Characteristics of oil paint

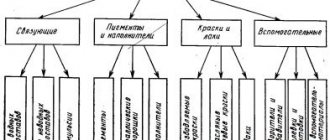

The basis consists of two components:

- The pigment that determines the color of the product is a filler, the number of which reaches 2 thousand. Pigments are divided into:

- organic (derived from animal and plant components) and artificial origin, rarely used;

- mineral: natural (ochre, umber, mountain cinnabar, ultramarine) and artificial (cadmium, cinnabar, manganese, whitewash and others obtained from metals)

Some pigments require large production costs, while those that are commonly found have low costs.

- A binder is used to hold the pigment particles in place as they are applied to the canvas. For many centuries, linseed oil has been the main oil, but now others are being added. All oils used are divided into: drying oils - linseed, poppy, nut, hemp; semi-drying - sunflower, cotton, maize, rapeseed; non-drying - olive, almond, palm, castor, pistachio.

In addition to oils, a wax solution is used as a binder (added for fluidity), natural resins (for brightness), as well as some additives that can increase durability.

The entire range of oil paints is divided into categories intended for different purposes and degrees of professionalism.

Professional

Used by professionals for painting or conducting a master class. For their production, high-quality binders, highly light-fast pigments and a minimal amount of fillers are used. Paints have an accelerated drying time.

Semi-professional

It is based on high quality binders, but analogues are used instead of expensive pigments. The paints have ideal light fastness and good concentration.

First level

Produced on the basis of synthetic, cheap binders with fillers. This affects the quality of the pigment concentration.

How to identify low-quality paint

There are several points to pay attention to when choosing:

- High fluidity or, conversely, pasty;

- Separation of the pigment from the binder when the oil first flows out of the tube;

- Presence of foreign impurities in the recipe;

- The strokes form stripes and an uneven layer;

- It spreads when it dries.

Explanation of icons

Tubes of paint have special markings in the form of stars or plus signs (on foreign copies).

+ or * - low light resistance; in the sun, such compositions fade within a year. Useful for writing sketches, but not for paintings.

++ or ** - average light fastness, paintings will “live” for 25 years. For beginners, this is a good choice.

+++ or *** - an excellent option for painting. The brightness of the flowers lasts up to 100 years.

The squares indicate the degree of hiding power or the degree of paint coverage:

- white – transparent, used for glazing;

- black and white – translucent; when mixed, pure shades are obtained. Interaction with transparent and solid views is possible;

- black - good hiding power, another name for paint is body paint. Ideally covers the canvas, used for thickness and texture. It is impossible to achieve transparency with any thinner.

Club Young Chemist

Is it possible to make your own oil paints?

Technically this is possible. The economic feasibility of the experiment is questionable: some of the reagents will have to be found, and their cost is not so low; In addition, the quality of the dye at the output will be noticeably inferior to industrial products. However... Leonardo and Galileo were also driven only by curiosity, weren’t they?

Here are the simplest instructions for preparing oil paint.

Drying oil

Of course, you can just buy it. However, this idea is clearly flawed, runs counter to our plans to satisfy our curiosity in the field of chemistry and may even lead us to buying ready-made paint. (See also the article Wall decoration: options.)

Let's nip it in the bud.

- Place 50 grams of rosin (you can find it at a radio parts store) in a porcelain or metal bowl.

The main component of the dryer is rosin.

- Place the dish in the oven and allow the rosin to completely melt at 250 degrees.

- Remove the melt from the oven and, while stirring continuously, add 5 grams of CaO (quicklime, “boiling liquid”) into it.

- The resulting mixture is again placed in the oven and heated there until clear. No, no, we are not talking about the spiritual perfection of the reagent: a drop of the mixture placed on glass should become absolutely transparent as a result of the reaction. As soon as this happens, the desiccant (calcium resinate) is ready.

- To obtain the finished drying oil, all that remains is to mix the drying agent with linseed oil heated in the oven to 200 degrees. The proportion is 3-5 parts of calcium resinate per 100 parts of oil.

Attention: upon contact with water, the oil boils instantly. Splash burns are very painful. It is better to mix drying oil components with thick rubber gloves, glasses and an exclusively dry object.

A dry wood stick is used for mixing.

Pigment

For this purpose we have to use zinc white.

- We lower the glass from the discharged battery into concentrated hydrochloric acid. It can be found in hardware stores as a cleaning agent for earthenware plumbing fixtures.

- We are waiting for the zinc cup to completely dissolve. Before us is an acid solution of zinc chloride ZnCl

- Gradually add an aqueous solution of washing soda to the container. After the neutralization of the acid, which is accompanied by a violent reaction, a precipitate will begin to form in the dishes - zinc carbonate ZnCO3.

- The precipitate is filtered and calcined at a temperature of at least 280 degrees (for example, in the flame of an alcohol lamp). At the same time, it breaks down into carbon dioxide CO2, which immediately evaporates, and zinc white ZnO.

All that remains is a mere trifle: add about 30 volume percent talc (baby powder) and pigment to the drying oil with thorough mixing until a rich white color is obtained.

Baby powder will serve as a filler for paint.

Paints for beginners

They are less dense and more pliable than for professionals. The Russian company produces paints of different price categories, including for beginner artists.

Ladoga

Many professional artists recommend this brand for beginners and young painting enthusiasts. The pigmentation is medium and the consistency is perfect for learning how to pick and blend shades. Dries quickly.

Advice: professionals recommend purchasing cadmium shades from more expensive brands.

Available in tubes in boxes with different numbers of shades.

Price - from 1000 rubles. for 12 colors

oil paints Ladoga

Advantages:

- Dries quickly;

- Individual tubes and sets are available for sale;

- Affordable price.

Flaws:

- Lack of saturation

Studio

The composition contains natural oils and high-quality imitation of natural pigments, which makes color shades less saturated. The creamy texture is comfortable when applying strokes and is suitable for those who are just starting to learn painting.

There are packages on sale with different numbers of tubes and individually.

Manufacturer - Gamma Russia

Price - from 155 rub. for 10 pcs.

oil paints Studio

Advantages:

- Bright shades;

- Mix well and apply;

- Dries quickly;

- Availability.

Flaws:

- Poor color palette;

- Burn out

Georgian

Inexpensive English product, based on artificial dyes that apply easily. Different shades are easy to mix, dry quickly, and do not fade for a long time. Delicate creamy consistency is ideal for beginning artists.

Country: Great Britain

Price - from 255 rub. (tube 38 ml)

Georgian oil paints

Advantages:

- Good hiding power;

- Give a clear structure of the smear;

- Rich colors;

- Mix well.

Flaws:

- Takes a long time to dry;

- High price

Master Oil

A classic version of oil paints, which are made using traditional technologies. Well applied to any surface. The composition contains finely ground pigments, natural and synthetic, providing light-resistant shades.

The paint does not turn yellow and looks the same in daylight and artificial light. Suitable for mixing with Russian products “Ladoga” and “Master Class”.

Production - Ferrario Italy

Price - from 300 rub. per tube 60 ml

oil paints Master Oil

Advantages:

- Lightfast;

- Can be mixed;

- Large volume;

- Quality;

- Any solvent is suitable.

Flaws:

- Rarely found in sets.

Classico

The Italian manufacturer Maimeri produces products individually and in sets. Thanks to modern technologies, the compositions contain a minimum of harmful substances. For example, pigments that imitate: mercury, cadmium, cobalt. The composition does not contain wax or thickeners. These characteristics made the products safe for children.

The colors do not turn yellow when dry. All shades in the palette are rich, especially blue and orange. A thin layer dries in 48 hours.

Country: Italy.

Price - from 260 rub. per tube 20 ml.

Classico oil paints

Advantages:

- No harmful substances;

- Bright color palette;

- Quick drying;

- Convenient tube size.

Flaws:

- No

Royal Talens Art Creations

The recipe is based on a binder - linseed oil and high-quality organic pigments. Royal Talens Art Creations are recommended for beginning artists and have bright, long-lasting colors. Suitable for thin and pasty layers. Drying occurs in 7-10 days.

The picture does not lose its freshness even after 2-3 years. There are sets and individual tubes of 40 and 200 ml on sale.

Country: Holland

Price - from 200 rub.

oil paints Royal Talens Art Creations

Advantages:

- Economical consumption due to consistency;

- Rich colors;

- Mix well;

- High quality.

Flaws:

- Not detected.

Color palette of most coatings

If the substance is used as a primer, its color does not matter. In other cases, the shade of the coating matters. Oil paints have a wide palette. The properties and characteristics of oil paints also determine the buyer’s choice.

Coloring pigments

The color of the paint depends on the pigments in its composition. They are organic and inorganic.

Regardless of their origin, coloring pigments are found in the following shades:

- beige (120);

- blue (100);

- yellow (140);

- green (100);

- brown (100);

- red (65);

- light or pale blue (100);

- fawn (160);

- light green (140);

- gray (100);

- blue (100);

- ivory (200);

- dark red (100);

- pistachio (135).

In parentheses next to each pigment is the value of its hiding power for the painting consistency. Unit of measurement – g/m².

If the coating contains 1 coloring pigment, then the name of the paint color and the designation of the pigment shade will be the same.

In search of unusual color solutions, some combine 2-3 compositions with each other. There is a special color table with which you can check your experiments, since oil paints cannot be mixed with each other in any shade.

Semi-professional and professional

One of the advantages of this group is a successful combination of price and quality. The paints are popular among beginning artists, amateurs, and college students.

Rembrandt

Paint production is located in Holland. High quality pigments and binders; no fillers are used. The unique recipe of Dutch paint is to create a range of shades that have universal artistic properties: drying period and shine of any pigment number. The palette includes 120 colors, the most famous are translucent.

Metallic colors use pigments instead of copper powder that do not oxidize or fade over time. The manufacturer gives a 100-year guarantee for most paints.

Manufacturer: Royal Talens (Holland)

Price - from 800 rub. per tube 40 ml

Rembrandt oil paints

Advantages:

- High color fastness;

- Extra fine grinding of pigment;

- Pure, rich colors;

- Proven quality.

Flaws:

- No

Master Class

Domestic produces a Master Class series, which contains specially processed linseed oil and a high concentration of pigment. The paint has great coverage, saturation and density of strokes. The color palette includes 99 shades.

Contains high-quality pigments, produced in-house. Many artists rate the paint as highly professional. It can be mixed with colors from other Nevskaya Palette series.

Manufacturer - Russia

Price - from 246 rubles. per tube 46 ml

oil paints Master class

Advantages:

- High performance;

- Large color palette;

- Does not change tone after drying;

- Can be used for restoration work.

Flaws:

- No.

Winsor&Newton

The British company has been producing art materials for 170 years. The entire palette is distinguished by its purity and high quality. During production, only the best oils and technological methods of mixing mineral and organic pigments into the base are used. The process technology makes it possible to prepare paint using a single pigment that conveys the corresponding color. This allows the colors to mix well. Dry over several days, a thin layer dries from 2 to 12.

For example, Alizarin Crimson paint has been part of the Artists series for 130 years and has been popular with artists. A painting painted with such paints will retain its original appearance for up to 200 years.

Country: Great Britain

Price - from 550 rub. per tube 37 ml

oil paints Winsor&Newton

Advantages:

- Tested quality of raw materials;

- Great hiding power;

- Lightfastness;

- Mixes well;

- There are sets and individual tubes on sale.

Flaws:

- No

Schmincke

This German brand has several series based on high quality oils. For beginners: Akademie OL COLOR.

Professionals prefer the Norma Oils series. Manufacturing technologies are more than 100 years old, using ancient recipes and rare, high-quality pigments. Even thin strokes remain clean and juicy. The consistency of the composition allows use without thinner. Highest light fastness and hiding power. The colors are especially vibrant: red, yellow, orange.

The Mussini line is made from Mussini resin, which is a modern process for recreating Renaissance oil. The colors of the series mix well with other tones from this manufacturer.

Country: Germany

Price - from 900 rub. for 35 ml

oil paints Schmincke

Advantages:

- High quality;

- Environmentally friendly product;

- Highest hiding power, light fastness;

- Does not require thinner.

Flaws:

- No.

Lefranc&Bourgeois

The French brand does not use wax or fillers in its paint formulation. The Lefranc line is distinguished by high quality paints, ideal consistency and coverage. The Louvre series has perfectly matched colors, especially good shades of red and carmine.

The Extra Fine series contains 120 shades, most of which are single-pigment, using the purest pigments. This ensures high color rendering, light fastness and durability. The entire line has been redesigned: some old colors have been removed, for example, natural cadmium is no longer used (replaced with an analogue).

The product texture and design have been redesigned. Modern equipment is used in production. To obtain a stretchy, dense and thick structure, triple grinding is used.

Country: France

Price - from 353 rub. per tube 20 ml

oil paints Lefranc&Bourgeois

Advantages:

- High quality of raw materials and final product;

- Wide palette of shades;

- High light fastness, color rendition.

Flaws:

- It takes a long time to dry.

Da Vinci

The series refers to ultra-thin paints. They are easy to apply and dry quickly, the paints are highly lightfast and remain bright for a long time. The composition contains very finely ground pigment, due to which the strokes lie smoothly.

Paints can be found in professional stores or on the manufacturer’s website.

Country: USA.

Price - from 800 rub. per tube 35 ml.

oil paints Da Vinci

Advantages:

- Ultra-thin;

- High light fastness;

- Good consistency.

Flaws:

- Not always on sale.

Van Dyck

The Italian factory Ferrario produces a series of ultra-thin oil paints that appeared 100 years ago. The entire palette has a rich, dense color, good hiding power and light fastness.

Pigments provide high durability and economical consumption. The paints have a thick, oily texture.

The series is available in sets and separately in tubes of 20 ml, 60 and 150 ml

Country: Italy.

Price - from 500 rub. for 20 ml.

Van Dyck oil paints

Advantages:

- Finely grated;

- High quality;

- Economical.

Flaws:

- Not always on sale.

Consumption of oil paint compositions

In order to correctly determine the required amount of material, you should know the area of the surface to be painted and its consumption in grams per unit of measurement. The paint consumption data indicated on the can is the average standard version. In fact, the required amount of paint suspension depends on the following factors:

- structure and quality of the surface to be coated;

- material viscosity;

- the tools used;

- working conditions (indoors or outdoors, weather).

On average, when painting in one layer, 110 - 130 g are used per square meter of surface. However, the consumption of oil paint per 1 m2 on wood will require less material than painting metal. This is explained by the fact that the structure of wood allows paint to be absorbed quickly and easily, and it flows off a smooth metal surface, increasing consumption.

Another important fact: the need for a coloring material is also affected by its color. The fact is that paint of a certain color uses its own pigment component, which affects coverage. Therefore, if you plan to use white and blue colors in your design, then the consumption of oil paint per 1 sq. m of plaster should be calculated based on the indicator that one liter of white material is enough for 7 - 10 square meters of area, and blue - for 12 - 16 m2.

In addition, the need to apply one or more layers and the tool used are taken into account. The most economical option is painting with a spray gun, the most expensive is using a paint brush. A regular roller occupies the golden mean.

Subtleties in working with oil dye

Some subtleties in working with CM need to be studied in advance in order to obtain high-quality coverage:

- Liquid-grated and thick-grated paints are purchased for work. The first ones are immediately ready for use; the latter are diluted with drying oil (the coating will be glossy) or turpentine (for a matte coating layer).

- The addition of driers to the composition speeds up the drying process. Their share is 4% of the total volume. Non-dark siccatives are introduced if the shade of the dye is light. To apply the final finishing layer, no driers are introduced at all.

- To obtain a matte finish, a piece of laundry soap soluble in boiling water is added to the composition. It is grated and filled with liquid. The mixture is heated over a fire until the soap is completely dissolved. After this, CM is poured into it, mixing everything thoroughly. One bar of soap is used per 3 kg can of paint.

Staining is carried out in stages:

- The surface is being prepared. Use a stiff wire brush to remove the old layer of oily material. To quickly remove it, it is recommended to use a solvent. The old varnish coating is removed using a mixture of ammonia and chalk. It is applied to the varnish and wiped with a cloth after a few minutes. Water-soluble dyes are removed with water and a spatula.

- The base is treated with plaster, and later with drying oil. To make the paint coating durable, a primer is applied. It consists of drying oil and thickly grated oil material. Drying oil weighing 100 grams is combined with paint in a volume of 0.6-1.2 kg.

- Defects are eliminated with putty of the appropriate composition. You can make your own half-butter. For this you need the following materials: liquid soap - 20 grams, animal glue - 200 grams, drying oil - 1 kg, turpentine - 250 grams, drying agent - 50 grams. The glue is heated until hot. All components are combined and mixed thoroughly. By adding chalk, the consistency of the putty is adjusted. The resulting material removes unevenness and cracks. Leave until completely dry. After this, the surface is sanded.

- Paint is applied to the finished base. When the jar is opened, the film on the suspension is removed and everything is mixed. The coating is done with a brush. It is immersed in the coloring material by 1/3 of the length of the pile. This will help avoid drips. The brush with the base forms a right angle. Broad strokes are made by hand. The CM is applied first along a horizontal line, then rubbed vertically.

- The coating is done in a thin layer. The second time the finishing material is applied after the first layer has dried.

- To create a smooth wall, the following steps are performed: the first time a primer is applied, the second time - oil enamel. The primer is pre-dried and sanded with sandpaper.

- On average, the dye consumption is 100-150 g/m2. The indicator varies depending on the structure and roughness of the base, and the degree of its preparedness.

- The coating layer of the oil composition will last a maximum of 7 years.

Components included

Oil dye in composition is described as the interaction of a binder and a pigment, which gives the finishing material a certain shade.

Minerals act as a coloring pigment. They are processed into powder and added to the composition. These are heavy particles that do not dissolve and form a sediment at the bottom of the container. Before staining, the CM mass is thoroughly mixed. Pigments can change the technical properties of the suspension. The coating, for example, will dry faster or slower, corrosive wear will be reduced, and the service life will be longer. The component is classified by type: chromatic (with a tint), achromatic (black and white), organic and inorganic.

Drying oil - in the composition acts as a binder and its main component. Two types are used: natural, artificial. Depending on the intended use of the dye, it is selected by viscosity.

Barite, talc, barium sulfate are introduced as fillers. Their purpose is to control the economical consumption of pigment. If a desiccant (cobalt, manganese, zirconium, barium and others salt) is chosen as a filler, then the coating dries faster.

More recently, oil dye was the leader among paint and varnish materials. It covered the facades of house buildings, and it was used as a finishing material indoors.

There are two types of material on sale based on consistency:

- a product that can be used immediately;

- a dye that is diluted before dyeing. It is diluted with drying oil. Its share is 17-40%.

Types of drying oil, their description

Today, synthetic drying oil is widely used. The painted surface takes a long time to dry due to the slow evaporation of oils. Dryers will help speed up the process.

The natural product drying oil is made from vegetable oil. Visually it is fluid and transparent. The type of plant oil affects the shade of the drying oil. It is made from light brown to dark shades.

Oil dyes are produced on the basis of the following types of drying oil:

- Natural component. Contains 97% plant oils. This is a product made from flax, sunflower, soy, and hemp. The share of the process catalyst is allocated to 3%.

- Drying oil "Oxol". Consists of natural oil – 55%, solvent (white spirit) – 40%, drier – 5%. The material is cheaper in cost.

- Combined drying oil is not much different from Oxoli. Differences in the proportion of components: plant oil - 70%, solvent - 30%.

- Alkyd variety. This is a mixture: alkyd resin interacts with natural oil, solvent, catalyst.

- Synthetic binder. Consists of waste from the oil refining industry and products of other production processes.

Advice: the solvent is introduced into the oil CM composition carefully, in small portions. This chemical and its large portion destroys the relationship between the pigment and drying oil.

Description of oil CMs

The demand for the oil composition is explained by two main factors:

- accessibility to the average buyer;

- long service life.

The covering CM penetrates into the top layer of the surface, which increases its service life. The main component of the oil material is drying oil.

Positive aspects of the dye

Many technical characteristics are perceived as positive qualities of the material:

- The coating is resistant to high humidity;

- Temperatures below zero are tolerated, so the paint can be used outdoors;

- Apply on top of another dye, on a poorly prepared surface;

- The coating withstands the effects of detergents;

- High hiding power.

Negative qualities of CM

KM is not recommended for children's rooms and bedrooms due to the toxicity of some of its constituent substances, which can provoke an allergic reaction.

- Toxic substances disappear after a minimum of 6 hours and a maximum of 72 hours. At this moment you cannot move into the room; there is a strong smell.

- The dye dries in about 48 hours.

- The covering layer does not allow the walls to “breathe”. Under the coating layer, the walls peel off over time and become covered with cracks.

- Poor light resistance. The brightness of the shade is lost when exposed to direct sunlight. A bright composition is used to cover outdoor surfaces.

- The composition is not recommended for long-term storage. Its consistency changes. The material hardens and cannot be used.

Oil paint interacts with metal and wood. Used as a primer on wooden products. Due to the high level of filling, the material is economical. Although the recipe and manufacturing technology are improving every year, the oil dye is the same as it was many years ago. Turpentine, white spirit or solvent and gasoline, sometimes kerosene, are used as solvents.

Although the disadvantages are significant, oil dyes are produced in large volumes. Their quality is regulated by GOST. Finishing material by type is indicated by different combinations of numbers and letters.

Advantages and disadvantages of drying oil for painting

It is better to use oil-based paint based on drying oil. It acts as both a coloring and impregnating agent. This product appeared in Soviet times. It covered literally every surface in the room. Nowadays, a hardware store can offer a large number of variations of paint and varnish mixtures. Let's consider the advantages of drying oil for paint:

- The viscosity of the composition has good filling properties.

- Economical.

- Can be used on almost any surface.

- You can prime concrete and renew wood.

- Budget cost.

Despite the fact that it is possible to apply another paint coating to it, there are also disadvantages in this product:

- Poor adhesion to surfaces and other paints.

- Has a pungent odor.

- Long drying time.

- It is highly flammable because it contains white spirit.

- The fragility of the coated structure and the inconvenience of application.

Despite the presence of positive and negative sides of the product, most builders use drying oil as an initial coating, and then apply a coloring agent. To choose the right paint for this process, let’s analyze the features of this process.

Rules and features of application

Painting surfaces with oil-based compounds is carried out in two stages. First you need to prepare the foundation, which will require the following steps:

- Remove old paint and clean the surface using scrapers and solvents. If wood processing is planned, then before the procedure begins, it is necessary to replace the rotten parts. Old paint is removed using a special remover and hard brushes.

- Fill up any uneven surfaces.

- Sand the treated surface.

- Apply primer. Wood must be treated with compounds with antiseptic properties. In this case, it is recommended to apply 2 layers of primer.

- Cover with masking tape the areas that will not be painted.

See also

Description and types of fluorescent paints, their colors and application technology

At the second stage, you need to decide on the method of applying paint. If you plan to process a large surface area, it is recommended to use a spray gun. In other cases, rollers and brushes are used.

Before use, oil-based paint must be thoroughly mixed to a homogeneous and creamy consistency. If this is not done, the coating will be uneven after application. The film that forms on the surface of the paint must be carefully removed using gauze or cloth. If small particles get into the composition, then the material must be filtered.

It is recommended to first apply the coating to hard-to-reach areas using a brush. Then smooth surfaces are painted using a roller. Repeated treatment can be carried out after the first layer has completely dried.

If necessary, before starting work, you need to add a solvent (white spirit, gasoline, kerosene, drying oil or another) to the paint. This will help achieve the optimal consistency of the composition.

Operating characteristics

Manufacturers of oil paint declare its characteristics:

- The proportion of substances forming the film. The service life of the coating directly depends on this indicator. The larger their proportion, the longer the paint lasts. More than 26% of the total volume is the optimal ratio. Too high a value reduces the shelf life of the paint. But this applies to open containers. When closed, it can be stored for a long time.

- No more than 10% is allocated to volatile components. This is due to their toxicity. A pungent odor appears as they evaporate. For this, the air temperature must be 20°C. The room is ventilated after painting.

- Grind level. To create a smooth coating, the indicator is selected up to 90 microns; too large a figure threatens to result in the appearance of roughness on the surface.

- For staining, CM with a viscosity of 65-140 points is selected. This is the degree of fluidity of the material, which will affect the drying rate. A properly selected composition dries in 2 days.

- For exterior work, the hardness of the covering film is taken into account. The greater its hardness, the longer the paint layer will last, and the greater its resistance to various types of influences.

- For facades, paint with maximum water-repellent qualities is selected; for work inside housing construction, the hydrophobicity should be at the level of 0.5-1.0 units.