Glued laminated timber is a special building material whose pleasant appearance and high performance indicators make it possible not to carry out any finishing work. But some people still want to give such a building more individuality. In this case, painting the laminated veneer lumber would be an ideal option. In addition to changing the color of the walls and improving the appearance, the compositions used for painting significantly extend the life of the building.

This method is the simplest and quite cheap, but it allows you to protect the wood from the negative effects of temperature, sunlight, moisture and wind. In this article we will talk about how to properly paint a house made of laminated veneer lumber, when is the best time to carry out painting work, what paint to choose for these purposes, and we will try to analyze the technology of painting this material itself.

Return to content

Internal painting

Painting of the internal surfaces of houses made of laminated veneer lumber is carried out more often to create an exclusive design, and not to protect the material from premature wear. Walls made from this material are perfectly smooth and therefore do not require additional finishing work before painting. In order to successfully emphasize the charm and elegance of natural wood, you should use:

Varnish on a laminated timber wall

Wax, oils or drying oil . These materials will not be able to extend the life of the tree or protect it from moisture, but they can be used to improve the appearance of the building. As for the cost of these consumables, it is very affordable, and you can purchase them at almost any hardware or construction store.

Varnishes . These compounds are made on aqueous or synthetic bases. If a room whose walls have been painted needs to be quickly ventilated, then it is better to purchase a water-based varnish; if you are willing to wait a few days, it is better to use synthetic compositions, since such a coating will last longer.

With mastics . These materials are made on a wax base. And therefore completely environmentally friendly. Mastic can give laminated timber walls a velvety feel and also emphasize the natural texture of the wood. This material can also be used to mask small defects, such as cracks.

Return to content

Products for covering a house made of laminated timber

House made of laminated veneer lumber, painted with glazing compounds

There is no point in delaying painting a house made of laminated veneer lumber. You need to paint it right away, and it’s better to soak it with antiseptics for the first time before assembling. Various compositions of domestic and imported production are sold for coating.

But not all of them have the appropriate quality; experts recommend using Osmo, Sikkens (AkzoNobel), Tikkurilla products. If painting is done correctly, it will need to be repainted no earlier than after 4-5 years.

The qualitative characteristics of some of them can be seen in the table:

| Manufacturers | pros | Minuses | price, rub. |

| Sikkens (AkzoNobel) (German manufacturer) | They produce a water-based coating, do not fade in direct sunlight, excellent adhesion, many color options, low cost. | You need to constantly monitor it, because after 5-6 years it begins to peel off. | From 120 l. |

| Osmo (German manufacturer) | There are both water-based and oil-based coatings that do not fade over time, protect the wood from destruction, and are easy to clean. | The price is high | From 320 l. |

| Tikkurila (Finnish production) | An assortment of more than 35 colors, there are formulations based on natural oils and water, does not fade in the sun, and a reasonable price. | It will have to be repainted after 3-4 years. | From 150 l. |

| Marshal (Russia, Moscow) | Low cost, does not fade under the sun, a wide range of paint and varnish coatings. | Not durable, repainting will have to be done every 2-3 years, slight coloring. | From 100 l. |

| Finncolor (Russia, subsidiary of Tikkurila) | The assortment of flowers is more than 35, many different varieties, including water and natural oil, low cost. | You will have to update it every 3-4 years. | From 120 l. |

When choosing a coating composition after completing the construction of a house made of laminated veneer lumber, you need to focus on a number of factors:

- External or internal coating. (There are universal products that are used both outdoors and in the house, but it is better to use separate ones, since the main function of the internal one is decorative, and the external one is protective).

- The appearance of the walls (whether the owner wants to preserve the natural pattern and texture or not).

- What effect do you want to get (protection, or to emphasize beauty, or both at once).

For laminated veneer lumber, two types of coatings are used: film-forming and impregnating.

Impregnating compositions

Impregnation of a house made of laminated veneer lumber

Impregnating antiseptics can be divided according to their composition:

- Water based

- Organic based.

Impregnations - water-based antiseptics do not have a strong odor and easily penetrate the wood. The timber after such coating will not lose its quality characteristics. Water-based impregnations are used mainly indoors.

Organic-based impregnations contain various impurities that help prevent the development of mold and mildew. But they may have a specific smell, so these are mainly for external work.

Coating film compositions

These can be divided into transparent and matte. Transparent ones include glazes, which do not hide the wood, but only emphasize its texture and pattern. When coating, the shade may change slightly, but this depends on the number of layers applied, the species and the natural color.

Matte ones will hide the appearance of the wood and give the house the chosen color. These are rarely used for laminated veneer lumber, since the material itself has a noble and beautiful surface.

External painting

This procedure is carried out both to achieve maximum visual effect and to create protection for the tree from the negative influence of the external environment, such as drying in the sun, weathering or high humidity. This protective barrier can be represented by transparent or matte materials. The first type of materials is called glazing, and the second is called covering.

The above coatings can be applied independently using a variety of tools and a variety of methods. In most cases, a brush, roller, spray bottle or spray can is used.

External painting work

The modern construction market offers the buyer a huge amount of paint and varnish materials, both domestic and foreign. In such abundance, it is very easy to get confused and end up purchasing something that is not at all suitable for you. Therefore, before directly purchasing paint for laminated veneer lumber, you should find out what tasks you need it for.

Paints perform two main functions:

- protection of the material from the influence of environmental factors;

- decorative function.

Return to content

Processing results

- Long-lasting barrier against pests, insects, fungus. The sealant protects the end, the antiseptic impregnates the outer part, and the paint prevents the protection from being washed away.

- Ultraviolet light does not cause wood to darken. The house retains its “fresh” color. If the color is chosen correctly, then there is no resin release or burnout on the surface.

- Moisture protection. The film covers the entire wall, even after a serious rainfall the walls do not get wet.

- The house corresponds to the design project. The cottage is beautiful inside and out.

Wood protection

Really high-quality laminated veneer lumber can last for decades, but it still remains wood, which is susceptible to the influence of many environmental factors, and therefore requires protective measures. The service life of this material can be significantly reduced by:

Houses made of laminated veneer lumber are a real breakthrough in construction. By following the link https://vse-postroim-sami.ru/materials/lumber/6163_klej-dlya-kleenogo-brusa-naskolko-ekologichny-doma-iz-kleenogo-brusa/, you will learn about glue for laminated veneer lumber. This article contains information about the new protective paint.

Water . It gets into the pores of the wood, causing it to swell, crack, or rot inside. To protect against moisture, a sealant is usually used, which is used to impregnate the ends of the laminated veneer lumber. This consumable clogs the wood pores, preventing liquid from entering them.

Fungi or mold . Wood is a favorite breeding ground for various types of mold and fungi, which subsequently significantly reduce its service life. To prevent this problem, apply a layer of antiseptic primer.

Sun rays . Ultraviolet rays have a detrimental effect on any wood, and laminated veneer lumber is no exception. The fact is that this material contains lignin, which darkens under the influence of ultraviolet forms. Special sunscreen compounds will help cope with this problem.

Applying paint to laminated timber

Return to content

Varieties of painting compositions for exterior use

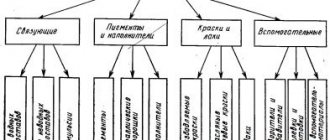

All materials for surface treatment can be divided into two main classes: impregnations and paints.

Impregnations

Impregnations are compounds that, when applied, penetrate deep enough into the wood. Their use allows you to solve several problems at once:

- Preparation for painting wood in a given color tone.

- Impregnation partially fills wood pores, cracks and surface unevenness. This will reduce the consumption of paint or varnish during their subsequent application, which saves money.

- Some types of paints have poor adhesion to wood. Preliminary application of impregnation strengthens the bond of paint with the surface being treated.

- Protection from insects, pests, mold and fungi.

Impregnation with an antiseptic will prevent the formation of mold and fungi Source build.4-u.info

- Giving wood fire-resistant properties.

- Reducing the harmful effects of the ultraviolet component of sunlight.

Each specific brand of impregnation has a set of necessary qualities. Therefore, it is necessary to discuss with the work performers the required parameters of the composition used and the expected amount of costs.

Paints and varnishes for exterior use

The main characteristics of paint and varnish coatings are type, color, service life. The service life of the paint is determined by its resistance to moisture, sunlight, and temperature changes.

If the wall surface looks good and has no roughness or defects, then it is best to use transparent or translucent varnishes or paints.

Such compositions include:

- Varnishes and paints based on polymer polyurethane. They have good resistance to external factors. Their high cost is explained by the durability and high strength of the coating.

- Water based paints. They are quite cheap, absorb and dry quickly. Unfortunately, without additional protection from water with a waterproofing layer, such paints quickly become stained, streaked, and sometimes simply washed away from the wall surface. It is preferable to use them for treating interior walls.

See also: Catalog of timber house projects presented at the Low-Rise Country exhibition.

A variety of shades of paints and varnishes allows you to choose a composition to suit every taste Source build.4-u.info

Old, and sometimes new walls, have defects, stains, cracks. Making such a surface uniform in texture is difficult and expensive. In this situation, it is necessary to use opaque paints. In this case, you will be faced with the question: what color to paint the pulp from the timber - the choice of colors and textures is very large.

- Oil paints. Due to their low cost and availability, they are still popular. The main disadvantage is that after 2–3 years such paint cracks and fades. Walls that have lost their attractiveness will have to be repainted.

- Alkyd-based compositions are less susceptible to fading. Alkyd paints are available in a wide range of colors. The main problem is low weather resistance.

- Acrylic paint coatings will last longer than alkyd or oil paints. Manufacturers offer a large number of colors and shades of this type of paint. Acrylic paint for external beams has a higher price, but this is more than compensated by the greater strength and durability of the coating.

A separate type of materials for processing are sealants and paint for the ends of the timber. It is not advisable to replace them with other compounds.

Home decoration

Buildings made from laminated veneer lumber have an attractive appearance, but over the years they lose their former beauty. This occurs due to the harmful influence of environmental factors. In this case, an excellent solution would be to paint the outside of the laminated veneer lumber using decorative compounds. Really high-quality and professionally executed painting consists of several processes:

- impregnation;

- padding;

- correction of defects;

- application of coating (varnish, tinting or enamel).

The color of this coating should be chosen based on the design of the building.

Contrasting tinting will highlight the natural beauty of the wood and highlight its relief pattern. Paints and varnishes can strip away wood and add richness to walls. When it comes to choosing a color, no one can advise you; here you have to use your imagination and make it to your taste. The main thing is that the material you select meets the following requirements:

- environmental friendliness and safety (this point is especially important for families with small children);

- ease of application;

- should not interfere with the movement of air masses;

- long service life;

- long lasting color;

- reasonable price.

Next, we will present several of the most common paints and varnishes from various manufacturers that can be used to paint buildings made of laminated veneer lumber, and we will tell you about all their advantages and disadvantages.

Painting laminated timber

Return to content

Technologies for processing a wooden house made of timber after construction

Antiseptic . Necessary to prevent the formation of fungus, mold, and insect damage. For antiseptic use, special impregnations are used that penetrate the wood and destroy pests.

It is especially important to use an antiseptic if the construction is carried out from ordinary timber or logs - beetles and microorganisms often grow in heartwood. Logs are often completely immersed in antiseptic baths directly on the construction site and further treated after construction.

Glued laminated timber is not so susceptible to rotting - the manufacturing technology includes several mandatory stages of testing and chamber drying. Glued laminated timber is treated with an antiseptic on the outside - this is enough.

Painting . This is the final stage of processing a wooden wall - the composition with colorant is applied to the wood in 2-3 layers, creating protection from ultraviolet radiation and moisture. When painting, the wood texture is preserved (glaze coating) or completely hidden (covering).

The paint is applied in 2 or 3 layers with preliminary and intermediate sanding. Painting technology depends on the manufacturer's recommendations.

Complex processing . To speed up and reduce the cost of processing, universal compositions are used: paint that contains an antiseptic. This approach speeds up construction and makes processing cheaper.

Common paints

German company Zobel . The coatings of this brand are made on the basis of water, and therefore are environmentally friendly. It is easy to apply on a wooden base; this material retains its color for quite a long time. Paint and varnish materials are presented in a large assortment. The price is in the average range. The only drawback is the need to renew the coating every 5 years.

German company Osmo . The material is oil-based, so it is not harmful to human health. Perfectly emphasizes the structure of wood and is very easy to apply. It retains its original shade for quite a long time and does not require frequent updating. Can be used for external and internal work. The most important disadvantage is the unreasonably high price.

Finnish company Tikkurila . Paints are presented in a wide range. Among the advantages is a relatively low price, color fastness and a pleasant color scheme; among the disadvantages is the need for regular updating - approximately every five years.

Domestic paints Thermika . The coatings are resistant to temperature changes, as well as moisture and ultraviolet rays, and are ideal for exterior painting. The prices are quite affordable, but the range of paints for wooden bases is quite poor.

Domestic enterprise Finn color . Paints are presented in a huge assortment, but the cost is quite reasonable. They retain their original color for a long time, but also require regular touch-ups at least once every five years.

Return to content

How to treat a wooden house after construction

To prevent protection from spoiling the feeling of a new wooden house, you need to choose a neutral composition of paints and varnishes. GOOD WOOD uses SEDIPAN products, a water-based acrylic paint. The coating applies smoothly, dries quickly, and leaves no odor.

For exterior painting, we use the WACT 640 line as a primer - the products contain a large amount of antiseptic and colorant, which additionally protects the wall from ultraviolet radiation. For interior decoration, it is enough to use WACT 650 - a paint with a lower antiseptic content. We seal the ends with a special compound WV 024, which completely blocks the sap-conducting channels, without disrupting the moisture and air exchange of the wood.

Technology of painting laminated timber

Required Tools

Painting houses made of laminated veneer lumber is a rather complex and labor-intensive process that requires the worker, if not highly qualified, then at least to have experience in painting work. Therefore, if you do not have certain skills and experience and are not confident in your abilities, it is better to put the brush aside and seek help from specialists.

The complexity of the work depends on the type of laminated timber from which the house is built, as well as the type of coating that you are going to apply. All painting work is divided into the following stages:

Applying varnish

- Cleaning and leveling the surface of the walls. This operation is carried out using a grinding machine or grinder with a grinding wheel. The fabric should be finely dispersed. Glued laminated timber itself is a fairly smooth material, but this cleaning procedure will hide small defects and also increase adhesion, which will help in future work.

- Applying sealant to the ends of laminated timber. This operation is necessary to protect the material from the influence of rainwater or moisture. In this way, the service life of the building can be significantly increased.

- Impregnation of wood with special antiseptic compounds. This procedure is necessary to prevent the development of various types of fungi and mold.

- Applying a primer layer. A layer of special adhesive compounds is applied to the material. After completing the priming work, you need to let the wood dry. The drying time is indicated by the manufacturer on the primer packaging.

- Staining laminated veneer lumber. This operation must be carried out in several stages. As a rule, it is customary to apply three layers of paint and varnish to wooden walls. After applying the first layer, you need to wait some time (indicated on the packaging) until the material dries completely, then proceed to the second layer, and then the third. You can easily create a matte or glossy wall surface using various materials.

- After completing all painting work, you need to wait about three months, after which it is necessary to carry out sealing. First, you should check the surface of the walls for defects; if any, you should cover them with sealant or mastic. Window sills, window frames and trims also need to be covered with a sealing compound. Experts advise using only wear-resistant sealants for these purposes. This completes the painting of the walls of the laminated timber building.

It is important to know! Painting work cannot be carried out in an environment that is too humid, so it is better to choose summer time to carry it out. Also, do not forget that after three months sealing should be carried out, so it is better to paint a house made of laminated veneer lumber in late spring - early summer, if at this time it is not possible to start repair work, then know that the minimum temperature at which it is permissible to apply paint is – 5 degrees above zero.

All that remains is to operate it correctly, renew the paint layer at the required time and annually inspect the walls for defects.

By following these simple recommendations, a house made of laminated veneer lumber will not only serve you for many years, but will also become a cozy, attractive and absolutely safe place for your family.

Return to content

Painting technology

Glued laminated timber practically does not deform during shrinkage, however, painting wood requires strict adherence to technology.

The optimal time to start painting work is three months after the construction of the building. Next, the timber will begin to gradually deteriorate under the influence of environmental factors: this will negatively affect the adhesion of the paint to the wood.

The surface must be prepared for paintwork. The painting process includes the following steps:

The surfaces to be painted are cleaned, sanded, and defects are removed.

Small cracks are covered with mastic, the unevenness is sanded (with a grinder with a special attachment or a grinder). A prerequisite is that the fabric must be finely dispersed; sealing the ends of the building. The sealant is selected taking into account the type of wood and the finishing layer (clear varnish, tinting, or paint of a new color); priming the surface of the timber.

This layer is mandatory: it promotes high-quality adhesion with finishing coatings (varnish, paint). The better the primer, the more wear-resistant the surface of the timber will be; painting the house. Opaque paints and transparent varnishes are used.

The minimum number of layers is two, the optimal is three. After applying each layer, it is necessary to wait for the time indicated on the packaging of a particular product, and only then begin to apply the next one; final sealing of the building. Three months after painting, window sills, window frames, platbands, and defects on the walls of the building are covered with sealant.

The technology for applying varnishes and paints to internal and external walls is practically the same. Exterior coating requires more primer and more coats of finish.

Paints are mixed with tinting components strictly in accordance with the manufacturer's instructions in a large and clean container (the same applies to varnishes). The composition must first be tested by applying it to a section of the wall. This will allow you to see the final result of painting, reduce or increase the amount of pigment.

The paint is applied with a roller, brush or spray.

It is preferable to apply the varnish with a brush. After the preparatory work, a base layer of material is applied: it should be as thin as possible. After complete drying, coloring is continued, from two to five words inclusive.

Sealing is carried out after one and a half to three months, after the surface of the building has dried. After sealing, paint (varnish) is applied to the surface of the sealant using the same technology as painting the entire house.

High-quality materials for painting timber are the key to the durability of your home: they will protect against negative environmental factors, preserve the original appearance and color saturation, and emphasize the natural beauty of the wood.

Regardless of the quality of the material at the delivery stage, sanding houses made of laminated veneer lumber is a necessary operation before painting. It is used for processing both external and internal surfaces. This procedure is monotonous, dusty and labor-intensive, but it allows you to obtain a coating of excellent quality.

- More than 12 years of experience in painting houses 5-year warranty We use German paints You choose the color, we do the rest

All worksSee pricesHouse 190 m 2 in Orekhovo-Zuevo

Thank you for painting a private house. I was pleasantly surprised by the prompt arrival of the surveyor with samples, as well as the timely start of work. The services are high quality and the price is reasonable.

All reviews

Prices for sandingServicePriceGrinding, rub./m2from 300 rublesPrices for sanding and painting a houseZobel and Remmers paintZobel and Remmers paints are environmentally friendly and completely safe for the environment and human health, since the composition consists mainly of natural components and substances of mineral originOsmo Paints and Osmo coatings are based on natural oils and waxes. The wood remains beautiful and elastic for a long time. Sanding and painting of walls, rub./m2650-700 rub. 780-850 rub. Sanding, painting and sealing of ends, rub./m linear 500 rub. 550 rub. DifferencesWater baseProtection period 10-12 years After this time, the house requires complete cleaning of the old coating before applying paintwork to it Oil base Protection period 20-25 years Enough to refresh every 4-5 years with one thin layer of paint No need to re-sand Find out the exact cost

Often during construction, materials with natural moisture are used.

Over time, its surface ceases to be smooth. The reason for this phenomenon, as well as the shrinkage of the structure, is a decrease in humidity. Glued laminated timber is less susceptible to such processes, but its surface also changes over time.

Sanding is an effective way to eliminate the negative consequences of changes in the moisture content of the material. Processing timber timber allows you to solve several problems: Reveal the texture of the wood. After removing the top layer, the beauty of the natural pattern of the material becomes available; Achieve a smooth wall surface. The absence of irregularities and roughness is important not only from an aesthetic point of view, but also for the economical use of paint in the future; Increase the service life of the coating due to more uniform penetration of the paint coating into the wood.

As a result, reliable protection of the walls is ensured; If necessary, remove the layer of material damaged by the fungus. Technique for processing a timber house When ordering sanding of a timber house, it should be taken into account that such work must be carried out before installing doors and windows. This is due to the fact that the procedure is quite dusty. The dry surface of the material is processed, including the ends.

To do this, use a grinding machine with a set of sandpaper of various grain sizes. It is selected depending on the condition of the wall surface. At the initial stage, a grain size of 40-60 is used, and at the final stage - 90-120.

To reduce the amount of dust, some machine models are equipped with a connection to a vacuum cleaner. Additionally, grinders can be used. The price for sanding a house made of timber in Moscow depends on several parameters: The need to use scaffolding; Surface area; Initial condition of walls; Required result. The number of passes and the time spent depend on it. After finishing the work, the polished timber inside the house looks smooth and presentable.

Subsequently, it can be coated with oil, wax, varnish or mastic. The outside of the timber house is protected with antiseptic and paint. It should be remembered that over time the wood hardens and the described procedure will require more time, effort and financial costs.

The technology for producing laminated veneer lumber became known only about half a century ago, so information about its durability can only be purely theoretical for now.

Based on the fact that a structure made of wood glued under pressure exceeds concrete and brick in strength, this long-term period should be more than ten years. Natural wood is used in the production of the material, so painting a house made of laminated veneer lumber is not only an aesthetic technique. This is also a means to protect the walls from the troubles that natural raw materials can be exposed to under the influence of time and atmospheric influences.

By painting laminated veneer lumber, you can be sure that you have protected the surface of the wood and made it beautiful.