When performing repair and finishing work, special attention is paid to creating interior design. Various materials and coatings are used to decorate walls. The most popular among the known options are decorative plasters.

One of the varieties of such options is decorative plaster, which creates the effect of stone on the wall. When using this material, a coating is created on the wall that imitates decorative stone. To create a stylish and unique design, you should study the features of choosing a material, as well as learn about methods of applying the composition to wall surfaces.

Composition and characteristics of stone-like plaster

Depending on the type of material, the composition of the plaster mixture may differ. However, there are basic components that should always be present in the mixture:

- A cement or gypsum composition is used as a base.

- Granular elements that include sand, quartzite, mica...

- Thickeners are added to give the mixture the desired consistency.

- Dye to give the solution a suitable shade.

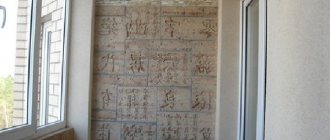

In rooms, stone-like plaster is applied in a thinner layer

The use of such a composition makes it possible to impart strength, moisture resistance and increased wear resistance to the coating. Plaster with a stone effect not only gives the walls a beautiful appearance, but also creates a reliable coating.

Pros and cons of stone plaster

Decorative material that imitates real stone weighs much less, which reduces the load on the walls. In addition, the plaster composition has the following advantages:

- The decorative effect created by plaster gives the walls a beautiful appearance.

- Walls with this coating allow steam to pass through well and also normalize air humidity.

- The coating has an increased service life.

- The special composition allows you to resist the spread of fungal colonies and mold.

- Facade coating options are resistant to sudden changes in weather conditions.

- Using imitation allows you to save on the purchase of real rocks for surface finishing.

Among the shortcomings that users noticed are the following:

- If a section of the decorative coating is damaged, it will be difficult to restore it, since a large area of the coating will have to be replaced.

- The material can accumulate large amounts of water, which leads to deterioration in the quality of the coating.

- Exposure to elevated temperatures can lead to softening of the plaster on the wall, this is especially true for the facade of buildings.

imitation stonework on the plinth

How to make an imitation stone on the wall with your own hands

Options:

- Polystyrene foam will help create an imitation of masonry or stone.

- If you need to decorate a small area, create an imitation using acrylic paints.

- Well, the simplest solution is wallpaper.

A more complex technique is papier-mâché.

- First, parts corresponding to the shape of the stones are cut out of cardboard.

- Then take the egg trays and cut them into pieces measuring about 7 by 7 cm. Stick them on the base, overlapping each other.

- When all this is dry, you need to dilute the putty with water to the consistency of sour cream.

- Cover the resulting workpieces with the composition.

- After drying, paint with a roller, starting with dark and ending with light shades.

- Then all that remains is to varnish them and glue them to the wall.

Required Tools

Before treating walls and applying decorative material, you must prepare a set of tools in advance:

- Trowel, spatula or trowel for application.

- Construction mixer for preparing the mixture.

- Roller, brushes or rags for applying the solution to the walls.

- Level, ruler and rule for distributing the mixture.

- Masking tape to determine the level of distribution of the solution.

- Container for mixing building material.

- Personal protective equipment for ease of work.

Preparing the mixture

Usually, when working on wall finishing, ready-made solutions are purchased for application. In this case, to prepare the mixture, you will need to pour the composition into a large container, fill it with water in the ratio indicated on the package, and then stir using a special mixer. It is necessary to stir until the mixture acquires a homogeneous consistency.

It is recommended to use stirring in two stages, this will create a homogeneous mixture without lumps.

A mixer attachment is used for mixing.

How to make your own mixture

If you want to save money on purchasing expensive building materials, you can make the mixture yourself. Decorative plaster to look like stone with your own hands is quite easy to do; you can use one of the following options:

- Mix putty with sand. For one bucket of putty you need to add 1.5-2 liters of regular sand. If necessary, water is added to the resulting mixture, and then everything is stirred with a construction mixer.

- Lime, cement and sand are mixed in a ratio of 1:1:2, then water is added in the required proportion and liquid glass (5% of the total mass of the mixture).

The prepared mixture can be used to decorate any surface. At the same time, a properly prepared solution will not differ in quality from mixtures purchased in a store.

Preparation of the composition

Dry ready-made compositions for plaster require the independent preparation of a homogeneous solution. To mix the ingredients, it is better to use a wide container or a construction mixer. Afterwards, the composition is left for 10 minutes to polymerize, and then the procedure is performed again.

The prepared mixture is used immediately after preparation, so you should correctly calculate the required volume and time of application to the surface. The quality of the coating depends on compliance with this point. To obtain the deep texture of the stone, the composition must have a thick consistency, which will create a relief.

The treated surface acquires the properties of decorative plaster. This coating is characterized by high vapor permeability, which eliminates the formation of condensation, and is resistant to mechanical stress.

Main components of the plaster composition

You can get the texture of natural stone and achieve the effect of a relief surface using special mixtures. The working compositions are based on crumbs, which are obtained by crushing natural materials. Marble and granite are often used for manufacturing.

Cement, acrylic and silicone resins, silicate are used as a binding element; the plasticity of the composition is ensured by the addition of lime. Decorative properties are provided by sand, mica, and mineral pigments.

The composition of plaster solutions includes plasticizers - PVA, soap solution. To make it resistant to fungus and low temperatures, special glue is added.

How to prepare decorative compositions yourself

The finished material allows for high-quality surface finishing. Imitating stone from plaster with your own hands will allow you to save on expensive compounds. A simple option consists of sand and putty. If necessary, water is added to the working mass.

To perform external work and finishing work, working material is used, which includes:

- lime - 1 kg;

- cement - 1 kg;

- sand - 2 kg;

- water;

- liquid glass (5% by weight).

A mixture made from lime paste, water, marble sand, cement and manganese peroxide is durable. Self-preparing stone plaster requires following the recommendations.

In this case, the water temperature should be above +10℃, lime dough should be prepared from the dry component. Binders are used in combination, for example, gypsum, lime, cement.

Preparing the base

To ensure quality work, care should be taken to prepare the walls. To prepare the base, follow these steps:

- Initially, it is necessary to remove all elements from the old coating (wallpaper, remnants of paint or whitewash, decorative inserts).

- After removing large parts, the surface should be treated to give it a smooth shape.

- Large defects, chips, cracks and other imperfections must be repaired with cement mortar.

- After the mixture has dried, you can treat the wall with antiseptics and chlorine-containing substances, and then rinse it.

- To improve adhesion to the solution that will be applied to the wall, it is recommended to coat the surface with a primer.

Decorative stone effect plaster will adhere firmly only to the wall that has been pre-treated. If preparation is not completed, the composition will not adhere well to the surface, which will lead to deterioration in the quality of the coating.

Types of imitation decorative stone

Plaster can be used to recreate a monolith and masonry. The surface of the wall can imitate expensive natural materials (marble, granite) or building stone (limestone, sandstone). Before starting work, you need to calculate the material consumption. The volume of the mixture depends on its texture and fraction size.

Flat imitation of natural stone on the wall

The technology for creating stone-shaped plasters is based on the depth of texture development. Using Venetian plaster, a smooth coating is created that imitates marble and granite.

The surface is made smooth, covered with a wax composition and polished, which allows you to give the wall a semi-matte gloss. The texture pattern is created by mixing plaster solutions painted in different colors.

Textured

Textured walls imitating a monolith of limestone or sandstone have a rough surface, which is inherent in natural stone. This type of coating is created with a small and voluminous pattern and slight roughness.

Flat-relief

Plaster can be made in the form of masonry with deep or small seams. The technology for creating a flat-relief surface is suitable for simulating processed stone, blocks, and bricks.

Convex

Convex 3D surfaces are created by applying large volumes of working composition with layer-by-layer painting. Volumetric plastering can be performed using special forms.

How to make an imitation of a building stone slab

Natural material is characterized by roughness, the presence of chips, and marks from the tools used for processing. In this regard, the imitation stone slab, which is characterized by a complex texture, does not require leveling.

Imitation stone effect imprints

A drawing can be applied to a fresh layer of plaster. You can recreate the masonry effect using a ruler. If the design is supposed to be in the form of roughly processed stones, then the design is applied freely. Plastering walls to look like stone, done independently, requires phased completion of the work.

If the layer thickness is 1 cm, then the surface can be decorated with a mesh in the form of cracks and impact marks. Thanks to these elements, it is possible to obtain a natural texture. Decorative plaster “stone effect” requires proper elaboration of the applied contours and leveling of the surface.

After the material has completely dried, defects are eliminated with sandpaper or sanding mesh. Before painting the wall, the surface is primed in a single color. When the applied layer dries, the bulges are formed. Contrasting paint emphasizes the relief.

Techniques for creating imitation stone from plaster

There are various techniques for creating a wild stone coating on the facade and indoors. The choice of method of applying the material depends on the characteristics of the base, the quality of the plaster composition, as well as the experience of the master. To decide on the choice of technique for creating decorative stone from plaster with your own hands, it is worth considering the features of existing options for performing the work.

Smooth stone surface

The decorative coating on a smooth surface in the form of stone is similar to decorative plaster Travertine. Usually, to create a pattern that imitates stone, solutions with different colors are used. In this case, the prepared composition is applied to the prepared surface in several stages. Then a multi-layer coating with different patterns of stones is formed. At the final stage, the wall is processed with a grinding machine or a trowel to create an even coating.

Textured stone surface

Plaster can be used to create textured coatings. In this case, one of the following methods of performing the work can be used:

- Applying plaster in a continuous layer with further scratching of recesses to form a textured coating.

- Layer-by-layer application of the solution. In the first layer, the mixture is applied evenly, the second layer forms a textured surface on the wall.

Masonry

One of the most common design options is to create brick or stone masonry. In this case, seams are formed on the wall, resembling recesses between individual elements:

- The building mixture is applied to the wall.

- After the solution has partially dried, a seam is formed using a trowel or chisel.

- You can create a pattern in another way, for this you will need a stencil. It must be applied before applying the solution. When the mixture completely covers the wall, all that remains is to remove the stencil.

- In the final stage, it is necessary to process the coating with a sanding disc.

Imitation with impressions

You can imitate natural or artificial stone using impressions or matrices. The process consists of several stages:

- The prepared solution is applied to the pre-treated wall.

- A matrix, previously moistened with water, is applied to the wall.

- The matrix is pressed tightly against the wall to form a pattern, after which it is removed. This must be repeated until a uniform pattern is formed on the wall.

- If a section of the material comes off the coating, it must be reapplied and then the procedure repeated.

- Uneven surfaces on the wall should be sanded using a sander.

Using an impression to imitate masonry

Imitation of stone masonry for interior decoration.

Stone masonry is somewhat more difficult to imitate. It can be flat-relief and volumetric. It is easier to create a flat one, especially if the plaster imitates a wall made of stone blocks. The masonry of uneven stones is somewhat more intricate.

How to make an imitation of stone masonry with your own hands.

A pattern is applied to the freshly laid plaster: for masonry in blocks - under a ruler (rule), for a wall of roughly processed stones - freely.

Sequence of work:

- Plaster. Single-layer plaster (at least 7-10mm thick) is covered with a network of “cracks”, “impacts”, and recesses. A believable stone texture is achieved.

Two-layer plasters discussed above do not require additional preparation: they have a natural, realistic structure.

- Sketch. “Graphics” is applied to fresh plaster - a contour drawing with a sharp object (knitting needle, awl).

Even when creating masonry with uneven, torn stone, a building level is used so that the rows of masonry do not “collapse.” The rows should lie flat. This will add credibility.

- Elaboration. The line is deepened to almost the entire depth of the plaster, the edges are expanded. A corner of a spatula, a triangular piece of tin or plastic is used.

- Alignment. Small lumps of plaster are cleaned off when the plaster solution dries.

- Grinding. Small “notches” are sanded after the finish has completely dried with sandpaper and a sanding mesh.

- Coloring. The imitation stonework is painted in several stages: first, the entire surface is covered with a general tone, then with additional ones - the recesses are darker, the bulges are light.

Good results are obtained by additional tinting of individual stones so that they differ by half a tone from other stones.

Imitation of natural stone should have many shades. Then it looks so realistic that it is indistinguishable from real stonework.

Imitation of stone with impressions.

Plaster, in which the design is squeezed out using molds, is performed according to the same scheme as decorating by hand. The only difference is that the masonry is imitated using a template.

Imitating stone with impressions is the easiest to do with your own hands, does not require special experience and is faster.

High-quality forms create a very realistic relief.

The work is done like this:

- Wet the mold. The impression is moistened to prevent the plaster from sticking to its surface.

- Press in. The form is “sinked” into fresh solution as far as the depth of the template requires.

- Correct deficiencies. Minor distortions and deformations are smoothed out with a spatula or knife.

If the plaster solution sticks to the print and comes off the wall, the area needs to be worked on again: wash and wet the mold, throw the mixture onto the wall and squeeze out the design again.

Speed and simplicity make work fun. True, the price of a good mold (with the most realistic relief) increases the total cost of the plaster.

Features of plastering work on the facade

When decorating the facade of a building with decorative plaster, the following features of the work should be taken into account:

- For the facade, you should choose stronger and more wear-resistant materials, since the plaster will be in contact with the external environment.

- It is worth taking into account sudden temperature changes, so before purchasing the mixture you need to pay attention to the main characteristics of the plaster.

- For external walls, it is recommended to use decoration in the form of stones and cobblestones. This coating will create an imitation of real rocks.

- If overheated for a long time, the composition may dry out, which will lead to a deterioration in its properties. In this regard, it is recommended to periodically moisten the composition while performing work.

What mistakes to avoid

Before you start decorating, you should pay attention to the most common mistakes that beginners encounter. When performing finishing work, the following mistakes should be avoided:

- It is necessary to remove all small granules, eliminate unevenness and roughness on the coating. These small details not only spoil the appearance, but also spoil the quality of the coating.

- When creating artificial masonry from stones, the depressions between them should be made of different widths and shapes. This will create maximum resemblance to natural rocks.

- If you want to create brickwork or block design, you must use a grid. Without a special mesh, the pattern of lines will be uneven, which will ruin the appearance of the wall.

The tips and recommendations presented will help you avoid the most common mistakes when creating decorative wall coverings.

Stone-like plaster photo on the facade and inside the house

If you want to evaluate the possible options for decorating walls using decorative stone-like plaster, you should look at photos of the finished works. In the photographs you can see how the interior of the room will look depending on the chosen decoration method. Also, thanks to the photographs, you can pre-select a design option that will suit a specific type of room.

Tyutyunnikov Dmitry

Article verified by a decorative finishing specialist

Imitation of a facade to look like natural stone

Finishing façade walls with natural stone, external walls of buildings or fencing of adjacent areas, especially their basement part, gives buildings a very attractive design look. However, to carry out such work requires certain financial costs, as well as the involvement of finishing craftsmen. The irregular shape of the material compared to brick requires careful selection of components for high-quality masonry.

To use a cheaper method to decorate the walls, an imitation of a facade imitating natural stone is used, consisting of decorative plaster and a stencil to imitate natural stone.

As decorative plaster, you can use the material Ceresit ST 710 Visage (sandstone), which has the texture of natural stone and is the finishing (final) layer when finishing the surface of the walls. But before this, it is necessary to apply Ceresit ST 16 adhesive primer to the wall in a color that will contrast with the decorative plaster.

Decorative plaster Ceresit CT 710 Visage Granite Tanzania Gray

To properly prepare the surface for the stencil, it is necessary to apply the adhesive layer as evenly as possible. This can be done easily using a paint roller. After application, you need to wait until the layer dries completely: this will usually take from three to five hours, depending on the ambient temperature.

Next, you can start gluing the stencil, taking into account the air temperature from + 10 ºС to + 30 ºС and humidity not exceeding 80%. It is best to do the work together, as removing the protective film from the stencil and gluing it to the wall requires special care. The stencils are glued end to end and tightly to the surface so that the decorative plaster does not penetrate under them. Otherwise, the stencils may peel off. There are times when the stencil breaks due to carelessness. In this case, there is no need to despair, but simply glue the gap with tape.

Installation of stencils Visage Ceresit

After the stencils have taken their place, you can begin to apply decorative plaster Ceresit ST 710 Visage, which must be thoroughly mixed before use. The material is applied in an even layer to the wall surface (with a stencil) with a metal spatula: the thickness of the coating should be about 3–4 mm.

Visage stencils “under the stone”

In this case, the spatula should not be pressed too hard against the base to avoid damaging the stencils. It is necessary to smooth the plaster until it hardens. In order to subsequently make the imitation of a natural stone façade look more natural, you need to create a rough surface on the surface of the plaster using any available method.

It is important not to skip the moment of removing the stencils: the plaster should still be wet and at the same time begin to set. The stencils are removed carefully (two people together) along with excess material, leaving a very high-quality imitation of natural (wild) stone on the wall surface.