How to paint the boat? In order for the boat not to be too heavy, but at the same time strong and more resistant to corrosion, it is made from various metal alloys (duralumin, aluminum, etc.), less commonly from steel.

It is easier to paint ordinary “black” metal, because... There is a large selection of paints for steel, but specialized paints for “non-ferrous” metals are less common.

What to do if you need to paint just such a boat. There are several options here.

To begin with, general points, old paint that has already peeled off must be cleaned, it is not necessary to remove all the paint, if it sticks - leave it, metal and areas of old paint must be sanded/sanded with sandpaper to create a scratch on the surface so that subsequent paints and varnishes clung to her. Next, we degrease, not with acetone, not with gasoline, not with solvent, but with a DEGREASER! Because It is this that properly cleans the surface without leaving “greasy” marks like gasoline and does not react with old paint like acetone or solvent.

Next we move on to preparation and painting options.

Option 2 Using phosphating primer

We apply a 2K acid/phosphating/etching primer to the prepared surface, because it applies to any type of metal (steel, aluminum, stainless steel, galvanized, etc.), the most important thing is to apply it thinly, in 1 or 2 layers (depending on the manufacturer), bypassing the old paintwork and putty areas. The soil should be transparent, the metal should be visible through it. And no earlier than 1 hour and later than 24 hours after application, cover it with primer with a foam filler/leveler and, after it has dried, sand again with P320-P400, degrease and paint.

Subtotal

Priming

It is obvious from the above options that the first thing you need to do is prime the metal; for this, only 2 types of primer are suitable, which are guaranteed to stick to any type of metal:

phosphating and epoxy

Then you decide for yourself whether you need a primer filler; its use will only hide minor unevenness and scratches.

Dye

The paint is chosen at your discretion. The paint can be used both specialized and automotive, but only 2-component acrylic (or 2K acrylic automotive varnish). It will give good strength and rapid polymerization after painting.

Next is an option that combines both primer and paint.

Yacht painting and boat painting

paints yachts, boats and boats in a special painting booth. We select paint and paint application technology. We guarantee high-quality work, please contact us.

Repairs and general work

Specialists will carry out both minor repairs to the yacht hull and cope with more complex problems. They repair and paint ships of different displacements. The main thing is that your watercraft does not exceed 20 meters in length. Restoration work is carried out by service center professionals. The workflow for painting boats and yachts includes:

- Yacht hull repair.

- Elimination of scratches and large holes.

- Painting yachts with color selection, using special programs and computers.

- Polishing the ship's hull.

- Application of antifouling components.

To paint a yacht, you need to understand that this is a complex technological process that requires:

- Careful attention to detail.

- Gained experience.

- Highly qualified craftsmen.

- Availability of special equipment.

Note! Complexity of the process: processing of vessels is not allowed in the open air. Dust and other particles will inevitably fall onto the surface being treated. If the master is not competent enough to paint the yacht well, this often leads to a negative result.

Information for clients

For high-quality painting of yachts, the company has at its disposal:

- Modern painting booth.

- Special equipment.

- Staff and highly specialized specialists.

- Warehouse of certified paint and varnish products.

General stages of painting a boat

The initial stage is preparatory activities, which are the basis for compliance with the technological process. Initially, the ship's hull is cleaned of old paint and defects are eliminated. Paint removal is carried out by specialists using a modern, powerful sandblasting machine with a high feed rate of cooper slag.

The second stage is degreasing the surface, applying primer in several layers using a special coating. We use combination technology. When the paint is mixed according to the manufacturer's recommendations with reagents. This allows the paint to adhere better to the hull of the boat being repaired. Third stage. By agreement with clients, specialists can treat the hull of a yacht or boat with ceramic-coated varnish. The protective layer in question is the most expensive option for keeping the vessel in good condition. But it is what gives the “depth of color”, making your watercraft unique. Therefore, this type of work is performed by our highly specialized specialists. Ceramic coating allows you to:

- Protect the ship’s hull from the negative effects of the environment: sand, stones, water, and so on.

- Improves the appearance of the boat.

- The boat's hull successfully withstands external aggressive factors.

However, with the general technology of painting yachts and boats, there are differences in processing that are associated with the material used in the production of the hull.

Features of painting an aluminum boat

Painting a boat made of aluminum consists of three stages:

- Choice of coloring matter.

- Preparatory process.

- Applying paint.

Our experts find out how intensively the vessel was used. Check the boat for mechanical damage. They find out from the client what waters the boat sailed in (salt or fresh).

When choosing paint for an aluminum body, we give preference to polyurethane color, alkyd enamel, epoxy resin or erosive anti-fouling paint.

- Preparation process.

It is important to understand that painting an aluminum boat has its own characteristics. It is necessary to properly prepare the body, otherwise the paint will not adhere. The aluminum sheet used to make boats is too smooth. Therefore, it is necessary to remove old paint mechanically. Cover the bare metal with a layer of phosphoric acid or zinc phosphate. This will protect the metal from the formation of oxides. Then, the body is washed, dried, and degreased before applying a new layer of paint with acetone.

- Padding.

Applying the mixture is the final preparation of the boat for painting. A primer for treating the hull of a boat is sold in the retail chain, both in aerosol packaging and in a mixture consisting of two components.

- Painting.

An aluminum boat is painted indoors, which is equipped with a compressor. This allows you to speed up your work. We dry individual parts of the boat: oars, frames in natural conditions. To speed up the process, you can use forced structures: air heaters and high-power mercury lamps. Working with professionals is profitable and productive

When we take on an order, we do not miss deadlines. We follow painting technology. We work with clients on an individual basis. We use proven technologies. We use original certified products.

Finally

To receive a free consultation and additional information, dial the telephone number provided. The Kotrak acceptance master will answer questions, talk about the nuances of cooperation and advise on prices and terms.

Option 3 Epoxy or polyurethane primer-enamel

This type of paint allows you to save not only on preparation time, because... in options 1 and 2, it was necessary to prime, then apply more primer and filler, only then paint, not to mention the fact that at all stages it was also degreased, but also at the cost of the materials themselves used in the preparation.

In the case of primer-enamel, the paint is applied to a previously prepared surface (sanded and degreased) in 2-3 layers, the drying time is 3 hours at +20C. There is no need to bother with sanding the primer and additional degreasing before painting.

Boat hull priming

Please note that after cleaning and degreasing, you need to coat the surface with a primer as quickly as possible. If you leave aluminum treated with sandpaper in the air, then after a short time it will begin to darken - this is the result of the oxidation process, and primer and paint do not adhere well to oxidized aluminum. This is why it is so important to apply the first coat of primer as soon as possible.

Considering the specific nature of non-ferrous metal, we use primer specifically for this material - acid primer VL-023 or primer VL-02. It is also possible to use epoxy primers.

VL-023 primer is a two-component material: base and acid thinner. The basis of the primer is a suspension of pigments and filler in a solution of polyvinyl butyral and iditol resin in a mixture of volatile organic solvents. An alcoholic solution of orthophosphoric acid acts as an acid diluent. VL-023 creates an anti-corrosion phosphate layer on the painted surface.

Primer VL-0 is universal, applied to almost all metal surfaces (not recommended for cast iron and steel castings) and used in complex coating with most putties and finishing enamels. The coating formed by the VL-02 primer increases the corrosion resistance of the metal, which leads to an increase in service life, and also improves the adhesion of the paintwork. Coating systems with VL-02 primer can be used outdoors in various climatic zones. After mixing the primer base and acid thinner, let the mixture sit for 20-30 minutes and can be applied in 1-2 layers. Remember that the viability of the mixture is limited depending on the ambient temperature, for example, at temperatures from + 10 C to + 20 C - 8 hours, from + 20 C to + 30 C - 6 hours, so it is better to dilute the primer in small portions.

What is the difference between VL-02 and VL-023 primers?

Types of primer enamel

Paints applicable in this case (boat painting):

Polyurethane and epoxy

The difference is that polyurethane goes on steel and galvanized steel without primer, while epoxy goes on all metals.

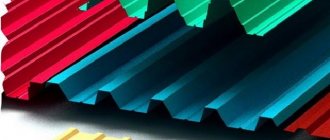

And polyurethane paint also has the ability to produce different degrees of gloss: 20%, 50% and 80%.

It is also possible to combine a polyurethane primer-enamel with a phosphating primer to paint aluminum, duralumin, etc.

Types of housing materials

The choice of materials depends on what material the body is made of and what budget is allocated. What types of boat hulls are there? Let's look at them in descending order of popularity.

Housing made of duralumin alloy. These are Soviet riveted boats, which are still found in abundance on reservoirs. There are several types of alloys: D1AT - Kazanka, Oka-4 is made of D16T, the Ob motorboat uses D16 in combination with D1. They were painted with VL-02 primer and XV-16 paint.- Welded aluminum-magnesium alloy housings. For example, Soviet motor boats Crimea, made from AMg5. Modern boats are welded from AMG5M. In new buildings, instead of painting, PVC film is mainly used.

Fiberglass housings made of fiberglass and its varieties, impregnated with polyester (less commonly, epoxy) resin. A gelcoat dyed in the mass is used as the outer layer.- Plywood bodies. Mostly self-built. They are based on waterproof plywood covered with fiberglass impregnated with epoxy resin. They are painted with epoxy paints, for example, EP-140.

- Inflatable boats made of rubberized fabric, PVC and Hypolon. Rubber boats are becoming obsolete; boats made from high-poly rubber are almost never seen due to the high cost and peculiarities of repair. The most popular boats are made of PVC. The material of the cylinders is dyed in the mass. To change the color, it’s easier to change the boat, since now the range of colors, including camouflage, is quite large.

- Boats made of thermoplastic and polyethylene are practically never found on Russian water bodies. Thermoplastic is used in some Polish and Finnish boat models, while polyethylene is good for small hunting boats and kayaks. Boats made from these materials are painted in bulk and do not require painting during operation.

Steel hulls, as a rule, are used on inexpensive boats of the “Volga party” type and expensive cruise hulls. The owners of the former are satisfied with oil paint, while the latter usually entrust painting to specialized shipyards.- Wooden cases. In the central region they are practically not used. They are painted with resin, varnish or oil paint depending on the purpose.

In this article we will briefly look at how to paint a boat made of aluminum alloy and fiberglass.