How to drill through a concrete wall with a regular drill

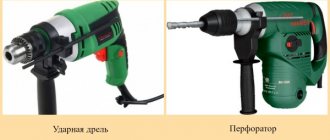

A hammer drill is intended for drilling concrete, but if one is not available, in many cases a hand-held electric drill will do the job. You can achieve success if you choose the right drill or crown. To figure out how to drill a concrete wall with a conventional drill, you need to know a clear algorithm of actions and take into account a number of important drilling nuances.

Additional tool for drilling concrete

It is wise to start drilling concrete if the electric drill is equipped with a hammer function. Using a drill with a hammerless tool is pointless. The drill will simply overheat, which will result in the motor burning out. Using a non-impact tool, you can drill a large hole with a diamond core, if the power of the electric motor allows.

For simple hammer drilling of small holes, you will need an additional tool:

- A set of concrete drills of different diameters. They can be distinguished by special soldering on the carbide end. The element is a small plate with sharpened edges at an angle of 60°. The screw part and cylindrical shank are made of ordinary tool steel.

- Punch. The tool is made in the form of a rod with a sharpened end. A punch helps to destroy concrete by hitting it with a hammer.

Concrete drills have one weak point. Upon contact with the fittings, the solder breaks off. If the immersion of the drill into the concrete has stopped and a characteristic whistle appears, the hole is tapped with a punch. If there is reinforcement, move the drilling site to the side.

When it is necessary to cut a large hole for a socket box with a drill, a crown is used instead of a drill. When choosing a nozzle, look at the shank. Its shape must be suitable for clamping in the chuck. The drill will fit a hex or SDS shank.

Drilling concrete is carried out by three types of crowns:

- Carbide bits have a serrated cutting edge. Crowns are used only for impact drilling. If the drill does not have a hammer function, the soldering tips overheat and fall off the bowl. The crowns are afraid of contact with the reinforcement. To preserve the cutters, before drilling, try to drill through the wall with a drill. Additional action will help determine whether there is reinforcement in this area.

- Drilling a concrete wall with a hammerless drill is carried out with a diamond core bit. The nozzles are not afraid of contact with the fittings. Air-cooled crowns are produced for domestic use. They are recognized by the presence of holes on the cutting edge. Drill bits are not used for wet cutting. Diamond coating can be hard, soft or medium hard, which is reflected by the marking of the nozzle with the letters “T”, “M”, “C”. “KS” bits are usually used with a drill. The design of the nozzle provides slots for air cooling. The cutting edge is made of medium-hard diamond chips.

For drills, bits made of carbide materials are sold, where instead of soldering there is a coating of tungsten carbide chips. The nozzle can be used to carefully drill into a tiled wall. It is reasonable to use crowns if the drill power exceeds 1 kW.

Drilling a wall with a drill

The drilling process with a hammer drill requires maximum effort. It will take more time than when working with a hammer drill due to the lower power of the tool. Drills periodically give time to rest. The entire procedure for making a hole with a drill consists of the following steps:

- The location of the future hole is marked on the wall. Place a punch on the mark and hit it sharply 2-3 times with a hammer.

- After impacts, a small crater is formed in the concrete. A tapped drill is inserted into the recess, the hammer mode is turned on on the drill, and they begin to drill. When the hand feels overheating of the electric motor, the tool is given time to rest.

- The drill may stop going deep for two reasons: solid fractions of concrete or reinforcement have entered. Drilling is stopped. A punch is inserted inside the funnel and sharp blows are applied with a hammer. When the solid fractions are destroyed, continue drilling. If reinforcement gets in, it is better to move the hole to the side. If this option is not suitable, the rods can be cut with a diamond core bit or a metal drill.

Actions continue until the desired hole depth is reached.

The nuances of proper concrete drilling

In order for concrete drilling to be successful, a number of important nuances are taken into account:

- Making a hole with a diameter of more than 12 mm and a depth of 100 mm is best done with a hybrid power tool, a hammer drill.

- For plastic dowels, the depth of the hole is 7 mm greater than the length of the fastening element. The stock will become clogged with concrete dust when inserting the dowel.

- Work begins at medium speed of the drill without impact mode. The speed is increased when the drill reaches 4 mm deep. At the same time, the drummer mode is turned on. This measure is necessary to prevent the drill from moving along the wall due to strong vibrations.

- The drilling process is accompanied by a large amount of dust. If you turn on the vacuum cleaner, flying concrete particles will be immediately sucked up and will not clog the room.

- When clamping the drill in the chuck, check that the shank is inserted all the way.

- Operate with a low-power drill for a maximum of 15 minutes. 10 minutes is enough to rest. Before starting work, the drill is dipped in water. A little trick can reduce wear on the cutting tip.

- When making a through hole at high speeds, a piece of concrete may break off from the back side of the wall. Reducing the speed helps avoid damage.

Preparation

Drilling through tiles is not an easy task. The drills jump off, the tiles crack, and instead of a carefully made hole, you may end up with another local repair. Preparation for drilling includes not only determining the drilling location, but also the choice of drill.

How to drill tiles correctly so that they do not crack:

The drilling points should be located 15–50 mm from the edges of the tiles. It should be noted that the tile is not just a ceramic piece: it has a top layer of enamel applied to it. Therefore, when choosing both a tool and a drill, you must remember that the cutting edge of the equipment used must be harder than the tile itself - this will allow you to easily pass through the top layer and go deeper into the ceramic part. To drill a hole in a tile, it is advisable to use a power tool with a low number of revolutions

This will prevent splitting, which is inevitable at high speeds when neither the enamel nor the tile itself can withstand sudden pressure and heat. It is important to determine how to properly drill bathroom tiles. Much depends on what kind of drill will be used to drill it.

The following drills are best suited for this type of work: spear-shaped, with one-sided sharpening, and with crowns. A spear-shaped drill or a drill with one-sided sharpening allows you to carefully pass the top layer of enamel without disturbing it along the edges of the hole, and go deeper into the tile itself without splitting it due to the pointed end. This is explained by the fact that there is minimal pressure on the entire area of the tile. Drill bits can be either diamond or tungsten carbide coated. Both options allow you to make a hole without causing cracks in the wall. When using such tools, the resulting holes can have a diameter from 10 to 70 or even 90 mm. A crown or drill with diamond coating is quite expensive equipment, so it is purchased by professionals who are constantly engaged in this type of work.

What do the professionals advise?

Concrete structures are quite strong and difficult to drill. In addition, quite often drills come across crushed stone, which is part of the concrete mixture from which wall and ceiling slabs are formed.

Holes in concrete have to be made quite often, especially during the process:

- finishing works;

- furniture installation;

- air conditioner suspensions;

- additional electrical wiring device;

- installation of plumbing.

There are two ways to solve the problem of holes in a concrete wall:

- an impact drill, or better yet a hammer drill, with a Pobedit drill bit;

- diamond drilling.

It is worth noting that it will not be possible to make a hole in a concrete wall with ordinary drills, so before starting work you need to purchase drills with specially soldered plates made of high-strength pobedit alloy, which do an excellent job with concrete and brick. But it is not recommended to use them for soft materials, since pobedit drills do not cut them, but crumble them.

Preparation for drilling

Before drilling, you need to fix the screwdriver in drilling mode. The tool has an arrow pointing to a drill icon. The screwdriver must be held slightly perpendicular to the drilling axis. In order for the drill to go deeper into the material, you must press down on the tool. But not too much, otherwise you might break the drill and hurt your hands. During operation, the pressure should be loosened and the drill should be removed from the hole to remove metal chips and dust. This information will be useful to know how to drill a wall with a screwdriver.

The drill icon may look different depending on the tool model. Impact screwdrivers will have a picture of a drill with a hammer.

Surface preparation

Before you start drilling, you need to make sure that there are no wiring, pipes, or electrical cables in the selected area of the ceiling. A metal detector will help you cope with this task, as it reacts to non-ferrous metals, iron and steel.

If you ignore this condition, you may stumble upon the fittings, damage the drill, or cables/pipes that were hidden in the ceiling. If this area satisfies all the above requirements, then a point is marked on the wall, and then a small indentation is made in it at slow speed using a drill. It is also worth remembering that the surface of a concrete wall is looser than subsequent layers.

How to use a conventional drill with a Pobedit drill bit

Diamond drilling of concrete

After all the accessories necessary for the work have been prepared, you can begin the hole preparation procedure itself . Even before starting the procedure, we recommend that you familiarize yourself with the following recommendations from specialists:

- When working with a conventional drill, you need to carefully ensure that the drill does not overheat, for which it is periodically cooled in cold water.

- After digging a little into the concrete, you should use the same pin, which you need to insert into the recess and hit it with a hammer several times (with simultaneous rotation).

- Then “drill” a little more and repeat the same operations with the pin again.

Avoid overheating of low-power tools; take breaks from work every 15 minutes.

Old-fashioned way

More recently, when pobedit drills were in great short supply, and drills with impact functions were new, ordinary drills were used, using unusual technology.

To do this, a pin was made from one drill. Its end could be flat, like a screwdriver, or it could be made conical, like a tap. Periodic drilling and striking were carried out. That is, first a hole was drilled, then a pin was inserted into it, which was struck with a hammer. Then again drilling, then blows. In essence, the person performed the percussion functions of a hammer drill.

How to drill a small hole for a dowel

To place a small shelf on a tiled surface, you must first make holes not only in the wall, but also on the tile itself. To ensure reliable fixation of the suspended element, it is necessary to provide a sufficient depth of the hole that penetrates deep into the wall. A nylon dowel will be placed in it, into the center of which a self-tapping screw will eventually be screwed.

What drills to use for drilling tiles

Tools with a diamond coating have good performance. The disadvantage of such a drill is its high cost. For the average person, there is practically no practicality in such a purchase for the sake of 2-3 holes. And for professionals who often deal with drilling holes of different diameters on tiles, these are necessary tools. Self-sufficiency of such drills occurs quite quickly. The spear-shaped pobedit drill is designed directly for making holes in tiles; the risk of splitting when used is significantly reduced. Special sharpening gives the cutting edge an arrow-shaped shape, which eliminates sliding movements of the drill when starting drilling. An acute angle allows you to reduce the contact of the drill with the surface being processed. This allows you to apply less force to the drill during operation, which eliminates the occurrence of cracks on the tiles, but for this you need to know how to properly sharpen drills by hand, on a sharpening wheel or using a sharpening attachment for a drill. In the absence of any specialized tools, you can use a carbide drill to work with concrete structures. It must be well sharpened or have pobedite coating on it.

It is worth considering that when using such a tool you need to work with the utmost caution, since it is not used for ceramic surfaces and has a completely different configuration.

Drilling tiles using technology

If you don’t know how to start drilling tiles, then first of all you need to make markings to clearly understand where the hole will be. To do this, you need a marker that can clearly stand out on the surface of the tile. Place a small point in the place required for drilling. Do not forget that before the drill penetrates deep into the ceramic tile, the tool may slide, which will lead to its displacement. To eliminate this point, you can use a patch or paper tape, which should be glued to the site of the future hole.

When starting to drill into a tile surface, make sure that the minimum rotation speed is selected. Start drilling steadily. By going deeper you can increase the speed a little. But do it without much effort, everything should be smooth and neat. The use of the impact mode of a drill or hammer drill is prohibited. This will quickly break the tile covering.

If, in addition to the tiles, it is necessary to drill into the wall to drive in a dowel, then in this case you need to work in stages. First, a through hole is made in the tile. After this, the drill chuck is replaced with the one most suitable for drilling concrete. At this stage, you can use the impact mode of the power tool, since there is no other way to drill through the concrete structure.

How to drill?

The correct way to drill concrete is as follows:

- Before drilling begins, a hole is made by hitting the punch with a hammer.

- The process begins by installing the drill in the hole and turning on low rotation speeds. The drill does not move along the wall, and after reaching a certain depth, speed is added or the breaker mode is turned on.

- With frequent use, the drill chuck and drill bit wear out. Then they are poorly fixed. To avoid injury and poor quality results, they are replaced.

- If the process is stalled, the material is softened by striking a punch inserted into the hole.

- The drill must be periodically moistened with water. This will prevent it from letting go.

- Drilling continues using these techniques until the desired result is achieved.

Tool selection

To make a hole in a tiled wall you will need a quality tool. You can rent what you need, borrow it from friends, or purchase it, because it will come in handy many times during the renovation process. One way or another, you need to get a good drill and hammer drill. They must meet the following requirements:

The drill must support various drilling modes, be able to operate at low speeds, and have sufficient power

Pay attention to battery-powered models, which are easy to use due to their light weight; they are not “tied” to an outlet. It is not advisable to use a hammer drill to process tiles, as this impact tool creates vibration, which can lead to cracks on the surface of the tile. It is useful for drilling into the wall under the tiles. The master must be able to control the force of pressing and the speed of rotation of the drill

It is advisable to start work at low speeds, gradually increasing the rotation to 200 rpm.

Drill Bosch

Selecting a drill and auger

You need to take care of purchasing a special drill and a drill suitable for working with tiles. They must be very hard and sharp, usually professional finishers, to make a hole in ceramic tiles, use:

- Spear drills made of tungsten carbide. The best option if you need to make several holes in the tiles. It is more expensive than pobedit drills, but it has greater hardness, so it drills more efficiently.

- Pobedit drills. The cheapest option. We do not recommend relying only on a pobedit drill if you need to drill more than 1-2 holes, because each one can take more than an hour.

- Diamond drills. The hardest glass, the hardness of which is much greater than that of tiles. Therefore, drilling with them is a pleasure. However, the high cost makes the purchase impractical for one-time use.

Purchasing a low-quality, unsuitable drill is a dubious saving that can come back to haunt you with chips, cracks and much higher costs.

Choosing a tool

So, the first question that a home craftsman should ask himself is not how to drill through a concrete wall with reinforcement, but with what. The main assistant in this matter will be a hammer drill, because it is intended for stone and concrete. At the same time, even powerful drills cannot cope with a wall more than 12 cm wide. Although, if we are talking about foam concrete, a drill is preferable, since a hammer drill will simply break it.

The quality of the drill also determines whether it will be possible to drill a hole in a concrete wall.

One of the best options is to use drills designed specifically for impact drills. Their working part is a plate made of strong metal. With the help of these drills, the question of how to drill through a thin concrete wall can be considered resolved.

There are also annular drills that are diamond coated. They are very strong, they are used in special drilling rigs, and therefore cost quite a lot. Therefore, solving the problem of how to drill a hole in a concrete wall at home with them is at least impractical.

Application of crowns

Often you need to get a large diameter hole in the wall for an outlet. How to drill through a load-bearing wall in this case? Then crowns are used, which have metal soldering around their circumference. Crowns come in a variety of sizes, but the most popular are the 68-centimeter ones, which are designed specifically for sockets. When working with these parts, you need to turn off the impact mode of the hammer drill.

There are also such bits for drills. But they have a coating of a different nature - from a tungsten-cabrid alloy. They are convenient to use, since it is quite possible to drill a hole in a concrete wall with a drill and at the same time make a hole in a tile. Such crowns are used only with powerful drills.

Drills are another tool for drilling into a concrete wall. Their diameter is varied. Experienced craftsmen advise making a selection based on the diameter of the dowels.

Drilling concrete with a hammer drill

So, how to drill a hole in a concrete slab using a hammer drill? The procedure is simple:

- the drill switches to impact mode, after which drilling begins; the tool must be held strictly at a right angle;

- after some time, the drill is moistened with water, this will help avoid overheating;

- after you succeed in drilling a reinforced concrete wall, the drill must be removed without turning off the device itself;

- To clean the resulting hole from dust, a drill is inserted into it several times.

Can't drill into a wall? Did the hammer drill hit something hard? This means you need to try making a hole in a different place.

We make do with a drill

How to drill a concrete wall without a hammer drill? The issue of using a conventional drill when working with concrete remains unresolved. So whether it is possible to drill through a concrete wall with a drill, everyone decides for themselves. The tool may break. Yes, and the procedure will take more time.

You can drill a hole in concrete with a drill if you use a special tool - a punch. It is simple to operate: place the sharp end at the place where the hole will be located, hit it several times with a hammer, after which you can start drilling.

It is important to prevent the instruments from overheating.

As soon as the drill hits an insurmountable obstacle, you need to use the punch again until the desired goal is achieved. Here's how to properly drill through a concrete wall with a drill. Although it takes more time and requires a lot of effort, in the absence of a hammer drill it can also be used.

What do you use to drill large holes?

Many people are interested in whether it is possible to drill holes of different diameters with a screwdriver. It is possible, but the tool must be equipped with additional devices.

There are several options:

- Crown (for metal products) . A small circle of a certain diameter with sharp edges. You need to place a drill in the center to pierce the metal. The bit at low power makes a hole or hole of the required diameter. During operation, the edges of the crown and the surface of the material must be cooled.

- Several stages . Here you need drills of different diameters, from smallest to largest. You need to start with small diameter drills, gradually increasing them, depending on the width of the hole.

- Cone-shaped device.

The above methods are suitable for working with metal. But if desired, they can be used with other materials.

Drilling cone

What is a concrete vibrator

A concrete vibrator is a tool that uses vibration to compact the poured surface, thereby compacting the upper and lower layers of the future structure. If you want to get a strong tie, you can't do without a vibrator. But you don't have to buy it at all. It is quite possible for a home craftsman to make a vibrator for concrete with his own hands from a high-power drill.

The principle of operation is quite simple: the device transmits mechanical vibrations from the top layer to the lower layers. Under the influence of vibration, the remaining air bubbles burst and are filled with solution.

In order to assemble a surface vibrator, you need to take a metal or wooden plate to which your drill will be attached using a broken or unnecessary attachment. The most simplified option is to place any flat metal object on the concrete-filled surface and press it with the chuck of a power tool.

When doing this type of work, it is necessary to press the drill at a right angle. This will ensure the most efficient use of the device.