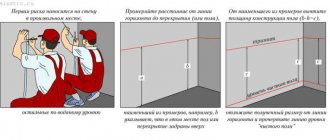

Preparing the wall

An important stage that should not be neglected. This will help you understand exactly where each decorative element will be located. If there are deformations (cracks, potholes) at the intended installation site, then it is worth repairing them. Proper preparation will ensure high adhesion and prevent peeling of the decor.

The cement mortar fits perfectly on a rough surface. A smooth coating does not provide good adhesion to the components of the cement mixture, so it gradually slides down. Even if you slow down the process, the bas-relief may fall off in the future.

You can solve this problem with the help of an angle grinder. After putting on safety glasses and outlining the outline of the intended decor, you need to walk the grinder around the inner space of the outline. Small frequent notches will increase adhesion and prevent deformation of decorative elements. The cuts do not have to be deep; light, frequent cuts are sufficient.

Some features of using decorative plaster for concrete

Both microcement and microconcrete are mainly used in minimalist design styles, which include loft and hi-tech. When decorating walls in such design directions, a variety of different colors are not provided. They are precisely replaced with plain cold colors that can visually expand the space.

Bright white and red spots on a gray cement background are a very original solution for decorating a room.

Eye-catching accents in interiors made in these styles can be some textiles, plastic or leather items that have bright shades that stand out sharply against a gray background.

Using one of the types of decorative plaster for concrete, it is possible to create various effects - this is an imitation of fresh or old concrete, untreated or rusty, as well as wet facade finishing.

Decorative plaster with various backgrounds of “mountain ranges” and “gorges” of the created relief

In addition, if you want to add additional decorativeness to the finish, you can add the selected color to the ready-made cement or concrete mixtures. Another option for adding an aesthetic touch to the decoration is to paint the protruding or recessed parts of the relief pattern created on the wall.

It would seem like just a concrete wall surface. But the original, deliberately sloppy relief immediately brings a special “zest” to the design of the room. Moreover, if it is combined with other decorative interior details

When creating a shallow relief pattern using this material, it becomes possible to reproduce unique textures using a variety of techniques. In addition, the materials are produced in a wide range of shades of gray and other colors, which also expands the range of its use in decorating the premises of a house or apartment.

Microconcrete can be polished to perfect smoothness, to the point that it feels like silk to the touch

.

Due to the fact that the viability of the finished mixture is quite high, it becomes possible to calmly create a relief in accordance with the developed sketch. The long-term plasticity of the mass also allows you to create wall drawings using polyurethane stencils.

Combination of facades with different finishes

Although concrete is a man-made material, its effect on perception is reminiscent of natural textures, and therefore can be easily combined with them. At the psychological level, the concrete surface is perceived as heavy (especially if the dark option is chosen). Therefore, this texture is more often used for lower facades, and the finishing of the upper part is made lighter or from a different material. The following materials are used for the upper facades:

- Wood . If you choose concrete and wood for your kitchen, the interior will always remain trendy. Wooden fragments maintain an atmosphere of warmth and comfort in the kitchen, balancing the strict gray color. The interior turns out lighter and visually lighter.

- Plastic . It is valued for its color and texture diversity, as well as for its budget. The combination of plastic and concrete facades is successfully practiced, especially when it is necessary to create an unusual color accent, and wood is powerless.

Concrete and plastic Source ctfassets.net

Advantages and disadvantages of formulations

In addition to the advantages of the previously listed types of decorative concrete, there are several more noticeable advantages of this coating.

Decorative concrete for walls has the following positive characteristics:

- working with the material is quite easy, especially if you have instructions and advice from designers at hand - an ideal option for those who decide to do the repairs themselves;

- despite the minimalism and ease of application of such plaster, the end result looks aesthetically pleasing and original;

- Concrete-like plaster can be used to finish concrete, wood, and plasterboard walls;

- such walls go well with any other material in the interior - glass, metal, wood, textiles, leather;

- large scope for creativity - a variety of colors, textures, reliefs and compatibility allows you to create the perfect interior;

- a wall with decorative plaster can be painted and varnished;

- in a room whose walls are finished with concrete plaster, it becomes much warmer and quieter due to the characteristics of the material;

- Decorative concrete can be used to decorate any room from the inside, and any part of the building from the outside.

Take note: painting the walls to look like concrete will allow you to complement the interior design with bright colors, original drawings, motivating inscriptions, etc.

Concrete plaster - an ideal solution for a residential loft

The disadvantages of this material include:

- high cost;

- the need to use protective equipment when working with it.

Naturally, a significant disadvantage may be the fact that you simply do not like the look of partitions with decorative concrete as a finishing touch. That is why we recommend that you familiarize yourself in advance with photographs of interiors where this material is used.

Variety of designs

Kitchen sets with concrete facades are not as varied in appearance as furniture made from other materials. Homeowners evaluating different kitchen options often consider the color of concrete as a drawback, because they are afraid that the interior will look heavy.

Manufacturers, trying to expand their range, offer combined kitchen options with concrete and wooden facades:

- Concrete and light wood . For this combination, light types of wood are selected: oak, ash, maple. The contrasting combination of concrete and wood textures in the interior looks refreshing. Light gray and gray-beige facades look harmonious with wood in a natural light tint.

Concrete and light wood Source arthur-bonnet.com

- Concrete and dark wood . The combination turns out to be more brutal, and is not suitable for all interiors. As a rule, the tinting of wood matches the shade of concrete in saturation, which looks impressive. The combination is often chosen for the design of loft interiors.

- Combinations with dark interior concrete . The dark, uniform color of the concrete surface enhances the impression of the furniture. This option is chosen if the interior involves bright color accents (typical for loft, high-tech).

Concrete and dark wood Source wixstatic.com

Varieties

Plastering under concrete involves the use of profile decorative compounds that combine aesthetics, reliability and uniqueness of the finished coating. Cement-based plasters serve these purposes.

Microconcrete

Decorative composite coating based on cement with the addition of resins, fillers and mineral pigments. Suitable for exterior and interior use. It features an absolutely seamless coating. Provides high adhesion to most wall materials:

- concrete;

- drywall;

- tree;

- metal;

- tiles, etc.

We recommend: How to putty internal and external corners of walls

Advantages:

- wide range of textures and colors;

- shockproof, wear-resistant;

- water resistance;

- vapor tightness;

- chemical resistance;

- anti-slip properties;

- absence of construction waste;

- does not increase the load on the structure (layer thickness 2-3 mm);

- environmental friendliness, safety;

- antiseptic properties;

- easy to clean.

Important

The material sets in 30-40 minutes, so you need to work quickly and as a team. A coating of 2-3 layers of protective varnish is required, otherwise the plaster will collapse.

There are five types of material:

- aqua cement;

- microbase;

- microfino;

- microdeck;

- and microstone.

They differ in texture, color and modifying additives. Decorative composition of microconcrete in the photo:

Microcement

Another name for micro concrete. In essence, the materials are no different and have the same characteristics. Finishing with microcement most often includes smooth and thin decorative coatings, which are distinguished by the absence of mineral chips and the presence of polymers in the composition. They are created using the materials aquacement and microfino. Aquacement is resistant to salts and chlorine, therefore it is suitable for finishing bathrooms, restrooms and other rooms with high humidity. Microfino forms a very fine texture and is intended primarily for plastering walls, furniture and ceilings. Microcement decorative composition in the photo:

How to make a concrete wall in the interior: concrete finishing

You can make this finish yourself if you use:

- gray wallpaper;

- decorative plaster with imitation concrete.

The advantage of the latter option is that the surface will be resistant to various mechanical damage, the material is made of environmentally friendly, non-toxic material. You can do this decor yourself if you have experience in finishing work.

A large selection of wallpaper with imitation concrete will suit any room. They can be on a textured or thin basis. The color of the concrete is gray, but the wallpaper can be of different shades. For example, lighter or darker, with a cold bluish tint or with a warm beige tint.

Hue and saturation are selected depending on the size of the room, the selected snowstorm, and the color of other finishing materials. For example, the floor material has a warm shade, then the walls should be made in this color.

In the bathroom

It is not advisable to use wallpaper in the bathroom. Decorative plaster with imitation concrete is suitable here. It must be treated with a special coating, for example, acrylic varnish, which prevents condensation and water droplets from penetrating into the wall.

In the living room

Finishing with plaster or wallpaper that imitates the pattern of a concrete surface would be appropriate here. You can make such decor on just one wall, which will serve as a dominant feature in the interior.

In the bedroom

You can use all types of wallpaper in the bedroom: paper, vinyl, non-woven. Decorative plaster will also look organic here.

In the hall

The hall in a spacious apartment will serve as both a place for receiving guests and a relaxation area for the whole family. For large rooms, textured plasters with an imitation of rough finish are suitable.

In the kitchen

For the kitchen, washable non-woven wallpaper is more suitable. They can be textured or smooth, their main advantage is the ability to remove dirt using wet cleaning.

Tabletop

The material for the countertop is interior concrete, which has a porous structure. It is not afraid of water, but it is quite difficult to get rid of impurities that get into the pores. In addition, the binder contains calcium, which quickly breaks down in an acidic environment. If the concrete panel is not protected, any acid (for example, in lemon juice) will leave a dull stain on the surface.

Therefore, the concrete countertop is covered with a protective polymer coating. It is applied in a thin, invisible layer and closes the pores on the surface, after which the countertop behaves impeccably. The polymer is not dangerous to table vinegar (9%) and other acids; You don’t have to be afraid of ordinary coloring liquids, like wine or coffee.

The varnish coating can be glossy or matte, and lasts for many years without updating (subject to careful use).

Loft style kitchen project Source altastore.ru

See also: Projects of houses with a kitchen

Manufacturers offer ways to make a concrete countertop more decorative:

- There are pigments that can give concrete color (including white). The palette is not very diverse, but color is not the main advantage of the material.

- During production, a large aggregate is added to the solution: shell rock, broken glass or natural stone. The top layer is then sanded off to reveal the resulting texture.

- An option popular in Western countries: the tabletop is inlaid with solid wood of valuable species.

Loft interior Source pinimg.com

Features and types of material

Few renovations take place without the use of decorative plaster - the high versatility combined with the modern appearance of this material expands the scope of its use.

It is customary to distinguish two main types of decorative concrete:

- Microconcrete is a cement mixture enriched with quartz chips, as well as various polymer additives and dyes. This composition is characterized by increased plasticity, is resistant to elevated temperatures, does not absorb odors, however, microconcrete is quite hygroscopic.

- Microcement. Its composition is a cement-polymer mixture. The fundamental difference is the absence of quartz chips. It is ideal for finishing surfaces made of metal, wood, plastic, and also for applying to ceramic tiles.

About the types of architectural concrete

Since explanations regarding the terminology regarding art concrete are very contradictory on the Internet, many people cannot really understand what it is. So first let's give a brief explanation.

There are three main areas of application for architectural concrete. This:

- Production of monolithic facade structures, including those with a three-dimensional front surface.

A building with an unusual facade made of architectural concrete

- Application for casting artistic objects (sculptures, bas-reliefs, elements of facade decor and stairs), small architectural forms, monolithic surfaces with relief.

Outdoor flowerpot

Art concrete: wood for the garden terrace

The area in front of the house made of printed concrete

- Finishing the external and internal surfaces of existing building structures in order to give them a finished appearance. When using it, as in the first two cases, the shape obtained with the help of formwork is not used, but only the texture is important. That is, the third type of art concrete is simply decorative plaster.

Art concrete in the interior

The predominance of certain properties of polymer concrete depends on the specific set of ingredients in its composition. As you may have guessed, it was the third version of concrete that received the prefix “art” (art). Here, too, there are several technologies that were patented in the USA half a century ago, but they began to be used here not so long ago.

One of them is the so-called printed (stamped) concrete, which, being applied to the base, is processed in a still plastic form with a tool for applying relief. There is also sprayed decorative concrete, and there is colored concrete, with which you can very reliably imitate stone or brick masonry.

It's hard to guess that this design is made of printed concrete

It is enough to have a plastic or rubber matrix (stamp) on hand, with the help of which the desired relief is applied to the surface of the uncured plaster. This can also be an imitation of wood pattern. For maximum realism, the formatted surface is perfected using decorative paints.

Stamp for forming the relief of masonry

Composition of art concrete

Since the tasks assigned to concrete are different, their composition will not be the same. It is mainly varied with the help of additives that regulate physical properties (plasticity, hardening rate, hydrophobicity) and decorativeness. The polymer component, as well as some types of plasticizers and mineral additives, give the mixture excellent plasticity.

To create such beauty, the plasticity of the material is very important.

There is no coarse aggregate in decorative concrete; ground rocks (for example, volcanic tuff), limestone and, of course, quartz sand are used to strengthen the compositions. Setting and hardening times are regulated by special hardeners; if necessary, air-entraining, compacting or water-repellent additives are introduced into the composition.

But to achieve the desired texture, the following ingredients can be added to the art concrete:

- colored glass;

- mica;

- ceramic chips;

- dolomite, basalt, granite, marble crushed into flour.

Decorative tiles made of colored concrete

Note: To obtain colored concrete, a mineral pigment is introduced into it - mainly salts or metal oxides. But more intense colors are provided by dyes of organic origin. They are introduced into the composition together with leveling additives, which contribute to a more uniform distribution of color throughout the concrete mass.

This amount of additives is typical only for concrete used to create decorative coatings. They reduce the strength of the stone, so mixtures intended for structural use are made traditionally, with longer hardening times.

If the supporting structure must be colored, it is painted superficially, or the concrete is made white by adding the bleaching agent titanium dioxide, which also has a beneficial effect on cement, increasing its strength. That is why the elements of facade architecture are overwhelmingly white.

The splendor of façade architecture in Art Nouveau style

Photo in the interior of a country house

The interior of a country house has more opportunities for realizing ideas. A simple fireplace with a concrete cladding will look gorgeous. The contrast of cold and hot will look impressive in the interior of the living room.

The photo shows a living room in the interior of a country house. The niche, finished with concrete panels, is fully utilized, combining a fireplace, a seating area and a place for logs.

With the help of concrete columns or small partitions, you can divide the space into zones without compromising the area, without interfering with natural light.

A minimalist staircase with railings is suitable for both classic and modern interiors.

Island

If the kitchen area and the desire of the owners allows an additional island with a concrete base to be installed, it should certainly be used as an important aesthetic detail of the interior. Despite the fact that the island is perceived as a separate object, its decor is based on the appearance of the kitchen unit.

For the interior to look harmonious, the color of the island must match one of the colors of the facade. If the facades are decorated in the same color, the concrete surface of the island can be contrasting.

An island with an accent in the form of a countertop made of other materials looks advantageous. A wooden surface that can be used as a bar counter will look especially beautiful. For a large room, you can choose an island of an original shape, for example, with a two-tier tabletop.

Monochrome island Source wixstatic.com

Types of stamps

Since it is with the help of stamps that printed concrete acquires a unique texture, let us consider their varieties in more detail.

Currently, there are two types of dies for concrete pavement: cast aluminum and made of polyurethane.

Aluminum dies

The aluminum matrix is a massive form with special handles. Using cast aluminum stamps, brick and stone ornaments, various slabs and other relatively simple textures are imitated. The main advantages of aluminum matrices are strength and long service life.

Polyurethane matrices

The manufacturing technology of a polyurethane stamp involves casting on existing materials, the texture of which will be imitated. This method allows you to achieve absolute accuracy in conveying all the nuances characteristic of natural material. The most widespread types of polyurethane matrices are:

- brickwork;

- ship flooring (deck);

- skins;

- old pavement;

- fan;

- masonry.

There are other textures that are widely used in landscape design and landscaping of garden and park areas.

Mixing the solution

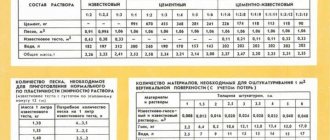

Everything here is extremely simple. Prepare a standard cement mortar by mixing together:

- sand - 3-4 parts;

- cement - one part;

- water.

The mixture should be poured with liquid gradually: the thicker the mixture, the stronger it will adhere to the surface. Add water until the solution acquires a thick, uniform structure. There should be no lumps left in the finished substance, as they deteriorate the quality of the cement mortar.

Useful lifehack! By adding a small amount of detergent to the resulting mixture, you can give the composition additional elasticity. This will greatly simplify the application of the mortar on the wall and the formation of a bas-relief along the contour.