TOP 10 best sealants for car seams

The main function of seam sealant for a car is to protect the surface of the weld from contact with the external environment. This makes the seam stronger and also minimizes the risk of corrosion (rust forms when metal comes into contact with water or air particles). Sealant in a car can be used to seal cracks, scratches, and small holes.

Sealants differ in composition, method of application, and technical characteristics. The most popular in the Russian Federation are compositions. Novol Gravit 630, Reoflex Brush Sealant, Body 999, Merbenit XS55 and others. Let's look at the TOP 10 best sealants and look at their pros and cons.

Novol Gravit 630

Polyurethane based sealant. Available in tubes for automatic pistols. Seals large and small holes well and does not crack due to deformation or vibration in the car. Before application, it is recommended to clean, degrease and coat the surface with a layer of primer. After application, the composition dries within 20-30 hours .

The average cost is 350 rubles per 300 ml tube.

Advantages:

- Good technical properties;

- Ease of use;

- Low price;

- Wide availability;

Flaws:

- Takes a long time to dry;

- Preliminary surface preparation is required.

Reoflex Brush Sealant

Another good polyurethane-based mixture. Sold in cans for brush application. Protects the weld area from debris, corrosion, and chemically active environments. Tolerates short-term temperature changes, vibration and mechanical deformation. Before application, the surface should be cleaned and degreased; application of a primer is also recommended. Hardens within 20-30 hours .

Price – 600 rubles per 800 ml jar.

Advantages:

- Good adhesion to the surface when applied.

- Good technical properties.

- Reasonable price, large volume.

Minuses:

- Takes a long time to dry;

- Before application, the surface must be cleaned and primed.

Body 999

The composition is made on the basis of rubber and synthetic resins. Sold in large banks. Suitable for protecting automotive seams, as well as for gluing damaged parts, sealing cracks and holes. Easily withstands mechanical shocks, temperature changes, and exposure to non-aggressive chemicals. It does not tolerate exposure to direct sunlight, so it should be used in closed areas of the body and spare parts.

Price – 500 rubles per 1 liter jar.

Pros:

- Good technical performance.

- Can be used for gluing damaged body parts.

- Low price, easy application.

A major drawback is that it can only be applied to closed surfaces.

Merbenit XS55

Made on a silane-modified base, sold in small tubes. Easy to apply to the work surface and dries quickly. Easily withstands exposure to ultraviolet radiation, chemicals, mechanical shock, and vibration. Retains strength in severe frosts and heat. The average cost is 850 rubles per 300 ml tube.

Pros:

- Excellent adhesion to the surface;

- Easily copes with temperature changes;

- Hardens quickly after application.

The disadvantage is the very high price.

APP PU-50

A cheap polyurethane composition produced in cartridges for spraying using guns. It has average technical characteristics. But it is resistant to vibration and mechanical shock, and withstands the effects of chemically active substances well.

Price – 250 rubles per 300 ml tube.

Pros:

- Low price;

- Ease of use;

- Not a bad level of protection.

Minuses:

- Cracks in severe frosts;

- It hardens for a long time.

ZM 08537

Universal type silicone sealant. It can be used not only for sealing seams, but also for gluing damaged fragments, sealing cracks and holes. Hardens in 15-20 hours, easy to paint and varnish. Available in the form of a sticky liquid poured into jars.

Cost – 2000 rubles per 1 liter jar.

Pros:

- Good technical performance;

- Dries quickly;

- Can be painted, varnished;

Cons: high price.

Teroson Terostat 9320

Another polyurethane sealant designed to be sprayed with a gun. Contains additives that accelerate drying of the composition (approximate hardening time is 12-18 hours). Resistant to ultraviolet radiation, chemically active substances, corrosion, and strong vibrations. Recommended for use on primed surfaces.

Price – from 1000 rubles per 300 ml tube.

Advantages:

- Good technical characteristics;

- Convenient use (gun).;

- Accessibility, online availability.

Disadvantages - high price, there are fakes.

Boll

A polyurethane mixture containing a number of useful additives is available in the form of tubes for spraying with a gun. It dries quickly, adheres to any surface, and can be used to seal weld seams, eliminate small cuts and cracks. Retains technical properties in frost. It is advisable to varnish before application.

Price – 700 rubles per 300 ml tube.

Advantages:

- Good adhesion to the surface;

- Hardens quickly;

- Convenient use.

Minuses:

- Rarely sold in stores;

- High price.

Crocodile

Inexpensive but high-quality polyurethane-based sealant. Available in the form of tubes for automatic pistols. It is distinguished by high levels of strength, adhesion, and reliability. It withstands precipitation, vibration, and thermal effects well. It is recommended to apply over a layer of primer.

Price – 300 rubles per 300 ml tube.

Advantages:

- Low cost;

- Good technical performance;

- Fast hardening;

Minuses:

- May crack in severe frosts;

- There are many fakes on sale;

APP Butyltape

It is a tape, on one side of which an adhesive sealing composition based on rubber with additives is applied. The tape is usually used to repair minor scratches and imperfections on the body. Can be used for sealing seams. This minimizes the risk of corrosion and protects against ultraviolet radiation and chemically active substances.

Price – 2000 rubles (width 20 mm, length 26 m).

Pros:

- Convenient use;

- Very fast hardening;

- Good technical properties.

Disadvantage : high price, not suitable for sealing large welds.

Body 999 sealant

Body 999 sealant is very popular and can be found in almost every painting store.

Bodysuit 999 is available in almost all of the above options. This is a 150 ml tube, 300 ml cartridge. and a 1 liter jar. Consists of a rubber base and various resins. Used to seal metal and protect it from environmental influences. Retains its elasticity for a long time. Virtually no shrinkage. Even with a very thick layer it does not crack and has excellent adhesion to the surface.

Surfaces to be applied:

- Steel

- Old paintwork

The product is ready for application and does not require additional dilution. After drying, it can be painted with any type of enamel. Apply exclusively to the internal parts of the car.

Types of joint sealants by composition

Joint sealants are made on the basis of various components - acrylic, bitumen, silicone, polyurethane mixtures. A special position is occupied by anaerobic compounds, which are very different from other sealants in composition and physical properties. Below each category a brief description will be given.

Acrylic

The composition is made on the basis of thick liquid polymethyl methacrylate. Acrylic sealant easily adheres to the metal surface, has high strength, but has mediocre elasticity. Therefore, in the case of high loads or strong vibrations, the stuck mixture may peel or delaminate. Therefore, acrylic should only be used to seal seams in stable areas of the vehicle. Acrylic has good contact with paint or paint, so it can be painted or varnished.

Pros:

- Ease of use;

- Good adhesion, strength;

- Friendly with brief and varnish;

- Low cost.

Minuses:

- May peel off under heavy loads.

Bituminous

The sealant is made on the basis of bitumen and is a thick sticky paste of black or dark gray color. Bitumen compositions have good adhesion, strength, elasticity, and do not come into contact with chemically active substances. Before application, the surface must be cleaned of debris and dust (otherwise, tightness is not guaranteed). Can be applied to any smooth surface.

Pros:

- Good technical performance;

- Effectively protects against moisture and chemicals;

- Easy to apply, dries quickly;

Minuses:

- Before use, clean the surface;

- Does not lend itself well to painting or varnishing.

Silicone

They are made on a silicone basis, and the consistency resembles a thick paste. When applied, it quickly hardens, creating a durable protective layer of silicone on the surface of the seam. Can be applied at sub-zero temperatures. Easy to paint and varnish. Good adhesion, strength, durability. The main disadvantage is that they are poorly suited for sealing small grooves (due to the large size of the fractions).

Pros:

- Good technical properties;

- Low price, sold in any stores and online;

- Can be used in cold weather;

Minuses:

- Not suitable for sealing small seams and surface defects.

Anaerobic

Made on the basis of acrylic monomers and oligomers with the addition of additive components. Made in the form of a liquid that hardens when applied. Recommended for filling small seams, cracks and grooves. When applied to large areas, anaerobic sealants do not harden. They have very high strength, but mediocre elasticity (they can crack under strong shaking).

Pros:

- They perform well when working with small seams;

- High strength, good protective properties.

Minuses:

- Not suitable for working with large areas;

- May crack under strong vibrations.

Polyurethane body sealants

They are made on the basis of polyurethane components, which quickly harden when the substance is applied to the surface of the seam. They are characterized by high strength, elasticity, and durability. Under heavy loads, they retain their shape, do not crack or peel off . Withstands high and low temperatures (can be applied in frost or extreme heat). Before application, the surface must be coated with a primer to improve adhesion.

Pros:

- Wide temperature range;

- Retains shape during vibration and shock.

Minuses:

- Apply only to primed surfaces.

Varieties by purpose

Each sealant is a unique product with certain properties and characteristics. Suture compounds differ in components, consistency, service life and area of use.

In a car, substances are used for various components and parts:

Pasting car windows. There are low-, medium- and high-modulus compositions. The glass gluing time is 30 minutes, the fit in the body is much stronger than when using sealing gaskets. Recommended application temperature is +20 degrees.

Gluing and restoration of headlights. Cracks in the driver's visibility instruments reduce the view of the road. Therefore, you can use silicone adhesive to carefully connect the optical fragments. The main advantages are elasticity and strength.

Body repair. It is necessary to use seam sealants, with the help of which it is easy to seal seams, joints, and gaps on welded elements. This helps restore the integrity and appearance of the factory structure. Tapes, pastes, and silicones are used for work.

Radiators. To eliminate leaks in the cooling system, special polymer-based products are used, which in a few minutes “tighten” the resulting holes with a diameter of up to 0.5 mm. The composition must be frost-resistant, moisture-proof and permanently sealed.

Special mention should be made of products for emergency vulcanization of tires. In case of a tire puncture, the driver will have time to get to the nearest tire shop to make a full repair. Machine engines (cylinder heads, pumps, crankcases) use heat-resistant substances with a wide range of operating temperatures.

What types of car seam sealants are there based on application method?

Seam sealant for cars is applied in three ways - with a brush, tape, using a tube (manually or with a gun). Each method has its own characteristics, and some categories of sealants have restrictions on the method of application. Each method will be briefly discussed below.

Brush

Such sealants are produced in the form of a thick liquid, and they are sold in metal or plastic containers with a lid of 200, 500 or 1000 milliliters. To use the composition, you need to carefully remove the lid, dip the brush in the liquid and apply it to the welding seam. It is recommended to carry out application work with gloves. The drying time for such compositions is up to 12 hours or more.

Any small width brush with a plastic or wooden handle can serve as a brush. Upon completion of application, the jar should be closed with a lid and placed in a cool, dry place for storage. Canned sealants for brush application typically have a shelf life of 1 year from the date of opening, but no more than 3 years from the date of manufacture . There are also more durable formulations - see the exact date of manufacture on the packaging.

Advantages of the method:

- Sold in containers of different sizes;

- Easy to apply to the weld;

- Can be stored for a long time;

- Convenient for workshops.

Flaws:

- Apply for a long time to the seam surface;

- The method is not suitable for applying paste.

Attention! If the date of manufacture is not indicated on the jar or it is covered up, then there is a high risk that the shelf life of the composition has expired. Or you bought a counterfeit.

Ribbon

It looks like a long tape, on one side of which a sealing compound is applied. To apply it, it is glued on top of the seam along the entire length, and after 1-2 hours it completely hardens and sets. The working surface is usually impregnated with bitumen sealant, although acrylic and silicone-based tapes are also available. There are also double-sided tapes, where an adhesive composition is applied to the second side (in practice, the need for double-sided tape is rarely necessary).

Most tapes are small in width (up to several centimeters). Therefore, this method is not suitable for sealing wide seams, as well as when working with seams of complex shape (roundings, bends). If you are dealing with a non-standard and/or wide seam, it is better to apply it with a brush or an air gun. Benefits of using tape:

- Very convenient application;

- Fast hardening;

- Low price;

- Easy to transport.

Minuses:

- A small variety of sealing compounds;

- Not suitable for sealing complex or wide joints.

Sealants for cars in tubes (squeezable)

Extruded sealants come in two categories:

- Tube containers. These tubes are compact in size. To use, you need to manually dispense the paste from the tube onto the working tool and apply it to the work surface. Paste-like sealants (acrylic, silicone, bitumen) are usually sold in tubes. Tubes are well suited for sealing small seams, while processing large seams with them is inconvenient and time-consuming. The main advantages are low cost, ease of use, large selection. Disadvantages - not suitable for working with large areas, limited shelf life after opening.

- Containers for a pistol. Such containers are made in the form of a narrow cylinder with a long spout at the end. For use, the container is inserted into a mechanical or pneumatic gun. Now the sealant can be applied using a gun to the seam (the gun itself will squeeze out the compound). Using the gun is very convenient, and with its help you can quickly and conveniently process any area. The main advantages are very convenient use, good selection, large capacity. No significant deficiencies were found.

How to remove old sealant

If you applied a sealing compound and it cracked, you need to select another sealant and reapply it. Before resealing, it is necessary to remove the old compound from the surface of the car. Usually old sealant is very fragile, and to remove it you just need to pry it with your finger or any other tool. If part of the old composition cannot be removed manually, you can try the following methods:

- Warm up with a hairdryer. Many powdered sealants become soft when heated, and can be removed using a handy tool. The heating time of the hairdryer depends on the power of the device and the composition of the sealant. Usually 3-5 minutes are enough to heat up.

- Use white spirit. This liquid is a universal solvent. FOR application, soak cotton wool with a small portion of white spirit, and treat the surface of the old sealant with the cotton wool. Repeat the operation 2-3 times, wait a few minutes, remove the remnants of the old composition manually or using tools.

- Use acetone. White spirit is a good solvent, but some categories of sealants do not respond well to it. If this is the case, then you should treat the old composition with acetone. It is applied in the standard way - saturate the cotton wool, wipe the surface, repeat the procedure, wait 3-5 minutes.

Attention! If, when applying new sealant, some of it gets into the wrong place, then immediately remove it with a rag or cotton wool. The sealing compound does not harden immediately, so there is no need to use a hair dryer, white spirit or acetone.

How to choose sealant for car seams

- If you can’t decide on a choice, buy polyurethane sealant in a tube for filling into a gun . Such sealants have a well-balanced composition, do not deteriorate during storage, and are easy to apply to the surface. In addition, they are often found on sale, so there should be no problems with purchasing.

- Acrylic compounds have a low price , but it is recommended to use them only for sealing small seams. In all technical indicators, acrylic is inferior to bitumen, silicone and polyurethane, and such mixtures are not much more expensive. In addition, acrylic often cracks during use, so you will have to constantly patch the seams.

- There is no need to be afraid of automatic pistols. Many novice mechanics prefer to take liquid sealant or mixtures in tubes, because they are afraid of pistol spraying. But this is the wrong approach: it is very easy to handle the gun - just do a couple of test sprays.

How to apply sealant

The method of applying the sealant depends on its composition, consistency and release form. In practice, a silicone compound is used to seal seams, and it is sprayed using a gun. Let's consider a brief application algorithm for this case:

- The surface to be treated is cleaned of debris and dust. If necessary, degreasing and drying is performed. At the end, a layer of primer is applied, and the master should wait for it to dry completely.

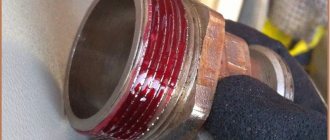

- The tube is inserted into the gun and the quality of the connection is checked. After this, a thin layer of the composition is sprayed in the desired area. Its excess is removed using gauze or cotton wool.

- Most sealing mixtures harden within 24 hours. After this time, painting or varnishing can be done.

How long does it take for car sealant to dry?

After quality work has been done, you need to wait until the preparation has completely dried and continue with the planned activities. If you do not know the exact drying time and the manufacturer does not indicate this information on the product packaging, keep the figure 24 hours in mind. This is the time during which any type of sealant will dry at an air temperature of +5 degrees Celsius.

Silicone. Initial polymerization (appearance of a film on the seam) occurs within 10 minutes. Complete drying should be expected within a day, and during this time it is better not to touch the material. As you know, silicone sealant can be neutral or acidic. Acid dries within 6-8 hours. Neutral dries for 24 hours at air temperatures from +5 to 45 degrees.