife; when purchasing paper and tin cylinders, you additionally need to pierce the protective film on the spout with a nail. Reliable packaging is a guarantee of high-quality composition. Before using assembly adhesive, special preparation of the surface, cleaning of dirt and grease, and removal of greasy stains are required. You can increase the adhesion of materials by pre-priming the surface.

If you don't know how to use liquid nails glue . It is recommended that you read the instructions, which explain everything in detail. The composition is applied in different ways - dotted and in continuous stripes; the technology usually depends on the type of product being glued. After application, the product is connected to the base. The composition should dry out within 7 minutes.

How to work with liquid nails at sub-zero temperatures?

At low temperatures it is quite difficult to carry out repair work. First, you need to remove the ice; it is advisable to warm the surface before gluing. To get the desired result, it is recommended to use glue from a trusted manufacturer that has been tested by independent laboratories. The best effect can be achieved by following the rules for storing the glue.

Liquid nails should not be frozen - this reduces the quality of the product. It is also not recommended to heat the composition; the maximum storage temperature for assembly adhesive is no more than +38 degrees; at higher temperatures, the adhesive will simply dry out; water should not get into the composition.

How long does it take for assembly adhesive to dry? ?

The glue may vary in composition and have its own characteristics depending on the manufacturer, and therefore the drying time also differs. You can find out how long liquid nails take to dry Most often, the setting time ranges from 20 to 40 minutes. – this applies to quick-drying adhesives. Complete drying time is 24 hours. The universal mounting KINKLEY is of high quality and has a number of advantages. The setting time of liquid nails manufactured by KIN-Holding is 20-30 minutes. Complete drying - 24 hours.

- Liquid nails for ceramic tiles What is it? Types Tips for selection Laying Methods of cladding Stages How to remove excess glue? How many…

- How long does it take for non-woven wallpaper to dry? How long does it take for non-woven wallpaper to dry? For those who plan to do renovations and use wallpaper with…

- Liquid nails how to use How to use liquid nails Category: Materials for repair and construction What are liquid nails heard...

- Why liquid wallpaper is perfect for decoration Finishing a room in a house is an important process that requires special attention not only during...

Where is the best place to use Moment Montazh glue?

In order to properly clarify the issue and areas of use of liquid glue, we must simultaneously consider what types of “Installation” exist today.

So, a series of heavy-duty adhesives that allow you to do without nails, screws, etc., consists of the following water-based products:

- "Montazh Express". It is used for attaching baseboards, trim, tiles, decorative elements and wall plaques. The glue is great for children's buildings, and for residential buildings in general. It is odorless and does not require additional solvents. Fairly good initial grip strength.

- “Editing Super Strong.” This type of liquid nails is used for fastening heavy structures - panels, window sills, decorative elements and door frames. It is also odorless and perfect for use in children's rooms. The initial grasp is simply tremendously powerful. The glue is capable of filling cracks whose thickness does not exceed one centimeter.

There are a number of other brands of glue that are made from synthetic rubber. This:

- “Universal installation”, which, as you may have guessed from the name, is suitable for working with any materials.

- “Installation Extra-Strength”, used for fastening particularly bulky structures and parts.

- "Installation for panels." Indispensable when attaching panels.

Liquid nails: material features

Unlike most similar products, liquid nails are capable of fixing various materials, including heavy ones, in a fairly short period of time. Some types of glue can withstand loads of up to 80 kg per square meter.

A huge advantage of liquid nails is their wide range of applications, since this glue will do an excellent job of gluing wood, slabs, metal, ceramics, plastic, glass, polystyrene and many other materials. Today in stores and markets you can see many varieties of liquid nails produced by different manufacturers.

There are universal brands of this glue and specialized ones used for processing and working with certain materials.

Instructions for using liquid nails “Moment Installation”

So, we’ve figured out the general characteristics, now let’s look at how “Moment” liquid nails are glued correctly.

First stage. Thoroughly clean and degrease work surfaces.

Second phase. Apply glue to the work surface using a construction gun. You can do this in one of three ways:

- mesh

- dots

- snake

Third stage. We press the two surfaces that need to be fastened with special density, give them the correct position and hold them there for two to three minutes.

Fourth stage. After this, we must wait until the liquid nails are completely dry (this is approximately twenty-four hours), and only after that the surface can be affected mechanically.

Construction gun for liquid nails

Separately, I would like to talk about the construction pistol itself. The fact is that few people know how the Moment Montazh liquid nails themselves are inserted into it. So, to begin with, we take a tube, a reservoir, and also the cartridge itself, which contains the actual liquid nails.

We screw on the dispenser, which must be cut at the end. Next we must insert the cartridge into the gun device. For this purpose, we move it to its original position, after which we fix a special tongue towards the gun.

Then we pull the rod all the way, insert a special cylinder and, using the release system, direct the drain with the ring forward so that the glue can be supplied to the dispenser. This procedure must be done until the gluing work is carried out or until the glue itself runs out.

To remove the cartridge, we again press the locking tab, hold it and at the same time pull the rod towards us in order to remove the empty cylinder from the device.

Among the advantages of this type of glue I would like to note the following:

- They do not harm the work surface and are not susceptible to rust.

- They are not only resistant to low temperatures, but also environmentally friendly.

- They harden extremely quickly, regardless of the environment.

- When working with liquid nails, no impact tools are required.

- The connections are characterized by particular strength.

- These nails can be used to glue any material, regardless of whether it is smooth or rough.

But there are also disadvantages (and where would we be without them?), and the main ones are the following:

- When working with them, it is recommended to use respirators, since for some time after work the material may emit unpleasant odors.

- Having no idea about such nails, it is quite difficult to manipulate them for the first time.

Other manufacturers of liquid nails

Among other manufacturers of liquid nails, in addition to Moment Installation itself, there are many good products. Thus, we can note the LN601 brand from the Macco company, known for its high performance in interior work.

In general, this is a universal glue, but it cannot be used when attaching mirrors or tiles. But Multi-Purpose, thanks to its excellent adhesion, can easily be used for plastic, brick, and foam.

Solvent Free is great for ceramic tiles as it dries quickly and is impervious to moisture.

If you need to glue a mirror, then the best option is probably LN-930.

And finally, it is better to fasten massive structures with Heavy Duty or Zigger 99 liquid nails. Here’s more for your reference.

about and how to do it'/>Liquid nails are widely used today in construction and repair. Instructions for using liquid nails will not be superfluous even for those who have already fastened surfaces with them and seem to have an idea of how to work with this glue. Of course, the basic techniques can be described in two words and they will coincide with the recommendations for gluing with any other compositions: apply - press. However, practice shows that everything does not look as simple as it seems at a quick glance.

Each task has its own subtleties and nuances, without knowledge of which you simply will not be able to connect surfaces quickly, reliably and accurately. And who wants to redo it afterward, returning to editing after a while? In addition, liquid nails have different modifications, determined by their purpose. In simple cases, you can use any, but if you have to deal with large, heavy objects or capricious surfaces, then you need to be more scrupulous in choosing glue.

The instructions for using liquid nails are simple, but everyone should read them before starting work. At least in order to decide whether the purchased glue option is suitable for your purposes and which of the two instructions for use concerns exactly the chosen composition. This is exactly what we will try to talk about in our article today. We hope that our tips and recommendations will help you in choosing and using this adhesive.

Compared to other construction adhesives (such as bustylate or PVA), liquid nails differ for the better in several ways:

- They are several times superior to competitors in terms of adhesion strength.

- To use liquid nails, the degree of evenness of the planes being connected is not important. Their smoothness also does not play any role: both rough and almost mirror-like surfaces are glued together.

- After drying, the glue retains a fairly high degree of elasticity.

- Does not wash out or soften with water; has good frost resistance.

- All known building materials can be glued.

- Initial setting takes little time.

Liquid nails are also used as additional fasteners when fixing parts to be joined with nails or screws. At the same time, they provide a tighter mutual fit of the elements and protect the hardware from corrosion.

If anyone doesn't know, there are quite a lot of them. There are those that can be called universal in their way, and there are highly specialized ones.

- "Snap Grip" is considered suitable for solving all problems and is used most often. Primary setting takes 5 minutes, bonds anything to any substrate: brick, metal, wood, plastic, ceramics, etc.

- Express Decor works especially well with wood, plastic and polystyrene. Received full recognition in gluing baguettes, friezes and light cornices.

- “For mirrors” lives up to its name precisely in the direction of connecting the mirror/glass with something else.

- “Super strong”, “Super strong transparent”, “Super strong plus” - all 3 varieties are used mainly for fastening various kinds of wall panels. The first 2 differ from each other only in the degree of transparency; the latter is also suitable for outdoor work.

- “Very strong” holds very heavy objects.

- “Express” is often used for wall cladding with artificial and natural stone. Suitable for façade and exterior work. When deciding on the purchase of glue, you need to soberly assess what will be installed and under what conditions.

For any type of liquid nails, there are several comments that always remain valid.

- It’s easier and faster to work with this glue using a gun - squeezing it out of the bottle with your hands is very difficult. Don't be stingy, spend 300-500 rubles on a useful device.

- Low temperatures promote longer drying times. Working with liquid nails if it is colder than zero is not recommended at all, although there are variations for such conditions.

- The glue must not be allowed to freeze: it takes a long time to thaw, and the adhesive properties of the thawed composition are lower.

- High temperatures also have a negative effect on liquid nails: at +38 they can simply dry out inside the cylinder.

- It is also undesirable to leave the glue in the rain or allow water to penetrate inside in any other way: it can cause the composition to delaminate.

Most types of liquid nails are used on it. Both bonding surfaces are cleaned. If necessary, wash and dry, and then degrease. If one or both surfaces are porous, they should be impregnated with a primer to increase the degree of adhesion.

The glue is applied to one of the surfaces in one of 3 ways: with a grid, stripes (snakes) or individual dots. For large, heavy objects, a mesh is chosen; panels are usually glued in dots, and narrow elements like baseboards are glued in strips. The part to be glued is pressed forcefully onto the base and held for a couple of minutes. It is desirable that the pressure be uniform over the entire area of the element.

If any further manipulations with the glued elements are expected, they should be postponed for at least a day - until the glue has completely dried. If the temperature in the room (or outside) is low, the humidity, on the contrary, is high, and one of the planes (and especially both) is characterized by low roughness, the setting time may take up to three days.

Some types of liquid nails require a slightly different approach. Points 1-2 are carried out with the same care: the reliability of the clutch depends on them. However, further actions vary.

- The part (object) to be glued is pressed firmly to the base for a few seconds.

- Afterwards the element is carefully removed from it.

- Wait 10 minutes. At this time, the glue will gain some thickness, but will not dry out and will not form a film on its surface that prevents bonding.

- The object is again pressed against the plane and held until it sets.

Note that it is physically more difficult to work with this type of glue: it takes much longer to press the part to the plane. Before you start applying glue, it is important to understand which instructions for using liquid nails described above apply to it. Otherwise, if you make a mistake in your actions, you will not be able to achieve good adhesion: either the glue will dry before pressing the element (if you need No. 1, and you acted according to No. 2), or, conversely, it will not set at all.

Why do you need liquid nails?

Liquid nails are a special adhesive for installation. This adhesive solution is made from polymer and rubber.

Currently, it is quite popular due to its ease of application and good performance.

This device has many other advantages, for which both professionals and amateurs love it.

For example, using liquid nails you can quickly glue wood, metal, ceramics or PVC.

In addition, this glue dries very quickly, but this does not happen immediately, so you can quickly change the position of the elements being glued together. In addition, after gluing it to a liquid nail, you can bend the material as you like.

It should also be noted that the adhesive solution is very frost-resistant and does not ignite. Liquid nails can support a weight of about 50 kg.

When gluing, you do not need to use percussion instruments, which is also quite important.

In addition, liquid nail does not allow rust to form if metal parts need to be glued together.

Glue can connect any surfaces - rough, soft, etc., and they will all hold equally tightly.

However, in order to properly glue the necessary parts, you should carefully consider the choice of liquid nails.

There are nails based on organic compounds. They adhere well and are resistant to low temperatures.

Before purchasing, you need to carefully study the instructions, because with organic-based glue you need to work with gloves.

As a rule, nails in this category have a pungent odor, so it is advisable to wear a respirator before starting work.

There are solutions based on acrylic. This glue is almost completely safe, but you cannot work with it if the temperature is very low.

It is also not recommended to glue something in rooms with high humidity, otherwise the adhesion will not be as good.

In general, acrylic liquid nails glue worse than organic ones, so it is better not to use them for serious installation work.

To use glue you need a liquid nail gun. On average, a standard cassette contains about 310 ml of glue.

As a rule, universal liquid nails are needed to glue small parts. But there is also heavy-duty glue that is used for more serious installation work.

However, glue also has its disadvantages. For example, when working with it, you need to have clothes covering your hands, and you need to wear a respirator, because the solution has a very unpleasant odor.

In addition, if you have no experience working with such glue, then using it is quite problematic. Before using liquid nails, the instructions must be read.

Video:

Rules of work - don't waste time!

The main positive quality of quick-drying compounds is also their main disadvantage. The high rate of hardening of the adhesive is present not only in the second and third stages, but also during the direct laying of the tiles. You need to work with such compositions very quickly, which requires some dexterity and skill. You will have no more than half an hour for all open work (kneading, distributing the composition on the tiles and base, correcting the position of the tiles).

Therefore, everything should be thought through and provided for in advance. It is especially important to prepare the base - to clean the surface from dirt, dust, sand, paint and other elements that tend to peel off in the near future. Then you won’t have time to scrape off a piece of frozen putty with a spatula - you risk ruining the whole batch!

By the way, it is better to make batches in small portions, although in this case it is more difficult to calculate the number of components. If you lack dexterity, calculate; if you are confident in your abilities, make a big batch. In most cases, before use, the glue should sit a little - no more than 5 minutes. When working, follow basic safety rules - wear rubber gloves and safety glasses to prevent glue from getting into your eyes. Otherwise, the recommendations are the same as when working with regular glue - how to hold a spatula, what other tools you will need, you can read in articles on laying tiles.

- Author: Mikhail Malofeev

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

How to choose the right one?

Most often, this glue is needed for adhesion of ceramic, metal, wood, brick, polystyrene and other parts.

Liquid nails can glue together even elements that do not fit tightly together.

In this case, the solution can withstand a load of about 80 kg. However, experts do not recommend gluing materials made from damp wood with nails.

Wallpaper made from natural materials is often glued to nails. In this case, there is no need to specially prepare the surface - just remove the excess plaster and start gluing.

As with conventional glue, liquid nails must be applied to the inside of the coating, after which the sheet is applied to the surface and pressed by hand.

Video:

Next, the canvas is removed for 10 minutes to allow the composition to dry, and then applied to the surface again, this time completely.

If the glue has leaked a little from the edges of the sheet, then you can take your time wiping it off. You should wait a little until the solution dries, and then carefully remove the excess.

Even ceramic tiles can be glued to this glue. In this case, the adhesion will be better than that of conventional tile mortars.

However, if you use nails on a large scale, it will be somewhat expensive - the price of glue is quite high.

It is best to use this adhesive solution for gluing fallen tiles, etc.

If you need to stick a heavy element to a vertical plane, then you need to fix the object on wooden supports until the composition is completely dry.

Usually the substance dries completely within 12 hours, but this depends on the brand and ingredients of the glue.

Many people advise reading the instructions for use when choosing liquid nails, but this does not always help.

If a person has never used this glue before, and there are dozens of varieties of adhesive solutions in the store, then it will be difficult to make a choice.

In any case, first you need to understand the most popular brands. For example, you can often see “Moment Installation Extra-Strong” adhesive based on neoprene.

This adhesive solution can withstand the load of heavy parts and elements. It is often used for gluing siding, stone, wood structures, etc.

However, this option is not suitable for polystyrene foam and other foam materials. For these purposes, it is better to purchase “Moment Installation super strong” based on water.

But you need to remember that you cannot glue polyethylene, polypropylene or Teflon with it.

There are also liquid nails LN601 on neoprene, which can only be used for interior work. But since the glue is universal, it can be used to glue almost anything.

However, this adhesive solution is not suitable for gluing tiles and other heavy objects.

There is also Multi-Purpose adhesive solution on neoprene, which can be used to glue brick, concrete or plaster.

In addition, this glue is suitable for plastic, wood, metal and ceramic elements, but it cannot be used for polystyrene foam objects.

It is worth remembering that nails that dry quickly are best for ceramic tiles. For example, Titan WB-50 and Solvent Free.

If you need to glue a mirror, then you need to choose LN-930 and other similar adhesive solutions. For work in a damp environment, it is better to take Nail Power.

Various wooden structures need to be glued together with Solvent Free or Tigger construction adhesive, they dry quickly.

If you need to glue something heavy, then high-strength Heavy Duty or Zigger 99 will do.

How to check if the glue is dry

There is no way to accurately determine the degree of hardening of the tiles after they are laid. The only thing you can do is try to rip it off. If she walks easily, it means the solution is damp.

You can also tap the surface of the tile, but not too much. If the mixture has already hardened, the sound will be loud, and if the mixture is raw, it will be muffled. What should you do if during the inspection you find that the tiles are not holding well? In this case, it should be carefully dismantled.

All the solution is removed from its surface. And re-apply it to the fresh solution. At the same time, do not rush to step on it, but wait until it dries.

How to use?

Liquid nails are very often used during installation. Despite the fact that working with them is relatively simple, you still need to follow a few rules.

For example, you should remember that glue is applied only to a clean, dry surface. In addition, after spreading the solution, you must press the parts tightly in the desired position for 2 minutes.

You should also remember that the glue is applied in strips or dots. In this case, there is no need to spread the composition over the entire surface; gluing will be good without it.

Drying usually takes about 12 hours, but it can last 18 hours or a day - it depends on the brand and manufacturer. It is better not to touch the structure while it is drying.

If the gluing elements are quite heavy, then it is advisable to wait a week, then the glue will dry completely and will be able to completely hold the structure.

The composition is needed for gluing parts in difficult places.

We should not forget that nails based on organic compounds are quite dangerous - you should not allow the composition to come into contact with the skin. The glue must be applied with a special gun.

In stores, liquid nails can be found in the form of cartridges, which helps to use the adhesive solution in doses and save money. At the same time, the shelf life of the composition is quite long.

However, everyone has situations when they need to not only apply glue, but also remove it. High-strength adhesive mortar is especially difficult to remove.

To remove newly applied liquid nail, you should try washing it off with water and solvent. You can use a regular sponge for this.

However, this option is not yet the most difficult, since the composition has not yet had time to dry. If the glue has already dried, you will have to wash it off with special substances that are available in stores.

Video:

However, not everyone has strong solvents on hand. For such cases, the use of a conventional scraper is indicated. You just need to work with it very carefully so as not to spoil anything.

You can try to heat the frozen glue. In this case, the mass will become liquid and viscous, it can be easily washed off, you just have to heat it up to 60 degrees.

Many people still have the question of how to properly use a nail gun. This is also quite simple - you need to press the metal tongue of the gun, then pull the piston in your direction, which will make room for the adhesive solution.

After fixing the cylinder, you need to press the piston back, and then you can squeeze out the nails by pumping the trigger.

Some people don't know how to open a tube of solution. This question is often asked by beginners, but in fact there is nothing complicated here.

Video:

The tube is either sealed - then you need to open it with a knife, or you just need to pierce it from the top if the container is tin. It is best to pierce with a nail, because there is a protective film inside.

Factors that determine the rate of hardening

The curing time of the adhesive composition is influenced by several factors. And this is despite the fact that the manufacturer on the packaging with the material indicates a certain curing time for the glue. But all this data is relative. The packaging indicates under what conditions the glue will dry completely.

For example, this could be at temperatures between 20°C and 24°C. In this case, air humidity should be within 60%. At home, it is not always possible to achieve such ratios. For this reason, a cured 24 hours is not enough for the mounting adhesive to completely dry.

It is especially necessary to wait until the tile adhesive on the floor has completely hardened. Floor tiles are subject to high mechanical loads. Therefore, the answer to the question of when you can walk on floor tiles depends on the conditions under which they were installed.

There will be several determining factors:

- Temperature regime. Tile adhesive dries much faster at high temperatures. However, this does not mean that the temperature should be raised artificially. The entire drying time of the tile adhesive should be in the most natural conditions possible.

- Season . How long the glue takes to dry also depends on the time of year. In summer, the curing time of the glue is significantly shorter. In winter, this period increases, since there is a risk of freezing, which will negatively affect the quality of setting. So, on average, floor tiles with adhesive will harden in the summer in up to 36 hours, and in the winter in about 48 hours. Only after this is it allowed to walk on its surface.

- Floor temperature. It is not recommended to lay tiles on frozen floors. If you have underfloor heating, you can turn on the heated floor to warm the entire area of the room. However, laying tiles on a heated floor that is turned on is prohibited. Because the glue will dry out quickly and will not hold the facing material. There is a temperature gap at which the tiles can be installed. The minimum temperature is considered to be +5°C, and the optimal temperature is +20°C. The lower the temperature of the floor, the longer it will take for the glued tiles to dry.

- Humidity. This is another important aspect that determines how long the tile adhesive takes to dry. Drying time is associated with high humidity. For example, if there is high humidity in the room, then the adhesive composition will gain all its strength only after at least 7 days.

As you can see, the question of when you can walk on the tiles after laying them is relative. The answer is influenced by several factors: humidity, substrate temperature, time of year and temperature conditions.

Types and purposes of the composition

Liquid nails are divided into several types, depending on the polymer composition. A mixture labeled “Instant Contract” is considered universal. This glue can be used for almost any task. It firmly bonds parts made of metal, ceramics, plastic, wood, and PVC panels in five minutes. To perform specialized work, there are the following varieties:

- “Express decor” - used for joining wood, plastic and PVC. Most often used for fastening cornices and baguettes;

- Liquid nails “For mirrors” are indispensable for fixing mirror panels and mirror tiles on any surfaces (some types of glue can damage amalgam, so it is important to attach mirrors using a specialized compound);

- “Super strong” - used for fastening wall panels made of plastic and PVC (may have differences in transparency and are intended for outdoor use);

- “Express” and “Very Strong” - used for external work on facing stone and any types of ceramic tiles.

It is convenient, for example, to attach bamboo wallpaper to this adhesive mixture, and there is no need to clean and prepare the surface in any special way. It is only necessary to remove the chalk or loose plaster.

It is convenient to attach tiles using liquid nails, and this installation option is considered more durable than traditional tile adhesive. The only negative is that liquid nails are more expensive and their use is only justified for repairing and replacing ceramic tiles.

To attach PVC panels, you need to choose a transparent glue that will not leave marks when dry.

Instructions for use

The following instructions for use are suitable for most mixtures (suitable for external and internal use):

- The surfaces to be bonded are cleaned and degreased. Porous materials are treated with a primer composition. PVC and plastic must first be brought into the room and the parts must be allowed to “get used” to the temperature.

- An adhesive composition is applied to one surface of PVC panels or tiles in a dotted manner or in thin lines.

- The parts are connected and pressed tightly against each other for two to three minutes.

- The glued surfaces are left until the liquid nails dry completely (24 hours).

For some types of liquid nails, the following instructions are more suitable:

- After preparing the surfaces as in the first case, glue is applied to them.

- The parts are connected for one minute and then removed.

- The glue dries for seven to eight minutes. During this time it will thicken.

- The surfaces are again connected and pressed tightly against each other.

- The parts are left for a day until the liquid nails are completely formed.

Before using the composition for external or internal work, it is important to study which of the two described methods is recommended in the attached instructions.

We take into account the conditions - humidity and temperature

To the question of how quickly tile adhesive dries, the answer is not at all simple. There are a lot of factors to consider! There are two main ones: indoor air humidity and temperature. Manufacturers, as a rule, indicate the curing time of the glue, calculated at +20°C and air humidity not higher than 60%, and any decrease in temperature or increase in humidity automatically extends the curing time. Therefore, a true master will never give an exact answer to the question of how long it takes for glue to dry without seeing the room and without knowing the conditions.

How to remove liquid nails

As practice shows, it is very difficult to remove this durable composition. There are several ways to remove liquid nails.

Fresh composition

An accidental drop of the compound that gets past PVC panels or tiles during work is removed with a clean, dry rag or the blunt tip of a knife. Afterwards the surface is wiped clean.

Hardening composition

The set adhesive is gradually removed from the tile with a scraper. To facilitate the process, the surface of the panels is moistened with water or acetone.

Dried composition

If liquid nails have been applied a long time ago and are completely dry, special substances must be used to remove them. First you need to study the composition of the glue and select the appropriate solvent. Next, the surface is treated in accordance with the instructions for using the solvent.