Sheathing materials

Purely decorative techniques are not suitable for restoring the surface of the door, since they are cosmetic in nature, especially when it comes to the entrance door leaf, which is exposed to the most intense effects of temperature and moisture. Finishing the sash with appropriate materials will not only restore the attractiveness of the product, but also improve its sound and heat insulation properties.

- Laminate – finishing boards 7–8 mm thick, made from high-density wood-fiber boards. The back side of the lamella is covered with a layer of waterproof paper, and the front side is covered with a moisture-proof film and a decorative layer. Laminate imitates the look of wood, stone, ceramics, which allows you to choose options to suit any interior. The material is characterized by good sound and heat insulation properties, but is quite hygroscopic, therefore it is used more often for interior cladding.

Finishing lamellas have gained great popularity due to their very affordable cost and durability. They are extremely undemanding in care - just wiping with water or mild detergents is enough.

- Lining - narrow wooden slats with special grooves for strong and easy fastening. The thickness of the products ranges from 6 to 20 mm, the length is 1.5, 3 and 6 m. During production, they are treated with antiseptic agents. The level of sound and heat insulation of the lining is significantly higher, and hygroscopicity is lower.

For external work, it is recommended to use boards made of coniferous wood - pine, larch; for internal work, more valuable species are used - cedar, ash, beech. The products retain the natural color and pattern of the wood, which adds a lot to the beauty of the front door.

- MDF panels are produced by pressing small wood chips. To cover the door leaf, a 16 mm thick plate is used, covered with a polyvinyl chloride film or anti-vandal. The material is characterized by mechanical strength and high heat and sound insulation, is not susceptible to fungi and is resistant to moisture.

- Plastic – narrow lamellas are made of polyvinyl chloride with special additives that increase the material’s resistance to low temperatures, moisture and ultraviolet radiation. The panels are extremely low maintenance, durable and easy to install. However, the mechanical strength of the material is low, so it is recommended to use it for interior work.

The panels are available in two versions: seamless and suture, in the form of lining.

How to do it yourself?

Finishing with panels is a fairly simple process that can be easily done with your own hands. But to get a quality result, you should stock up on some tools:

- Self-tapping screws. Please note that their length should not exceed the thickness of the door. This will prevent damage to the inner or outer side of the canvas during covering.

- Screwdriver and attachments for screwing in fasteners.

- Hammer.

- Jigsaw. With its help it will be easier to cut holes for locks and other fittings.

You will also need the MDF panels themselves. You can buy them in almost any specialized store. It is important to match their style to the design features of your home.

Please note that after installing the trim, the thickness of the door leaf will increase. In some cases, old locks simply cannot be installed on them, so you will have to buy new models adapted to these parameters.

You can decorate the door leaf with panels both from the inside and outside. It all depends on personal preference. This procedure begins with the following preparatory operations:

- First of all, the door is removed from its hinges. This is necessary in order to simplify further work and eliminate possible distortions.

- After this, the hinged hinges are removed from the canvas (if they are not internal), and all fittings are dismantled. The canvas must remain completely clean so that nothing interferes with the fastening of the overlays.

- At this stage, the doors should be thoroughly cleaned of dirt. If these are metal products, then they are wiped with compounds that remove grease.

Some experts recommend that before sheathing them, apply protective paints that prevent the development of corrosion. If the door is made of wood, its surface is thoroughly sanded and cleaned.

To improve adhesion, you can glue a special vinyl film around the entire perimeter.

The MDF panel installation algorithm is quite simple and consists of the following sequential steps:

- Before attaching, the panel is thoroughly wiped to remove dirt. If this is not done, the remaining debris inside may cause the sheet to simply peel off.

- At this stage, you should lay the panel on the door leaf and mark on it the location of the holes for the previously dismantled fittings. After this, the product is removed, and special adhesive solutions are applied to the surface of the door.

Experts recommend distributing the mixture in waves around the entire perimeter. It is important not to forget to coat all edges with glue.

When the mixture is applied, the overlay is placed on the door leaf and leveled. It is important to press it well so that it lies flat.

To fix its position, you can use clamps. This will not only make fastening easier, but will also eliminate accidental shifts and distortions.

The process is completed with additional fixation of the structure using self-tapping screws. To do this, holes are pre-drilled for them.

Please note that they do not have to be end-to-end. Therefore, it is better to mark the depth of the hole on the drill.

Often, fasteners are placed only around the perimeter of the door leaf at a distance of at least 10 cm. After this, self-tapping screws are screwed into the panel. To prevent them from sticking out, their heads are hidden in the lining itself. To do this, when drilling, you should form a small secret groove. The top of the fasteners is covered with decorative overlays. When the fastening of the lining is completed, holes are cut out for the fittings and handles and locks are installed.

Installation of MDF sheets is carried out according to the same algorithm, regardless of the side of the door. It is important to follow the manufacturer’s recommendations and measurement accuracy. Sometimes molding, which looks like a decorative strip, is used as fastening elements. They not only securely fix the structure, but also decorate the door, giving it a special appeal.

When upholstering MDF doors, you should understand that this is labor-intensive work. Therefore, if you do not have the skills to work with such materials, it is better to entrust the solution to this problem to an experienced specialist who will do everything faster and with better quality.

To learn how to properly cover a door with MDF panels, see the following video.

How to cover doors with laminate

Sheathing a door leaf with laminate can be done very quickly and easily, since the material is simply glued to the surface of the leaf.

- The door is removed from its hinges for ease of operation and placed on a flat surface.

- Locks, door handles and peepholes, if any, are temporarily removed.

- Laminate boards are cut to size.

- An adhesive composition is applied to the surface of each lamella - liquid nails or Moment glue, for example. The lamellas are placed on the canvas, lightly pressed down and left until completely set.

Please note that the material itself does not bridge the gap between the sash and the door frame. If sealing material was placed around the perimeter of the canvas, it should be restored.

The video shows a video with instructions.

The cost of installing MDF overlays on an iron entrance door

Installing a panel on the front door is an inexpensive procedure, not too expensive. The cost will depend on several aspects. If you want to order the installation of panels, the price will consist of the cost of consumables, transportation and labor, which directly depends on the complexity of the installation. But there are other factors that affect the final price:

- canvas dimensions;

- finishing of slopes, openings;

- replacement of locks, handles, armor plates;

- complexity, non-standard installation.

Still have questions or doubts? Then call us, ask your questions to the manager, and clarify them. Installing MDF panels on doors in an apartment is guaranteed to avoid the need to dismantle and replace the door leaf. These services are provided by experts who issue guarantees. This will protect you from poor-quality installation, scammers and unforeseen risks.

How to sheathe MDF boards

This is the most expensive finishing method, but also the most durable. It is usually used when decorating steel entrance doors. MDF panels can be installed either directly on the surface of a steel sheet or on existing cladding - leatherette, for example.

- Holes are drilled around the perimeter of the vestibule - that part of the sash that covers the door frame. The step is 20 cm.

- Along the perimeter of the canvas itself, a series of through holes are drilled through both steel sheets in increments of 20 cm. The diameter is 3 mm, the same as in the previous case.

- The inner MDF cover is fixed with screws, and then the outer one. The length of the screw should be a couple of millimeters less than the thickness of the sheet.

- The door fittings removed for the duration of the work are being installed.

Since the MDF panel usually represents the entire facade of the door, it is recommended to invite an assistant to install it.

Installation of MDF panels on metal doors

Installing MDF panels on doors is a quick, inexpensive and quite affordable option for updating the door leaf without replacing it. After covering with MDF panels, the front door looks impressive and aesthetically attractive. At the same time, no time is wasted waiting for the door group to be manufactured, there is not as much dust and dirt as during replacement, and the result is simply impressive.

WE MAKE PANELS OF ANY SIZE - TO ORDER

WE PRODUCE PANELS IN 3-5 WORKING DAYS

APARTMENT PANEL COATED WITH ECO-VENEER (wear-resistant film with wood pattern)

| Name | PICKUP | WITH DELIVERY | INCLUDING A TEAMMAN’S APPEARANCE, DELIVERY AND INSTALLATION (TURNKEY) | ||||

| MDF – 4mm (smooth) | 3 500 | 4 000 | 6 000 | ||||

| MDF – 6mm (smooth) | 4 000 | 4 500 | 6 500 | ||||

| MDF – 6mm (cutter-drawing) | 4 200 | 4 700 | 6 700 | ||||

| MDF – 8mm (smooth) | 4 600 | 5 100 | 7 100 | ||||

| MDF – 8mm (cutter-drawing) | 4 800 | 5 300 | 7 300 | ||||

| MDF – 10mm (smooth) | 5 200 | 5 700 | 7 700 | ||||

| MDF – 10mm (cut-drawing) | 5 400 | 5 900 | 7 900 | ||||

| MDF – 10mm (pseudo-film) | 7 000 | 7 500 | 9 500 | ||||

| MDF – 16mm (smooth) | 6 000 | 6 500 | 8 500 | ||||

| MDF – 16mm (cut-drawing) | 6 200 | 6 700 | 8 700 | ||||

| MDF – 16mm (pseudo-film) | 8 200 | 8 700 | 10 700 | MDF – 16mm (panel) | 15 000 | 15 500 | 17 500 |

OUTDOOR VENEER PANEL (made of natural wood) VINORIT (outdoor heat-resistant film)

| Name | PICKUP | WITH DELIVERY | INCLUDING A TEAMMAN’S APPEARANCE, DELIVERY AND INSTALLATION (TURNKEY) | ||||

| MDF – 4mm (smooth) | 4 500 | 5 000 | 7 000 | ||||

| MDF – 6mm (smooth) | 5 000 | 5 500 | 7 500 | ||||

| MDF – 6mm (cutter-drawing) | 5 200 | 5 700 | 7 700 | ||||

| MDF – 8mm (smooth) | 5 600 | 6 100 | 8 100 | ||||

| MDF – 8mm (cutter-drawing) | 5 800 | 6 300 | 8 300 | ||||

| MDF – 10mm (smooth) | 6 200 | 6 700 | 8 700 | ||||

| MDF – 10mm (cut-drawing) | 6 400 | 6 900 | 8 900 | ||||

| MDF – 10mm (pseudo-film) | 8 000 | 8 500 | 10 500 | ||||

| MDF – 16mm (cut-drawing) | 7 000 | 7 500 | 9 500 | ||||

| MDF – 16mm (cut-drawing) | 7 200 | 7 700 | 9 700 | ||||

| MDF – 16mm (pseudo-film) | 9 200 | 9 700 | 11 700 | MDF – 16mm (panel) | 16 000 | 16 500 | 18 500 |

How to cover doors with clapboard

It is recommended to first keep the material in the room for 2-3 days for acclimatization.

- The door leaf is removed from its hinges and laid on a flat surface. The fittings are removed.

- The lining is cut in accordance with the parameters of the door and the installation method: vertically, horizontally, diagonally, or even in the form of some kind of pattern.

- Sheathing begins from the edge - depending on the method, sequentially connecting the elements together and securing them with finishing nails.

- After installation is completed, the surface of the material is varnished.

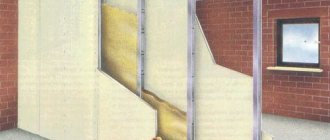

If you need to sheathe a metal sheet, then at the first stage you should attach the sheathing. Narrow wooden slats are secured with self-tapping screws, and wooden slats are mounted on them. You can use special gluers to attach the panel to the surface of a steel sheet, but this method fixes the lining quite rigidly, and subsequently the material can be deformed.

Source: dvernoigid.ru

Subtleties of replacing and installing MDF on a metal door

Replacement and installation of MDF panels on doors is carried out by specialists in a short time and at an affordable price. We use only tested and proven products in the door products market, therefore we guarantee high quality of the finished result.

We have been installing MDF panels on metal doors for more than 10 years, and we are ready to offer an exclusive finishing solution. Our specialists cope well with the assigned tasks and complete orders on time, working with canvases from any manufacturer. Installation of the decorative covering is carried out without removing the doors from their hinges, which avoids unnecessary noise and dust.

Why is this necessary?

It is necessary to trim the slopes of the doorway. First of all, to create an aesthetic appearance, because when removing the old box, the slopes were probably damaged. The next reason is the need to hide the installation process. The polyurethane foam doesn't look the best.

Note! If the polyurethane foam is not hidden from direct sunlight, it will literally crumble in 3-4 years. If it comes to the front door, then this is fraught with, at a minimum, the formation of drafts, and at a maximum, easy penetration of intruders into the house.

The designed slope must meet certain criteria:

- no condensation formation;

- aesthetic appearance;

- improving door thermal insulation;

- resistance to temperature changes;

- easy care and washing without loss of appearance.

MDF slopes for a door or window - like a frame for a picture: design corresponding to the content

Window and door slopes made of MDF are much more difficult to make than structures made of other materials. While any craftsman with minimal skill can handle plaster, drywall or plastic, working with wood-based boards requires almost a jeweler's precision of fit.

However, the result is worth the effort, so below I will provide all the information that needs to be studied before proceeding with installation.

It’s difficult to decorate your front door or window, but it’s still quite possible

Opening type

It’s clear why the opening needs to be sheathed, but not all of them are standard; there are many options. Coming out of this, the finishing materials also differ. Options:

- Rectangular opening. Sheathed with any material, including plastic panels. Moreover, it can be not just a place of passage to another room or into the house, but an important part of the design solution of the room.

- Arch. This option is not used in every room, as it is appropriate only in some styles. This solution is suitable if the rooms are decorated the same way and there is no need to physically separate them. For finishing, you should choose materials that do not stand out too much from the background of the rest of the room, otherwise they will “weight down” the opening. It is interesting that in modern interiors, in addition to classic rounded arches, ellipsoidal, trapezoidal, and even asymmetrical arches are created. They can be easily finished with plastic panels, which cannot be said about tiles.

- Imitation of an arch. This method is also called lazy, because an “arched” finish is formed in an ordinary rectangular opening; it will not be difficult to complete.

- A doorway without a door. It’s easiest to install the finishing here, but the main task in this case is to choose the right material, then the finished opening will look organic.

Slope finished with plastic panels

How to decorate the front door from the inside with MDF and platbands with your own hands

Every person has a door to their house or apartment, and it is an integral part of their home, as it ensures security.

But the metal entrance does not look very nice, and in order to make the entrance opening beautiful and fit into the interior, finishing material should be used. The design of the front door, slopes and trim with MDF panels looks very worthy. At first glance, it may seem that lining MDF doors is a complicated procedure, but if you follow the recommendations step by step, you can do the work yourself and nothing will be difficult.

Alternative options

Other options for finishing the doorway:

- Tile. The method is practical, however, not the most convenient. You will have to carefully consider the choice of tiles, and the question also arises of how to lay it over the doorway, despite the fact that it is important to ensure the adhesion of the adhesive. And laying tiles without certain skills is difficult.

- Artificial stone - this option will create excellent aesthetics, but even during the first attempts to wash it, this beauty will fade in the eyes of the owner, since such materials often have a fairly deep structure.

- Decorative plaster. It looks original, fresh, unusual, but only if it was applied by a specialist.

PVC panels are the best choice

This option is optimal, because this finish combines an affordable price, ease of installation and an attractive appearance. Manufacturers offer a variety of panel options to imitate natural materials; wood is especially popular. This material has a number of significant advantages:

- Environmentally friendly. The surface of the panels has no pores, which prevents the fixation and development of fungi and mold on it. When it comes to the slope of the front door, this is important.

- Fire resistance. If we compare it with other popular materials - fiberboard and chipboard, then PVC products have a ignition temperature that is 100 degrees higher. Even if a fire occurs, the panel emits less smoke than the specified materials, which means it will not create an obstacle to exiting the room. Plus, PVC is a self-extinguishing material.

- Durability. The panels can withstand intensive use, temperature changes, and repeated washing.

- Ease of installation - attaching them to the wall will not be difficult even for a novice builder.

- The doorway takes on a finished look.

Slopes finished with white panels

Advice! If the opening is wide, many people wonder what is better: installing a second door or finishing this space? The decision depends on the location of the opening itself. For the entrance group, two doors are still preferable.

Advantages of MDF finishing

MDF is a medium-density wood-fiber board used for finishing the front door outside and inside. Suitable for cladding doors made of iron, metal and steel - even steel doors with MDF finishing look amazing, impressing the most demanding aesthetes.

Why should you give preference to this particular material?

- Wide choose. Modern manufacturers willingly please the consumer by providing us with numerous options with a variety of colors and textures. It is possible to finish with materials that imitate natural ones - thus, entrance doors with MDF finishing acquire an elegant appearance. Design options are widely presented in the photographs provided by the manufacturer - choose your unique option, completely transforming the appearance of the hallway.

- Durability. Wood-fiber materials will retain their presentable appearance and useful qualities for many years. They perfectly tolerate various mechanical loads and are not afraid of temperature changes and sunlight. Compared to upholstery made from leatherette (easily torn and fading before our eyes), MDF boasts a combination of beauty and practicality.

- Safety. The panels contain absolutely no substances that can harm human health, unlike some other facing materials.

- Easy care. No difficulties are expected - forget about expensive detergents, delicate procedures - you just need to periodically wipe the panels with a damp cloth. In addition, MDF does not absorb unpleasant household odors at all - no additional care is required.

- Ease of installation. It is possible to finish with MDF panels without involving specialists. All you need is the necessary tools and extreme accuracy, then finishing the MDF door will be quick and successful.

- Sound insulation and thermal insulation. The materials will provide you with a cozy, warm hallway - it is possible to add a layer of insulation on the outside.

- Acceptable price. Depends on the specific type of panels, however, in general, they belong to the average price category.

- Possibility to install slopes made of similar material.

Related article: Silk wallpaper: liquid for walls, matting in the interior, photo, plaster, reviews, video, silk wallpaper

Installation of panels: preparation

Preparation consists of studying the technology of work behavior:

- The first step is to clear the opening from any remaining finishing.

- Next comes plaster. This step is optional, but it makes it easier to install the panels; provided the alignment is good, you can do without lathing.

- Coating with a primer to prevent the development of fungi and mold under the panel, since it cannot be dismantled without losing its integrity.

- Next, the sheathing (if necessary) and PVC panels are installed.

Tools and materials that will be needed for work:

- Level.

- Electric drill or screwdriver.

- Self-tapping screws.

- Hand saw or jigsaw.

- Pencil.

Wood-look PVC slopes

Installation of sandwich panels

Such panels protect the doorway from the cold thanks to their multilayer structure. It contains foamed polystyrene with a closed cell structure, externally it is protected by a special rigid PVC film. Such panels are durable and resistant to ultraviolet radiation. They can be used to cover door slopes of any thickness - from 5 to 150 cm.

The panels are installed using dowels. The ends are closed with decorative corners. The joints with the box must be treated with a sealant of a suitable color.

Note! The sealant must have a PVC base, then it will not create a sticky effect, like silicone compounds.

Wall panels: installation

This material is also used for cladding, but wall panels are more fragile, so you need to handle them carefully. They are available in different lengths and widths. Mounted on a sheathing made of metal or wooden blocks. To improve heat and sound insulation performance, it is worth laying insulation on the slope. A decorative corner is installed at the joints.

Multi-colored plastic panels